Method for cleaning liquid ejection apparatus and liquid ejection apparatus

A technology of jetting device and liquid jetting head, applied in printing and other directions, can solve the problems of increased ink consumption, high cost, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

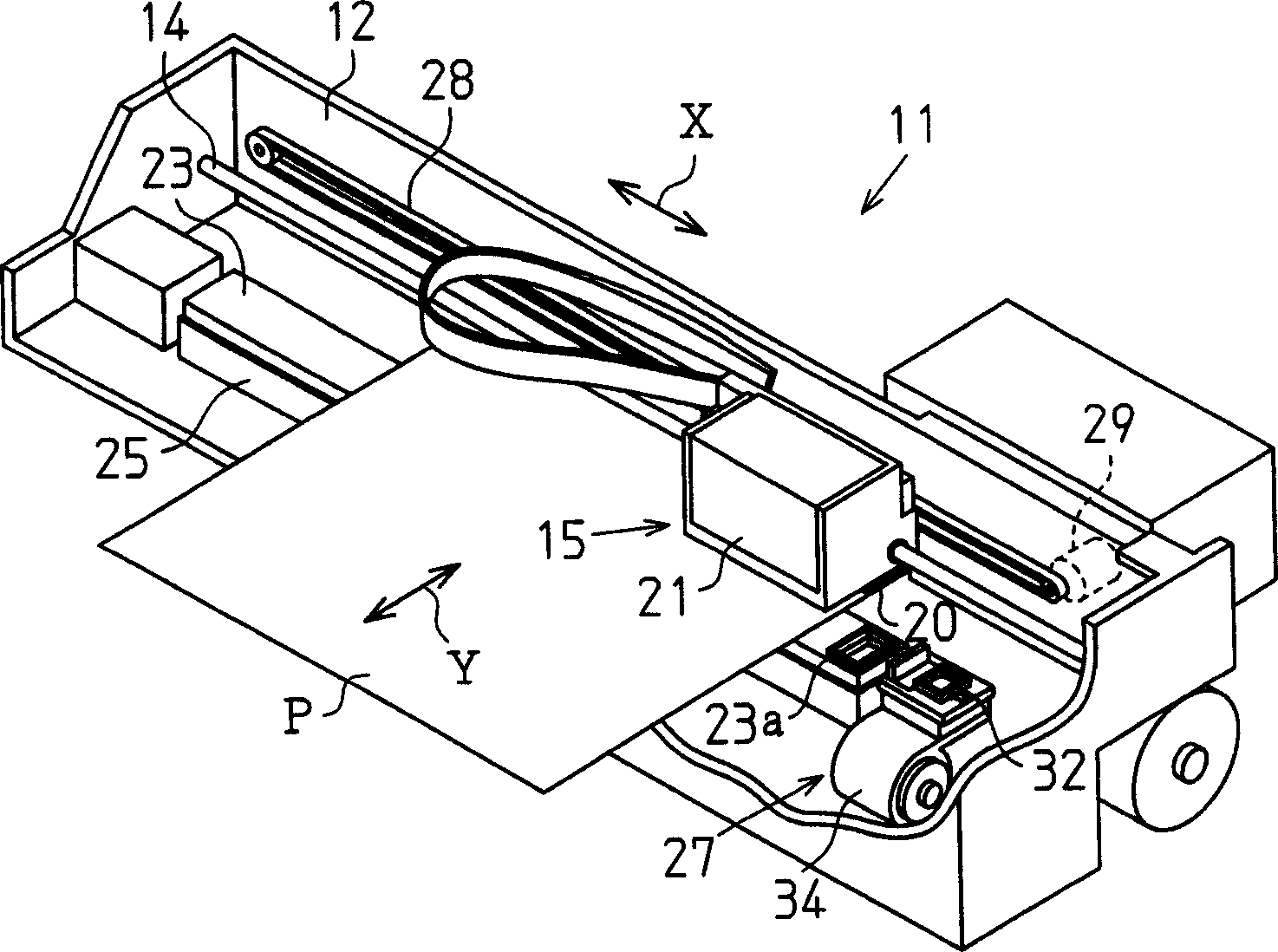

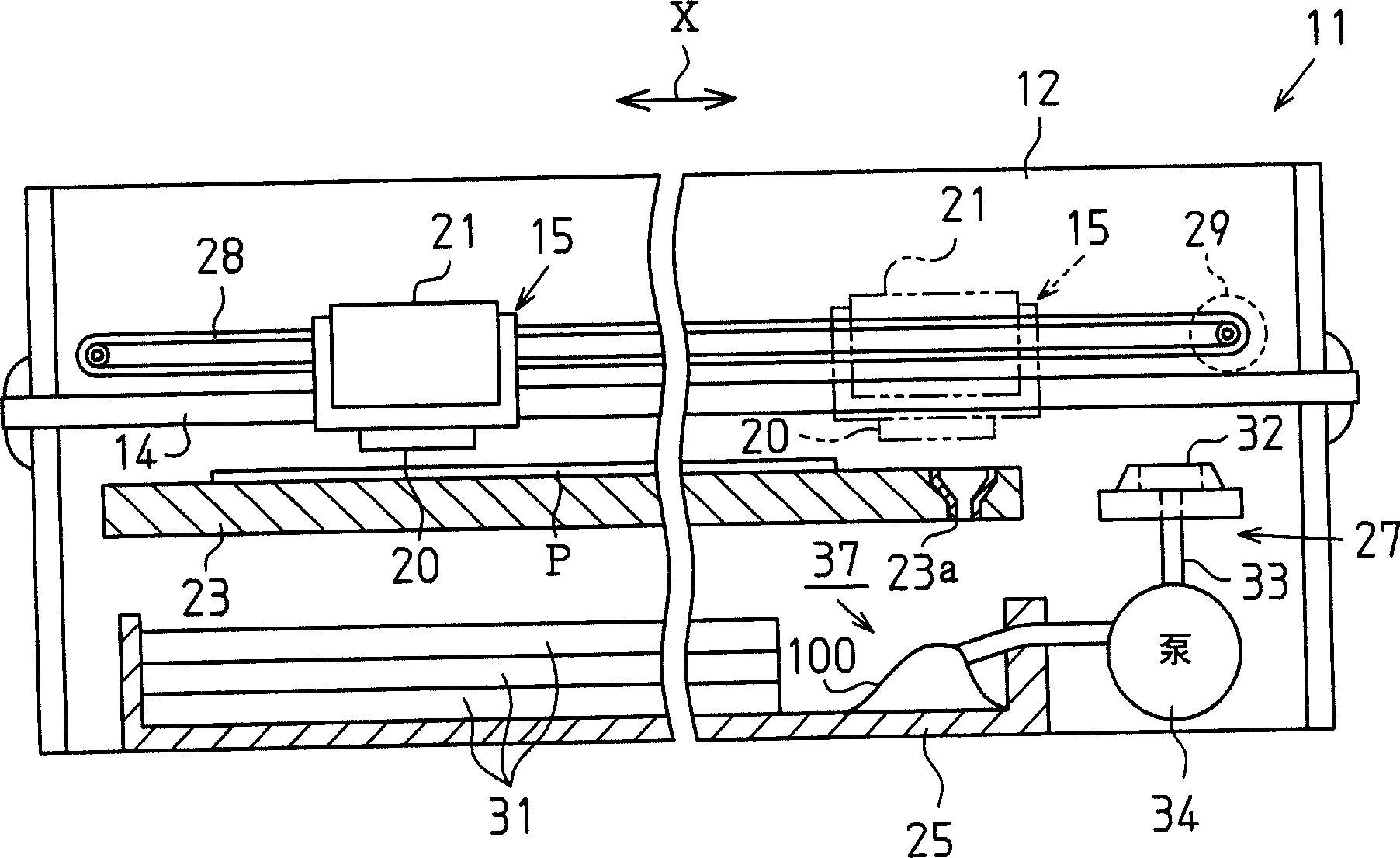

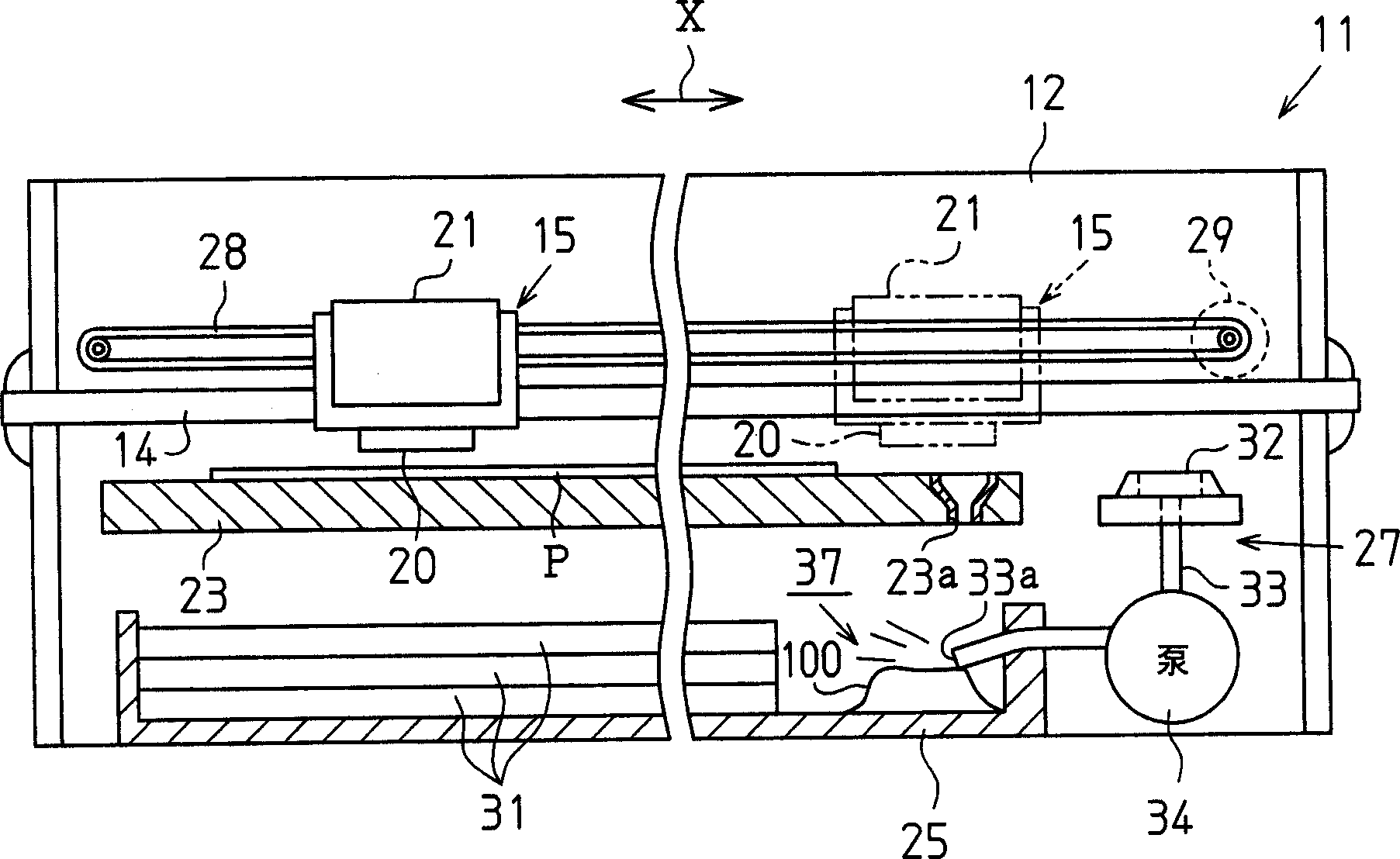

[0028] Such as figure 1 with figure 2 As shown, the printer 11 as the liquid ejecting apparatus of this embodiment is provided with a frame 12, a guide member 14, a carriage 15, a recording head 20 as a liquid ejecting head, an ink cartridge 21, a platen roller 23, a waste liquid tank 25, a head Cleaning mechanism27.

[0029] The frame 12 covers the entirety of the printer 11 . The guide member 14 is provided along the longitudinal direction of the frame 12 . The guide member 14 is inserted through the carriage 15 , whereby the carriage 15 is movably supported relative to the guide member 14 . The carriage 15 is connected to a carriage motor 29 by means of a timing belt 28 , and is driven by the carriage motor 29 to reciprocate along the direction of the guide member 14 , that is, along the main scanning direction X.

[0030] The recording head 20 is mounted on the lower part of the carriage 15, as Figure 4 As shown, a plurality of (in the Figure 4 4) Nozzle 20a in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com