Internal support net sheet type pressure reducing well pipe

A technology of pressure relief well pipe and mesh, which is applied in the field of embankment foundation engineering, which can solve the problems of reduced efficiency, inability to take out, and deterioration of relief wells, and achieve easy replacement of filter layers, convenient lifting of inner pipes, and good decompression effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

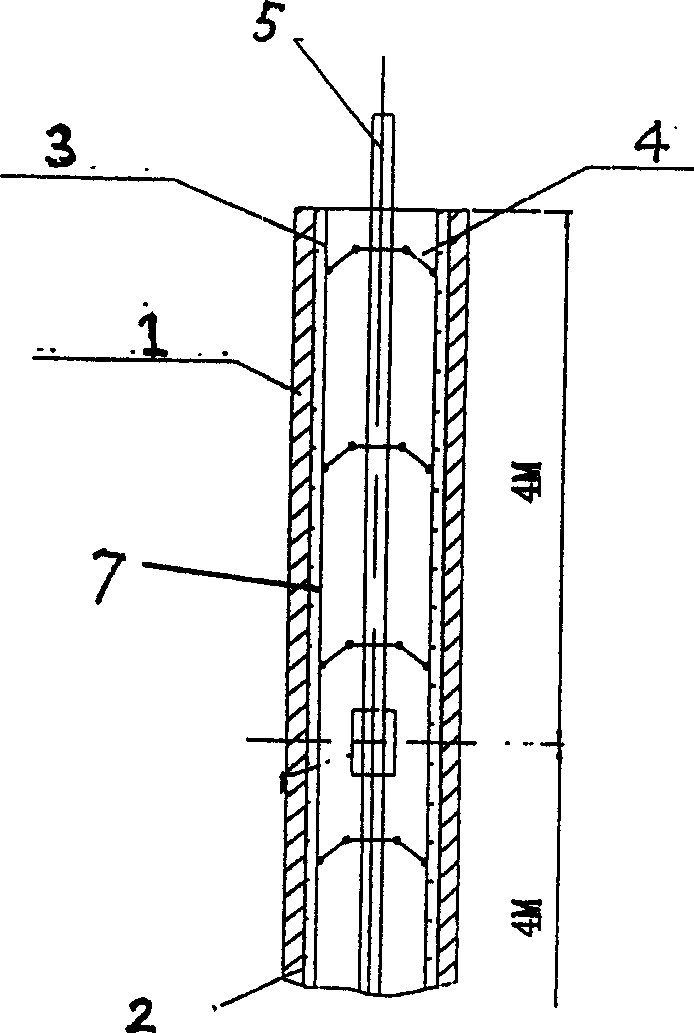

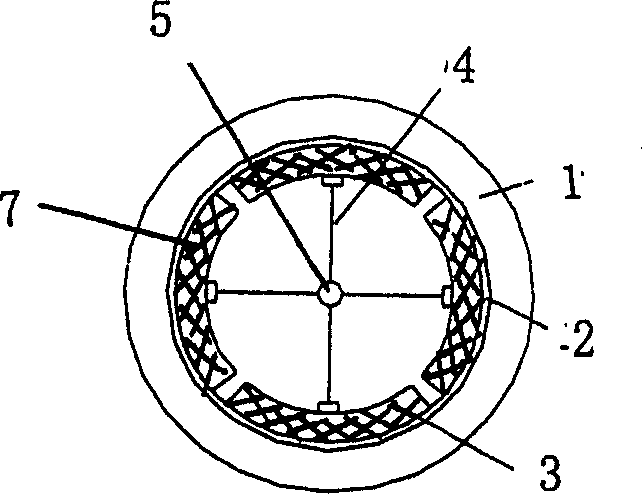

[0014] The outer pipe is a PVC porous flower pipe with an inner diameter of 100mm. The diameter of the small holes on the outer pipe is 20mm and the hole spacing is 80mm. The length of a single section of the outer pipe is 4m. Insert the outer pipe into the drilled soil hole. 95mm, 4m long, the inner tube is composed of four solitary mesh pieces, the mesh is made of multi-layer plastic mesh pressed into a round solitary shape, the mesh is hexagonal, the mesh diameter is 20mm, and there is a PVC material in the center of the inner tube. The supporting connecting rod and the power transmission shaft are formed. The supporting connecting rod is divided into upper, middle and lower layers, and each layer has 4 pieces. The hinges at both ends of the supporting connecting rod and one end are welded to the mesh, and the welded part of the mesh is welded and reinforced with a plastic sheet. , the other end is welded on the power transmission shaft, put the sewn geotextile filter layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com