Hybrid sphere-waveguide resonators

一种谐振器、微型谐振器的技术,应用在光波导光导、光波导的耦合、仪器等方向,能够解决未解决微球体和波导管耦合等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention can be applied to passive and active optical devices, such as sensors, filters, amplifiers, and / or micro lasers using micro resonators such as micro spheres and micro planar ring resonators. The present invention can be believed to be particularly useful for manufacturing such devices. Since the relative position of the microresonator and the waveguide can be controlled, the Q value of the microresonator can be high, and the light beam can be easily transmitted and received.

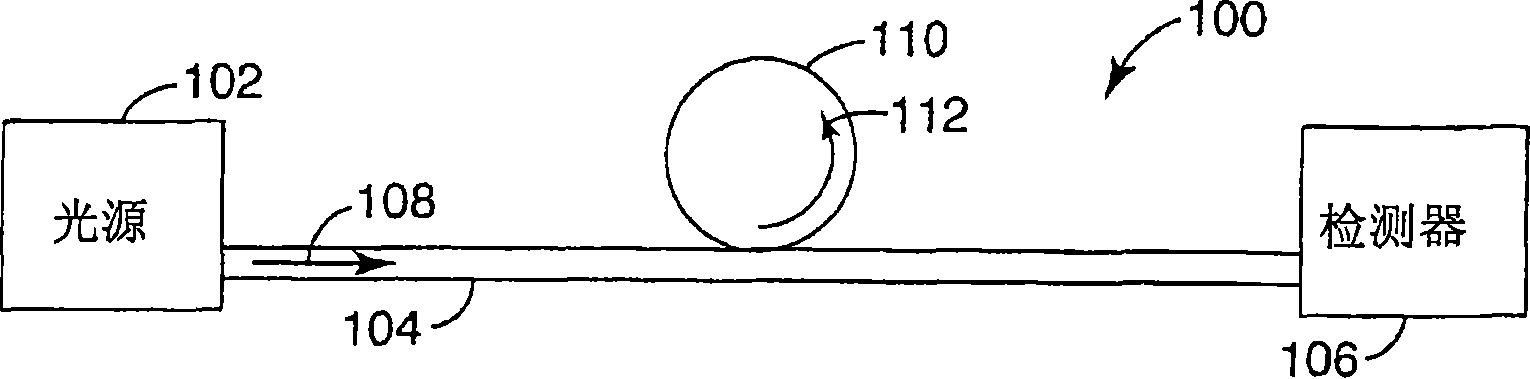

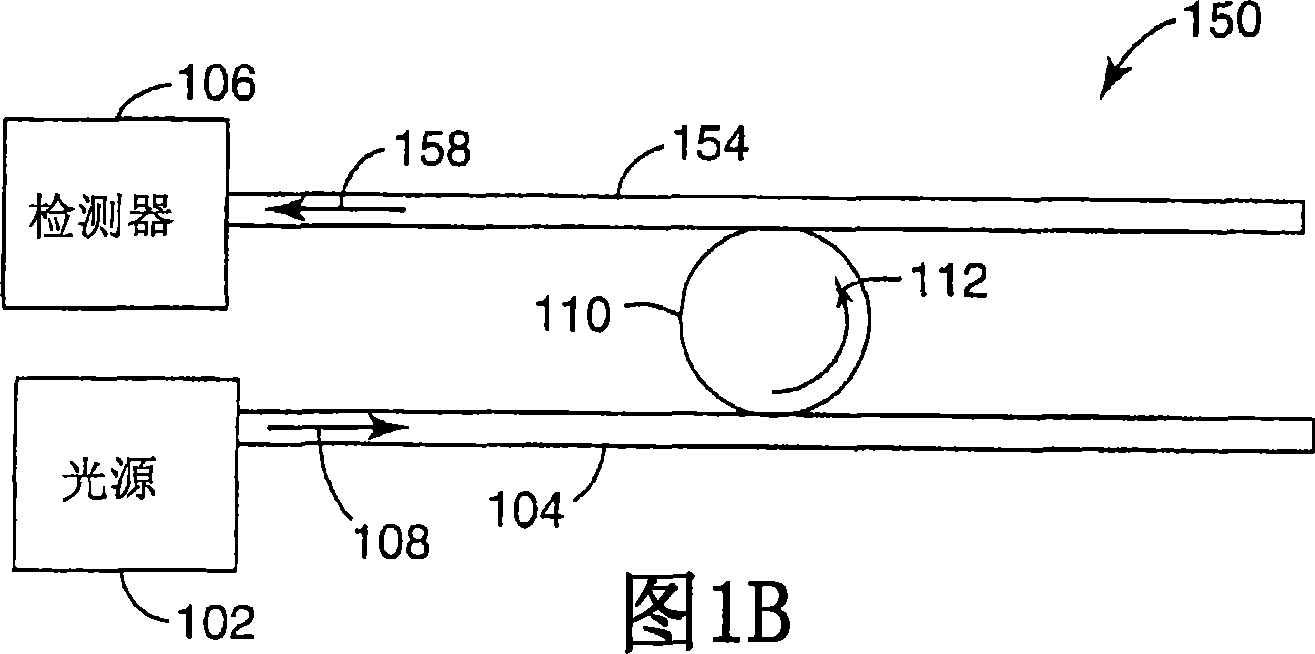

[0027] in Figure 1A The microsphere waveguide system 100 using microresonators is schematically shown in FIG. The light source 102 guides the light along the waveguide 104 to the detector unit 106. The micro resonator 110 is optically coupled to the waveguide 104. Light 108 is emitted from the light source 102 into the waveguide 104 and propagates toward the detector unit 106. The micro resonator 110 evanescently couples some of the light 108 out of the waveguide 104, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com