Wind-mill generator

A generator and magnet technology, applied in wind power generation, electrical components, electromechanical devices, etc., can solve the problems of reduced wind power generation efficiency, increased generator starting resistance torque, and increased cut-in wind speed, so as to improve wind power generation efficiency and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] specific implementation plan

[0036] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

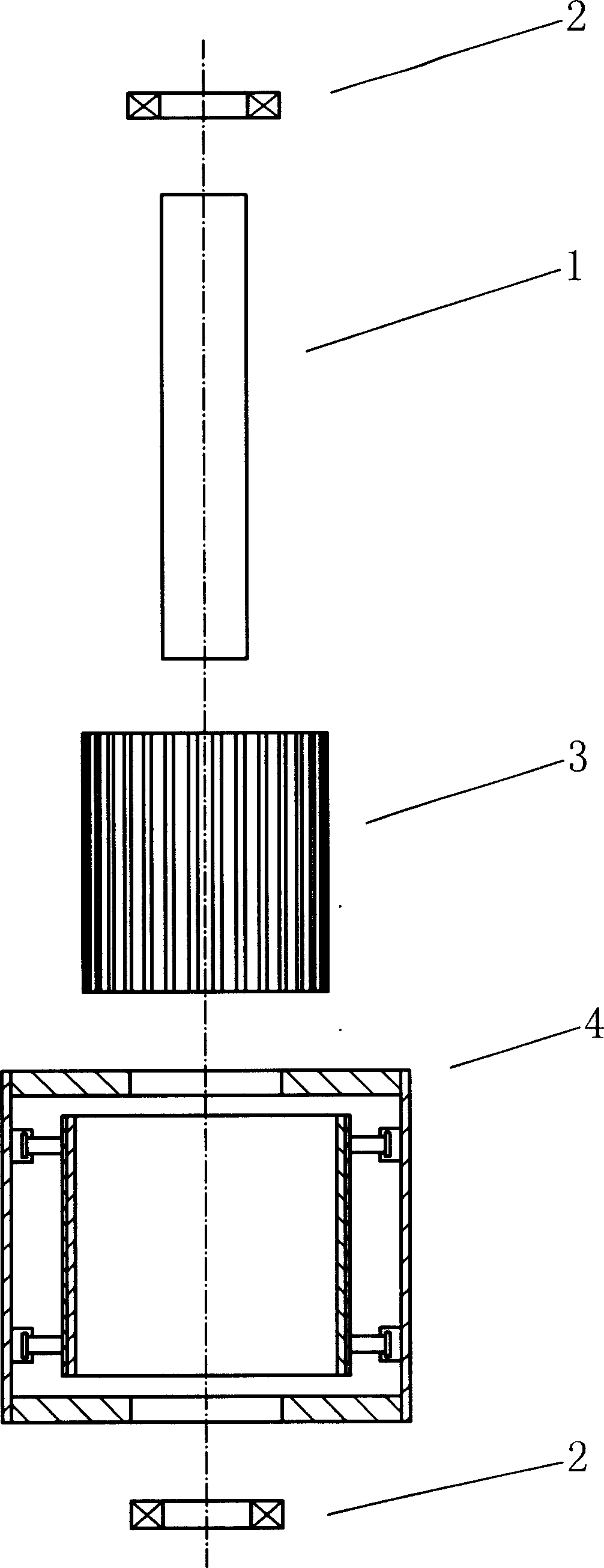

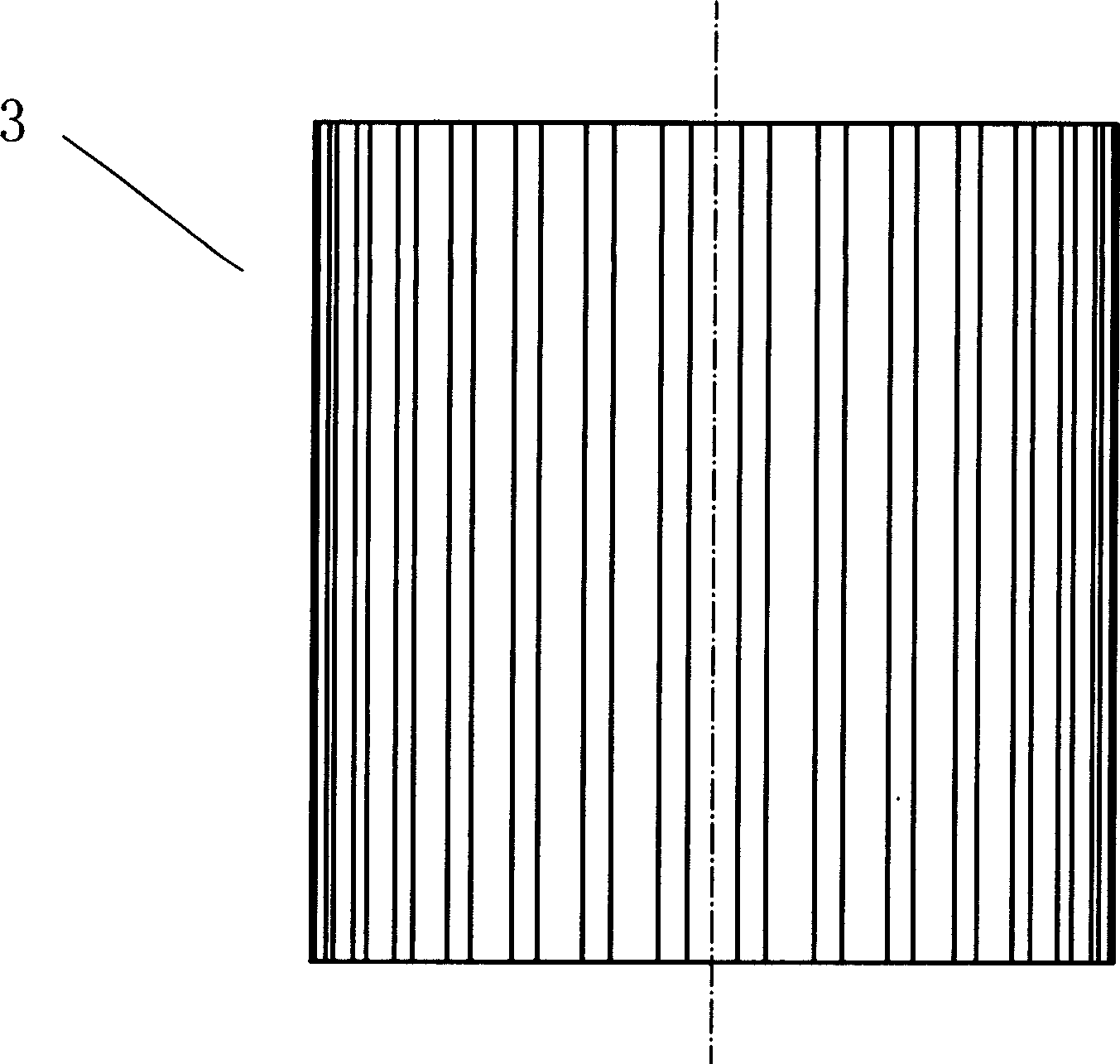

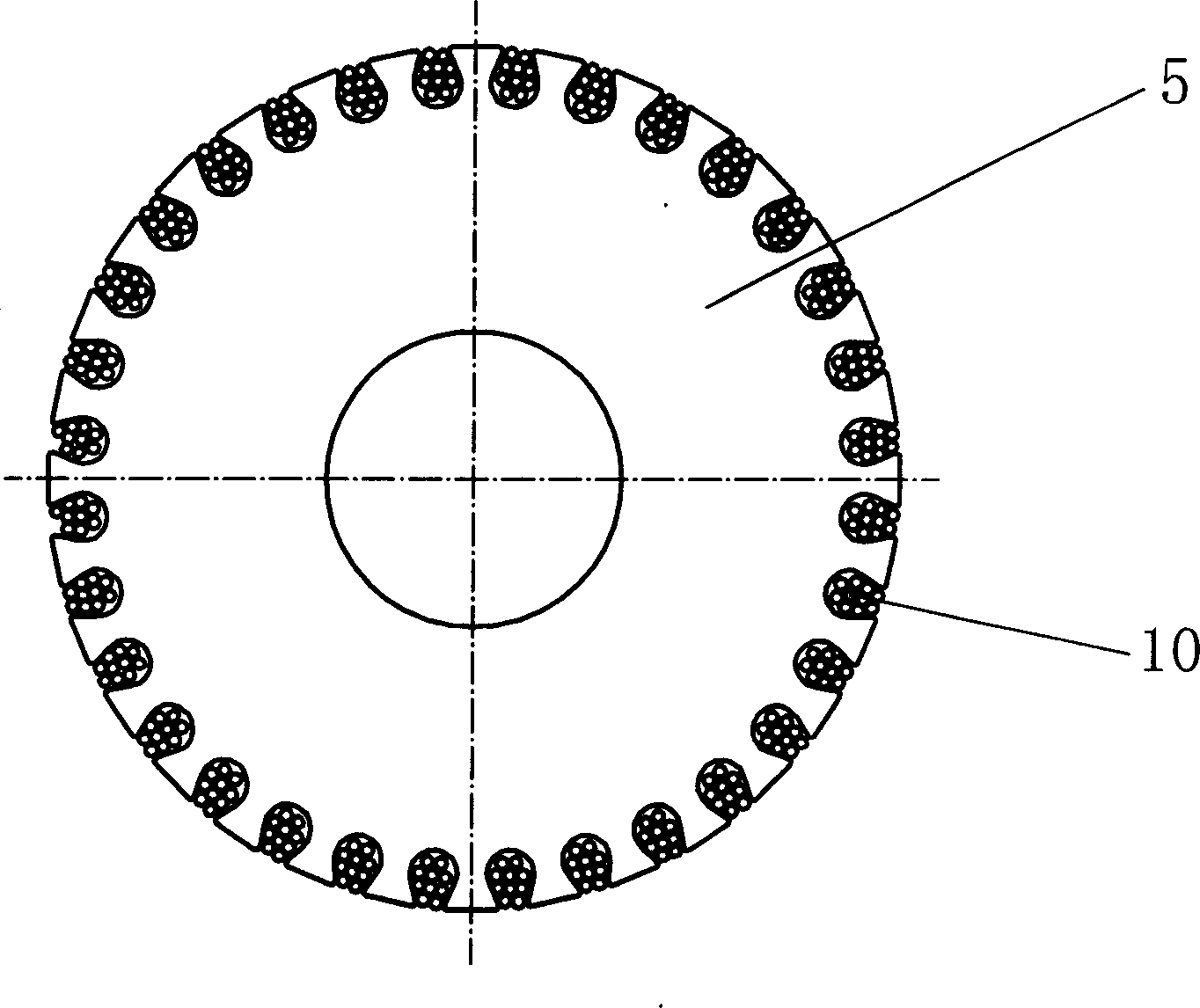

[0037] Figure 1 to Figure 9 , Figure 14 with Figure 15 It is the main assembly and its structure schematic diagram of the present invention. figure 1 It is shown that the generator of the present invention is composed of a main shaft 1, a bearing 2, an inner body 3 and an outer body 4, figure 2 with image 3 It is shown that the inner body 3 is composed of an iron core 5 and an armature winding 10, Figure 4 with Figure 5 is a structural schematic diagram of the exosome 4, Figure 14 with Figure 15 is another schematic diagram of the exosome 4; Image 6 , Figure 7 with Figure 8 It can be seen that the exciter is composed of a permanent magnet 11 and a magnet 9 formed with a yoke 12. Figure 9 It can be seen that the exciter can also be composed of a magnet 9 composed of an excitation winding 13 and a y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com