Rotor spinning machine

一种气流纺纱机、纺纱机的技术,应用在薄料处理、运送细丝状材料、运输和包装等方向,能够解决工作站长时间停机、延迟等问题,达到防止不希望地移除筒管、低控制费用的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

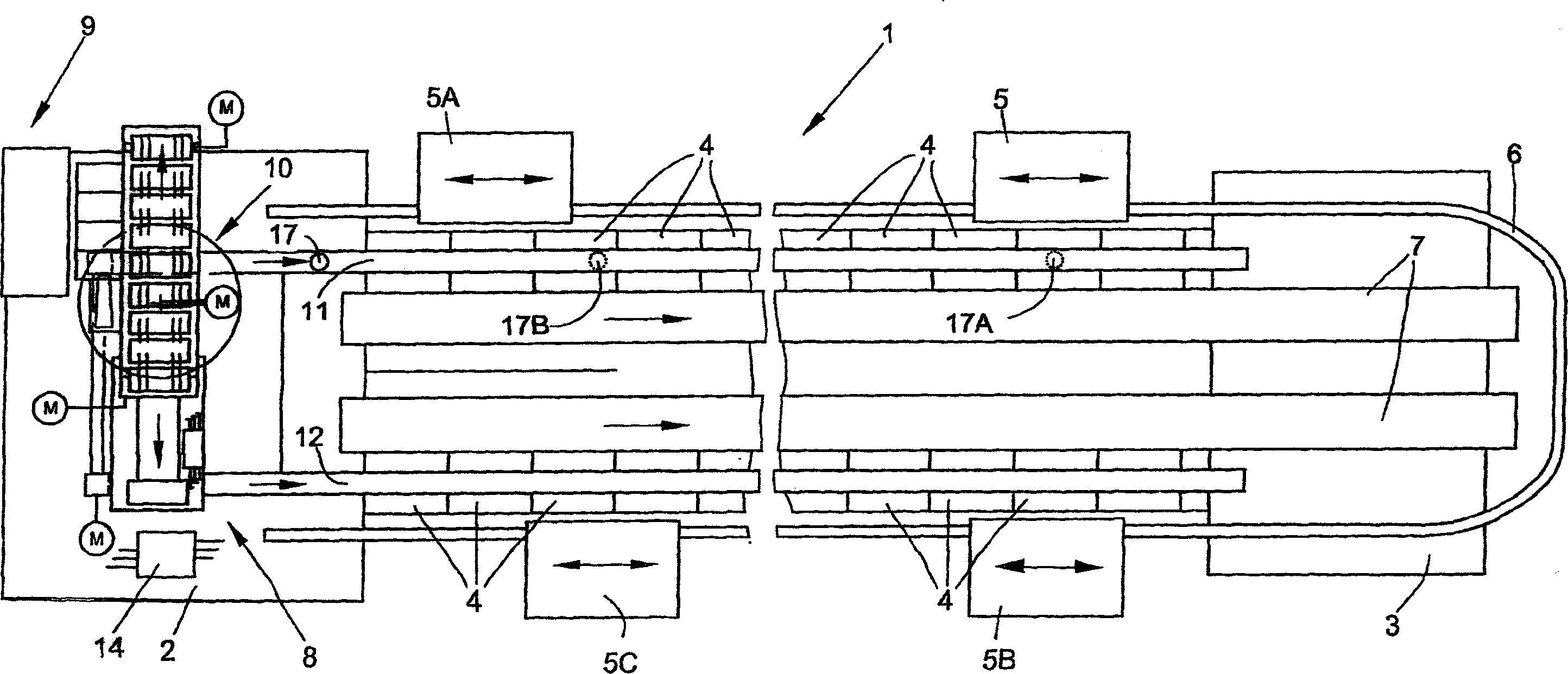

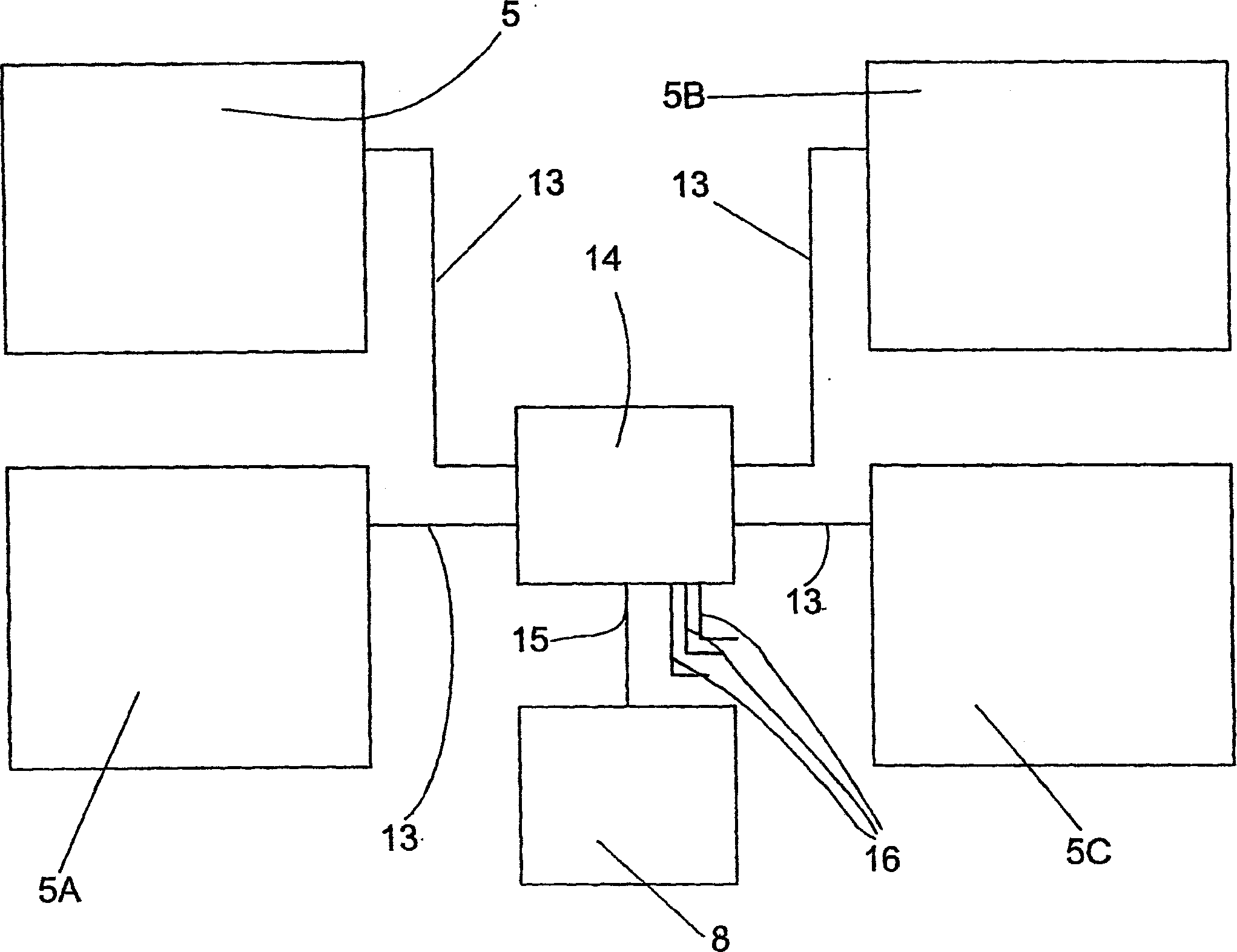

[0015] figure 1 The air spinning machine 1 shown has a plurality of work stations 4 between the end positions 2 and 3, which are arranged on both longitudinal sides of the spinning machine. The workstations 4 , which in each case include the weaving and winding mechanisms, are maintained by four maintenance units 5 , 5A, 5B, 5C. The maintenance units 5 , 5A, 5B, 5C are movable along the machine side on the guide rail structure 6 . One of the maintenance units 5, 5A, 5B, 5C works automatically if a yarn break occurs at one of the workstations 4 or a bobbin needs to be replaced. The air spinning machine 1 further comprises a cross-winding bobbin conveying device 7 and a bobbin feeding device 8 arranged between the workstations 4, the cross-winding bobbin conveying device 7 is used for conveying the completed cross-winding bobbins. The bobbin supply device 8 (in this example) comprises a central bobbin magazine 9 arranged at the end of the machine, a bobbin distribution device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com