Canned beer

A technology of beer and canning, which is applied in the field of finished beer and can solve the problems of beer oxidation and beer with large voids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

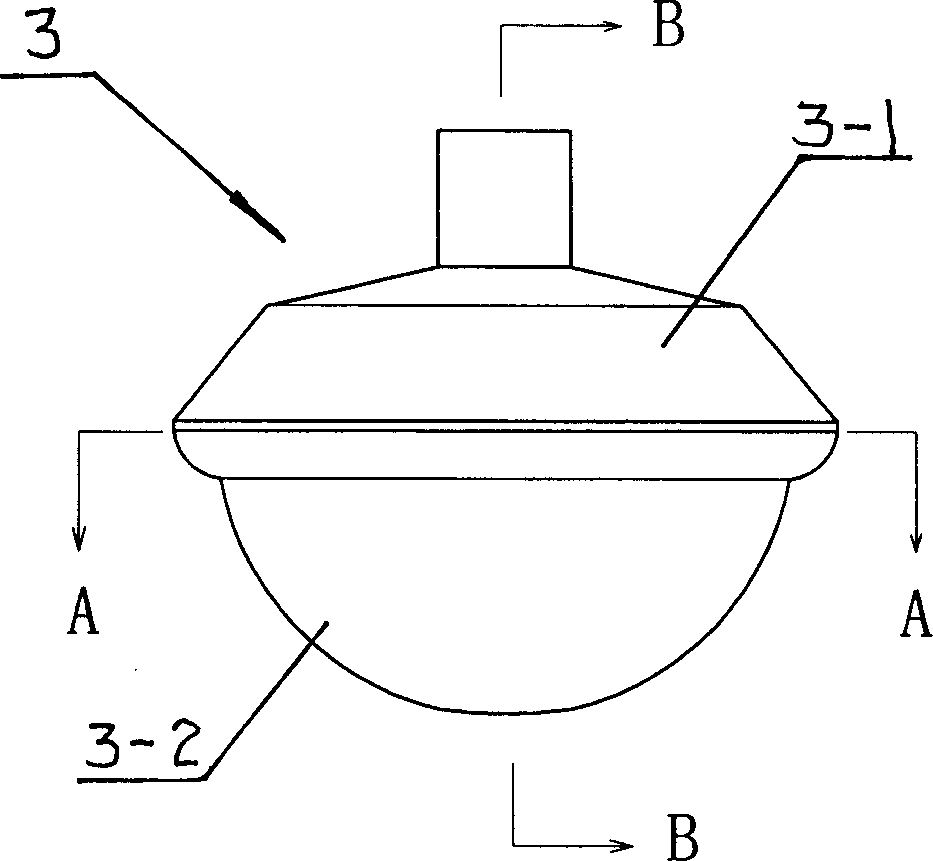

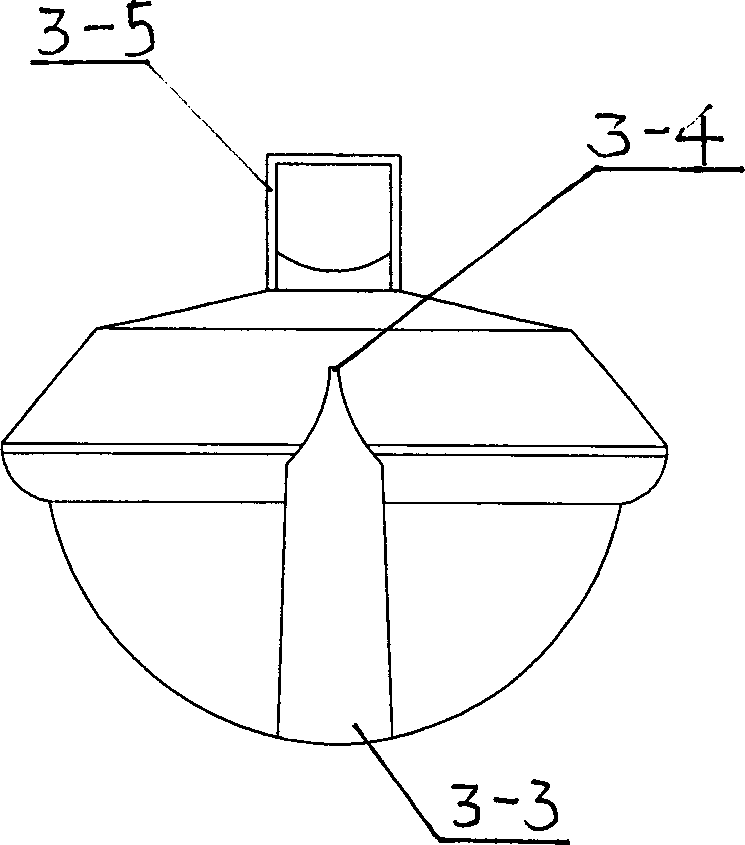

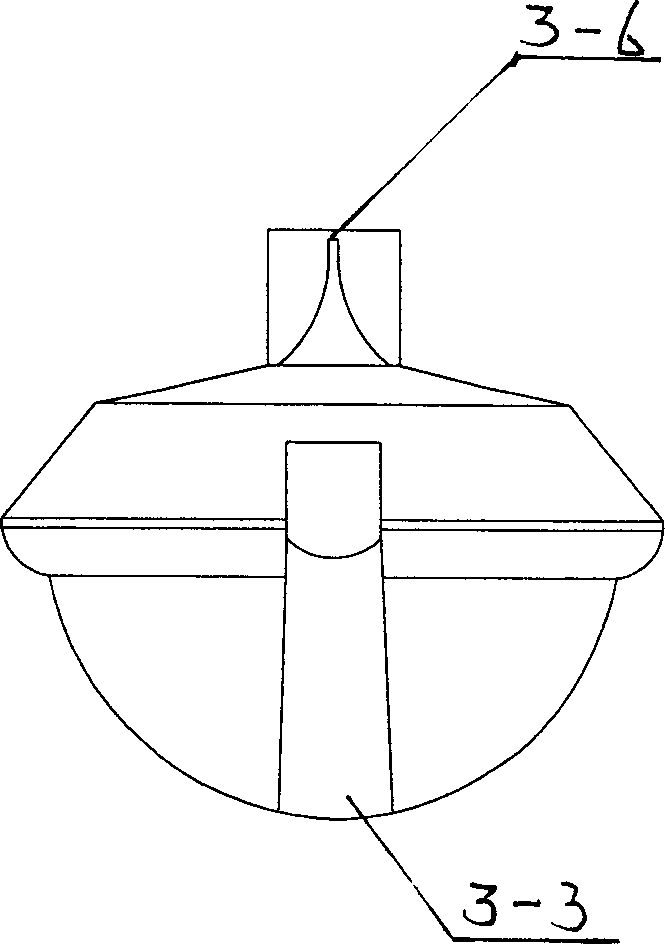

[0021] see figure 1 , figure 2 , image 3 and Figure 5 , the shape of the liquid nitrogen container is similar to a sphere, that is, the liquid nitrogen sphere 3, and the liquid nitrogen sphere 3 is spliced by two shells 3-1 and 3-2, wherein the shell 3-2 has an inner concave hole 3-3, and the hole The end portion is a flat mouth-shaped air inlet 3-4; the other housing 3-1 has a round tube 3-5 protruding from the surface of the shell, and the round tube 3-5 is provided with a flat mouth-shaped air outlet 3-6.

[0022] Liquid nitrogen ball 3 is made of PE or PP material, non-toxic, tasteless food packaging material, injection-molded into spherical liquid nitrogen ball.

[0023] The minimum diameter of the liquid nitrogen ball 3 should be greater than the maximum opening of the lid opening of the tank body, so as to avoid flowing out from the lid opening and entering the drinker's mouth.

[0024] Fill the liquid nitrogen ball with an appropriate amount of liquid nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com