Optical recording medium

An optical recording medium and recording layer technology, which is applied in the directions of data recording, temperature recording, recording/reproducing by optical methods, etc., can solve the problems such as the inability to obtain the effect and the lack of the medium structure of the low thermal conductivity layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

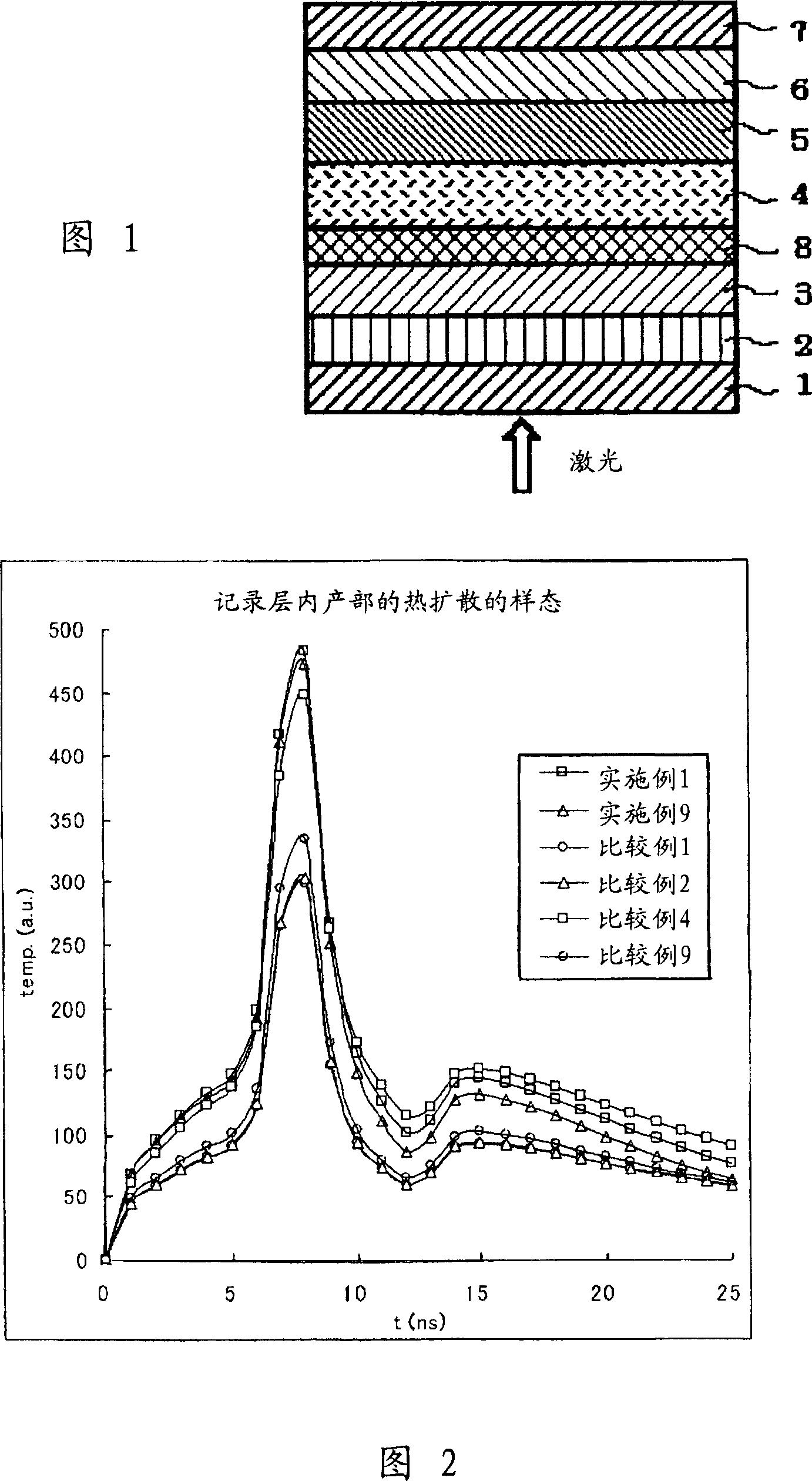

[0123] On the substrate 1, a first protective layer 2, a phase change recording layer 3, a second protective layer 8, a low thermal conductivity layer 4, and a reflective layer 5 are sequentially formed by sputtering, and a resin protective layer 6 is formed on it by a spin coating method. , and finally, the bonding substrate 7 is bonded, and an optical recording medium having the layer structure shown in FIG. 1 is produced and initialized.

[0124] As the substrate 1 , a polycarbonate substrate having a diameter of 12 cm and a thickness of 0.6 mm and a track pitch of 0.74 μm with guide grooves was used.

[0125] The first protective layer 2 uses ZnS-SiO with a thickness of 60nm 2 (80:20 mol%) (κ8.6W / m·K).

[0126] The phase change recording layer 3 uses Ga with a thickness of 16nm 12 Sb 88 .

[0127] The second protective layer 8 uses ZnSSiO with a thickness of 7nm 2 (80:20 mole %).

[0128] Low thermal conductivity layer 4 uses ZrO with a thickness of 4nm 2 (contains...

Embodiment 2

[0140] In addition to changing the material of the low thermal conductivity layer 4 to ZrO 2 (contains 3 mol% Y 2 o 3 )-20mol%TiO 2 Except for the point of (κ2.0W / m·K), an optical recording medium was fabricated and initialized in the same manner as in Example 1, and then evaluated.

Embodiment 3

[0142] In addition to changing the material of the low thermal conductivity layer 4 to ZrO 2 (contains 3 mol% Y 2 o 3 )-10 mol% SiO 2 Except for the point of (κ3.5W / m·K), an optical recording medium was fabricated and initialized in the same manner as in Example 1, and then evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com