Tensile Young's modulus measuring instrument frictionless mouable platform

A movable platform, Young's modulus technology, applied in measuring devices, instruments, using stable tension/pressure to test the strength of materials, etc. The effect of accelerated experiment progress, easy adjustment, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

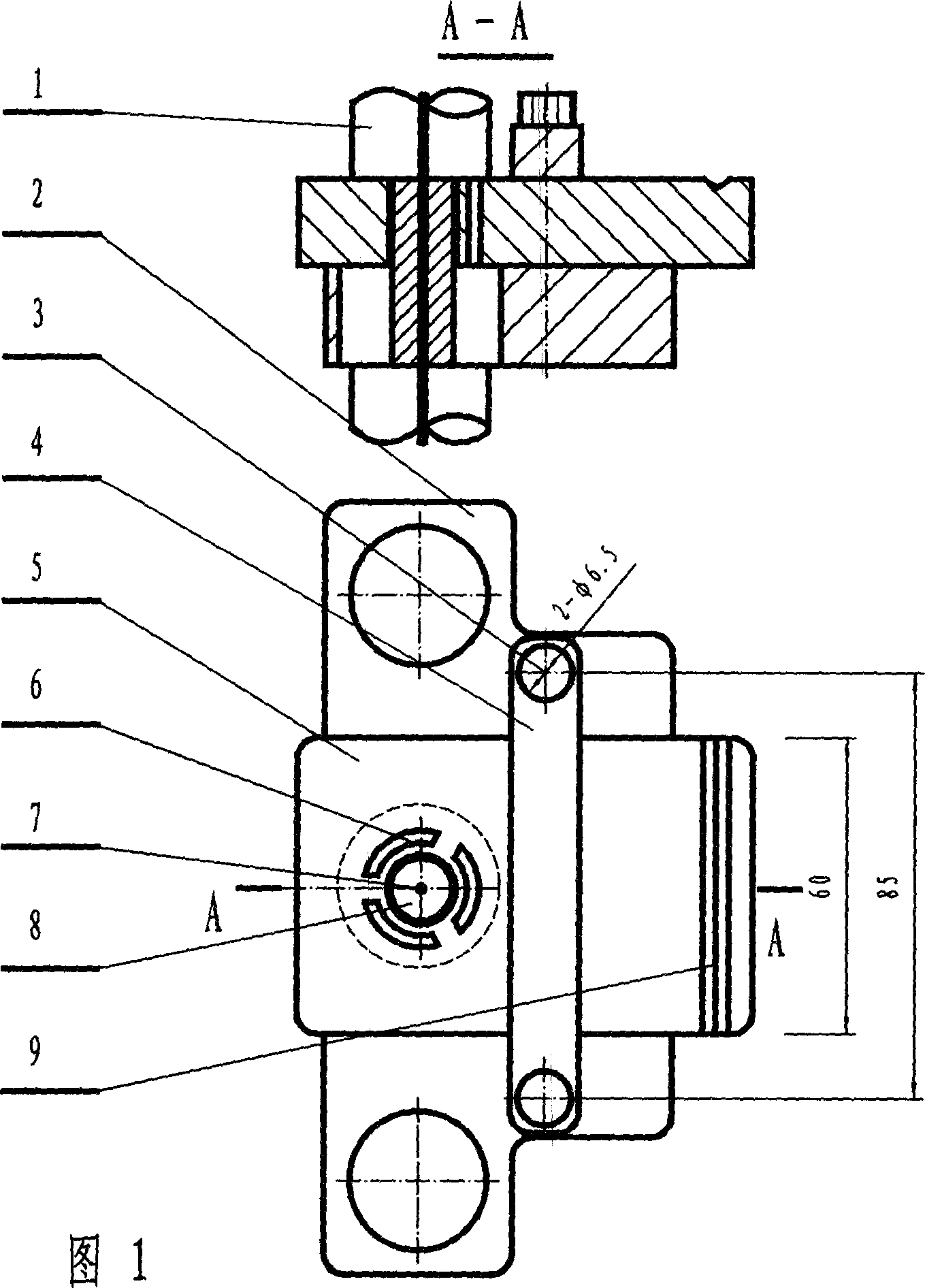

[0009] In Figure 1, the movable platform (5) is placed on the light lever support plate (2), and the movable chuck (8) fixed on the sample wire (7) to be tested is placed on the light lever support plate (2) and the movable platform at the same time In the middle hole of (5), the diameter of the middle hole of the light lever support plate (2) is 10-15mm larger than the outer diameter (or circumscribed circle) of the movable collet, and the diameter of the middle hole of the movable platform (5) is only larger than the outer diameter of the movable collet. (or circumscribed circle) is 1-2mm larger. The function of the viewing hole (6) is to facilitate the observation of whether the movable chuck is in contact with the middle hole wall of the light lever support plate (2). A small groove is machined in front of the movable platform (5). (9), so that the front foot of the plane mirror is located here, the pressure strip (4) is placed on the movable platform (5), and is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com