Continuous and pulse micro feeding device

A feeding device and pulsed technology, applied in the field of pulverized coal, biomass and waste combustion, can solve problems such as laboratory research difficulties, and achieve the effects of good stability and accuracy, and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with example and accompanying drawing, the present invention is described in further detail.

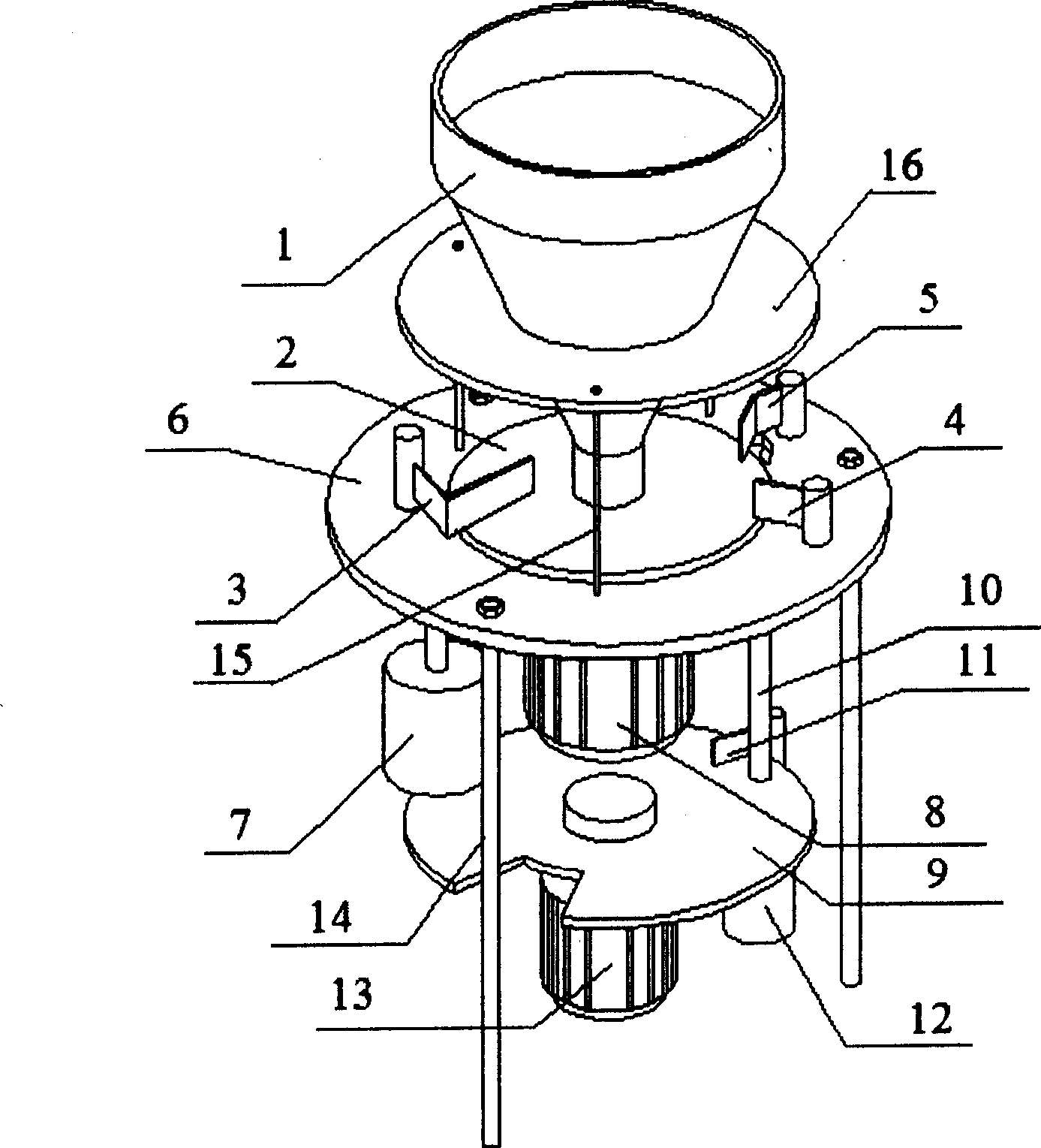

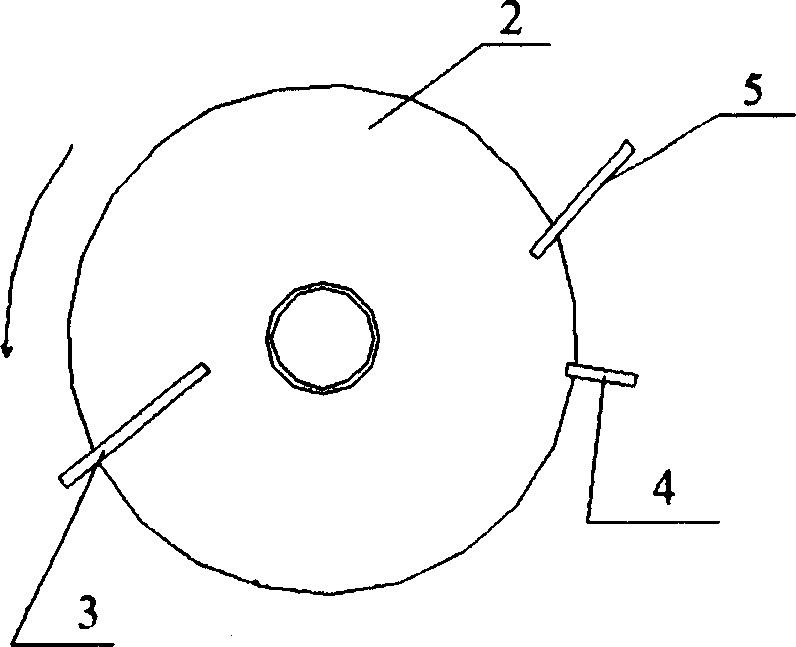

[0010] A micro-feeding device provided by the invention comprises a feeding unit and a pulse auxiliary unit. Feeding unit as attached figure 1 As shown above, the support platform 6 is fixed by the support column 14, which is convenient for placing various components. The upper rotating platform 2 is located above the supporting platform 6 . The feeding hopper 1 is fixed above the upper rotary table 2 by a bracket 16 . For the convenience of installation, the bracket 16 is fixed above the support platform 6 through the support rod 15 . The shape of the feed hopper 1 is a truncated cone, which is convenient for pouring samples, and can also control the quality of the samples falling on the upper rotary table 2. The upper rotary table 2 is connected with the first motor 8, and its uniform rotation is controlled by the first motor 8. The rotation shafts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outlet diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com