Shock reducing type generating and automatic charging device for electric vehicle

An automatic charging device, electric vehicle technology, applied in battery circuit devices, electromechanical devices, electric vehicles and other directions, to achieve the effect of making full use of energy, improving environmental protection quality, and increasing continuation mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

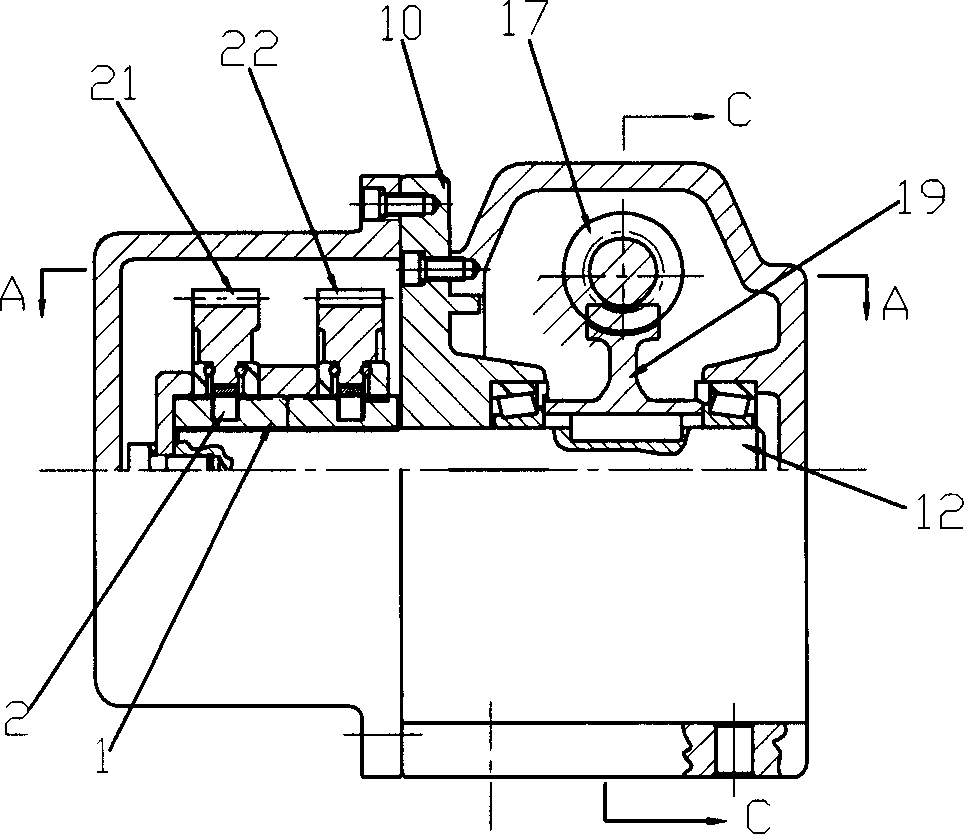

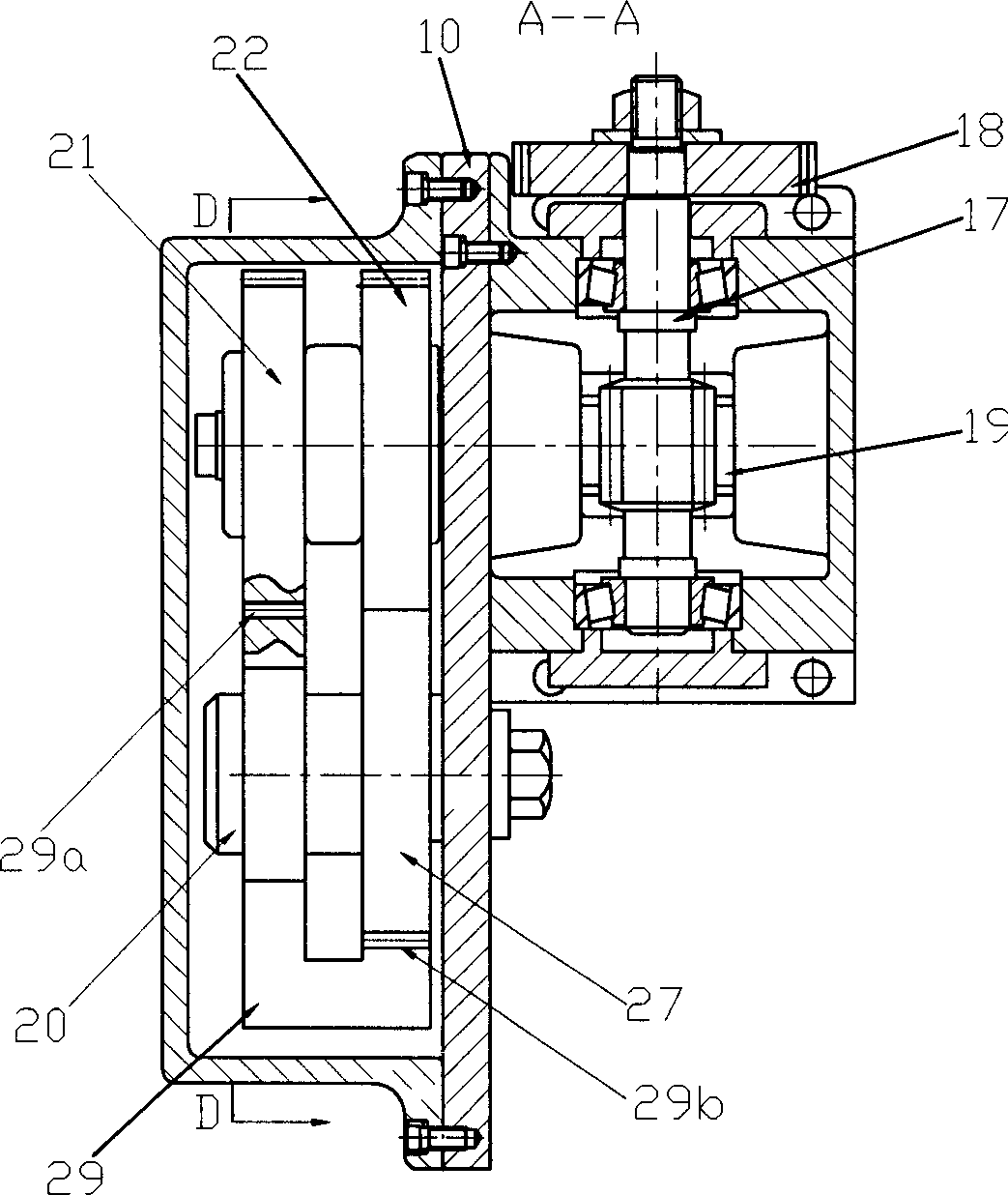

