Roller screw

A technology of roller screw and roller, applied in belt/chain/gear, mechanical equipment, transmission, etc., can solve the problem of undeveloped preload applied by roller screw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

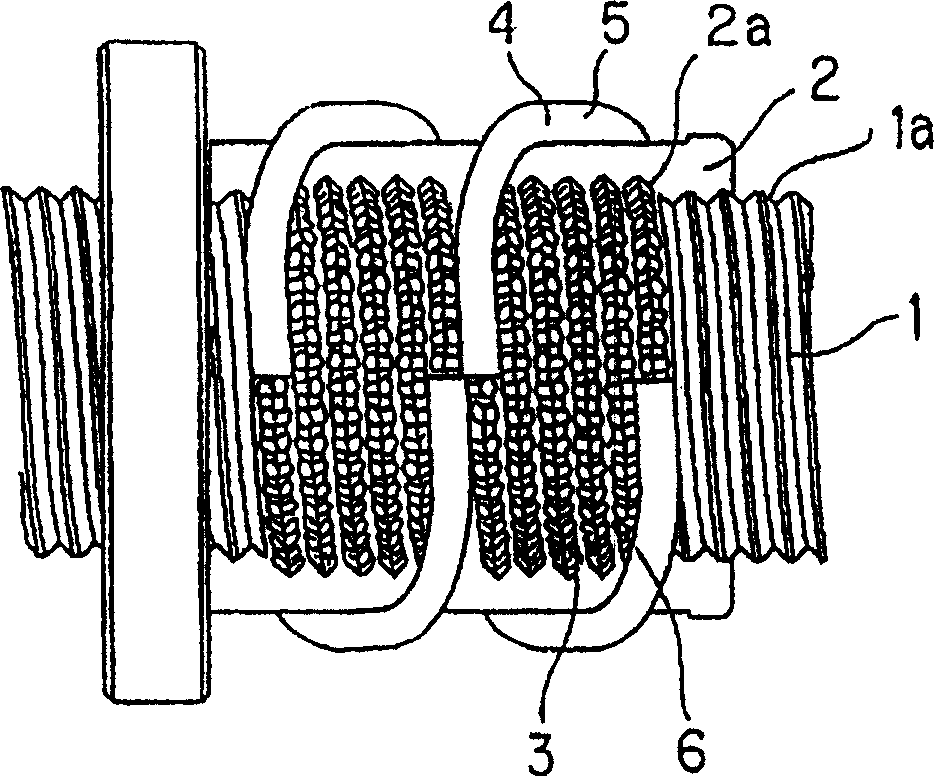

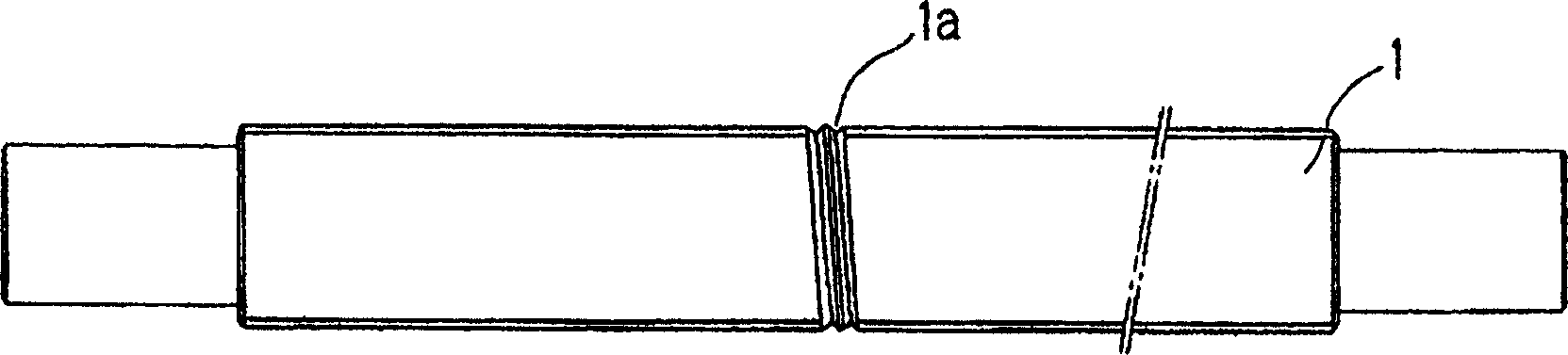

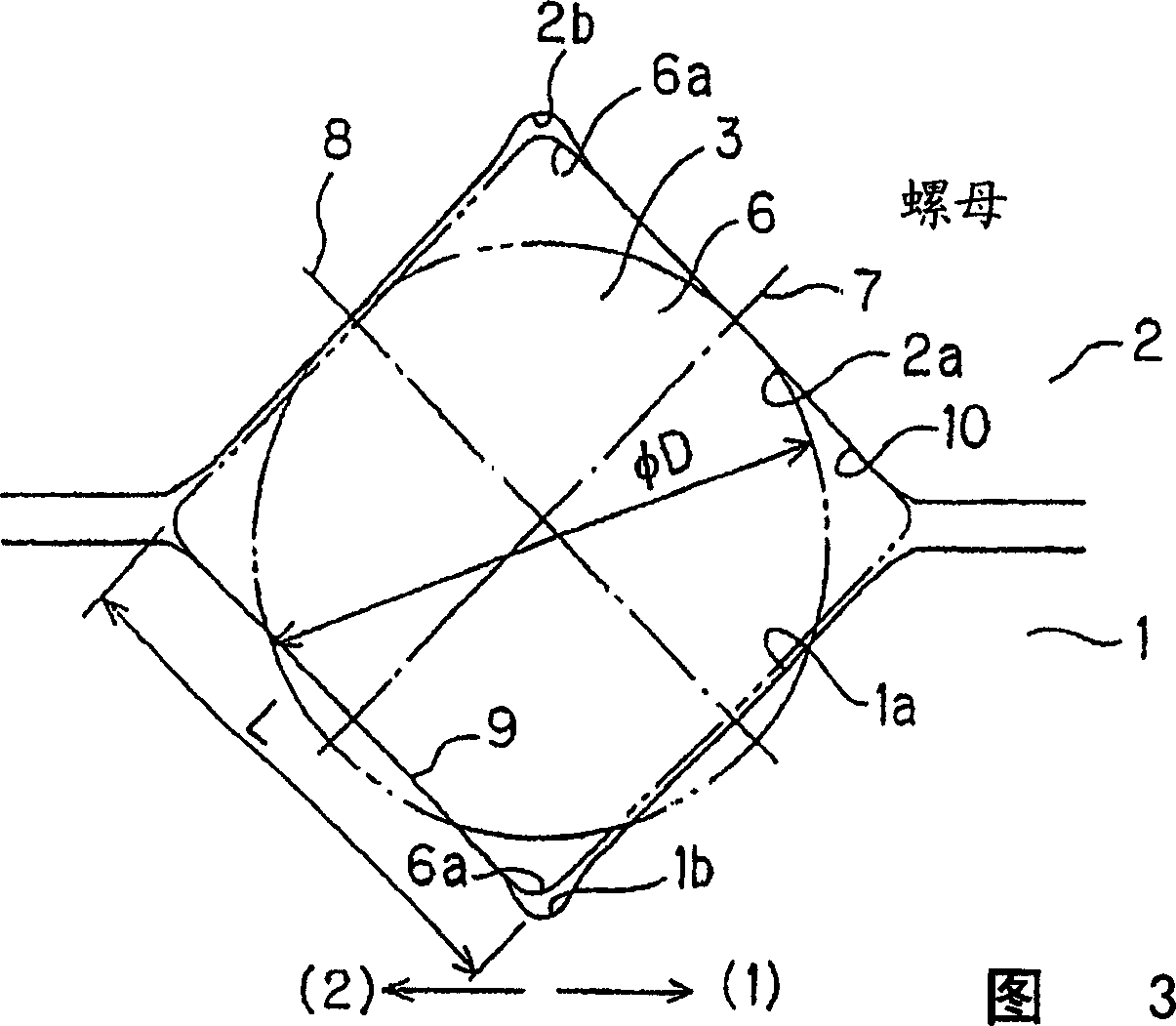

[0036] figure 1 A roller screw according to one embodiment of the present invention is shown. The roller screw has: a screw shaft 1 with a helical roller rolling groove 1a formed on the outer peripheral surface; The roller raceway groove 2a is relatively rotatably installed on the screw shaft 1. On the nut part 2, a return pipe 4 is mounted as a return part, and the return pipe rolls the loaded roller between the roller raceway groove 1a of the screw shaft 1 and the loaded roller raceway groove 2a of the nut part 2. One end of the channel 3 is connected to the other end. Inside the return pipe 4, a roller return passage 5 having a quadrangular cross-section, which is a square roller return passage 5 in this embodiment, is formed along the axial direction.

[0037] On the loaded roller rolling passage 3 between the roller rolling groove 1a of the screw shaft 1 and the loaded roller rolling groove 2a of the nut member 2, and the roller return passage 5 in the return pipe 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com