Five automatic industrial sewing machine

An industrial sewing machine and five-automatic technology, applied in the field of sewing machines, can solve the problems of low work efficiency and high operation intensity, and achieve the effects of convenient operation, good production efficiency and high degree of automatic operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

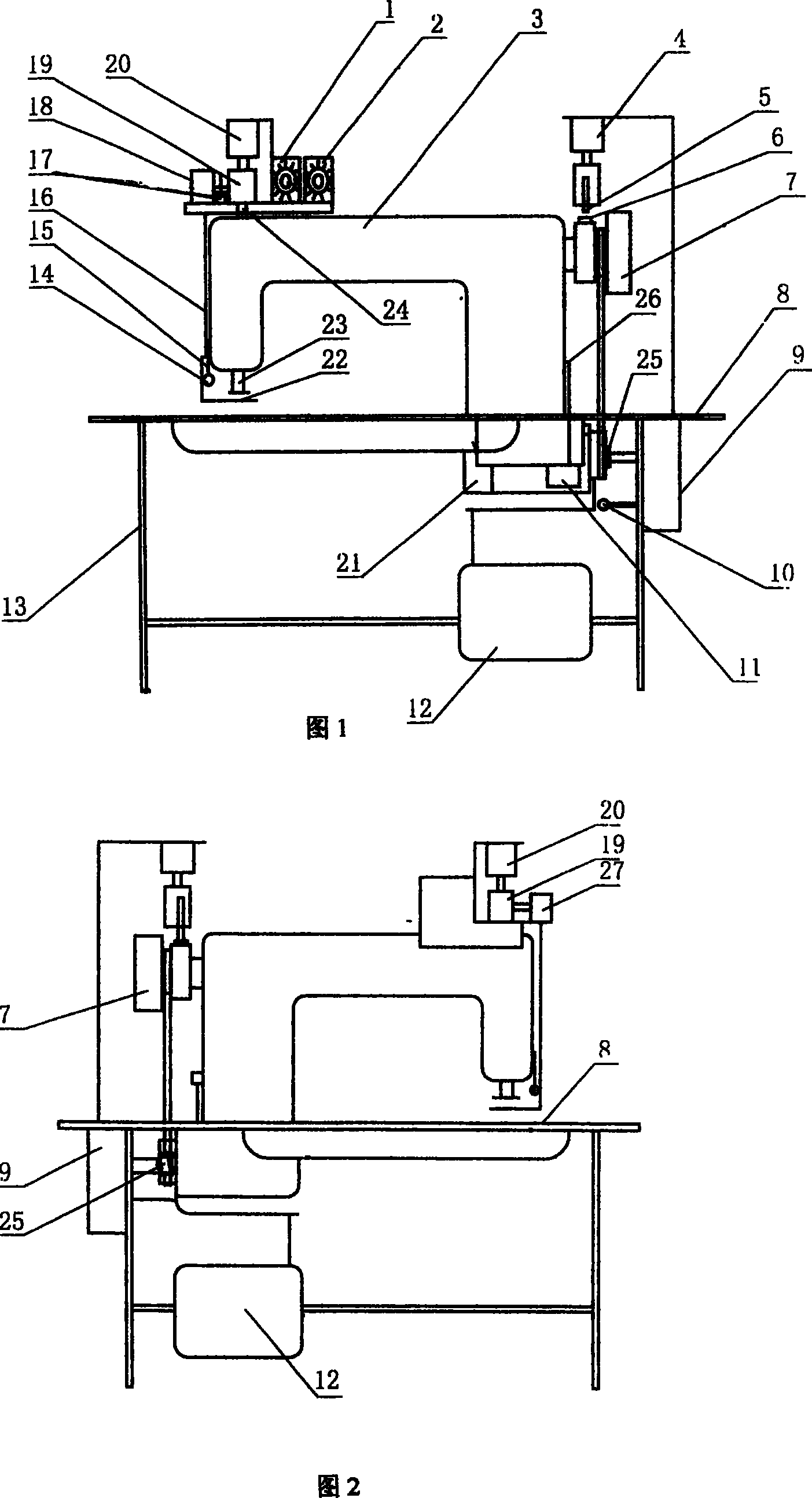

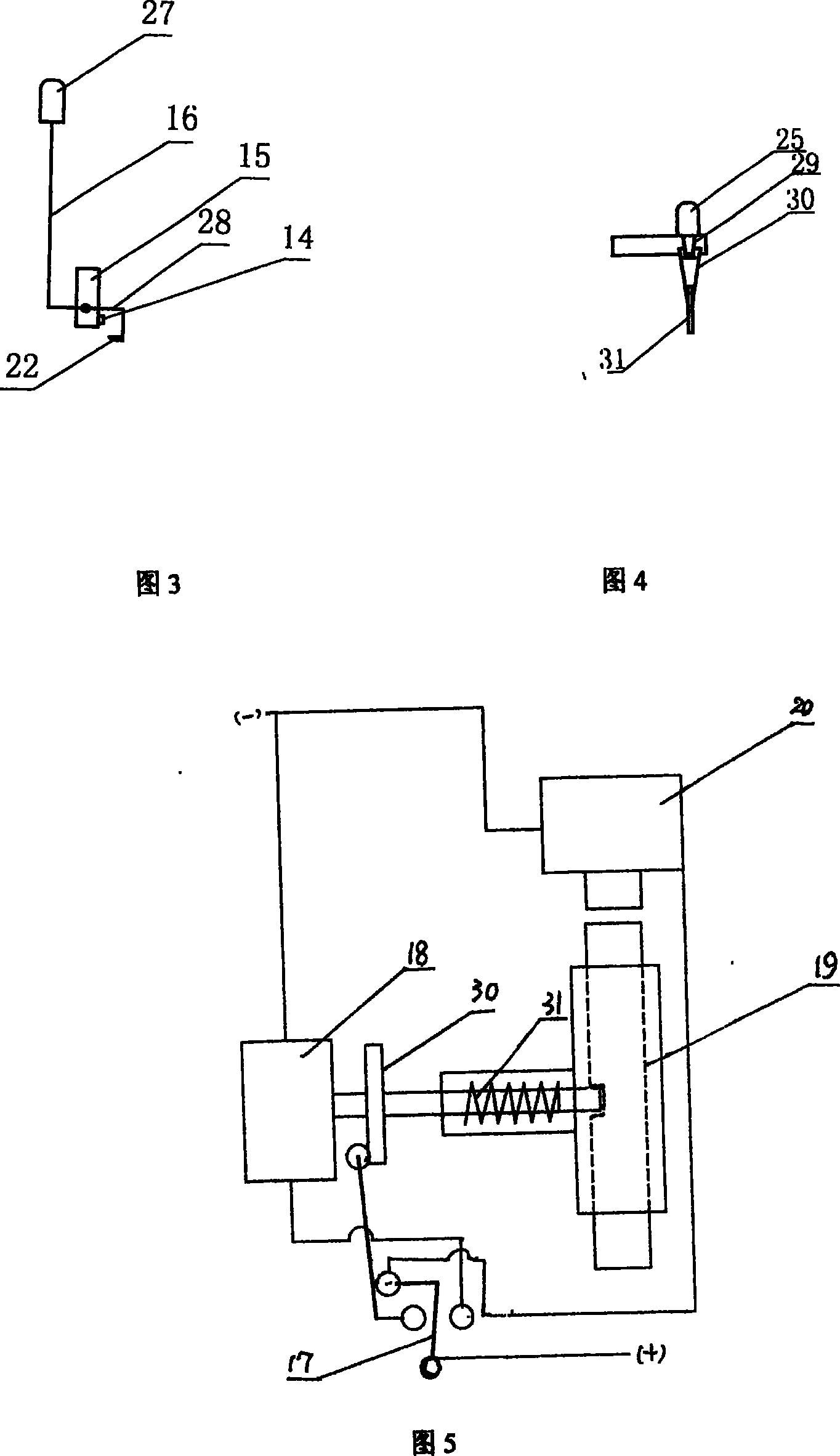

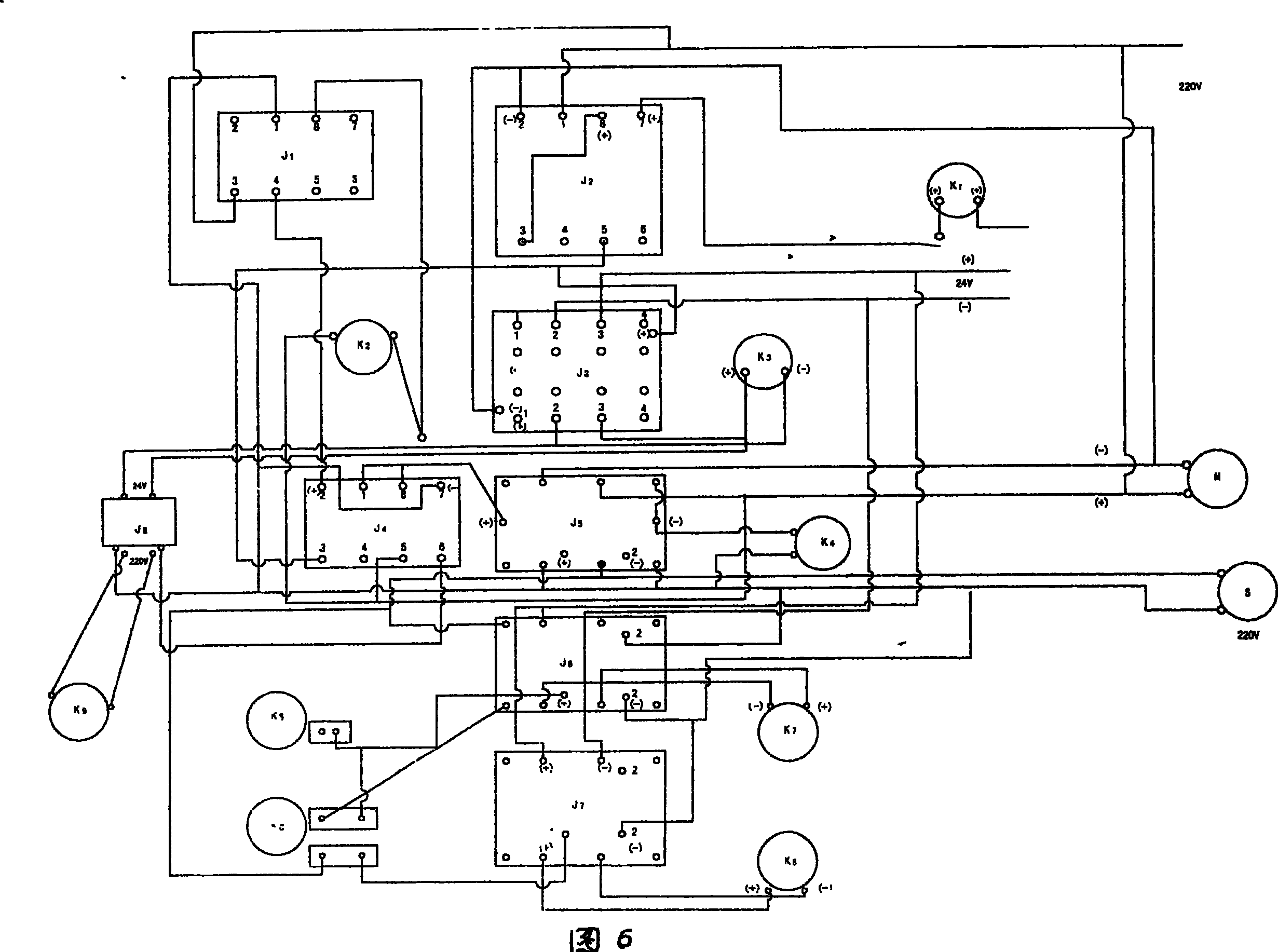

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0014] As shown in the figure, the present invention includes a machine head 3, a platen 8, a frame 13, a motor 21, a pedal 12, a clutch and a control circuit. The machine head 3 is equipped with an automatic thread trimming solenoid valve assembly, a high-position parking solenoid valve 4, a combined energy-saving solenoid valve for lifting the presser foot, a limit switch 14, a fixed piece 15, a start backtack time relay 1, and a stop backtack time relay 2 . A return needle solenoid valve 11 is arranged below the platen 8 , and a brake solenoid valve 25 and a distribution box 9 are arranged on the frame 13 . The automatic thread trimming electromagnetic valve assembly and the limit switch 14 are arranged at the head of the machine head 3, the high-position parking electromagnetic valve 4 is arranged at the tail of the machine head, and the high-posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com