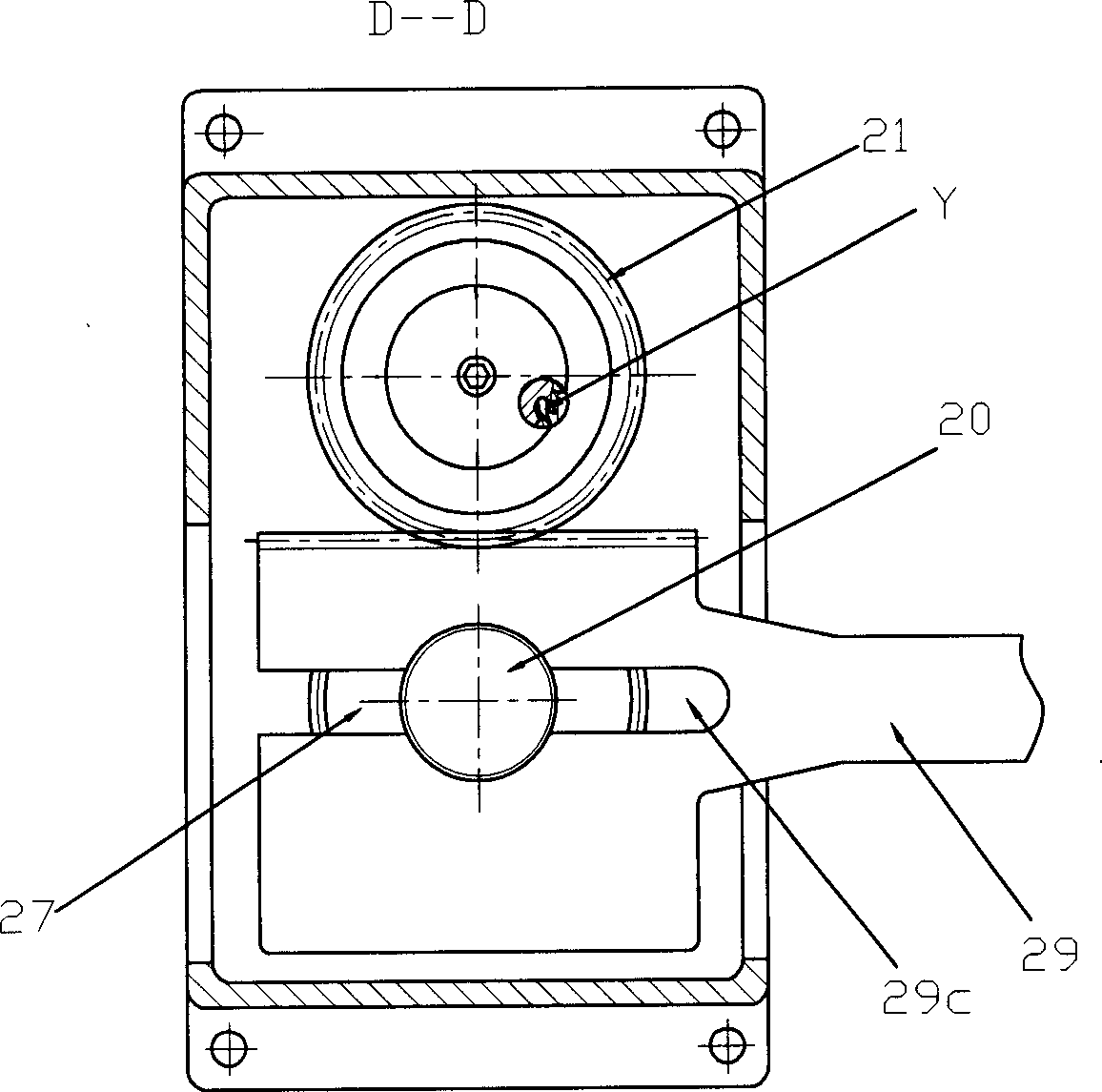

[0020] Figure 2-5 Shown, a kind of specific embodiment of the present invention is: image 3 , Figure 4 Shown, a, the shock absorber of electric vehicle is connected with the hanging handle of L-shaped spur rack 29, and the guide groove 29c of L-shaped spur rack 29 is inserted into the neck of guide shaft 20 fixed on the casing 10; L-shaped The long-side outer end 29a of straight tooth bar 29 has straight teeth, and the short-side inner end 29b also has straight teeth, and the long-side outer end 29a straight teeth of L-shaped straight tooth bar 29 mesh with the first gear disc 21 external teeth, and The straight teeth of the short side inner end 29b mesh with the reversing gear 27 , the reversing gear 27 is mounted on the guide shaft 20 through a bearing, and the reversing gear 27 meshes with the outer teeth of the second gear plate 22 . image 3 , Figure 4 It is shown that the first and second gear discs 21 and 22 are connected to the worm gear shaft 12 in the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com