Light projection lens structure

A lens structure and projection technology, which is applied in the direction of instruments, lighting and heating equipment, fixed lighting devices, etc., can solve the problems of difficult mass production, difficult structure volume, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

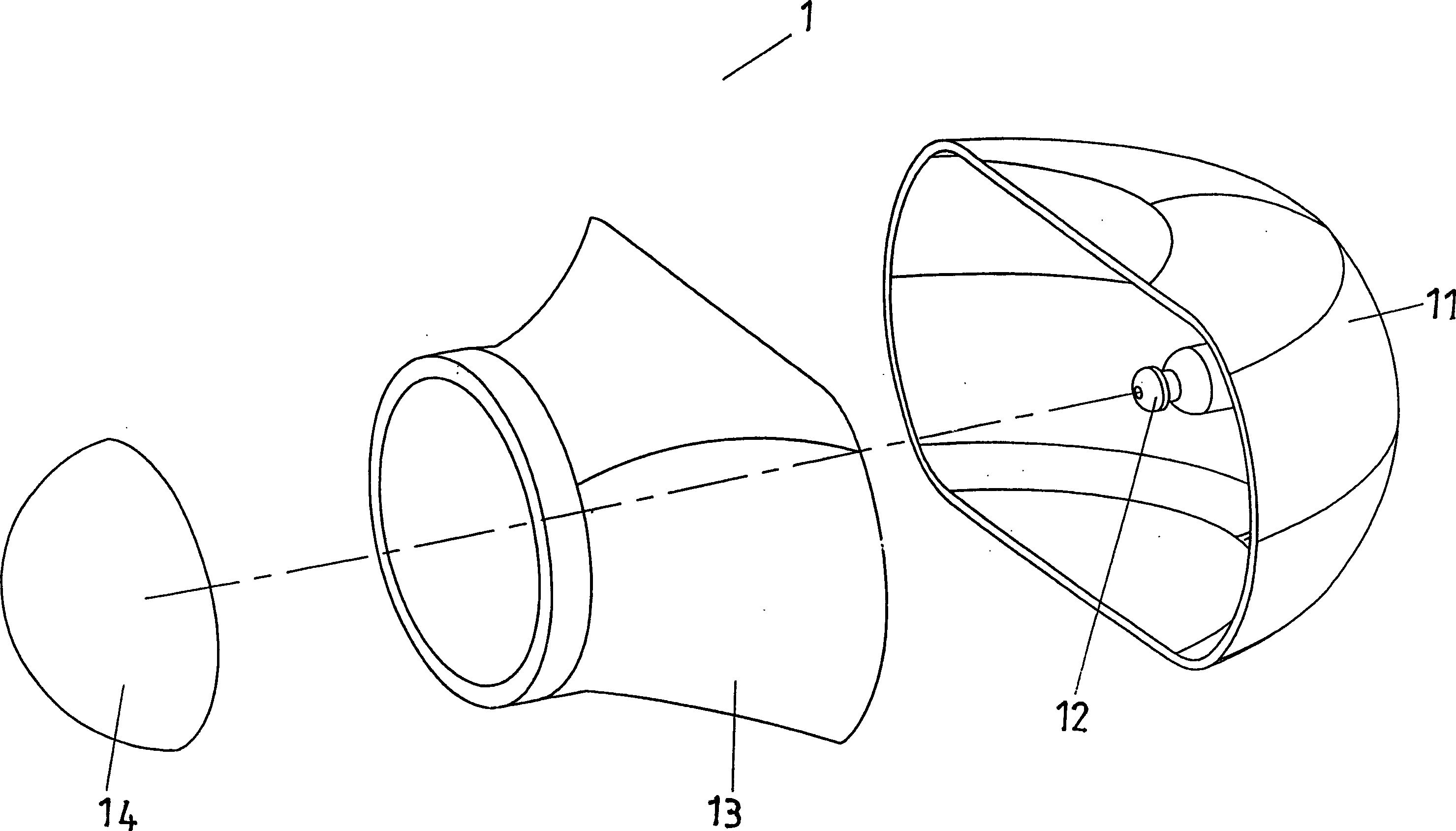

