Edible oil and preparation process thereof

A technology for edible oil and grease, applied in the field of edible oil, can solve the problems of reducing the gloss and quality of edible oil, affecting the quality and color of edible oil, and the inhibition effect is not obvious, so as to strengthen antioxidant properties and chemical stability, prevent High temperature browning phenomenon and the effect of preventing cardiovascular disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

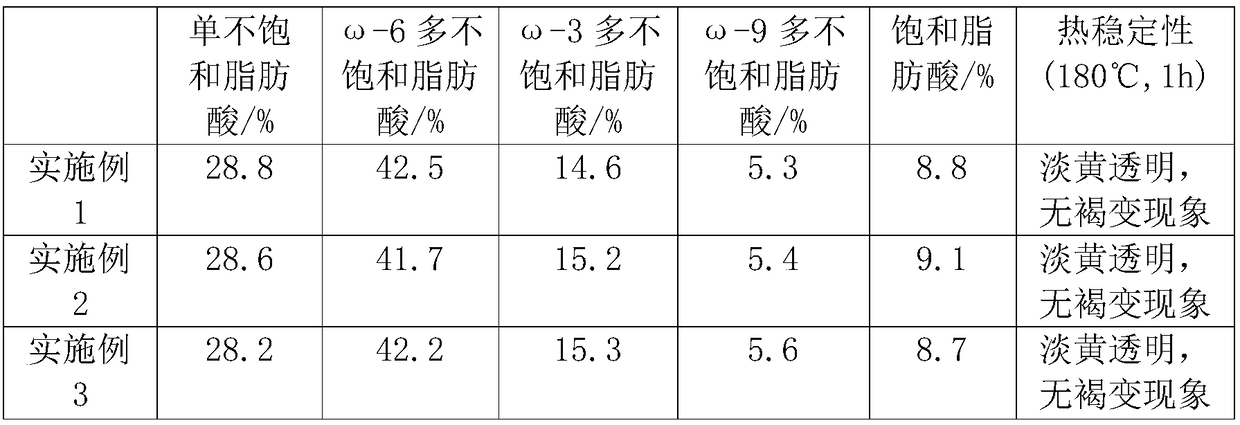

Examples

Embodiment 1

[0017] An edible oil, comprising the following raw materials in parts by weight: 50 parts of peanut oil, 30 parts of soybean oil, 16 parts of camellia seed oil, 11 parts of walnut oil, 10 parts of grape seed oil, 8 parts of argan oil, 6 parts of hemp oil, 5 parts of rice bran oil 10 parts, 10 parts of sheep oil, 0.1 part of grease improver;

[0018] Among them, the oil improver includes the following components by weight: 49% of glucose oxidase, 20% of lecithin, 9% of nano selenium, 2% of vitamin E, 1% of tea polyphenols, 5% of lycopene, 4% of carnosol %, chlorogenic acid 2%, phytic acid 8%.

[0019] The blending process of above-mentioned a kind of edible oil comprises the following steps:

[0020] S1: Mix glucose oxidase, lecithin, nano-selenium, vitamin E, tea polyphenols, lycopene, carnosol, chlorogenic acid, and phytic acid in parts by weight under nitrogen at 25°C to obtain oil improvement agent;

[0021] S2: Vacuum the mixing tank to 10Pa, add sheep oil, heat to 50°C...

Embodiment 2

[0024] An edible oil, comprising the following raw materials in parts by weight: 55 parts of peanut oil, 35 parts of soybean oil, 18 parts of camellia seed oil, 13 parts of walnut oil, 11 parts of grape seed oil, 9 parts of argan oil, 7 parts of hemp oil, 6 parts of rice bran oil 12 parts of mutton oil, 0.2 part of grease improver;

[0025] Among them, the oil improver includes the following components by weight: 36% of glucose oxidase, 25% of lecithin, 12% of nano selenium, 2.5% of vitamin E, 1.5% of tea polyphenols, 6% of lycopene, Carnot Alcohol 5%, chlorogenic acid 3%, phytic acid 9%.

[0026] The deployment process is the same as in Example 1, the difference is:

[0027] S1: The temperature is 28°C; S2: Vacuumize to 35Pa, heat to 55°C, heat up to 110°C, and the stirring pressure is 1.5MPa; S3: The stirring pressure is 5MPa.

Embodiment 3

[0029] An edible oil, comprising the following raw materials in parts by weight: 60 parts of peanut oil, 40 parts of soybean oil, 20 parts of camellia seed oil, 15 parts of walnut oil, 12 parts of grape seed oil, 10 parts of argan oil, 8 parts of hemp oil, 7 parts of rice bran oil 14 parts of sheep oil, 0.3 parts of grease improver;

[0030] Among them, the oil improver includes the following components by weight: 23% of glucose oxidase, 30% of lecithin, 15% of nano selenium, 3% of vitamin E, 2% of tea polyphenols, 7% of lycopene, 6% of carnosol %, chlorogenic acid 4%, phytic acid 10%.

[0031] The deployment process is the same as in Example 1, the difference is:

[0032] S1: The temperature is 30°C; S2: Vacuumize to 60Pa, heat to 60°C, heat up to 120°C, and the stirring pressure is 2MPa; S3: The stirring pressure is 6MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com