Automatic balance height shock reducer

An automatic balancing and shock absorber technology, applied in the direction of liquid shock absorbers, etc., can solve the problems that the shock absorber cannot automatically balance the height, the steering is easy to roll, and the stability is poor, so as to reduce traffic accidents, improve stability, and improve smoothness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Describe in detail below in conjunction with accompanying drawing and embodiment:

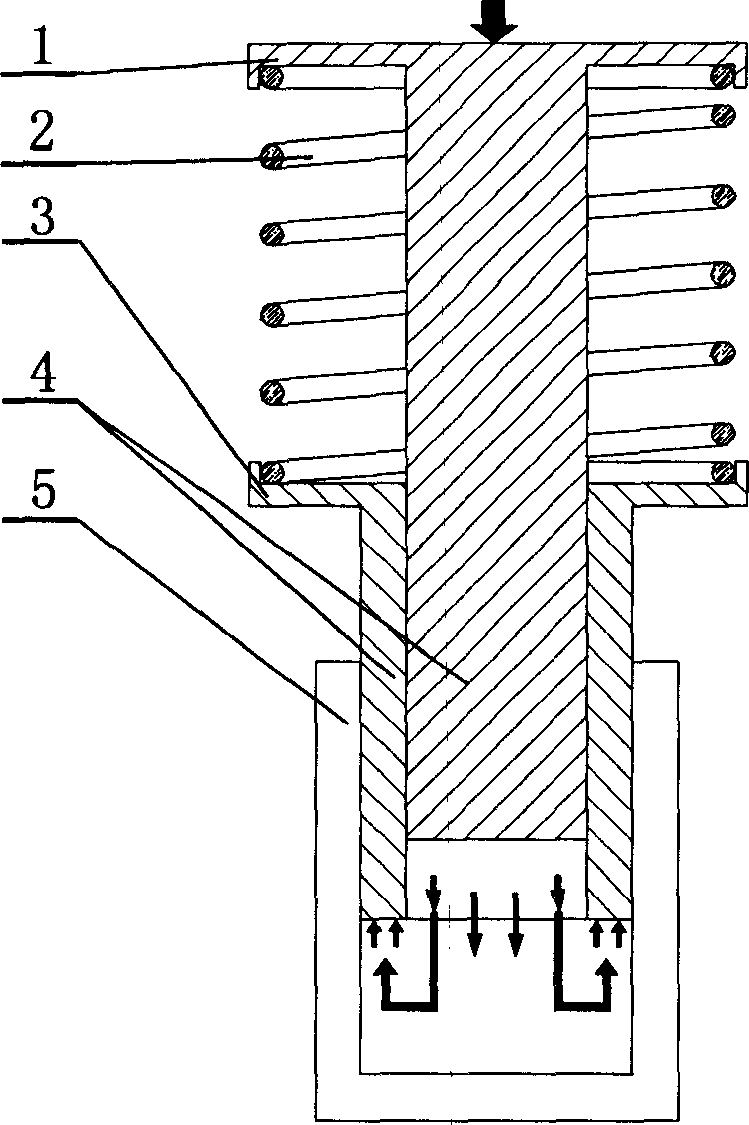

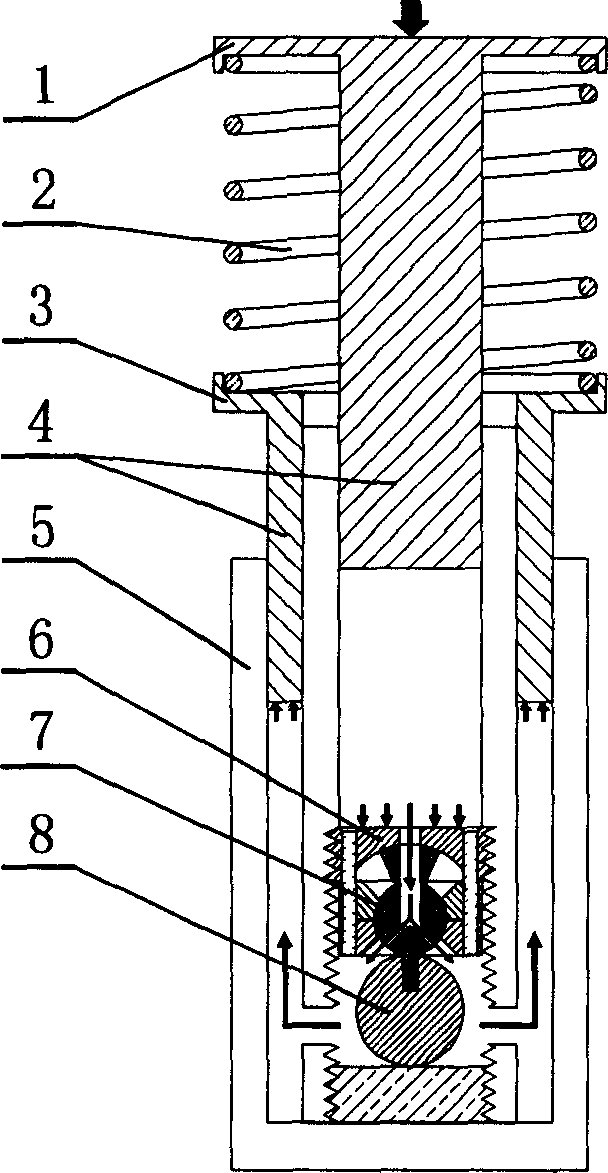

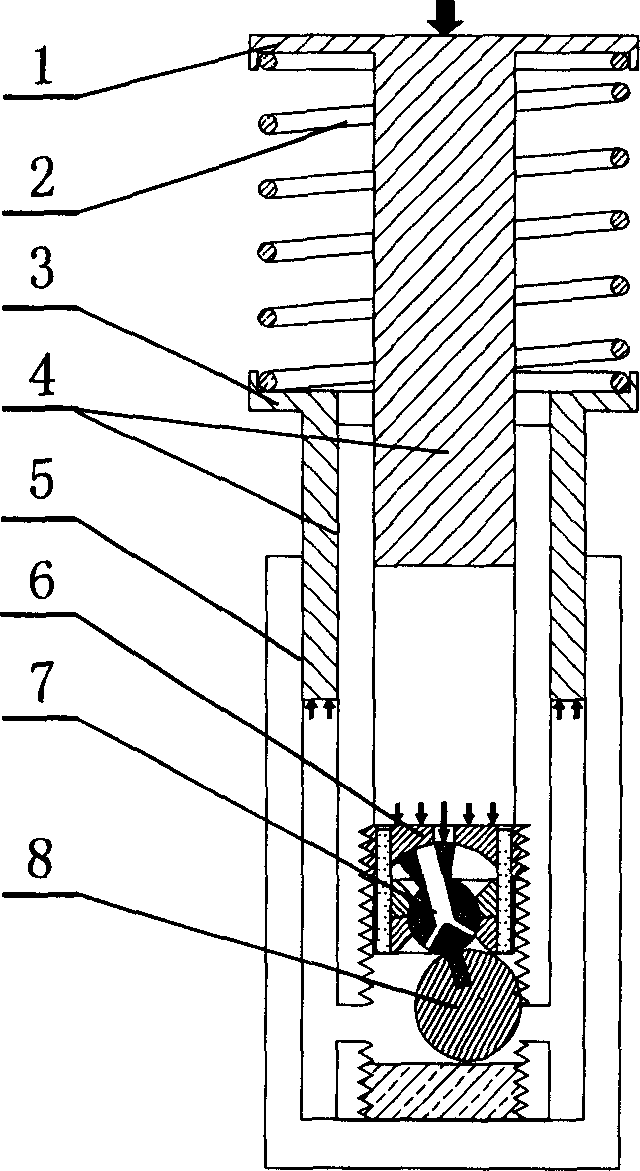

[0014] figure 1 , figure 2 and Figure 4 It is three kinds of shock absorbers used for automatic leveling height on vehicles of the present invention. It mainly includes a cylinder body 5, a cylinder chamber 11 and a piston 4. The main points are: the cylinder body 5 is provided with two pistons 4 whose top ends are respectively connected to the pressure plate 1 and the top plate 3, and a device is installed between the pressure plate 1 and the top plate 3. With balance spring 2.

[0015] In order to simplify the structure and improve the damping of the shock absorber, figure 1 and figure 2 All adopt a tubular piston, that is, a piston 4 is a tubular piston, another piston 4 is contained in the tubular piston, and two pistons 4 are set together and are contained in the same cylinder chamber 11.

[0016] In order to prevent the two counter-moving pistons 4 from interacting with ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com