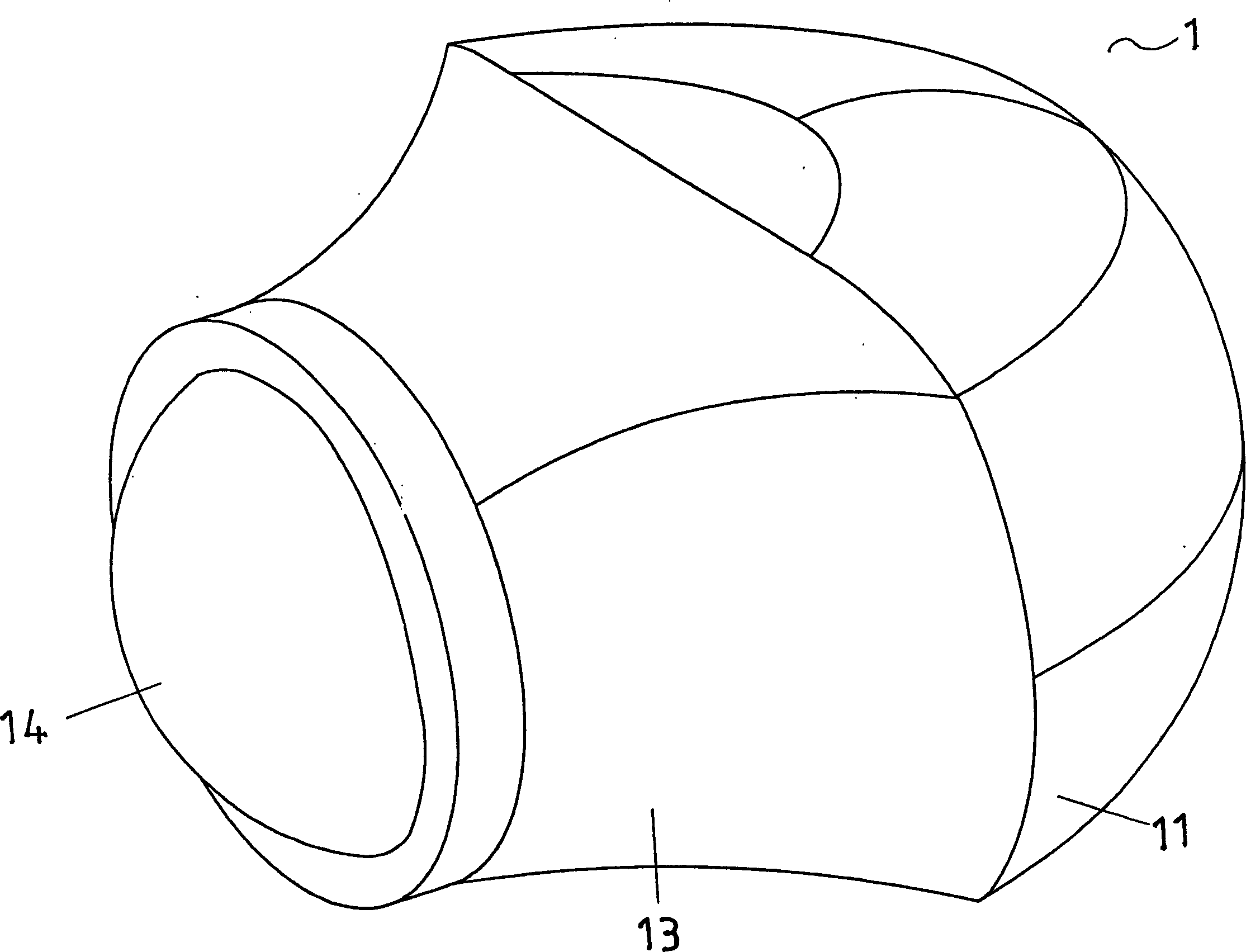

[0013] Such as figure 1 , figure 2 As shown, it is a schematic diagram of an embodiment of the light-weight projection lens structure of the present invention applied to a car lamp. The lens structure 1 is mainly connected to a light source 12 inside a reflector 11, and supports are successively assembled on the reflector 11. Body 13 and a lens body 14.

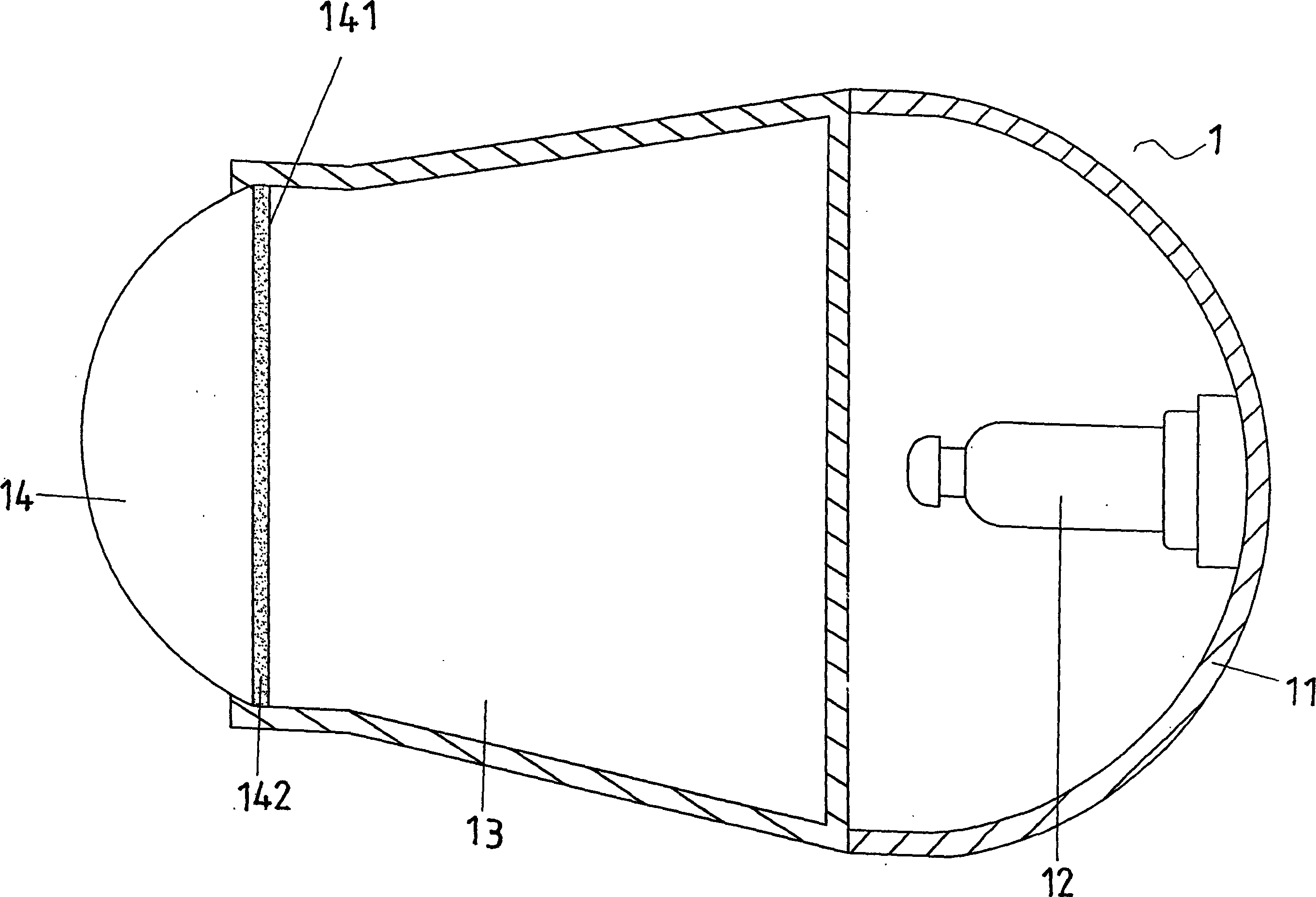

[0014] Such as image 3 As shown, the lens body 14 of the lens structure 1 is a light-condensing light-transmitting body, which is made of heat-resistant and yellow-resistant optical plastic material, and an inorganic oxide is coated on the light-entry surface 141 of the lens body 14. Thin film coating 142 persons.

[0015] Such as Figure 4 , Figure 5 As shown, because the lens body 14 of the lens structure 1 is made of optical plastic material and coated with a coating 142 , it can also achieve the same light projection effect as the glass lens A in the prior art.

[0016] Due to the design of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com