Transverse multicolor frozen drink and preparation method thereof

A frozen drink, horizontal technology, applied in the field of horizontal multi-color frozen drinks and its preparation, can solve the problems of groove defects at the edges of different materials, and the bottom layer of materials is easy to fall off, etc., to achieve the effect of avoiding easy fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

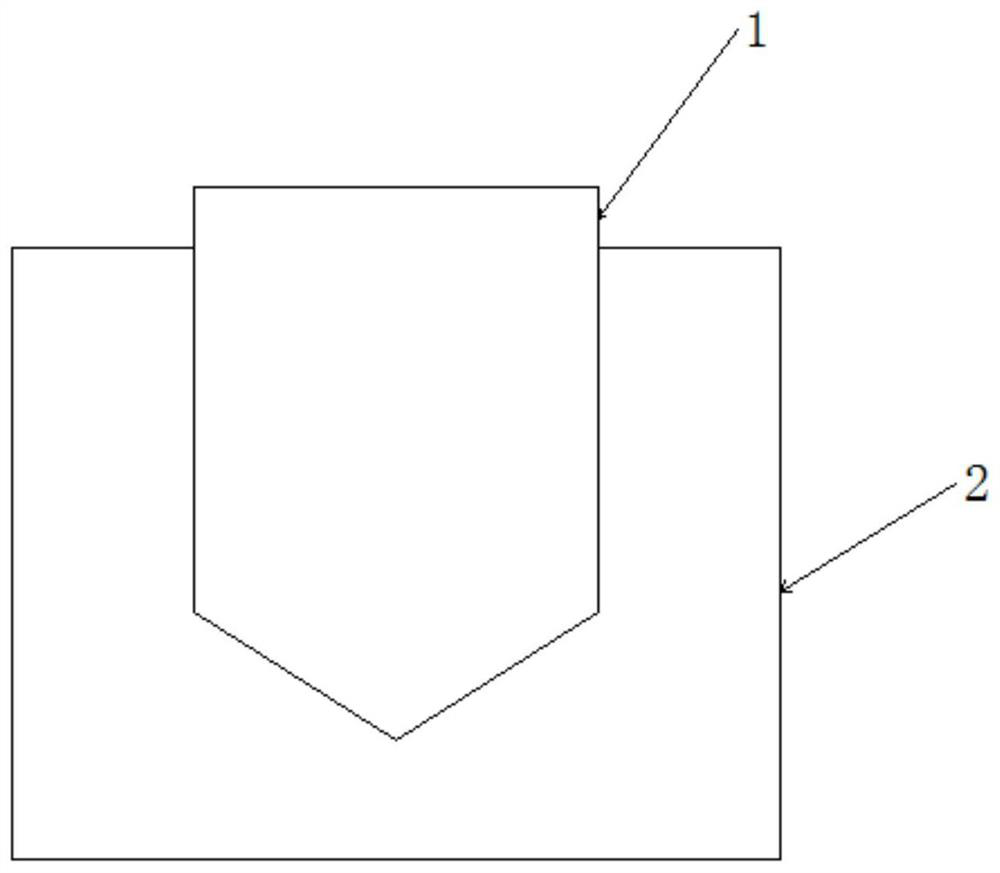

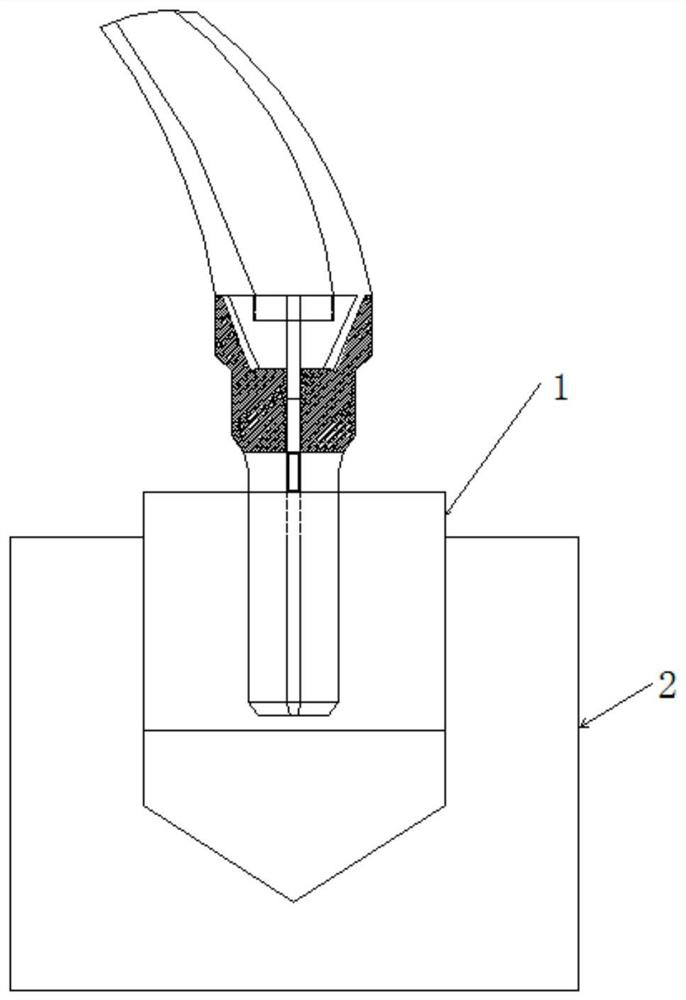

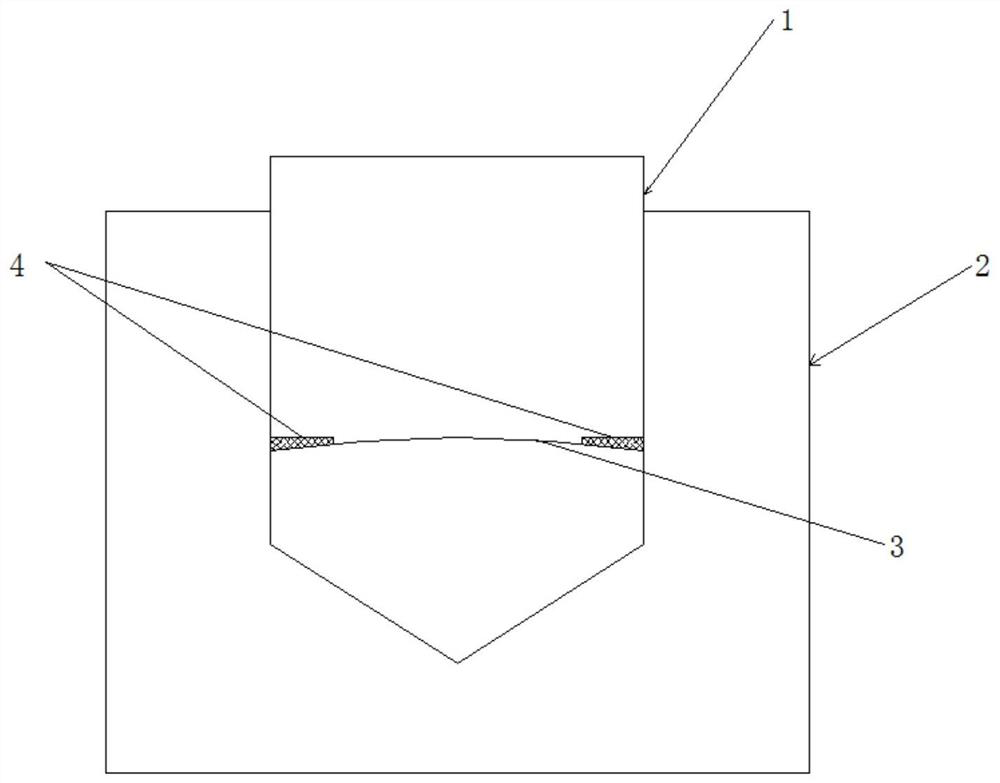

Image

Examples

Embodiment 1

[0046] This embodiment provides a horizontal four-color frozen drink, and the material composition of each color layer is as follows:

[0047]The formula of the first color layer (based on 1000kg): white sugar: 200kg, dragon fruit jam (including fruit seeds): 100kg, konjac flour: 2kg, xanthan gum: 0.5kg, CMC: 0.5kg, red pigment: 1.0kg, Essence: 1.0kg, the rest is drinking water.

[0048] The formula of the second color layer (based on 1000kg): white sugar: 170kg, passion fruit jam (including fruit seeds): 100kg, konjac flour: 2kg, xanthan gum: 0.5kg, CMC: 0.5kg, yellow pigment: 1.0kg, Essence: 1.0kg, the rest is drinking water.

[0049] The third color layer formula (based on 1000kg): white sugar: 140kg, maltitol: 30kg, konjac flour: 2kg, xanthan gum: 0.5kg, CMC: 0.5kg, blue pigment: 1.0kg, essence: 1.0kg, the rest for drinking water.

[0050] Formula of the fourth color layer (based on 1000kg): white sugar: 110kg, maltitol: 30kg, konjac powder: 2kg, xanthan gum: 0.5kg, CMC...

Embodiment 2

[0069] This embodiment provides a horizontal four-color frozen drink, and the material composition of each color layer is as follows:

[0070] The formula of the first color layer (based on 1000kg): white sugar: 210kg, dragon fruit jam (including fruit seeds): 110kg, konjac flour: 2kg, xanthan gum: 0.5kg, CMC: 0.5kg, red pigment: 1.0kg, Essence: 1.0kg, the rest is drinking water.

[0071] The formula of the second color layer (based on 1000kg): white sugar: 180kg, passion fruit jam (including fruit seeds): 110kg, konjac flour: 2kg, xanthan gum: 0.5kg, CMC: 0.5kg, yellow pigment: 1.0kg, Essence: 1.0kg, the rest is drinking water.

[0072] The third color layer formula (based on 1000kg): white sugar: 140kg, maltitol: 30kg, konjac flour: 2kg, xanthan gum: 0.5kg, CMC: 0.5kg, blue pigment: 1.0kg, essence: 1.0kg, the rest for drinking water.

[0073] Formula of the fourth color layer (based on 1000kg): white sugar: 110kg, maltitol: 30kg, konjac powder: 2kg, xanthan gum: 0.5kg, CM...

Embodiment 3

[0082] This embodiment provides a horizontal four-color frozen drink, and the material composition of each color layer is as follows:

[0083]The formula of the first color layer (based on 1000kg): white sugar: 200kg, dragon fruit jam (including fruit seeds): 100kg, konjac flour: 2kg, xanthan gum: 0.5kg, CMC: 0.5kg, red pigment: 1.0kg, Essence: 1.0kg, the rest is drinking water.

[0084] The formula of the second color layer (based on 1000kg): white sugar: 170kg, passion fruit jam (including fruit seeds): 100kg, konjac flour: 2kg, xanthan gum: 0.5kg, CMC: 0.5kg, yellow pigment: 1.0kg, Essence: 1.0kg, the rest is drinking water.

[0085] The third color layer formula (based on 1000kg): white sugar: 140kg, maltitol: 30kg, konjac flour: 2kg, xanthan gum: 0.5kg, CMC: 0.5kg, blue pigment: 1.0kg, essence: 1.0kg, the rest for drinking water.

[0086] Formula of the fourth color layer (based on 1000kg): white sugar: 140kg, maltitol: 30kg, konjac flour: 2kg, xanthan gum: 0.5kg, CMC:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com