Production method and equipment of dazzling plate

A production method and technology of production equipment, applied in the field of production methods and production equipment of glare panels, can solve the problems of poor performance and appearance quality, easy falling off of adsorption layer, low technical difficulty, etc., so as to avoid easy generation of bubbles and easy falling off , various styles of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

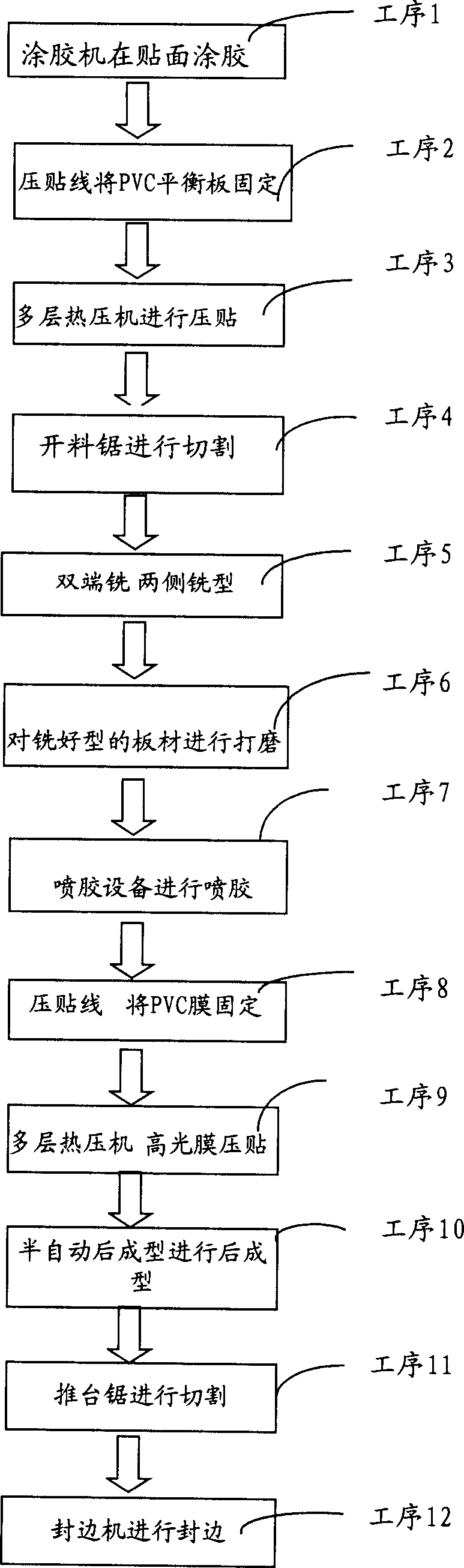

[0045] The production method of the glare panel provided by the present invention is characterized by changing the conventional adsorption processing process and adopting an innovative pressing process, which has the advantages of good gloss, high brightness, abrasion resistance, corrosion resistance, stain resistance, convenient scrubbing, and no deformation. , the surface pattern is rich in color.

[0046] In the production method of the glare board of the present invention, first, the balance board is fixed on the base material; then the combination of the balance board and the base material is pressed; then the high-gloss film PVC is fixed on the base material; and The high-gloss film PVC is pressed and pasted to form a glare board.

[0047] In addition, the production method of the glare panel of the present invention can properly adjust the order of pressing according to the different production lines of users, and can also fix the high-gloss film on the base material fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com