Energy saving anti-explosion electric heater

An electric heater and electric heating technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of poor heat insulation effect, large heat loss, and take away heat, so as to prevent heat loss. , strengthen the casing, enhance the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

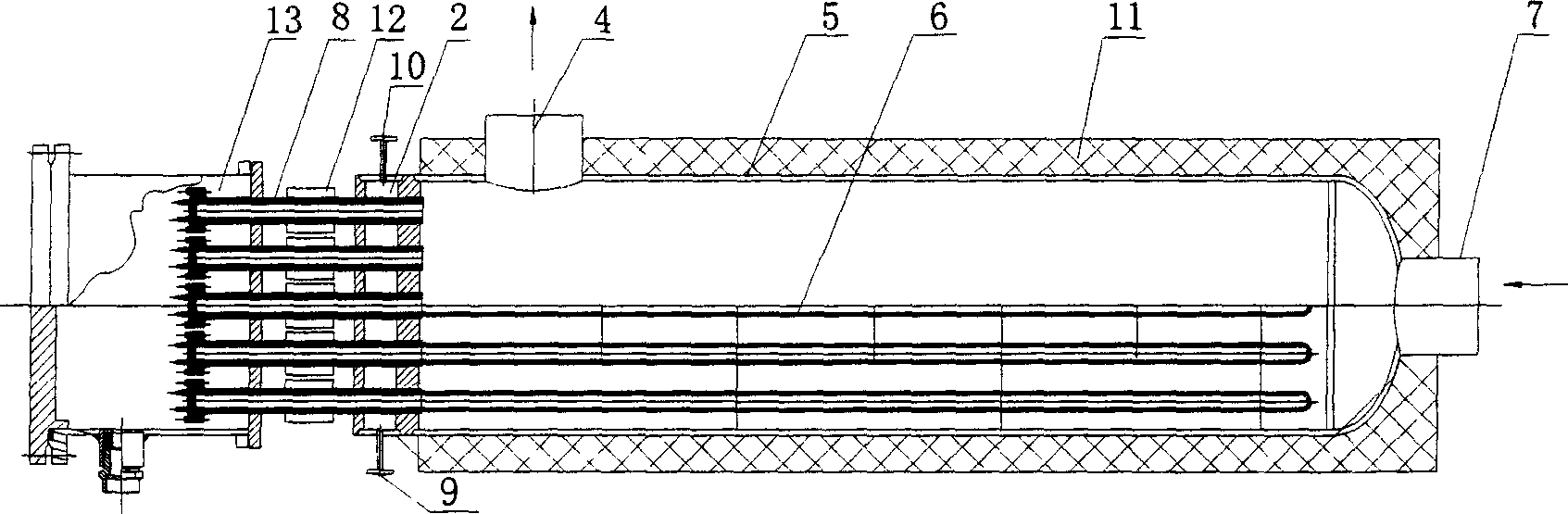

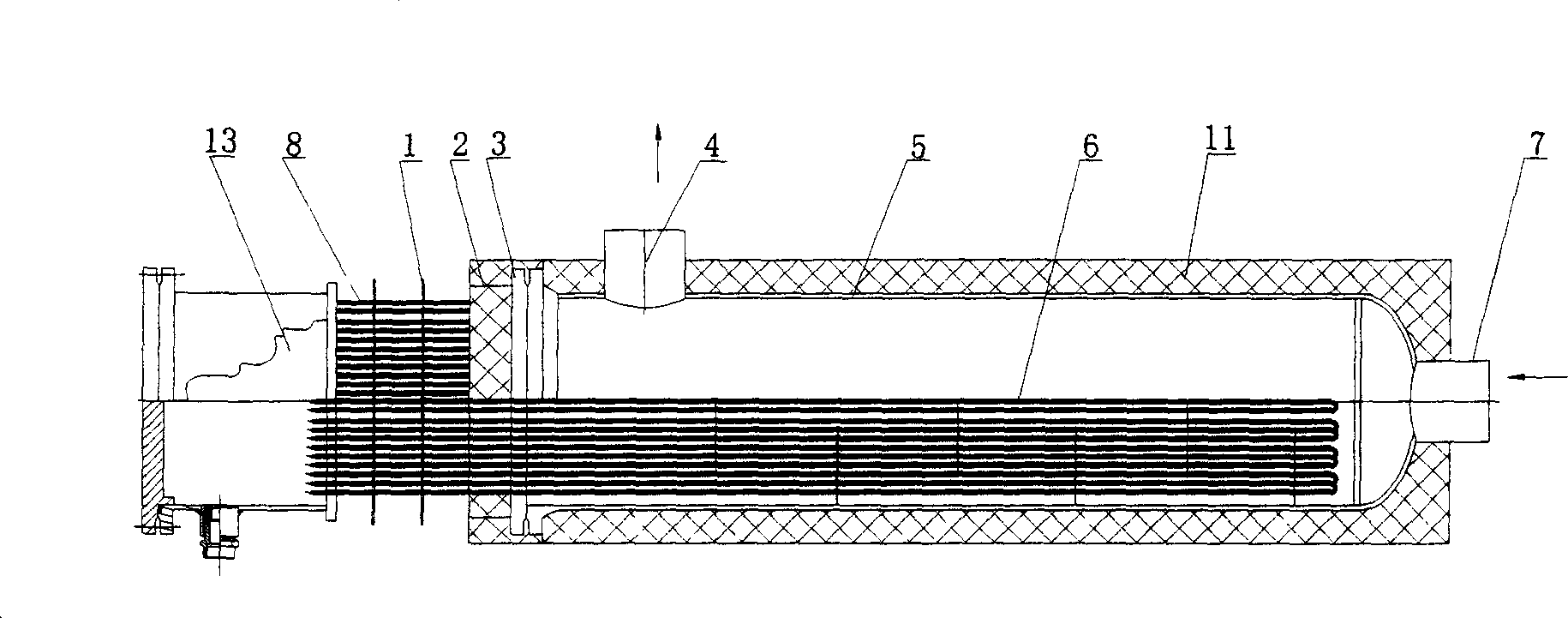

[0014] The energy-saving explosion-proof electric heater of the present embodiment is as figure 2 Shown, one end of container body 5 is shaped on inlet 7, and the top is shaped on outlet 4, and the exterior coats aluminum silicate thermal insulation cotton 11 (making at the construction site usually). The explosion-proof chamber 13 is located at the other end of the container body 5, and a set of casing pipes 8 are fixedly welded between the two, and two isolation plates 1 distributed at intervals are welded and fixed between the casing pipes, which can strengthen the casing pipes. An air-cooled convection channel is also formed. The electric heating device 6 penetrates into the explosion-proof chamber 13 from the direction of the container body 5 (through the flange 3, the insulation cotton 2 and the isolation plate 1) through the sleeve 8, and each sleeve passes through a U-shaped electric heater The gap between one end of the device 6 is 0.5±0.1 mm, which can prevent the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com