Production method of metal powder

A manufacturing method and technology of metal powder, which are applied in the field of powdering strip base material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

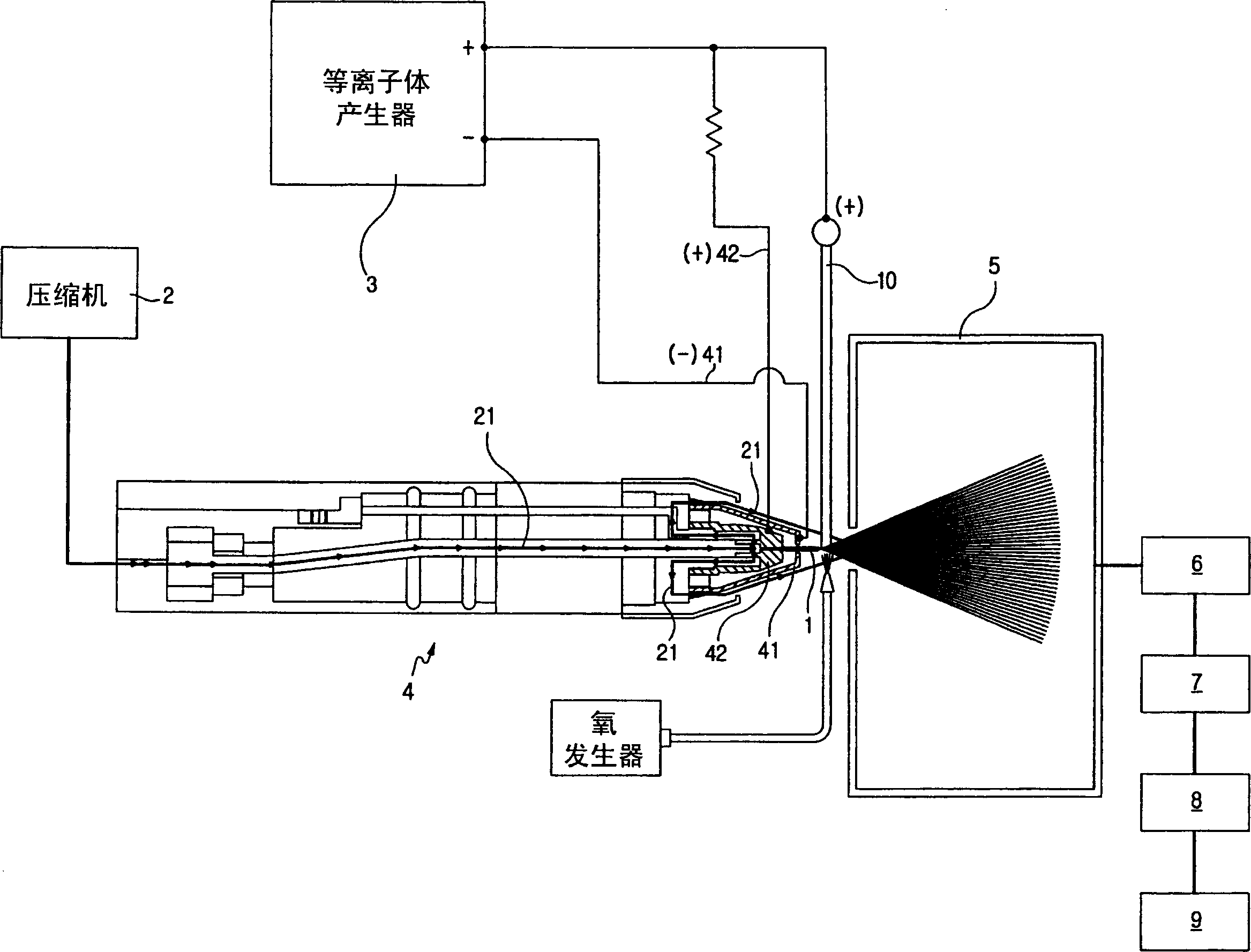

[0008] The first feature of the present invention is that a strip (scrip; linear, plate-shaped, tubular, etc.) made of a non-ferrous metal or a single substance of carbon is used as a powdered starting material, that is, as a base material 10, and a further aspect of the present invention It is characterized in that the base material 10 is heated by the arc (Arc) generated by the torch 4 of the plasma generator 3 to make it plasma, and then sprayed, cooled, and collected to produce powder.

[0009] Elemental strips of non-ferrous metal or carbon as the starting material of powder metal, including titanium, cobalt, copper (Cu), aluminum, calcium tungstate ore, zirconium, high chromium steel, corrosion-resistant nickel-based alloy (hastelloy), Silver (Ag) and Carbon (C). Among them, when the base material 10 is titanium, it is ideal for productivity to set the thickness to 1.5 to 2 mm. This tendency appears particularly in the case of producing products in nm units.

[0010] J...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap