Patents

Literature

91results about How to "Easily avoided" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

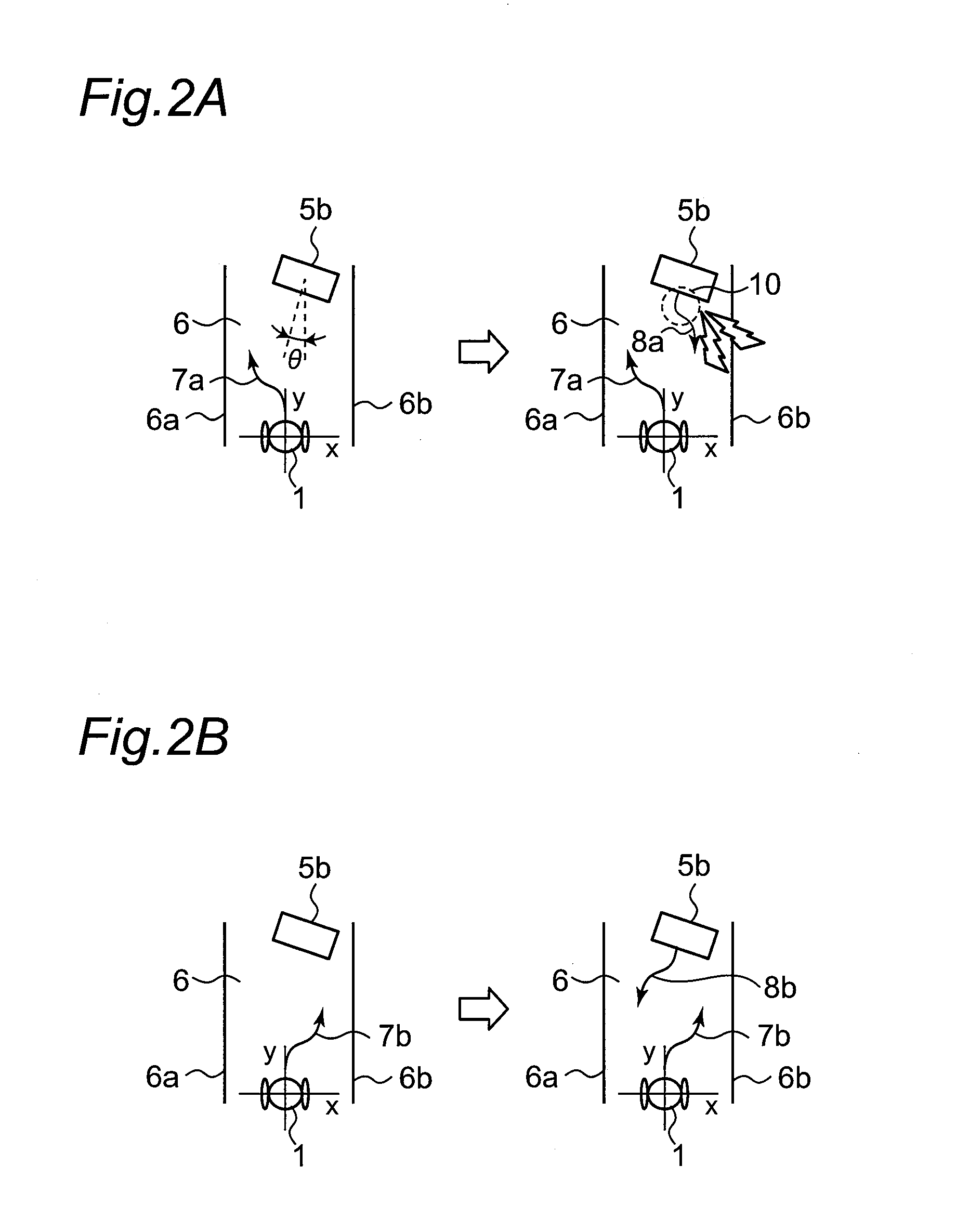

Optical integrator, illumination optical device, exposure device, and exposure method

ActiveUS20070132977A1Easily avoidedInhibit productionMirrorsPhotomechanical apparatusLight beamEngineering

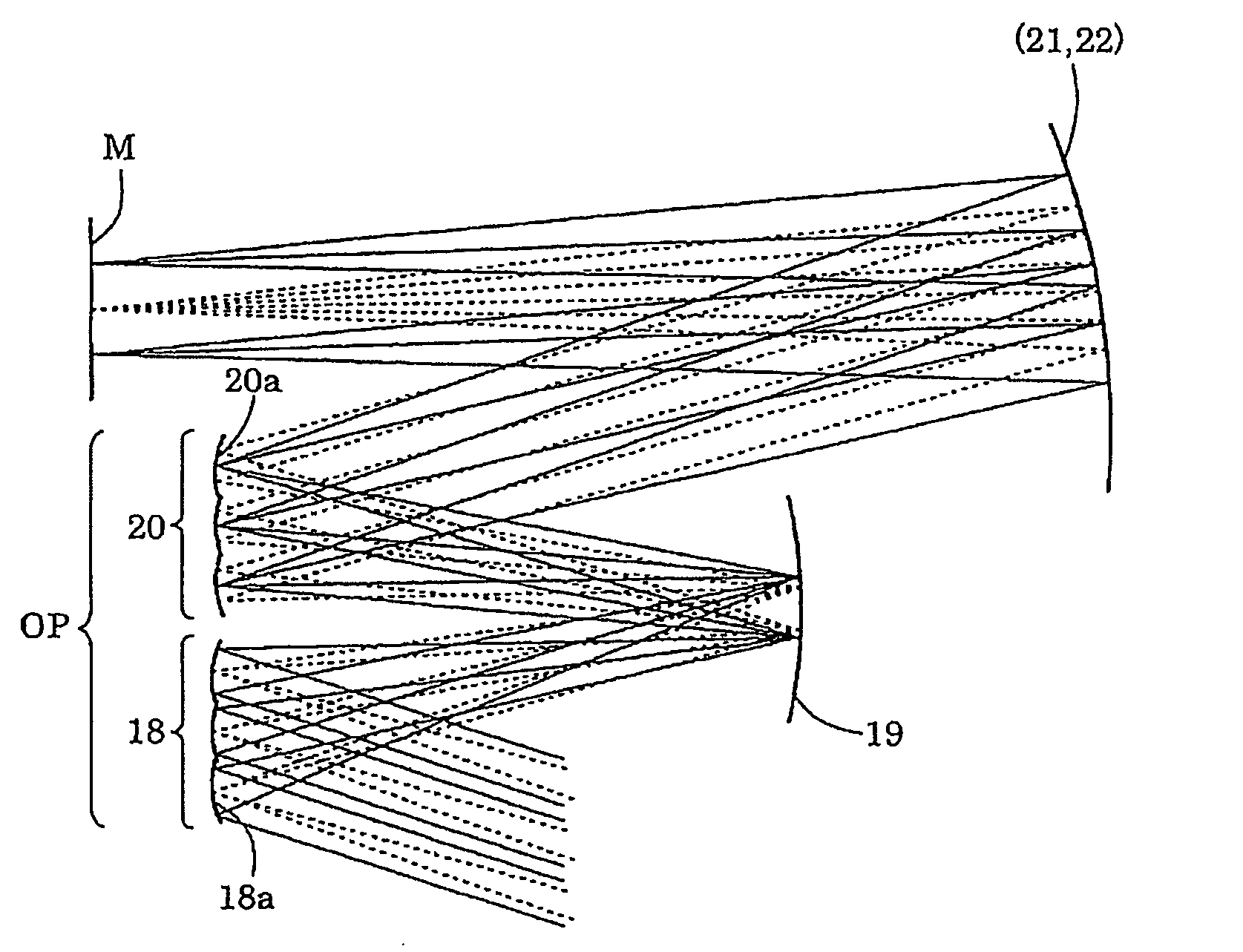

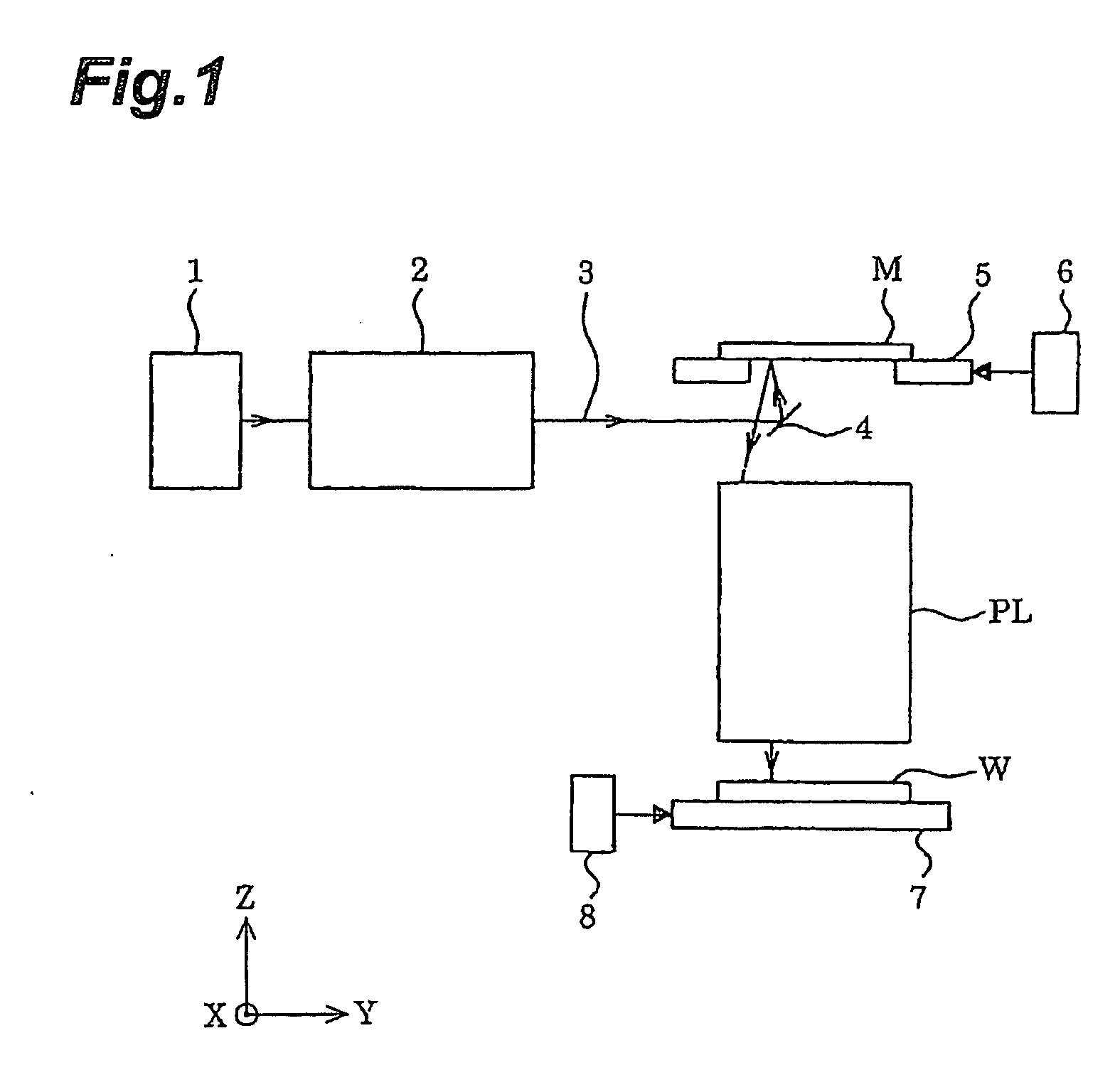

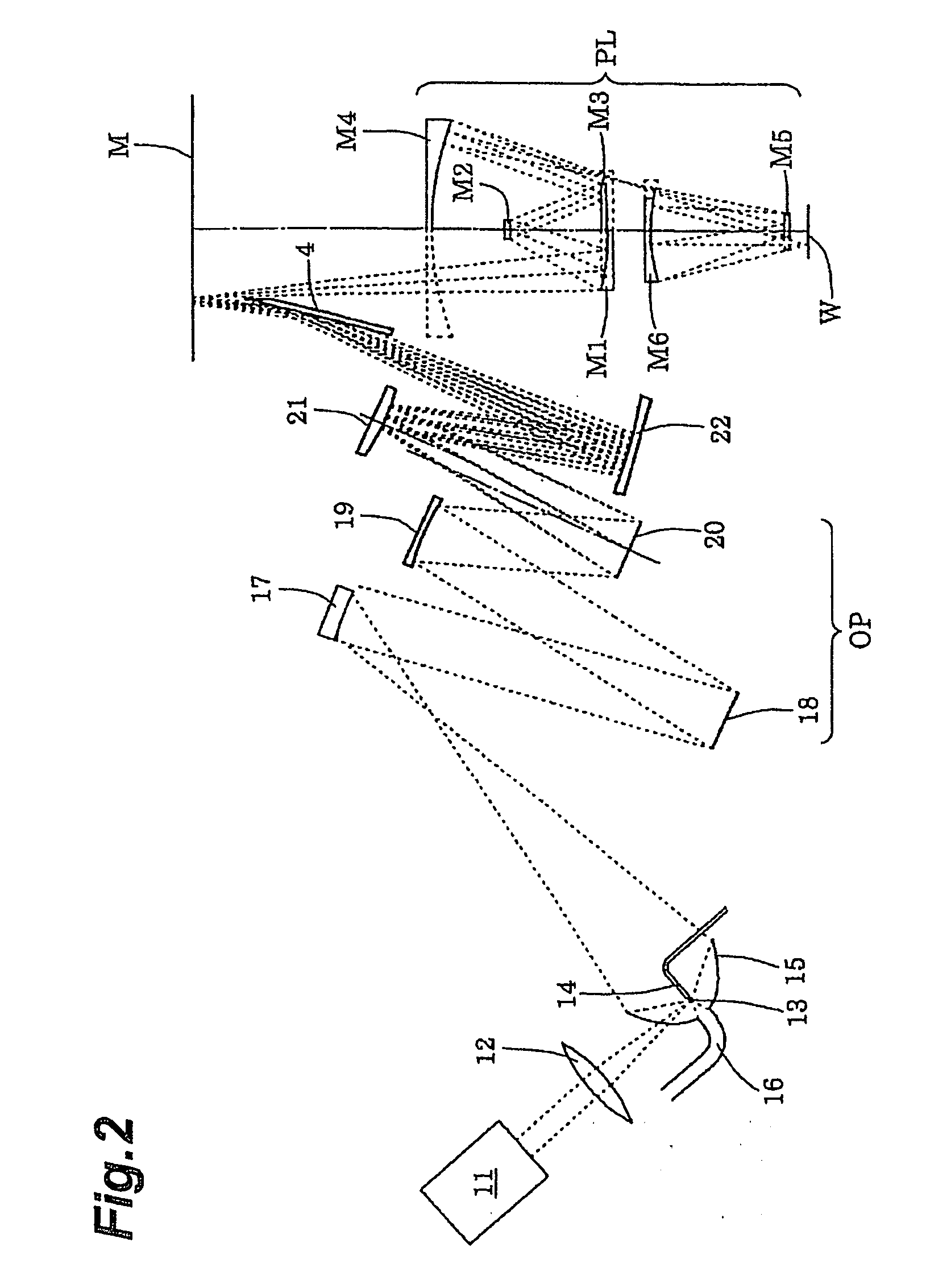

An optical integrator of a wavefront dividing type permits an arbitrary distance to be set between an entrance surface and an exit surface, without production of aberration and without reduction in reflectance on reflecting films. The optical integrator has a plurality of first focusing elements (first concave reflector elements 18a) arranged in parallel, a plurality of second focusing elements (second concave reflector elements 20a) arranged in parallel so as to correspond to the first focusing elements, and a relay optical system (19) disposed in an optical path between the first focusing elements and the second focusing elements. The relay optical system refocuses a light beam focused via one of the first focusing elements, on or near a corresponding second focusing element so as to establish an imaging relation of one-to-one correspondence between one of the first focusing elements and one of the second focusing elements.

Owner:NIKON CORP

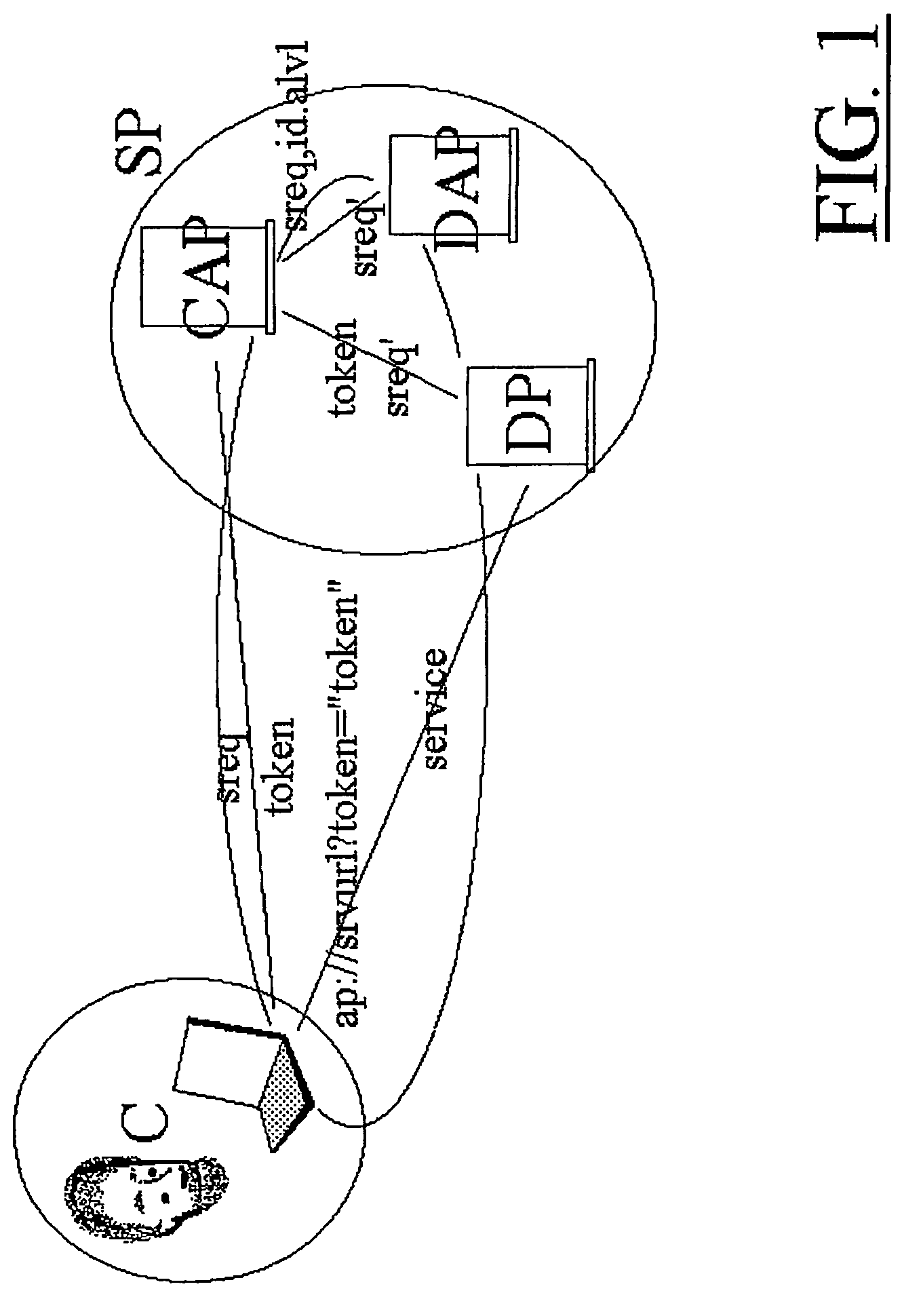

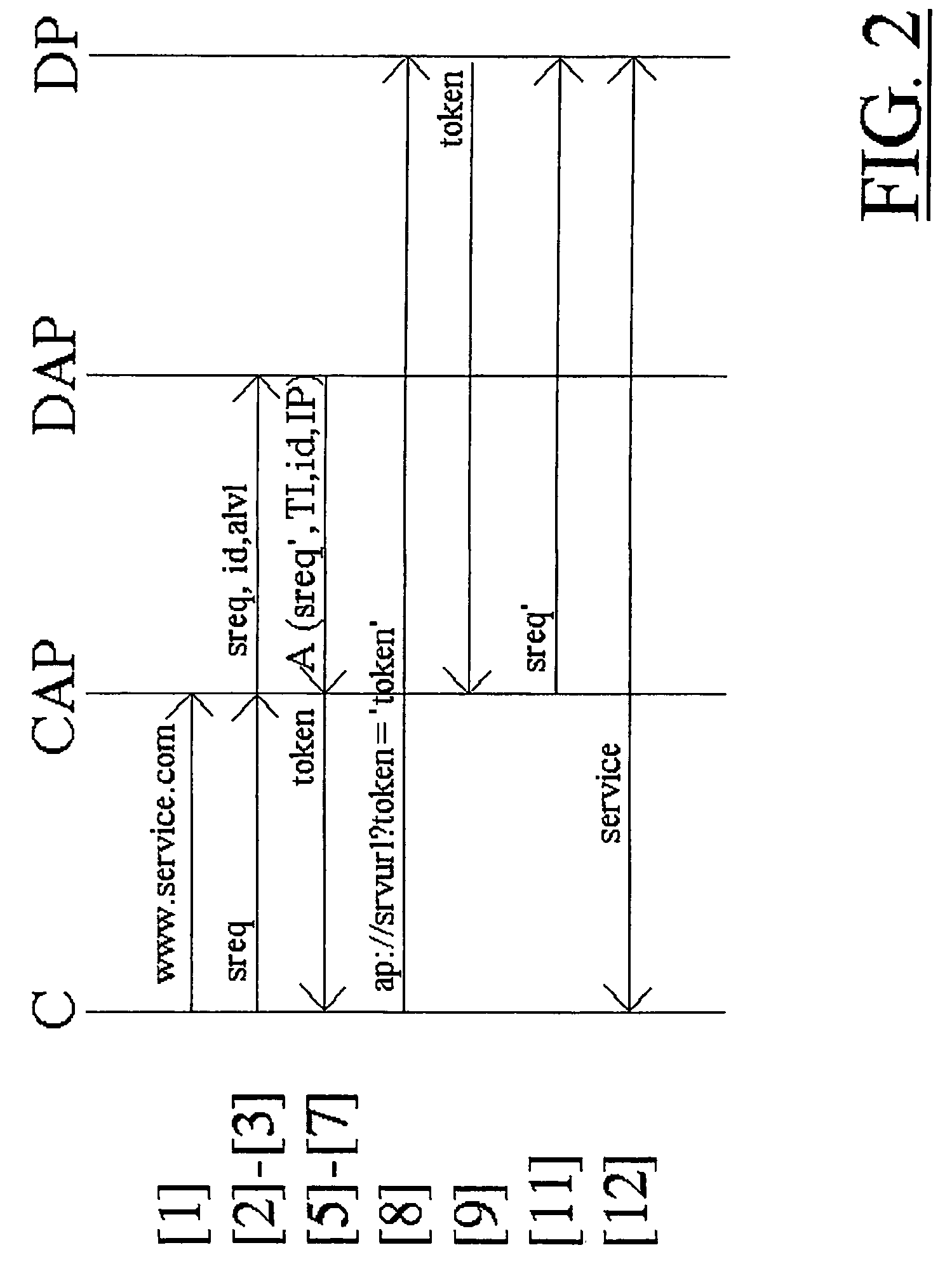

Method and system for a service process to provide a service to a client

InactiveUS7565554B2Simple interfaceEasily avoidedKey distribution for secure communicationUnauthorized memory use protectionAuthentication serverClient-side

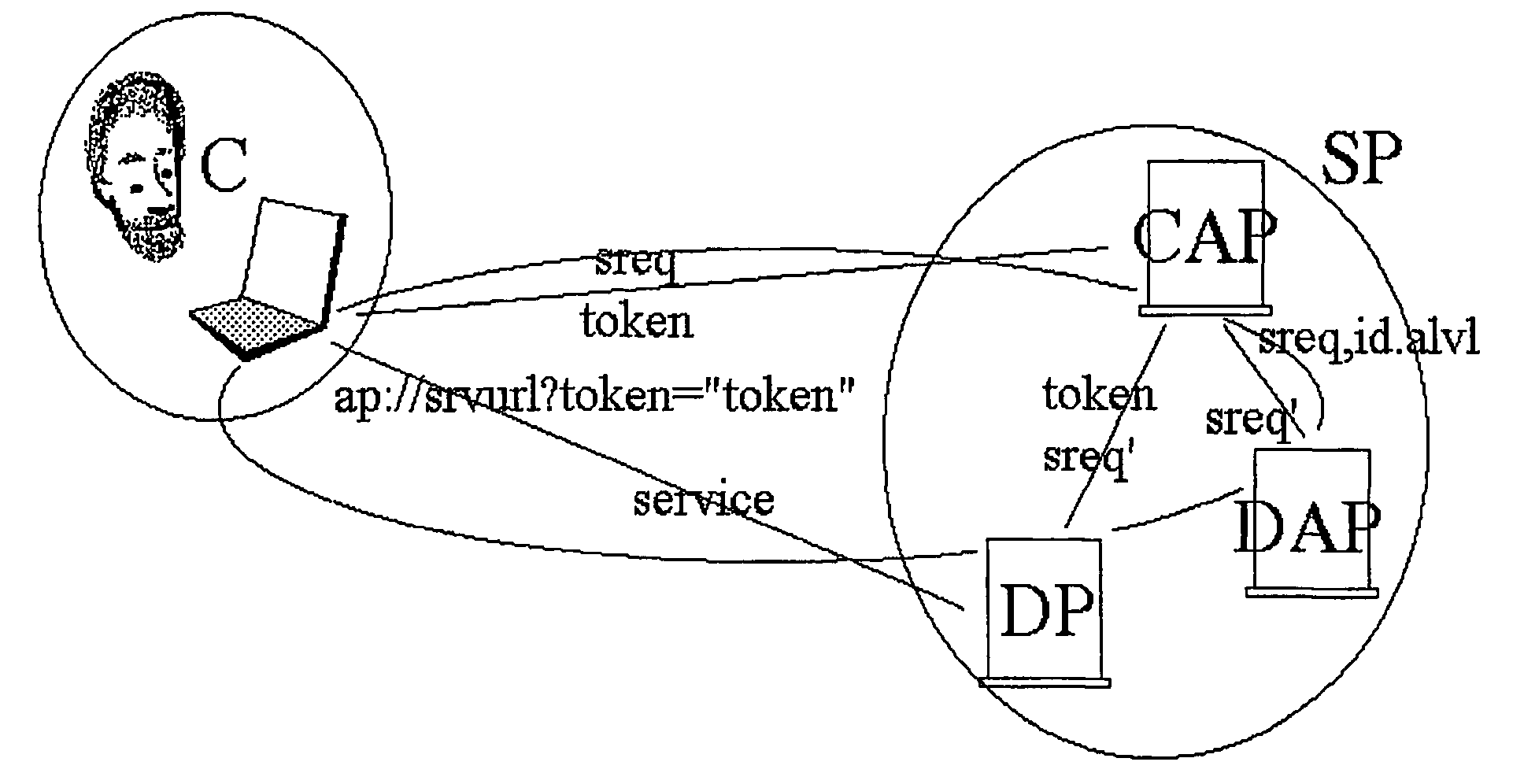

Method and system for a service server to provide a service to a client. The client (C) sets up a secure session to an authentication server (CAP) and sends its identifier and a service request stating the required service. The authentication server verifies the client identifier and sends the service request to a service authorization server (DAP). The authorization server checks whether the required service may be provided and sends the authorized service request to the authentication server. The authentication server generates a token, associated with the authorized service request. Via the secure session, the authentication server sends the address of the relevant service server and the token. The client sends the token to the service server, which then sends the token to the authentication server. The authentication server fetches the service request associated with the token and forwards it to the service server, after which the service server gives the client the required service.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

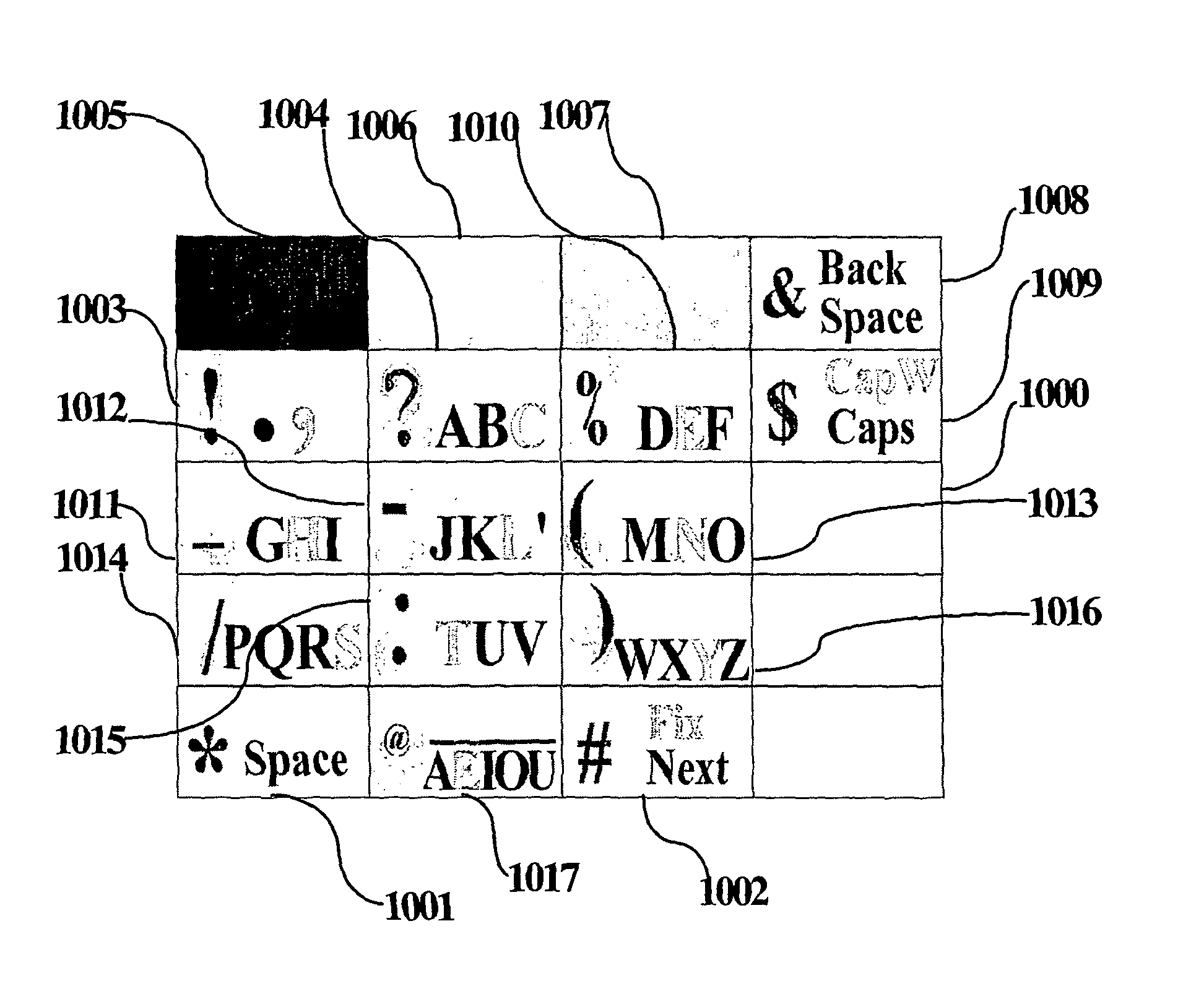

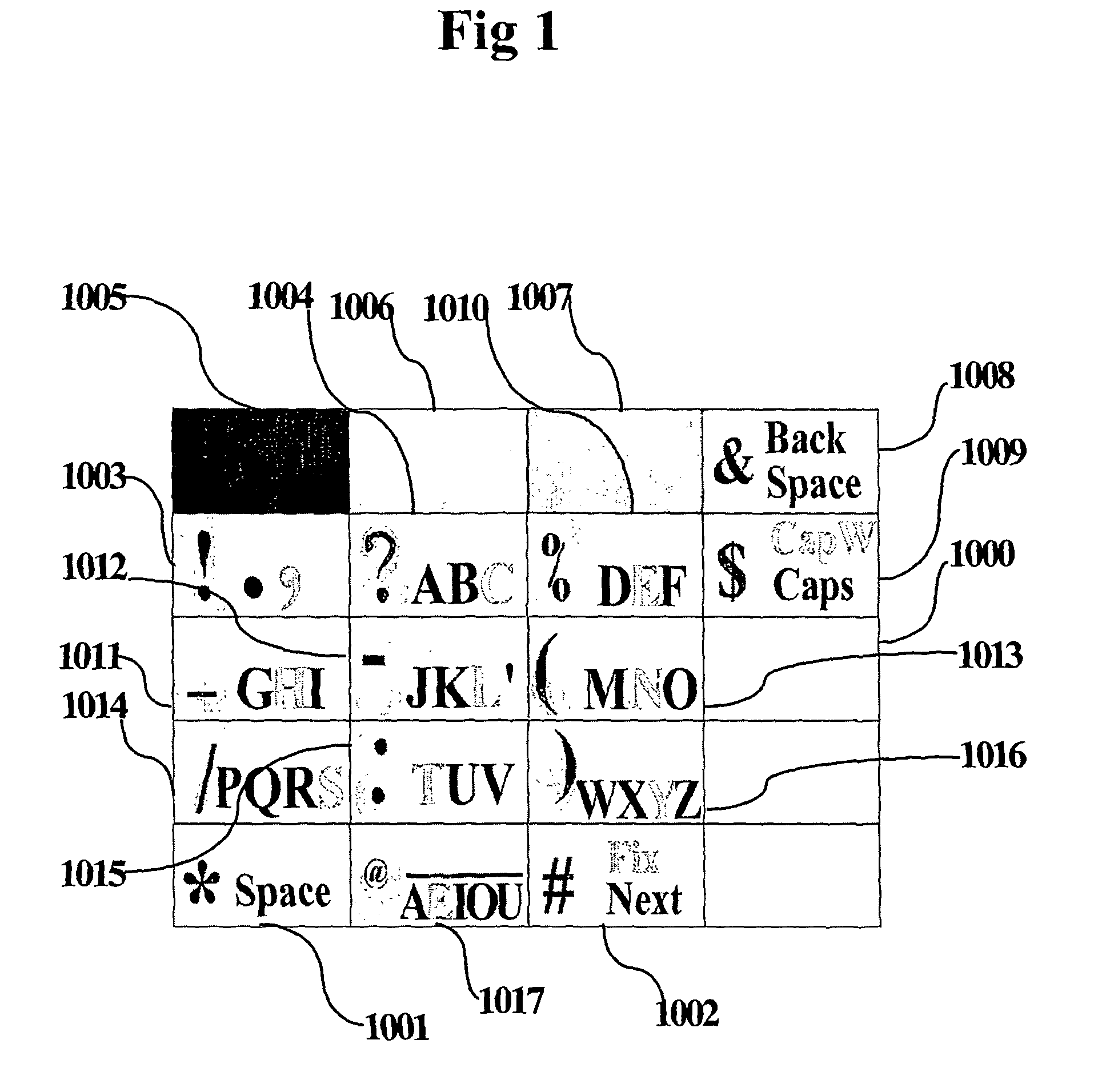

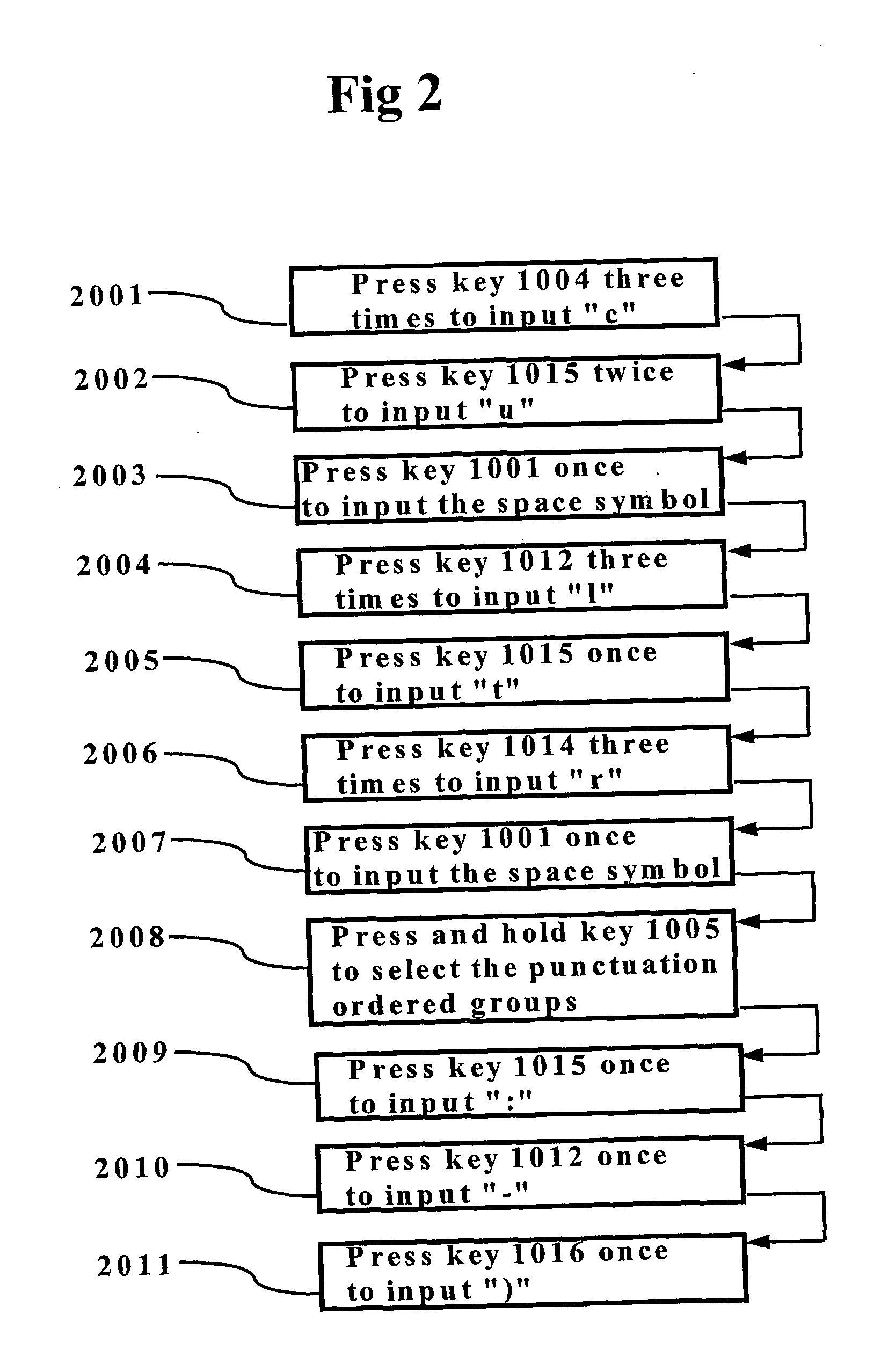

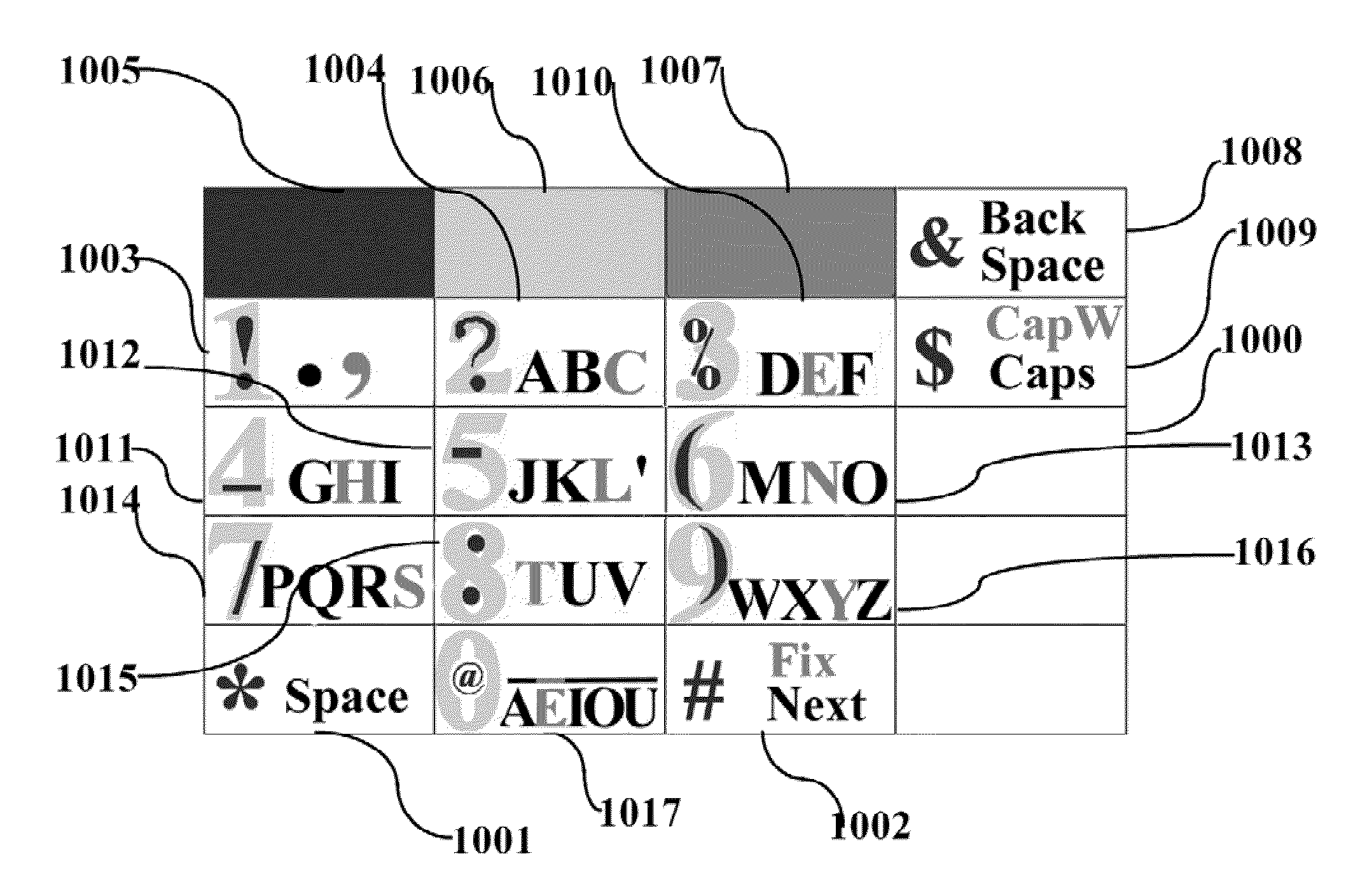

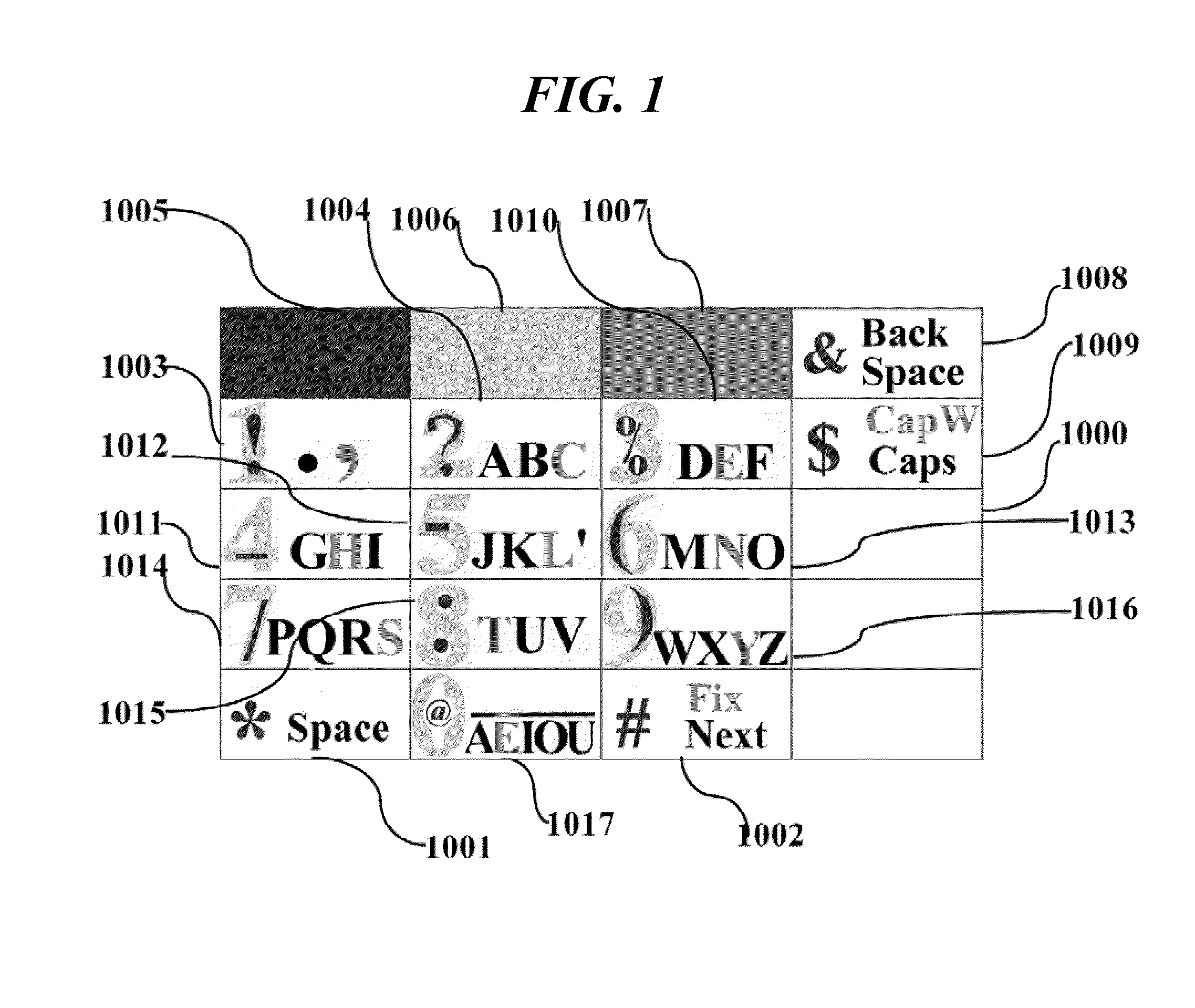

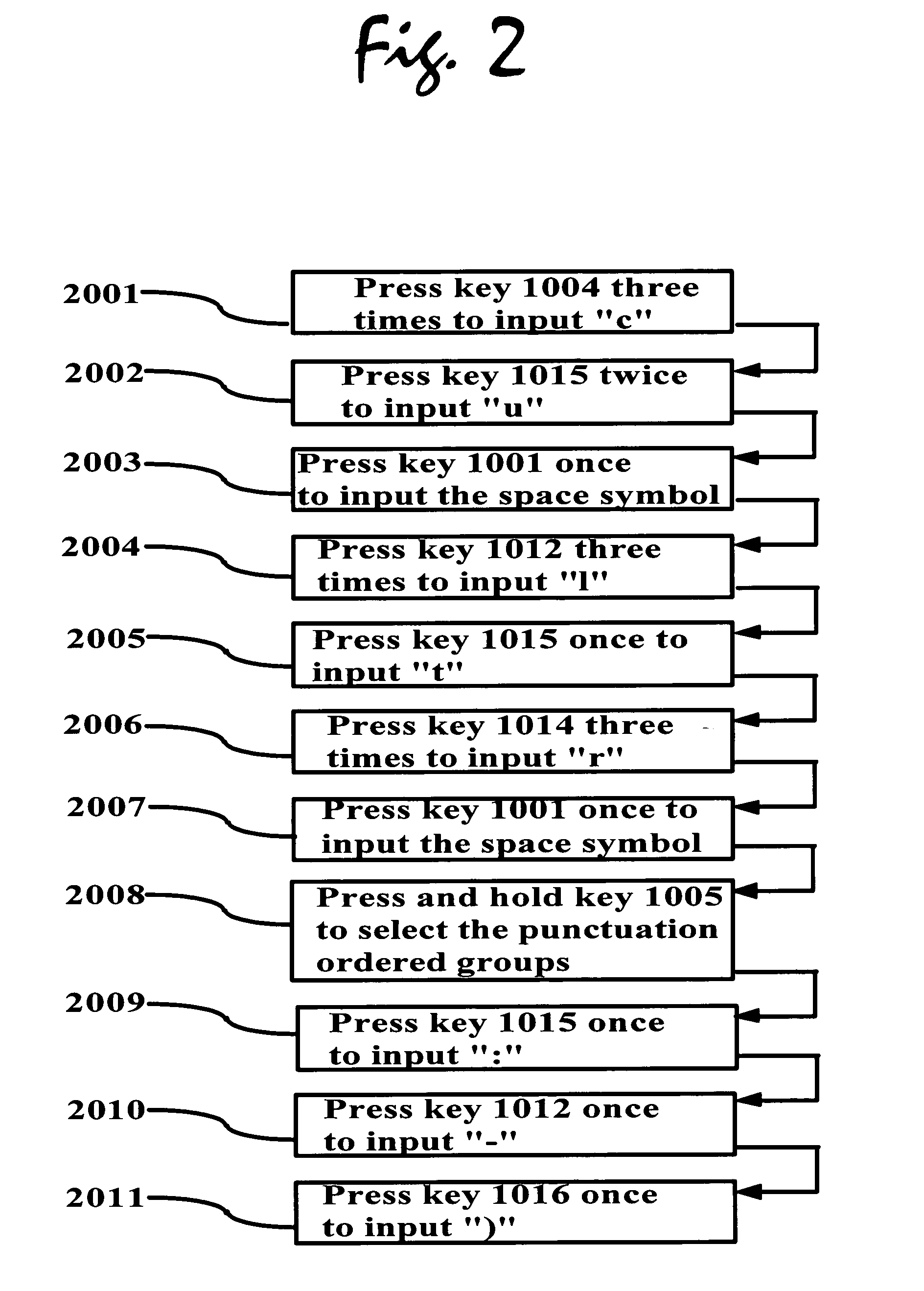

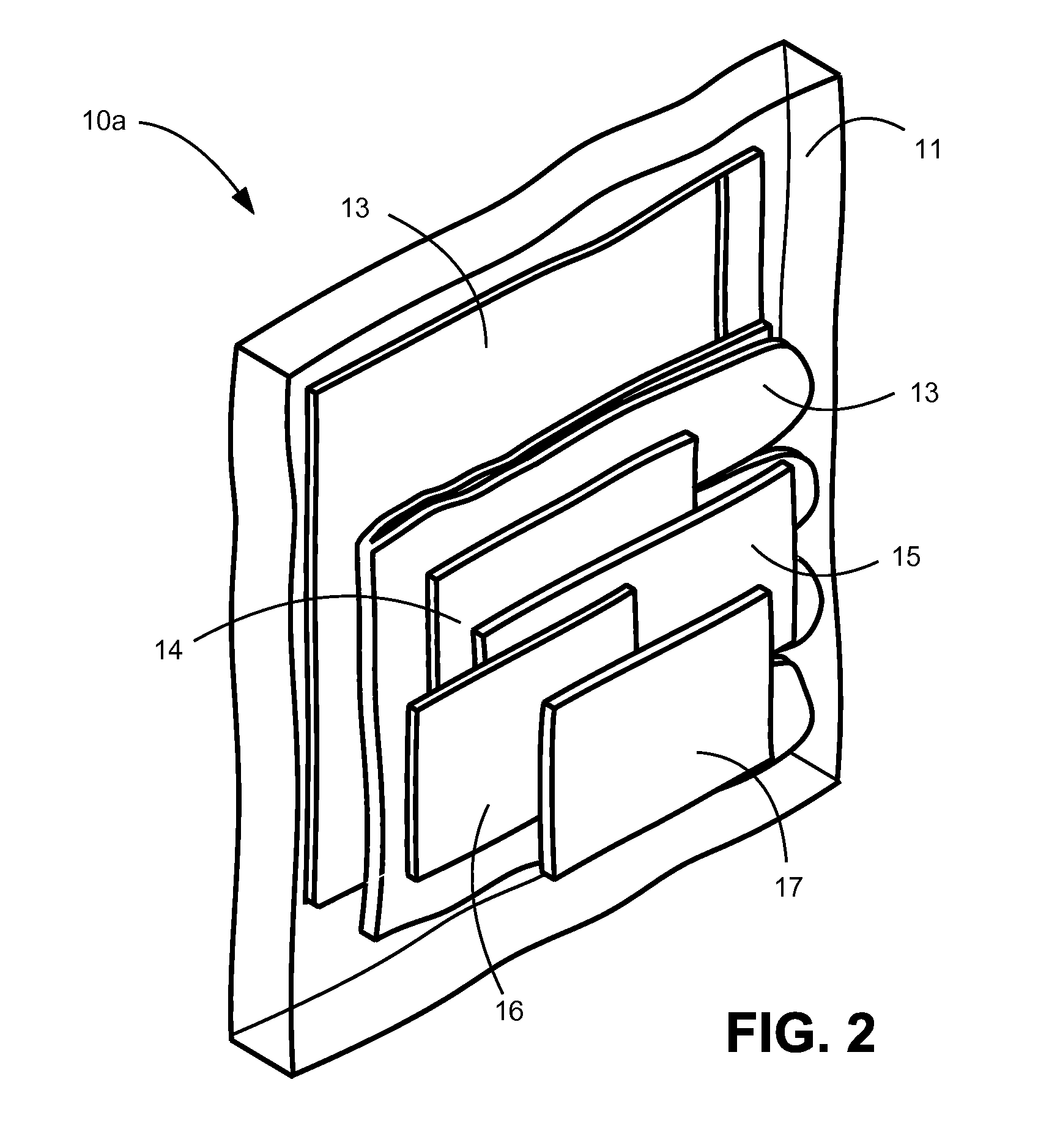

Method and apparatus for accelerated entry of symbols on a reduced keypad

InactiveUS20040056844A1Decrease expected numberReduce in quantityInput/output for user-computer interactionComputer controlPredictive methodsDiscoverability

This invention teaches that a single auxiliary key (1006) can support a multiplicity of ordered groups (1003-1004) and that only a subset of each group (1003-1004) needs to be visually represented on the face of a key, and that either multi-tap or predictive methods, or both, can be used to input members of each groups, and that auxiliary keys (1005-1007) are a convenient and effective method to select ordered groups, and to perform the multi-tap function. This invention teaches: limited multi-tap depth, reduced keystrokes per symbol, discoverability, graduated discoverability, compact presentation and seamless integration of multi-tap and predictive methods.

Owner:EATONI ERGONOMICS INC

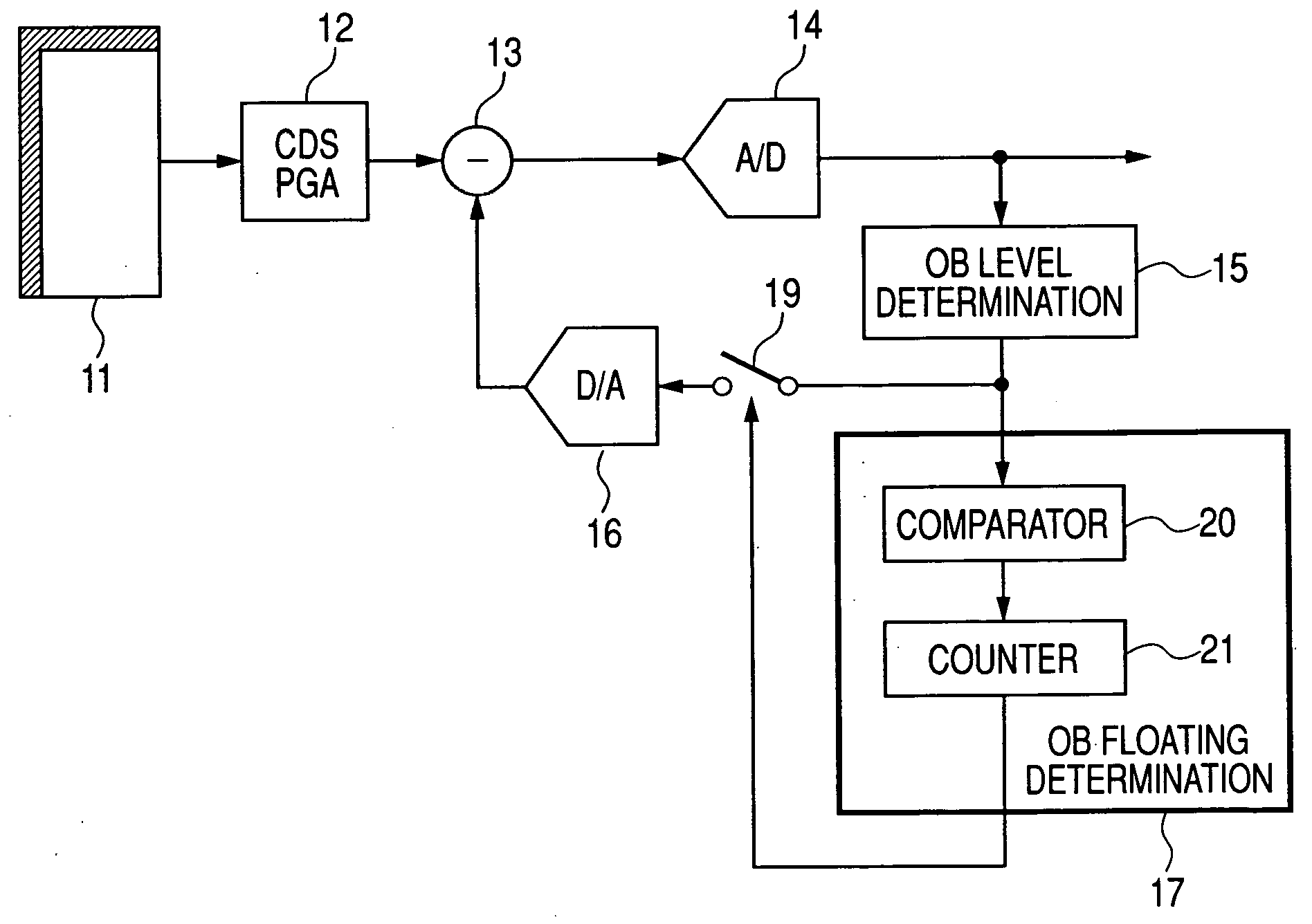

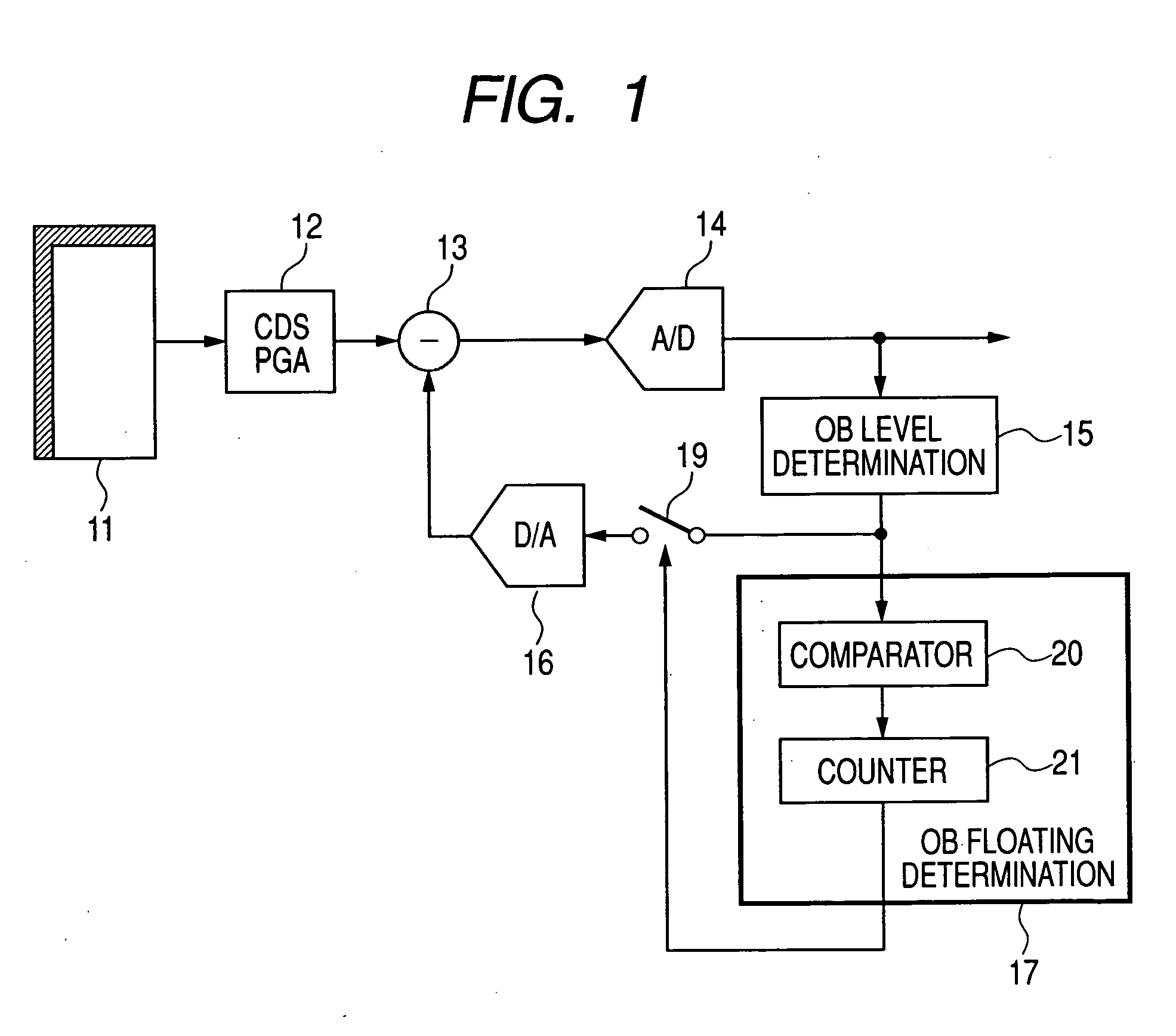

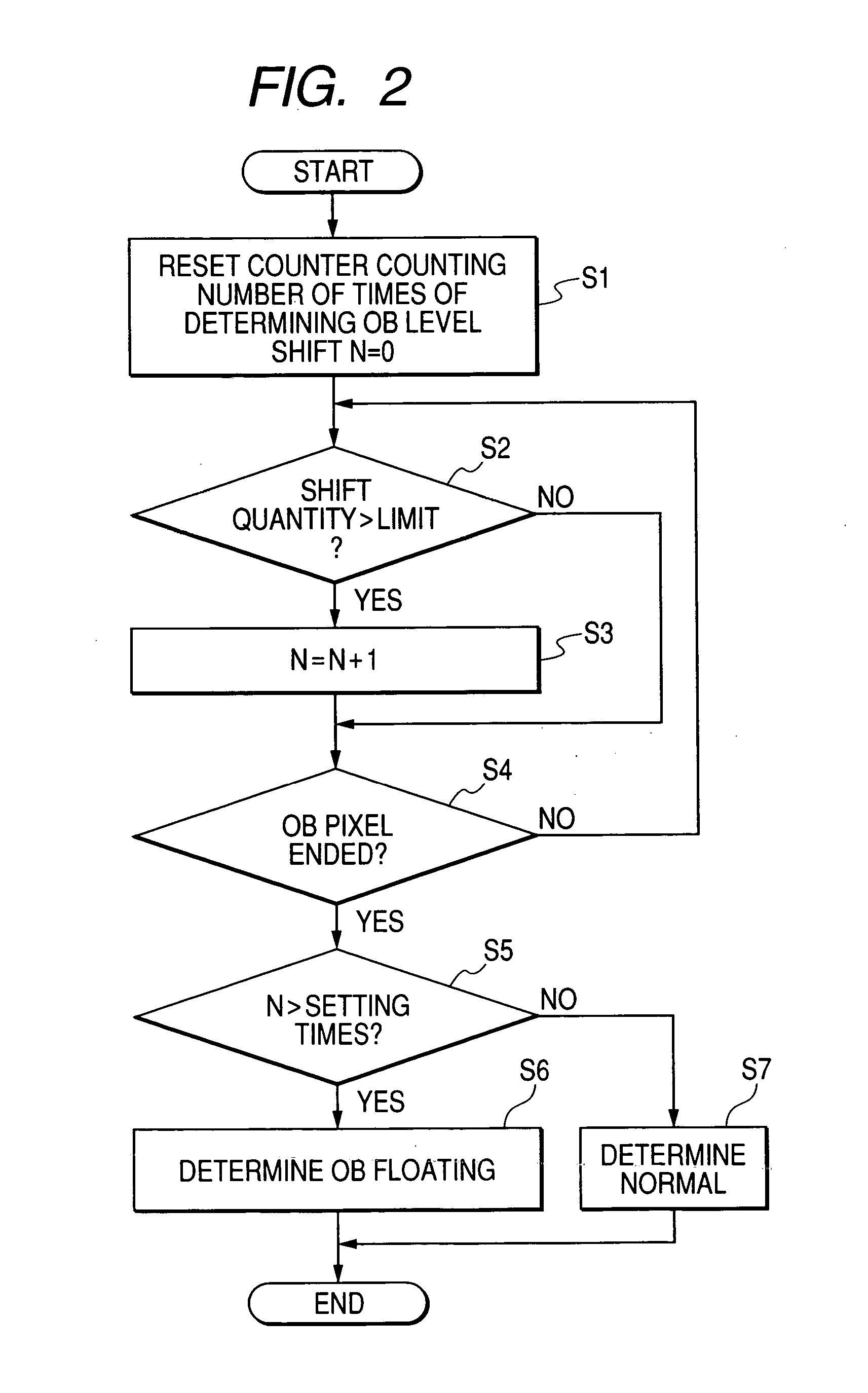

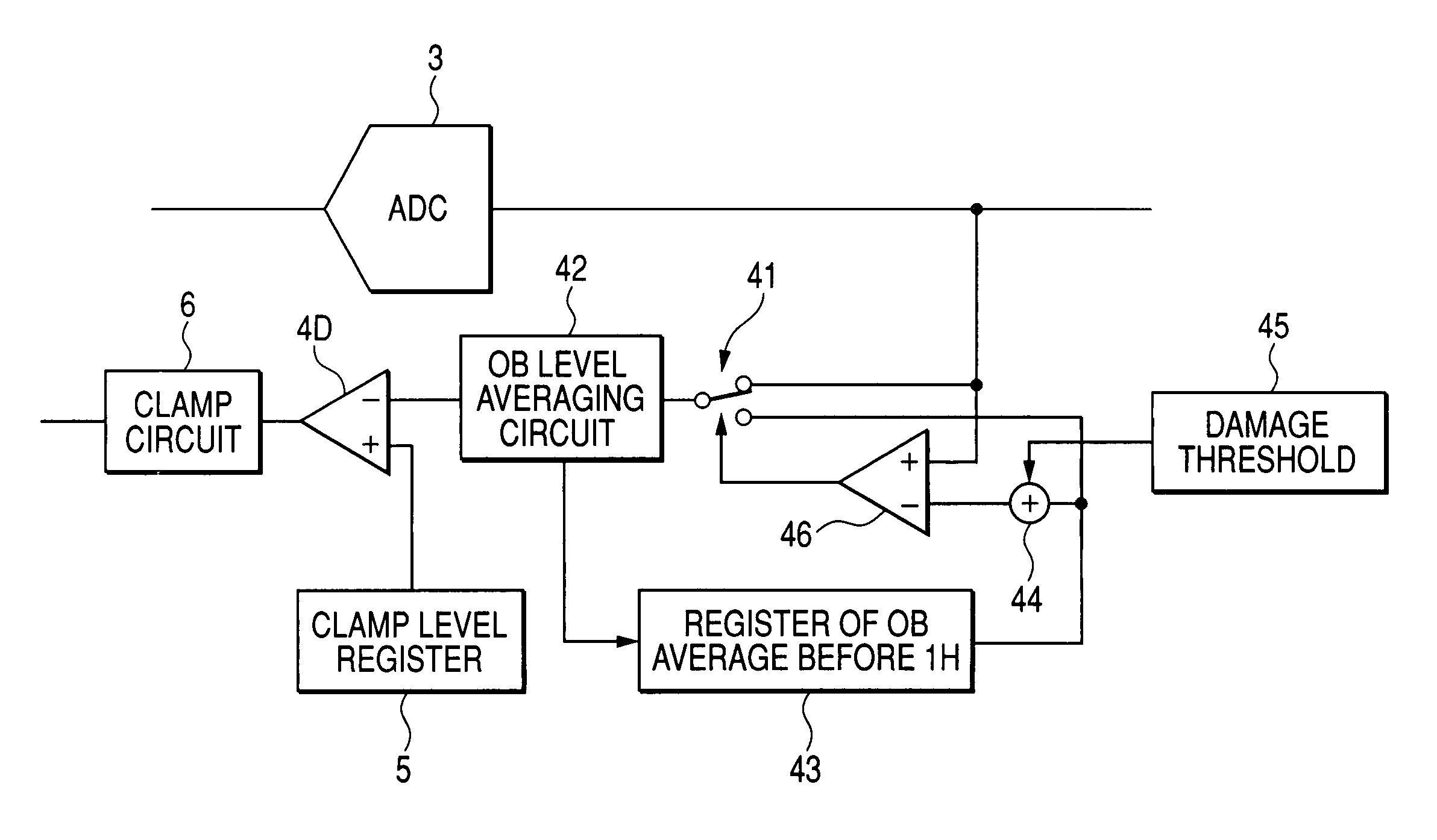

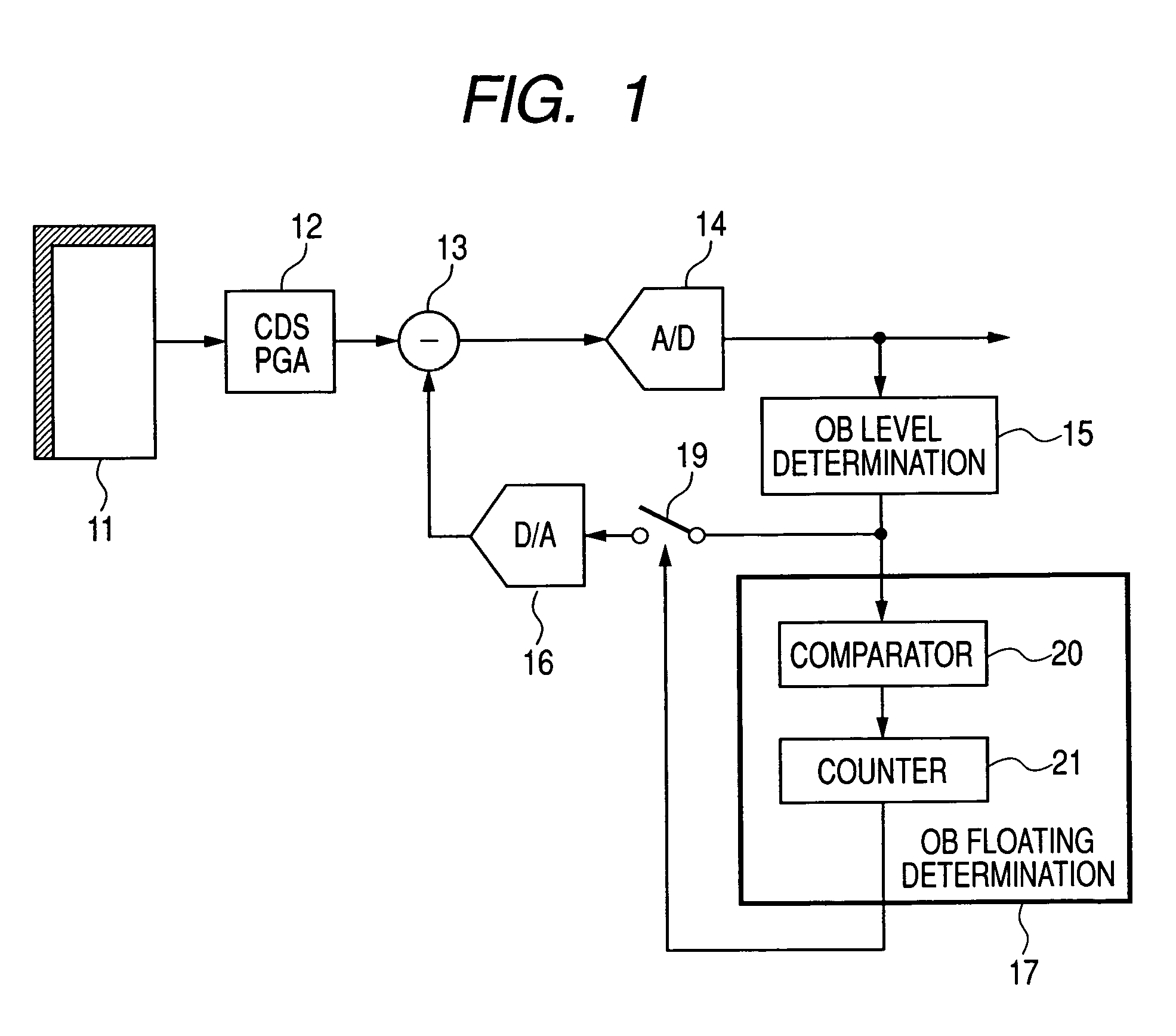

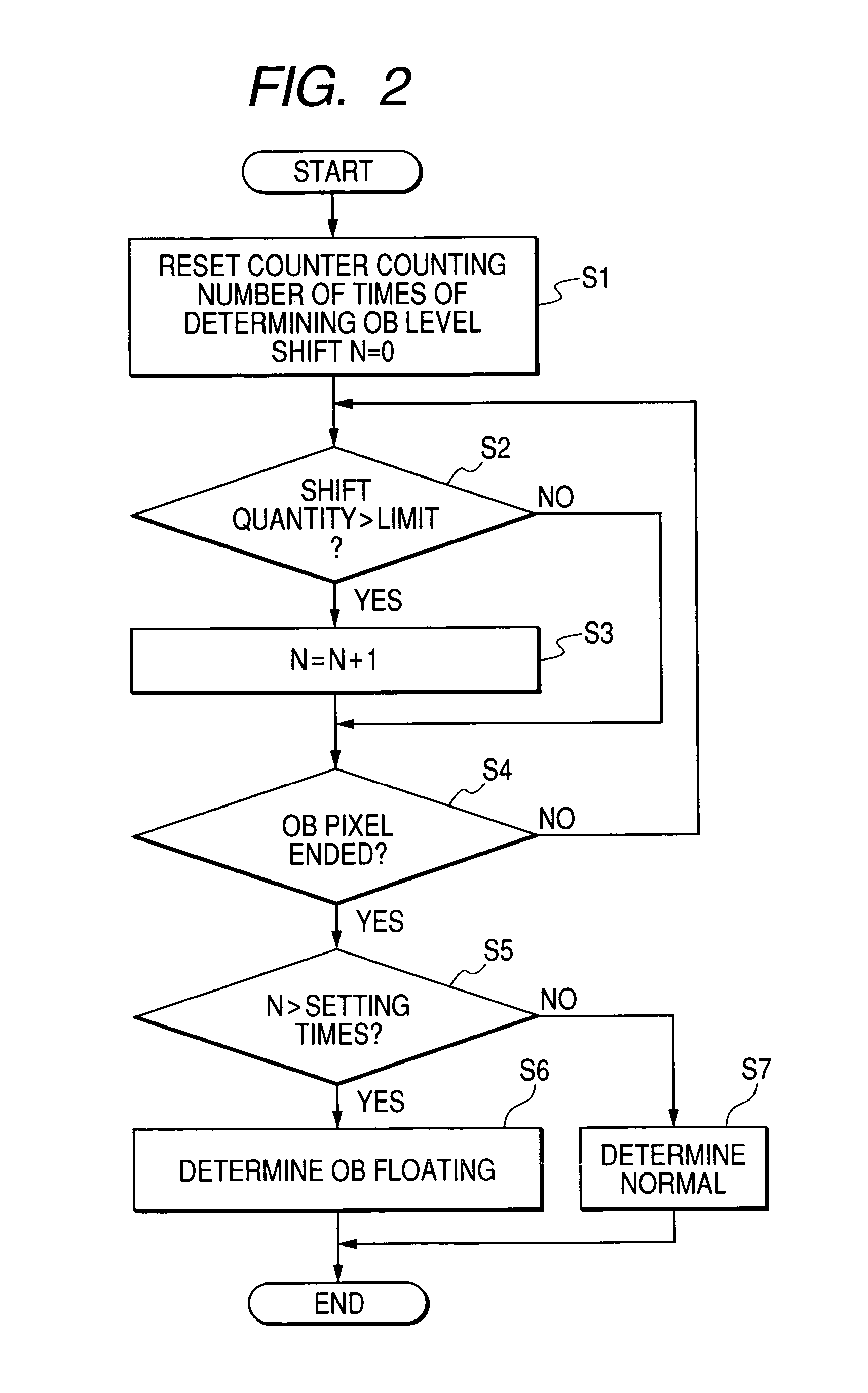

Image signal processing apparatus, image signal processing method and camera using the image signal processing apparatus

InactiveUS20060044424A1High-quality image signalEasy to adjustTelevision system detailsColor signal processing circuitsComputer scienceImage signal

When clamping a signal from a solid state image sensor, float of an optical black pixel output due to incoming of infrared light avoids a malfunction of a clamp from occurring. When clamping a signal from the solid state image sensor, the difference between the optical black pixel output and a clamp target level is output as a difference output, the difference output is compared with a comparison level to integrate the number of times larger than the comparison level every horizontal line. When the number of times is equal to or more than a certain rate (⅔) from the number of optical black pixels on the horizontal line, an optical black float state is determined and clamping operation is performed in accordance with a held value immediately before.

Owner:CANON KK

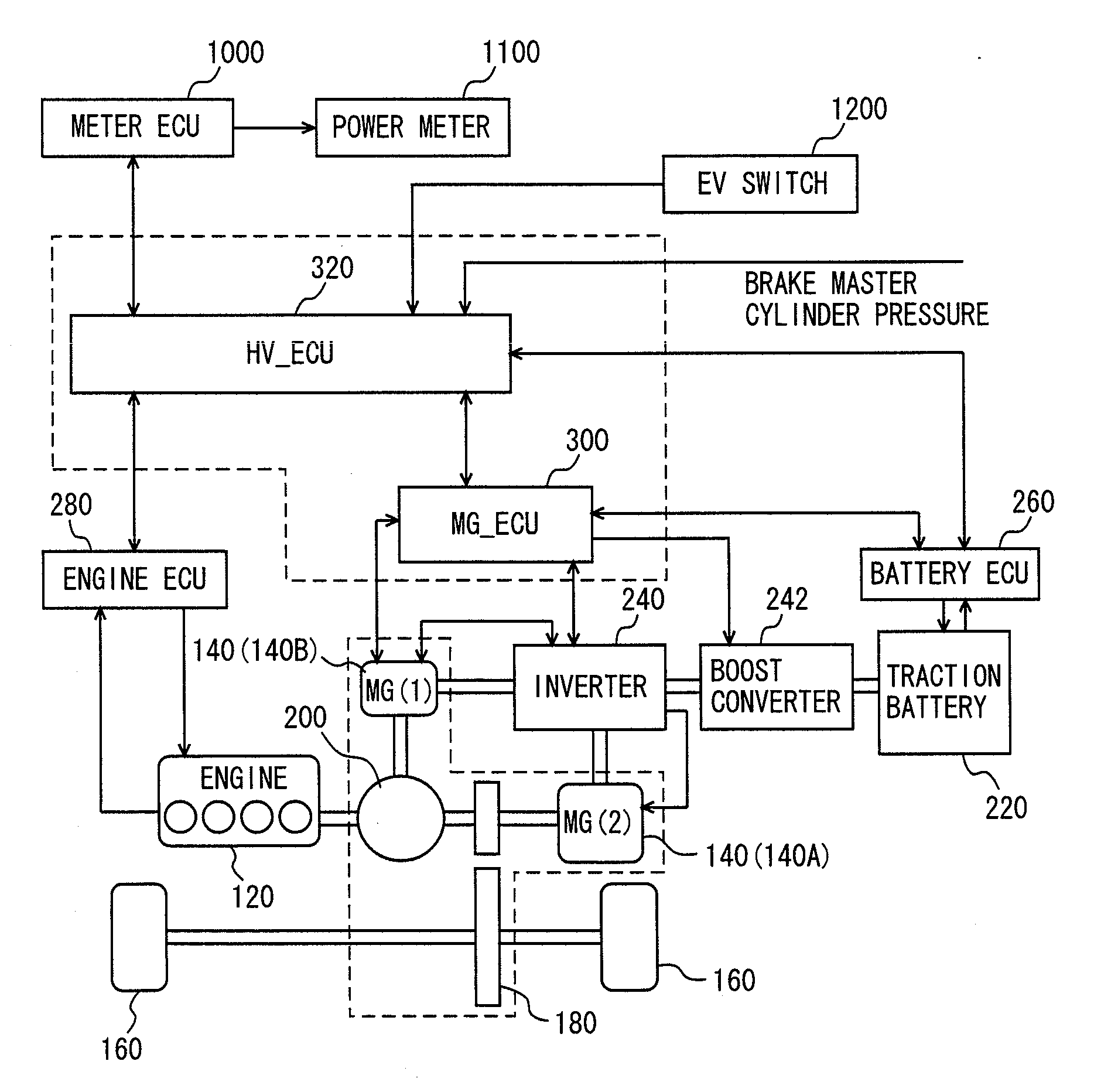

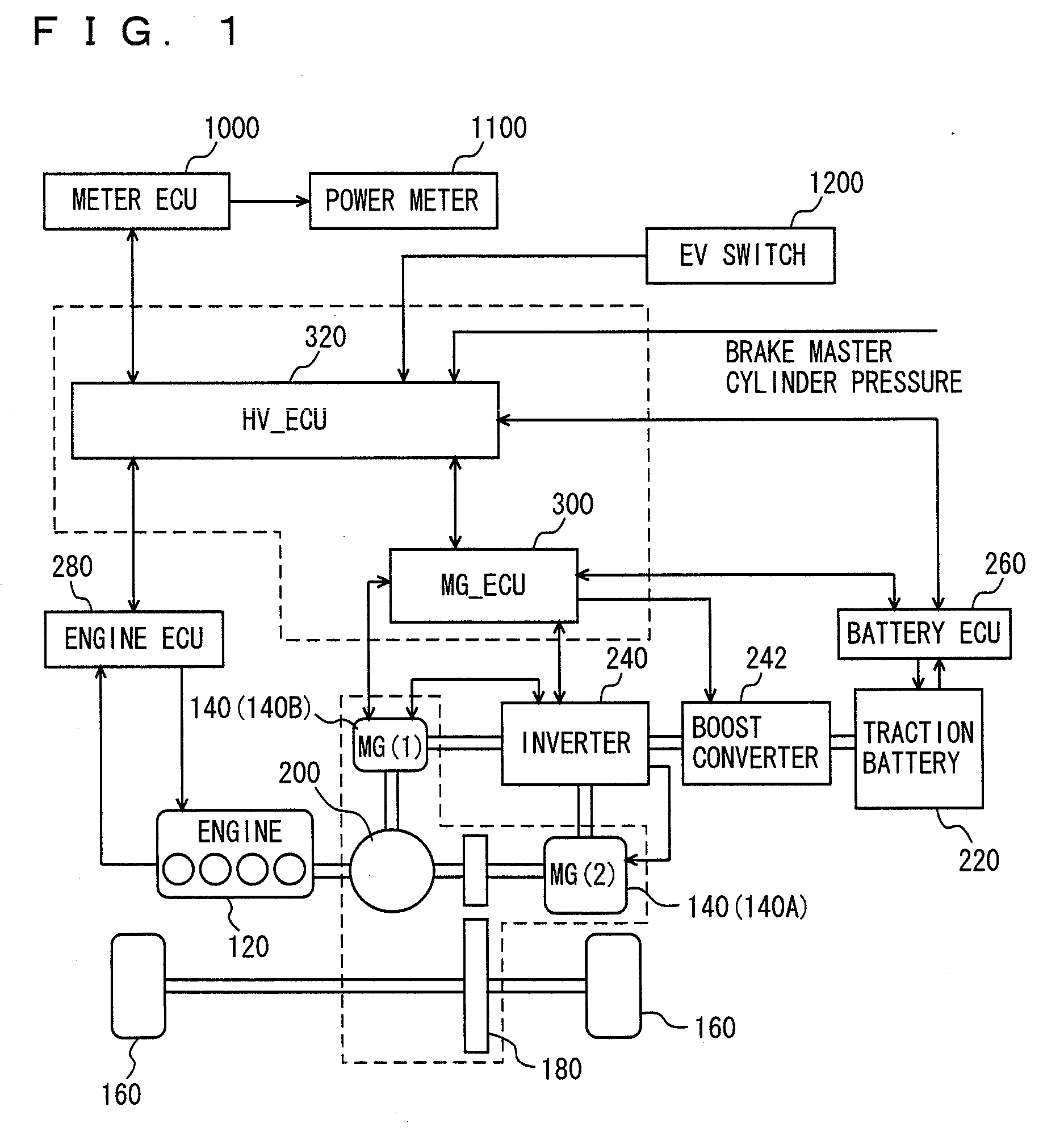

Indication apparatus for hybrid vehicle

ActiveUS20100030413A1Easy to identifyFuel efficiency deterioratesHybrid vehiclesAnalogue computers for vehiclesEngineeringHybrid vehicle

An ECU executes a program including: steps of detecting an SOC and a temperature TB of a traction battery; when an EV switch is on, a step of calculating a temperature correction coefficient α from TB; when EV switch not on, a step of calculating a temperature correction coefficient α from TB; steps of calculating an EV traveling allowed power value WOUT based on the SOC and the temperature correction coefficients; and a step of transmitting EV traveling allowed power value WOUT to a meter ECU in order to indicate EV traveling allowed power value WOUT on a power meter.

Owner:TOYOTA JIDOSHA KK

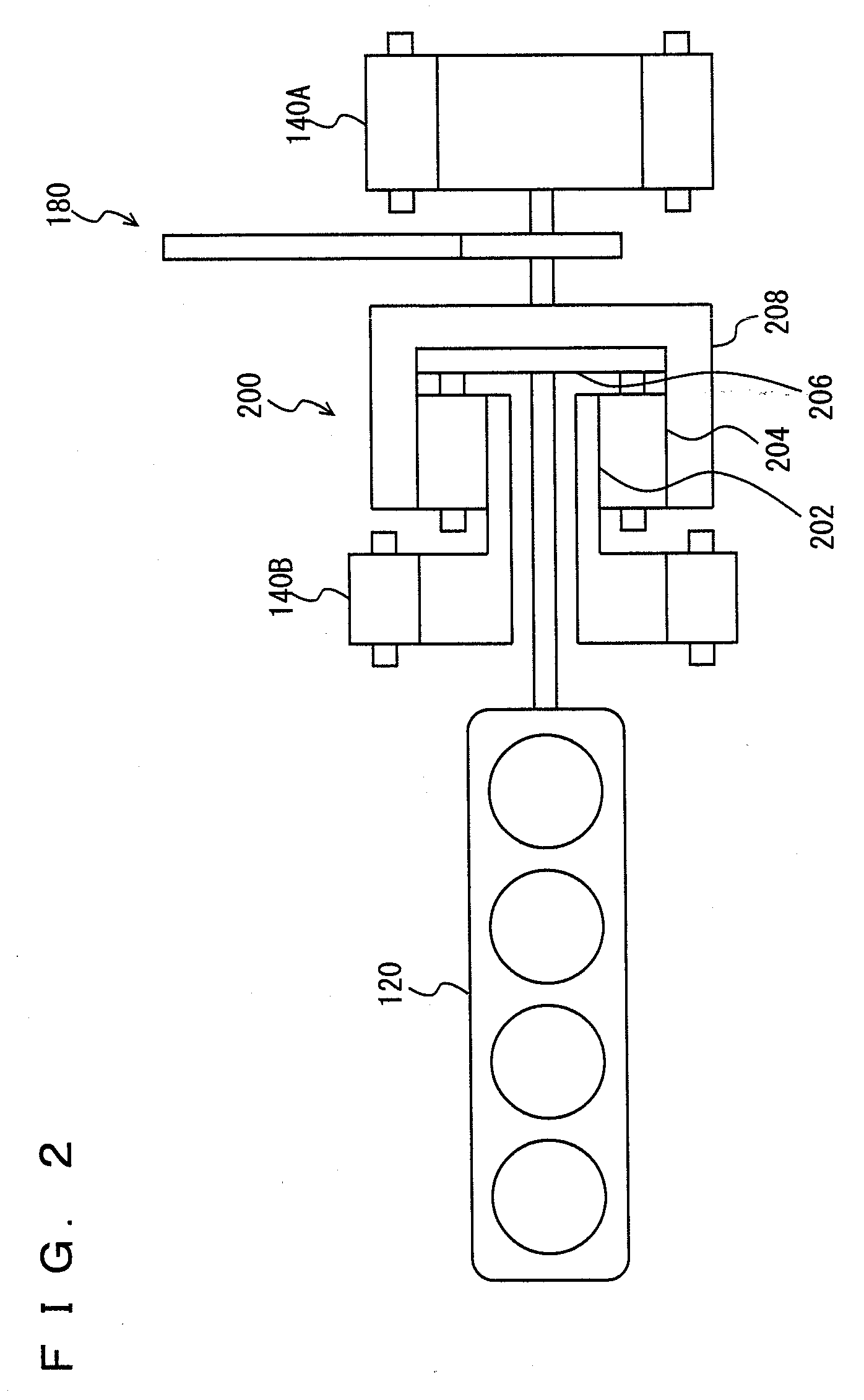

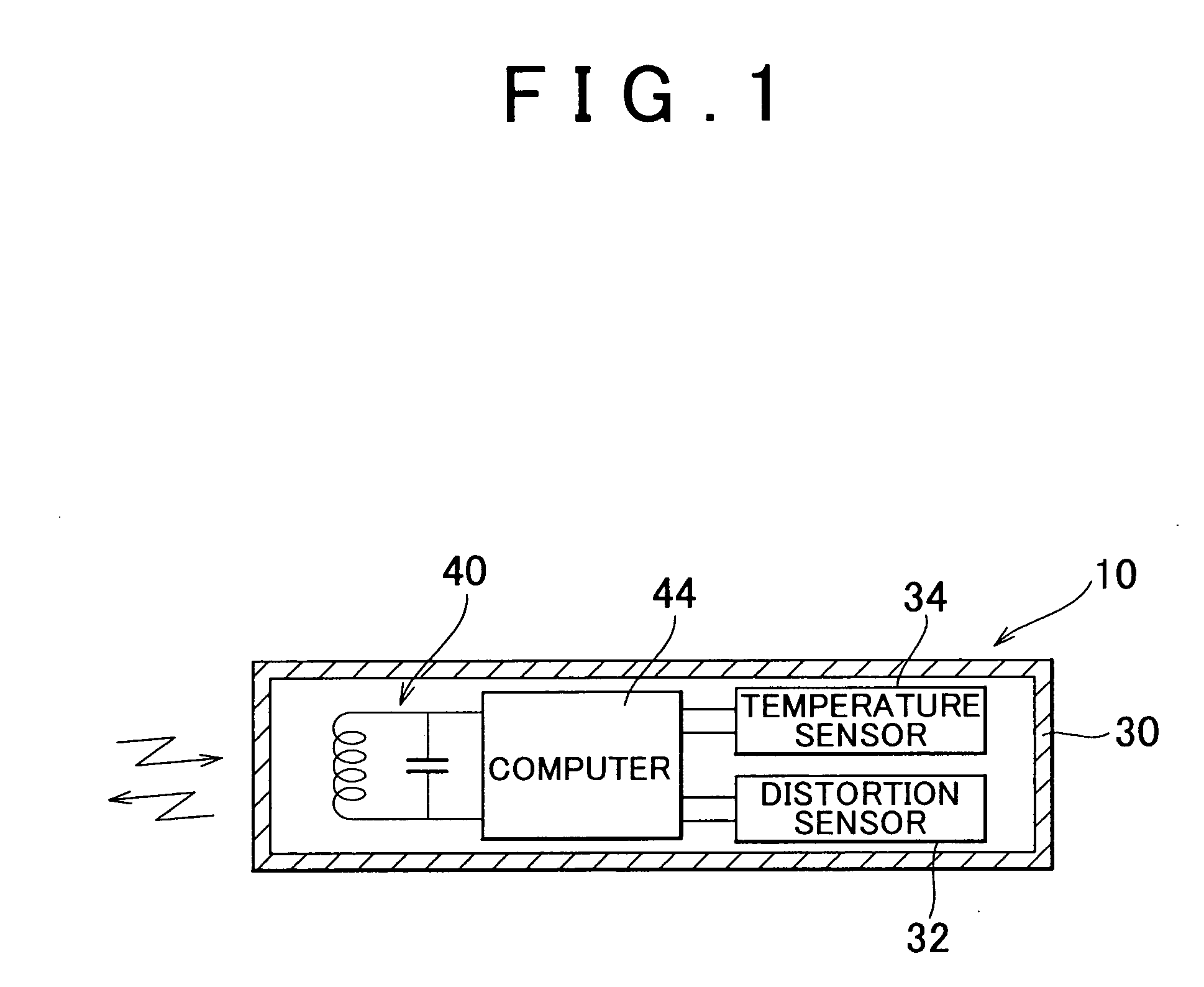

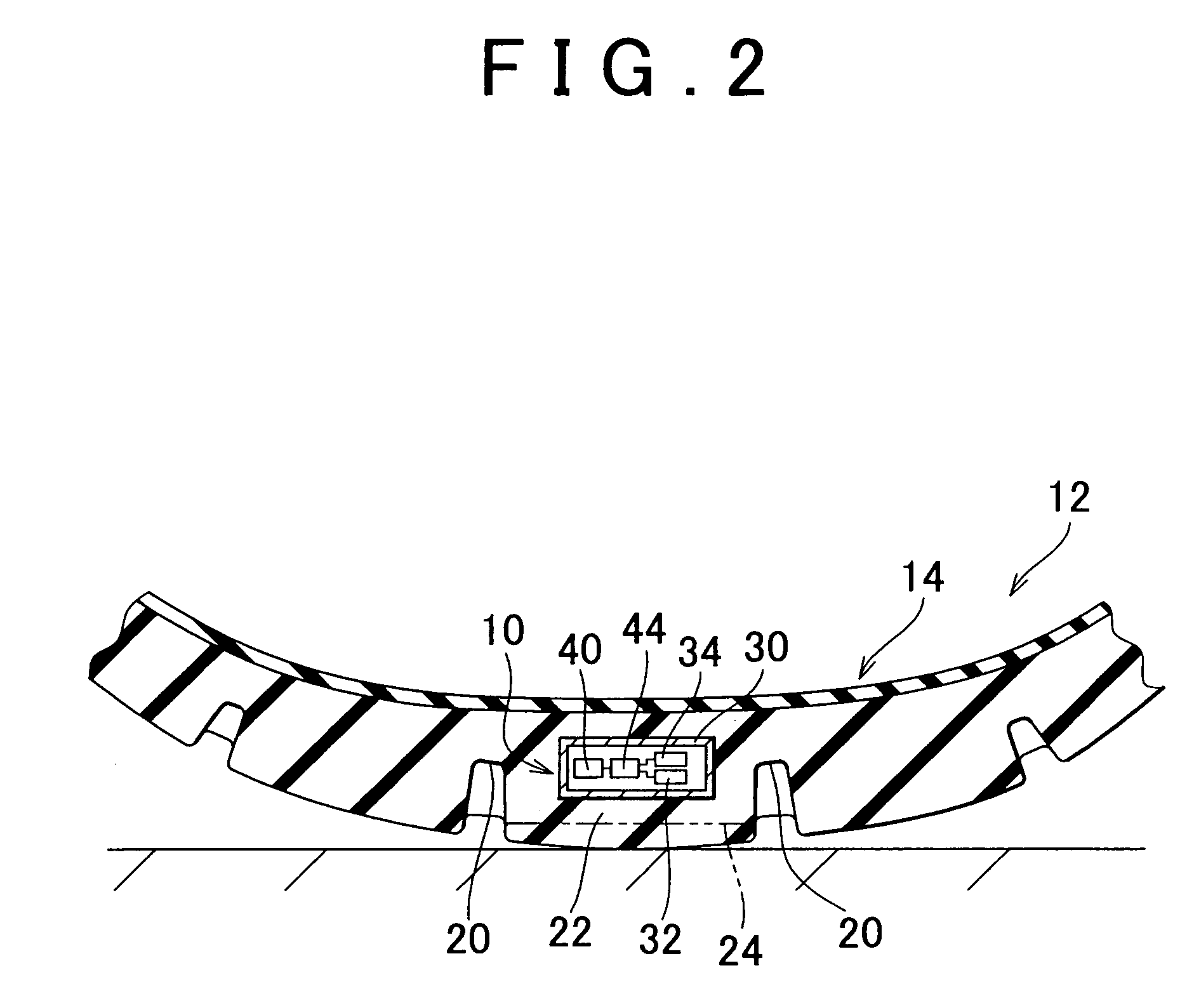

Tire state quantity detecting apparatus and method

InactiveUS20050057346A1Reliable signal transmissionReduced reliabilityOptical signallingTyre measurementsEngineering

In a tire state quantity detecting apparatus, a detector that deforms by force exerted from a tire and that outputs a signal corresponding to the quantity of deformation is embedded within the tire. The detector is enclosed in a capsule within the tire, so that the quantity of deformation of the detector is reduced relative to the quantity of deformation of the tire.

Owner:TOYOTA JIDOSHA KK

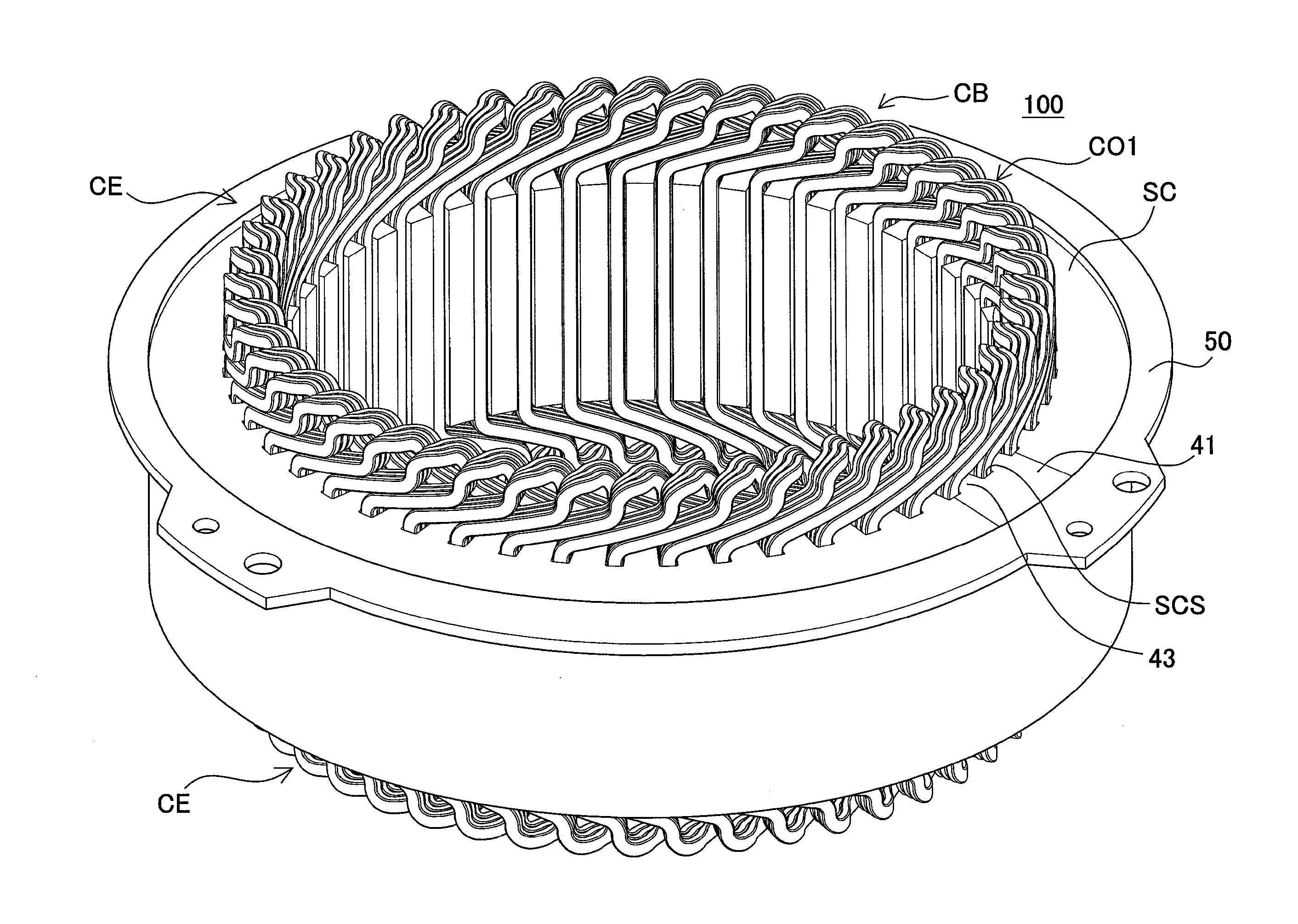

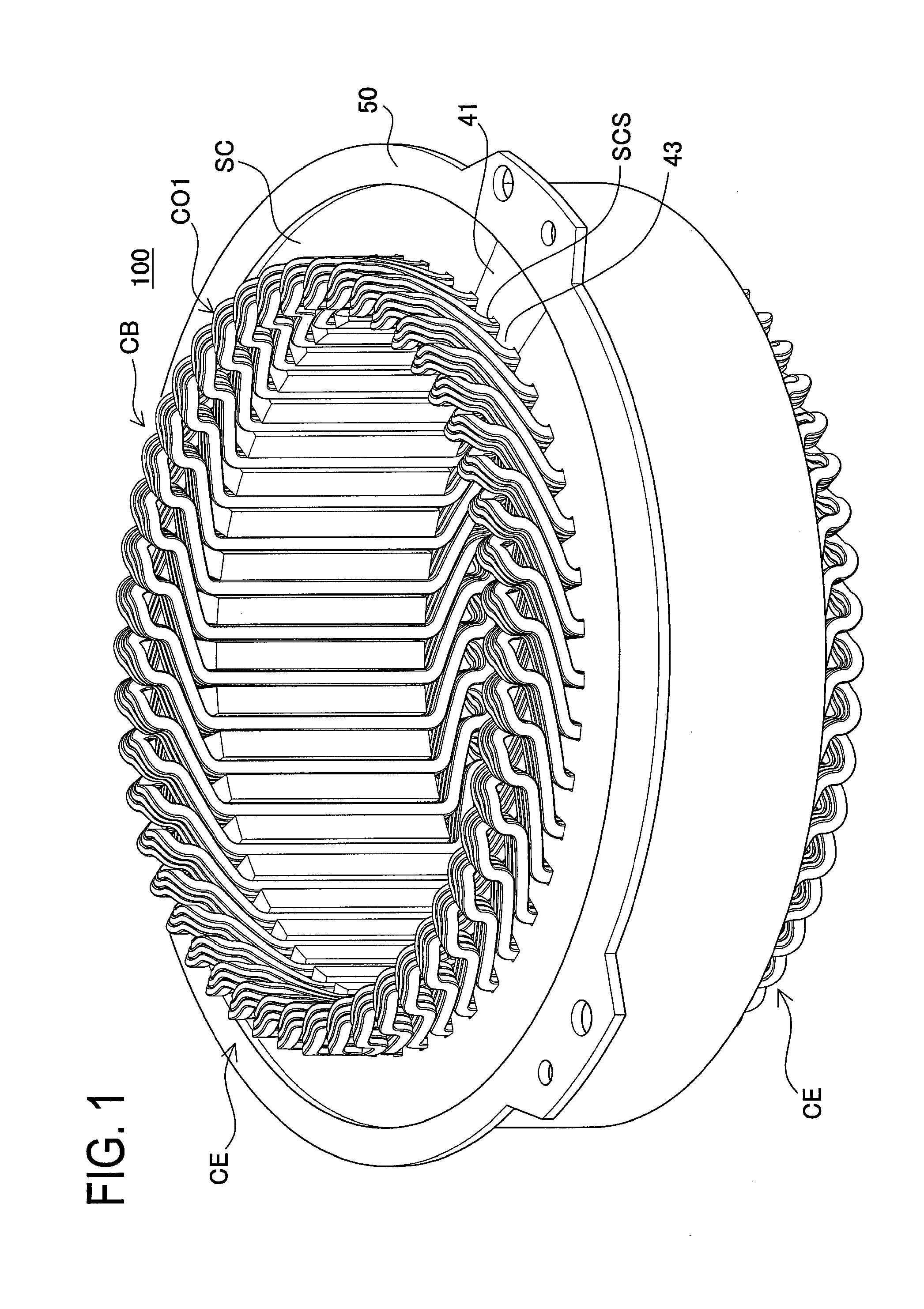

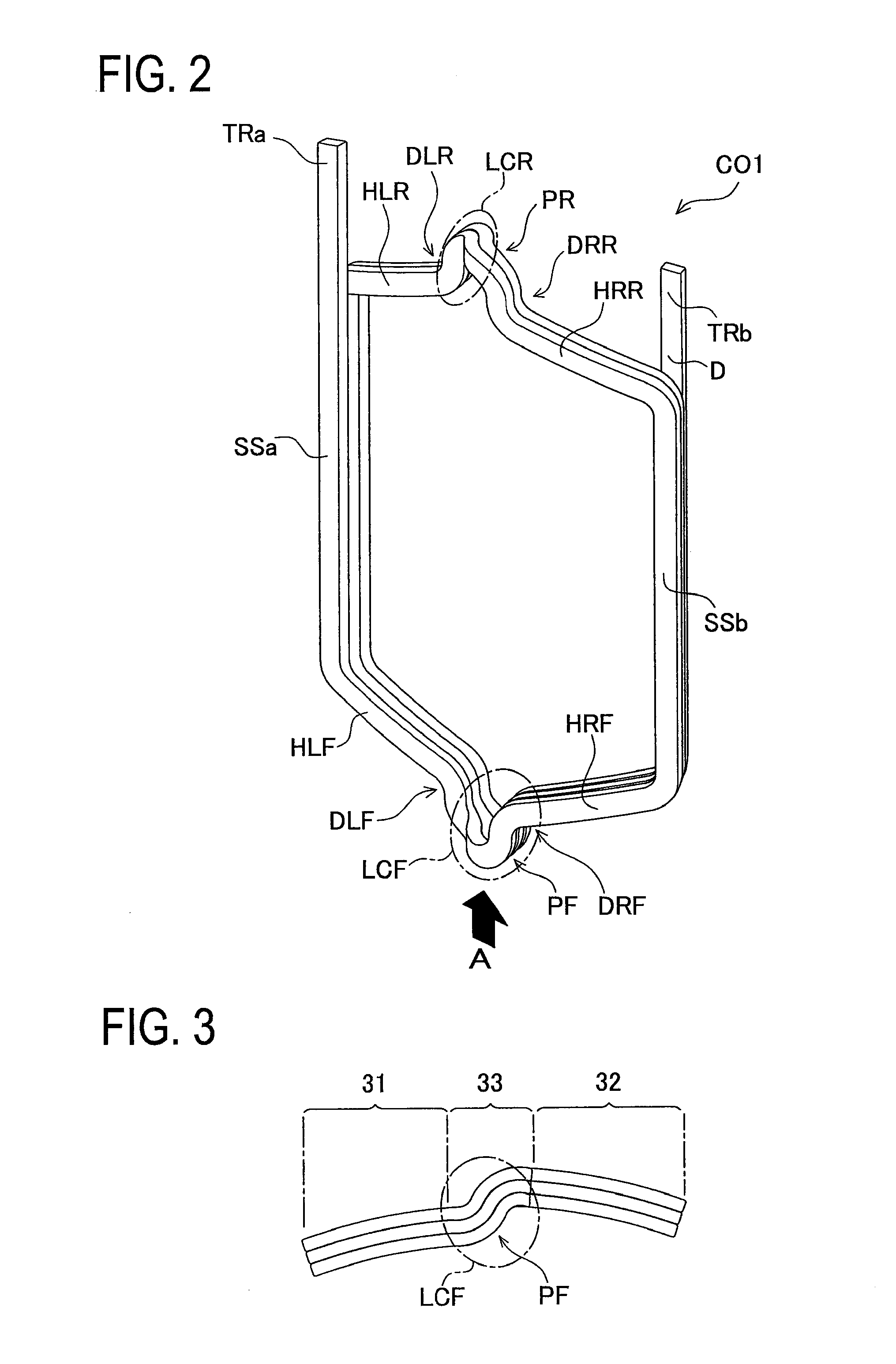

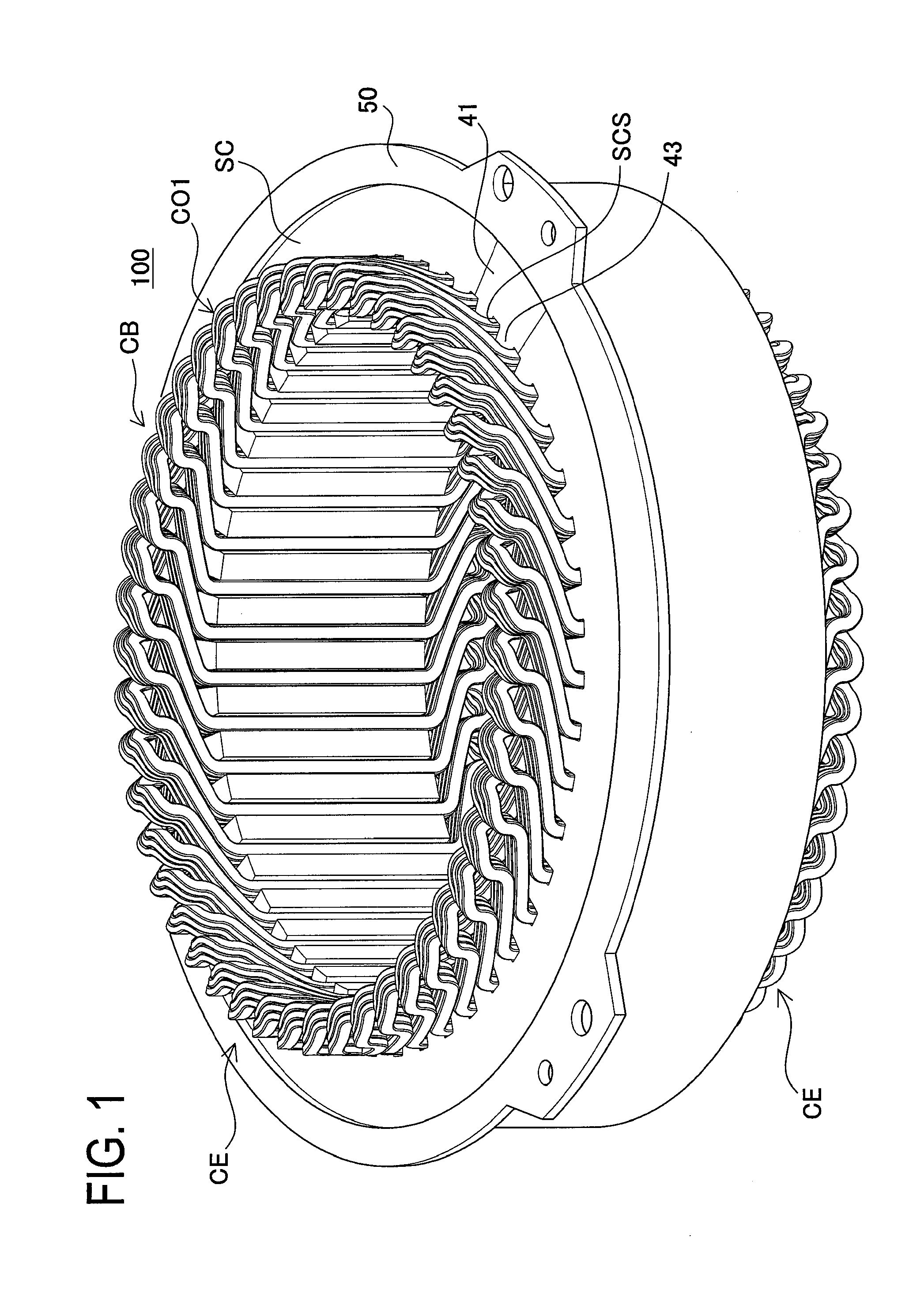

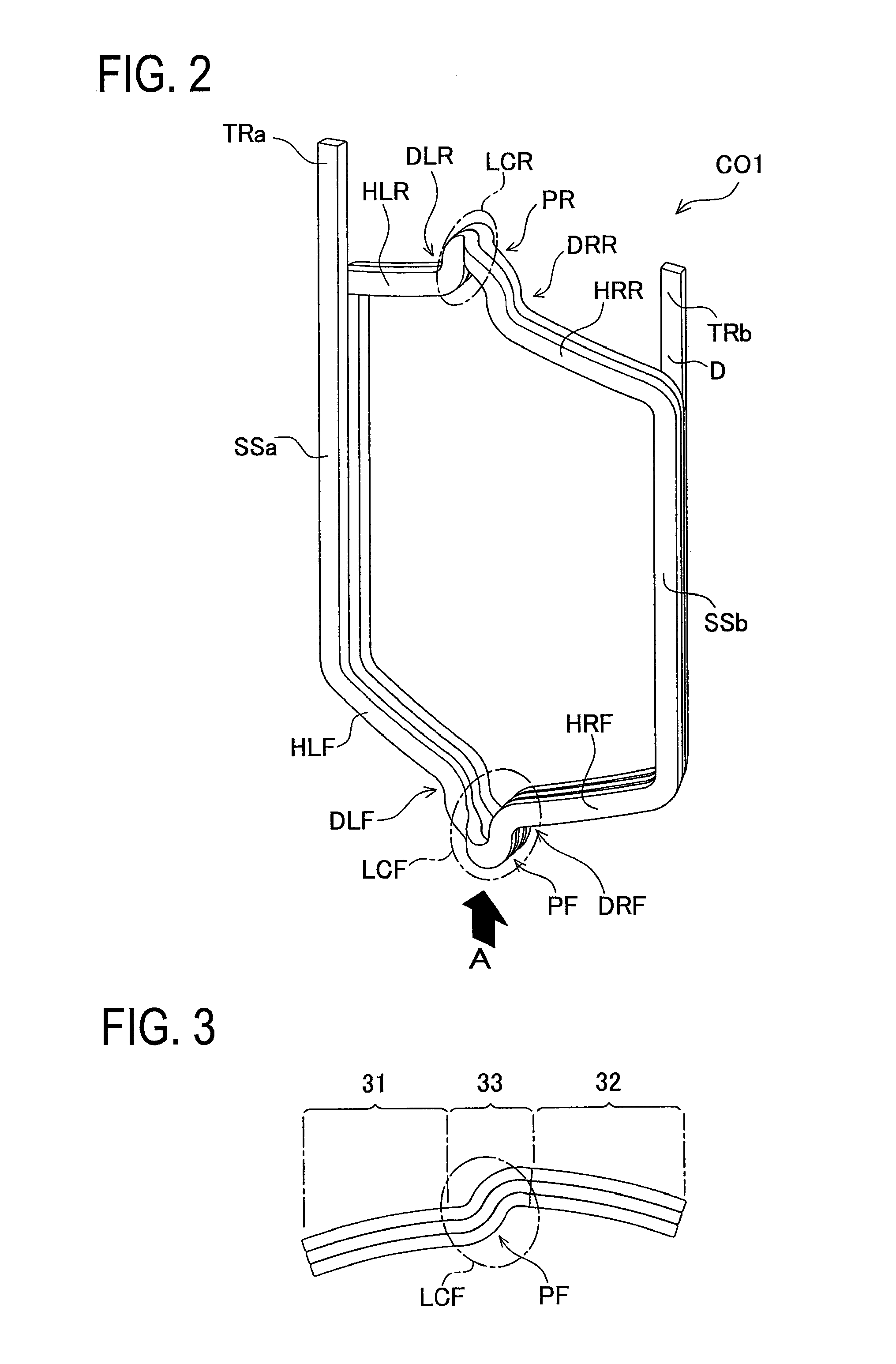

Stator

ActiveUS20120025658A1Avoid interferenceEasily avoidedSynchronous generatorsMagnetic circuitElectrical conductorPhysics

To provide a stator capable of achieving downsizing and high output power and a stator manufacturing method, a stator comprises a split stator core including teeth and slots formed between the teeth, and protrusion-formed coils each being made of a flat rectangular conductor and placed in the slots. Each protrusion-formed coil has a shape including, in a coil end portion, a lead-side protrusion or a non-lead-side protrusion formed to protrude upward in an axial direction of the stator core from a first oblique side portion, a second oblique side portion, a third oblique side portion, and a fourth oblique side portion, and a first oblique side portion, a second oblique side portion, a third oblique side portion, and a fourth oblique side portion. The lead-side protrusion or the non-lead-side protrusion is designed with a height to avoid interference between the protrusion-formed coils placed in the stator core.

Owner:TOYOTA JIDOSHA KK

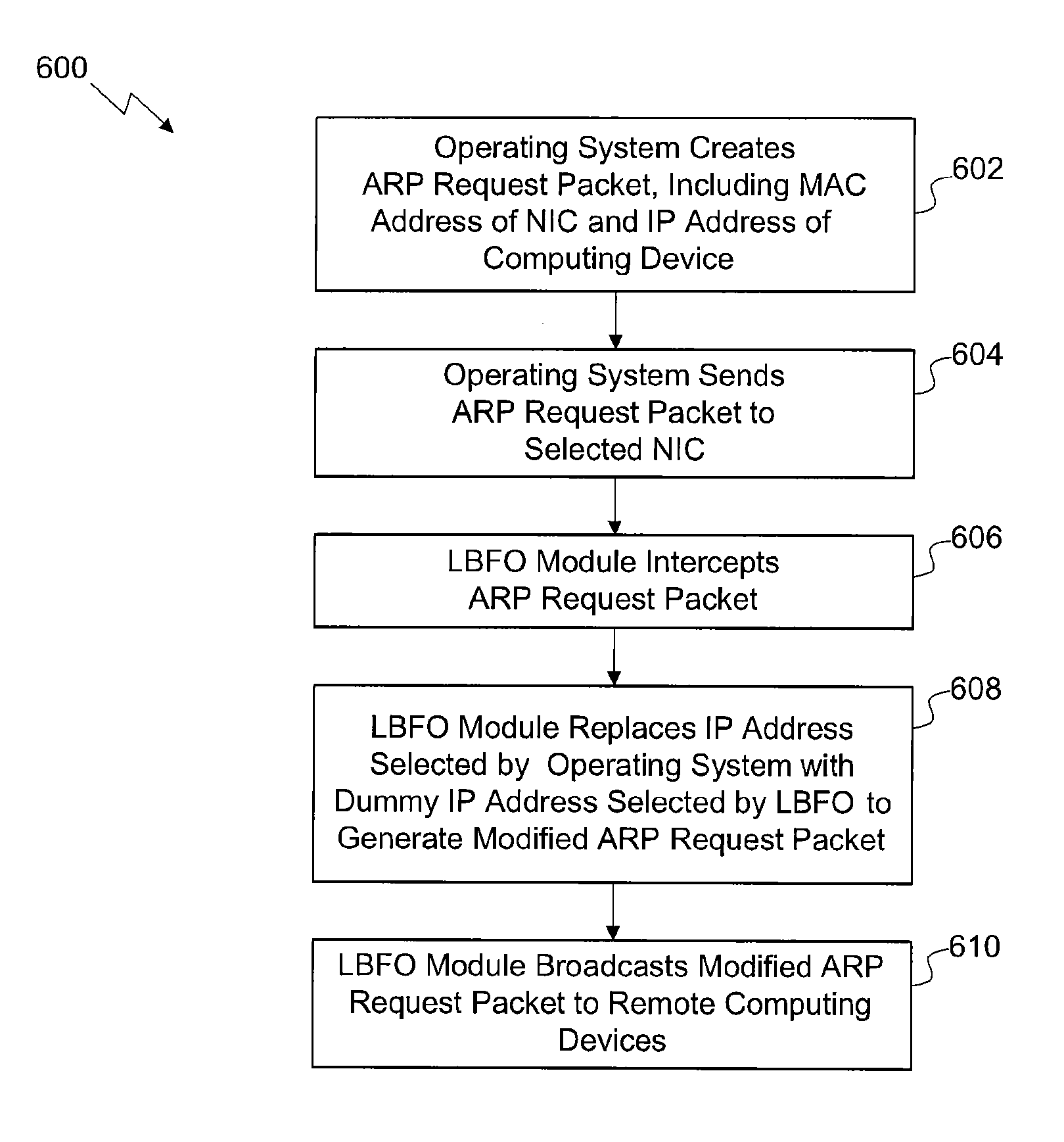

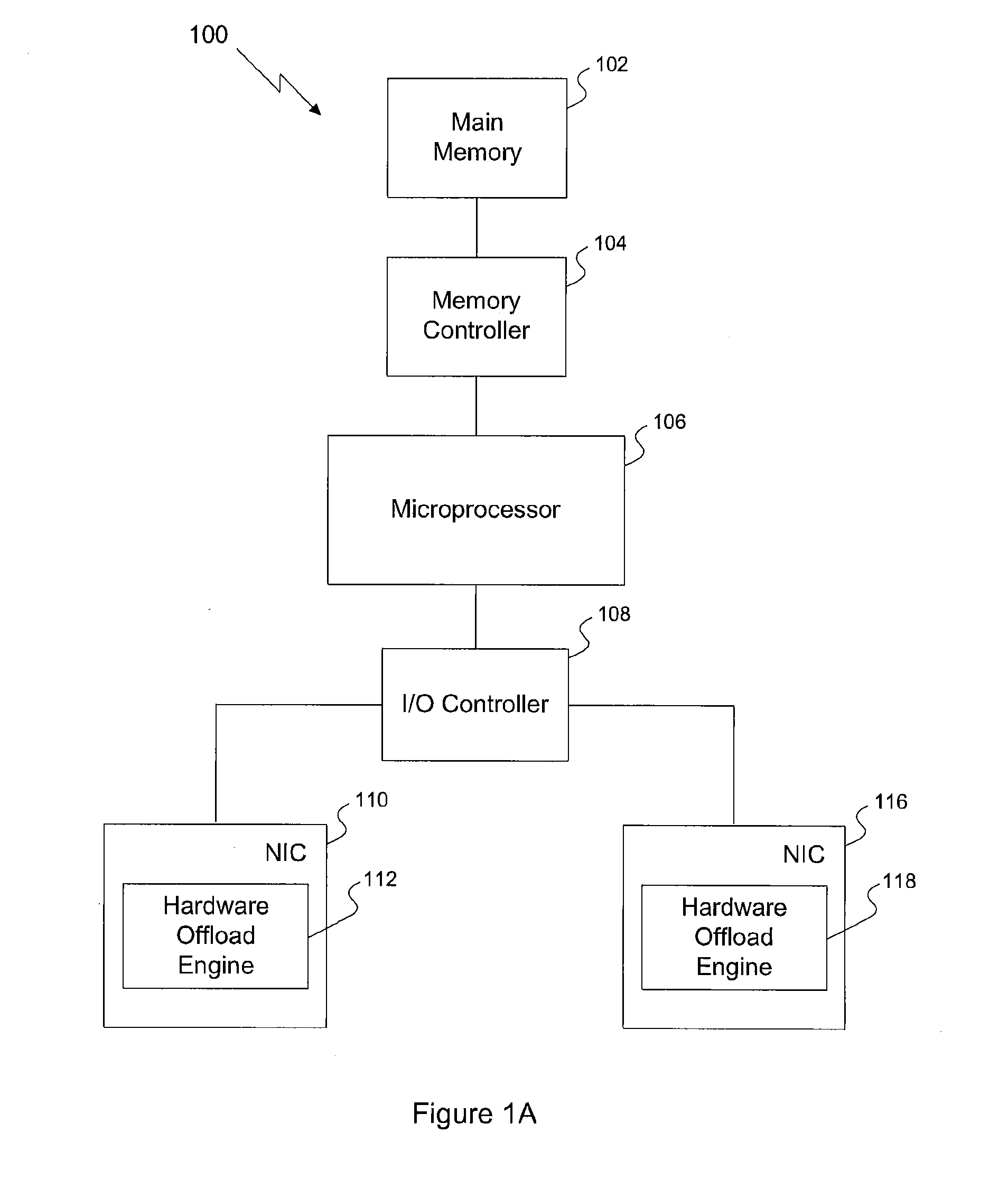

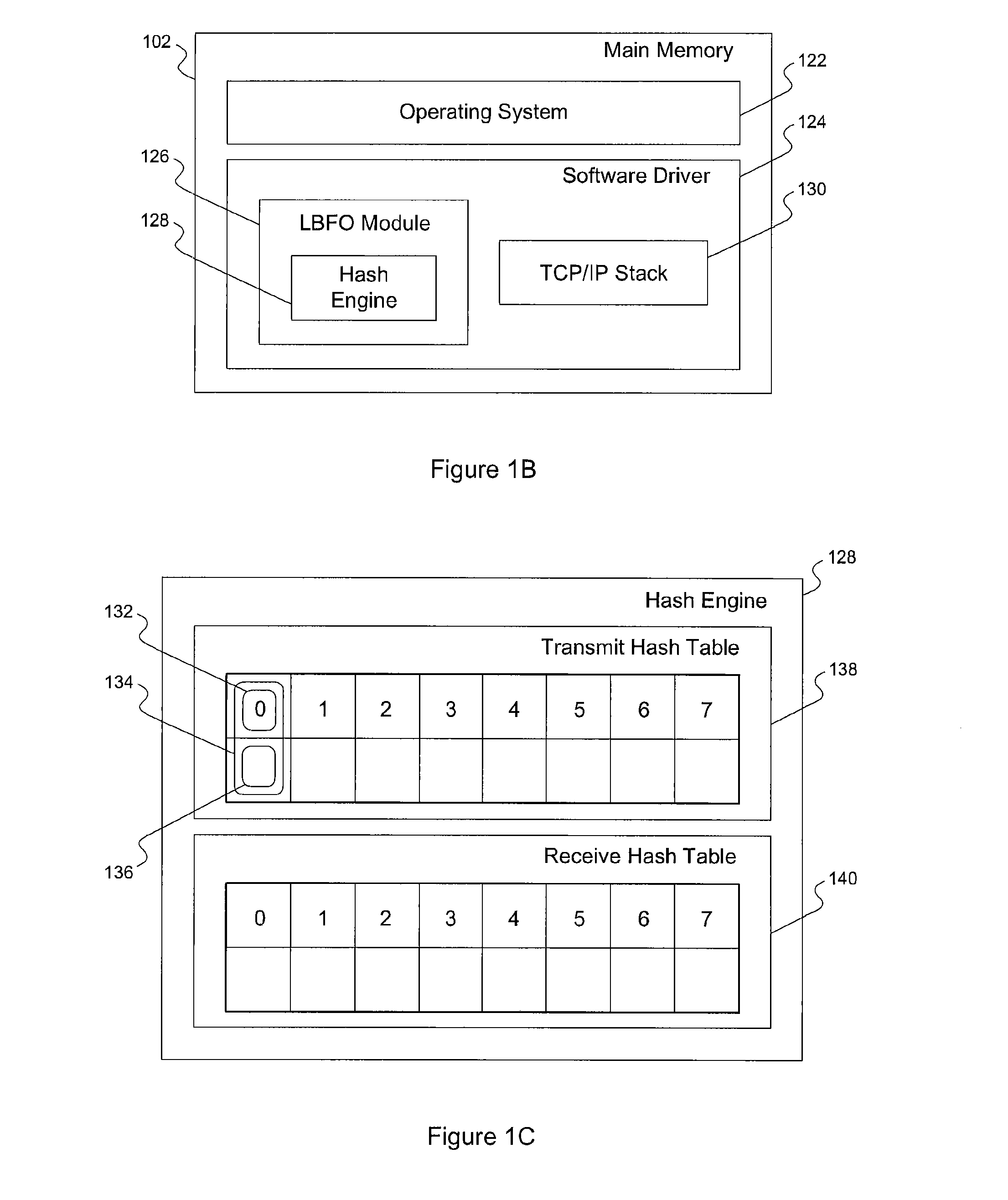

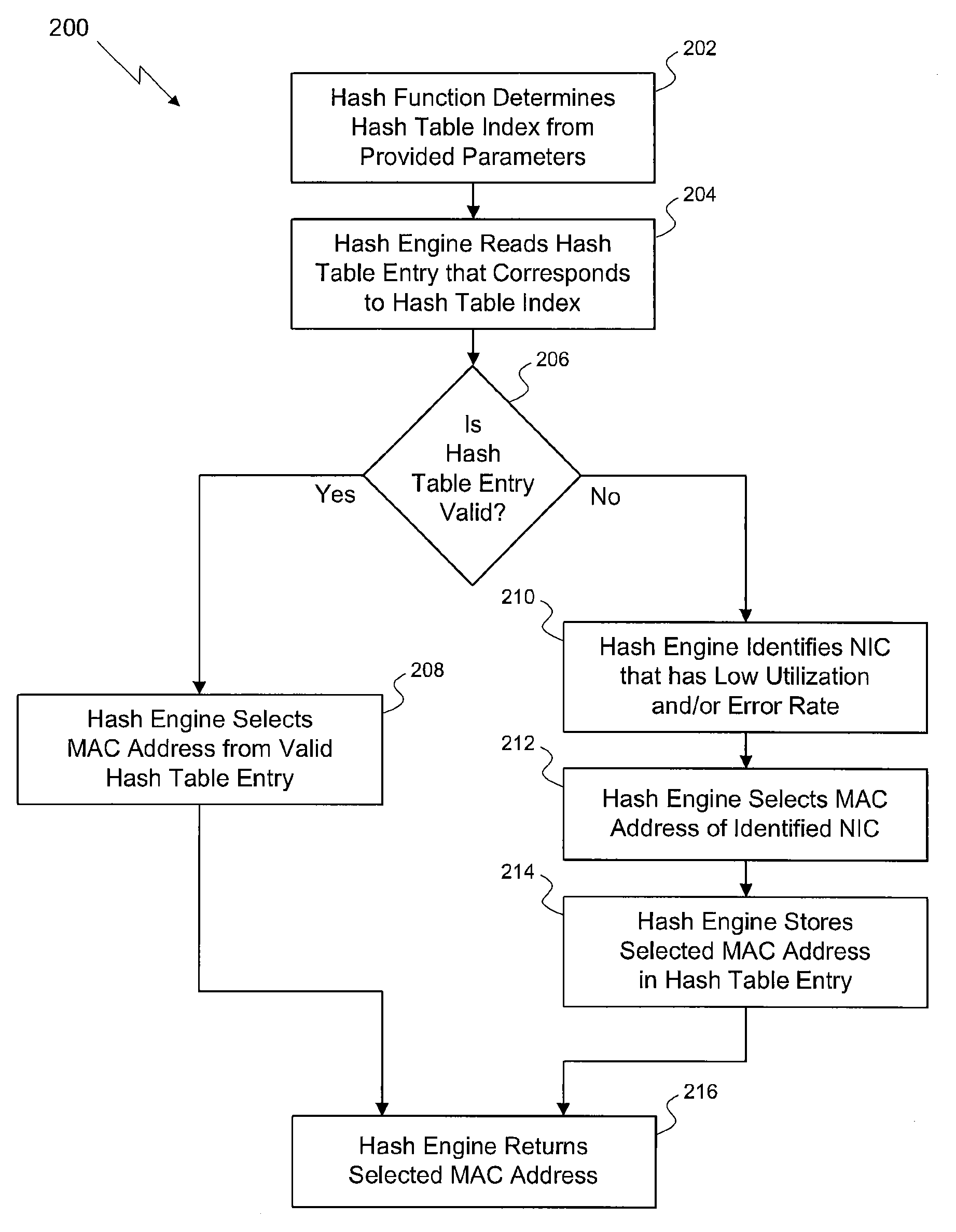

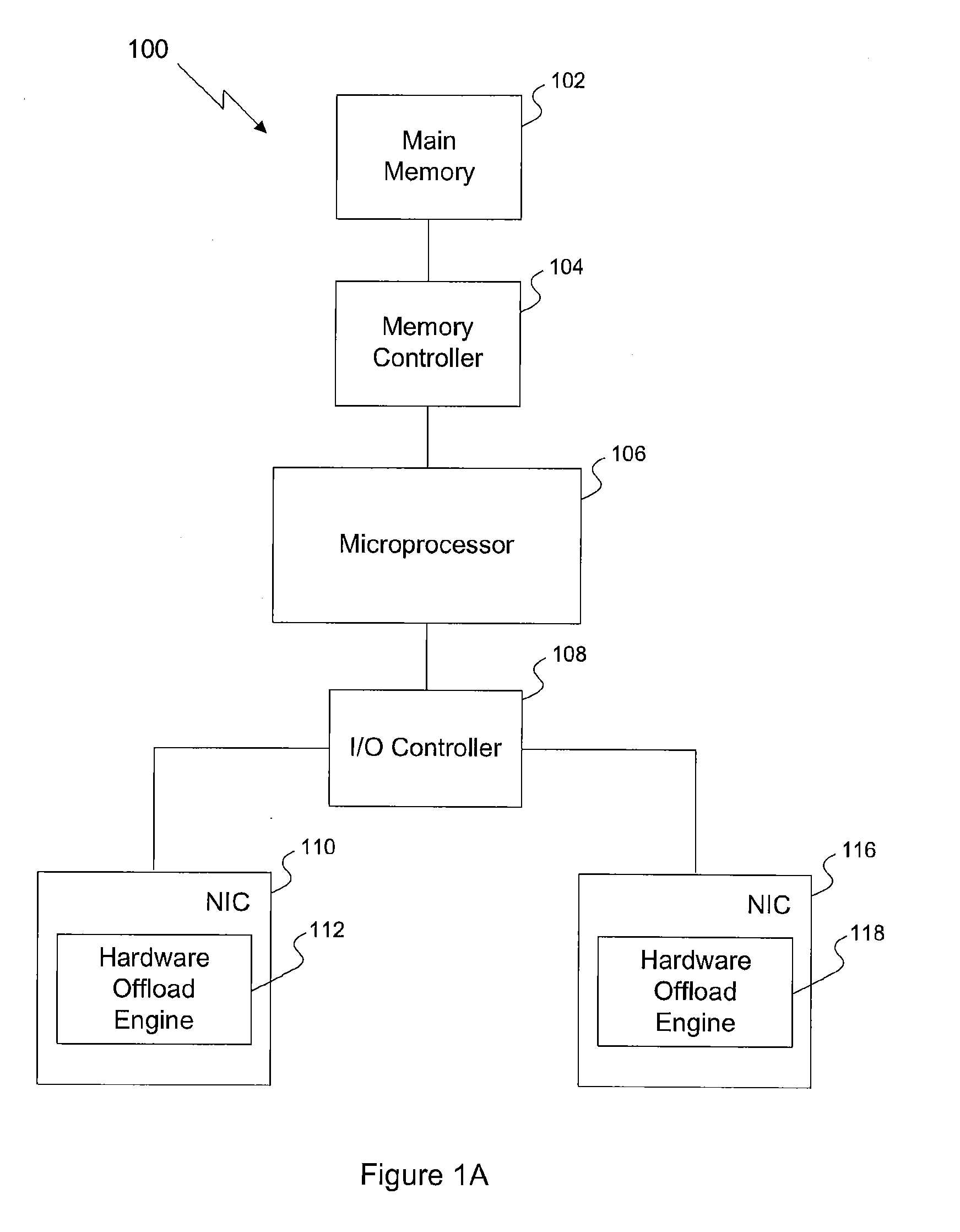

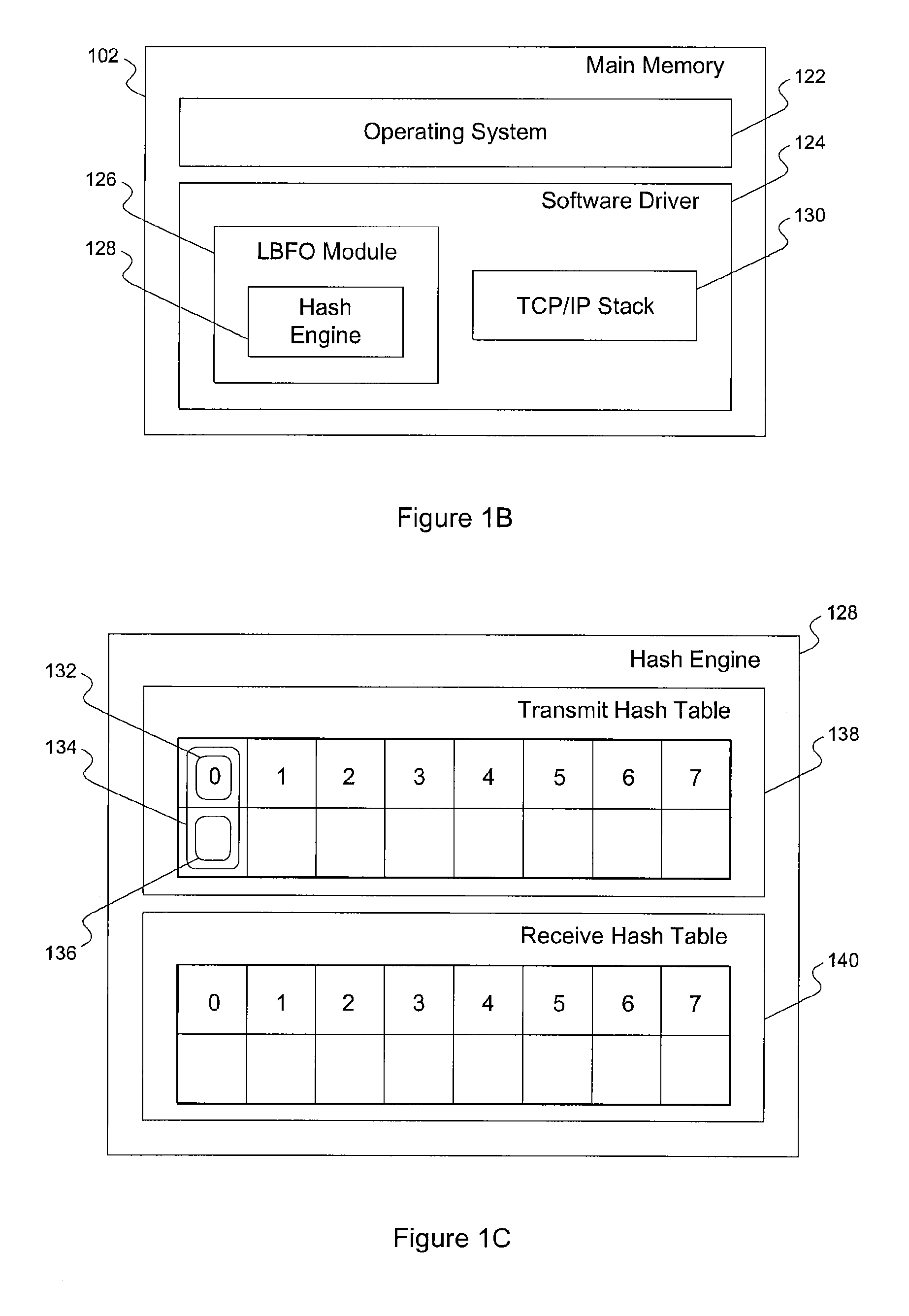

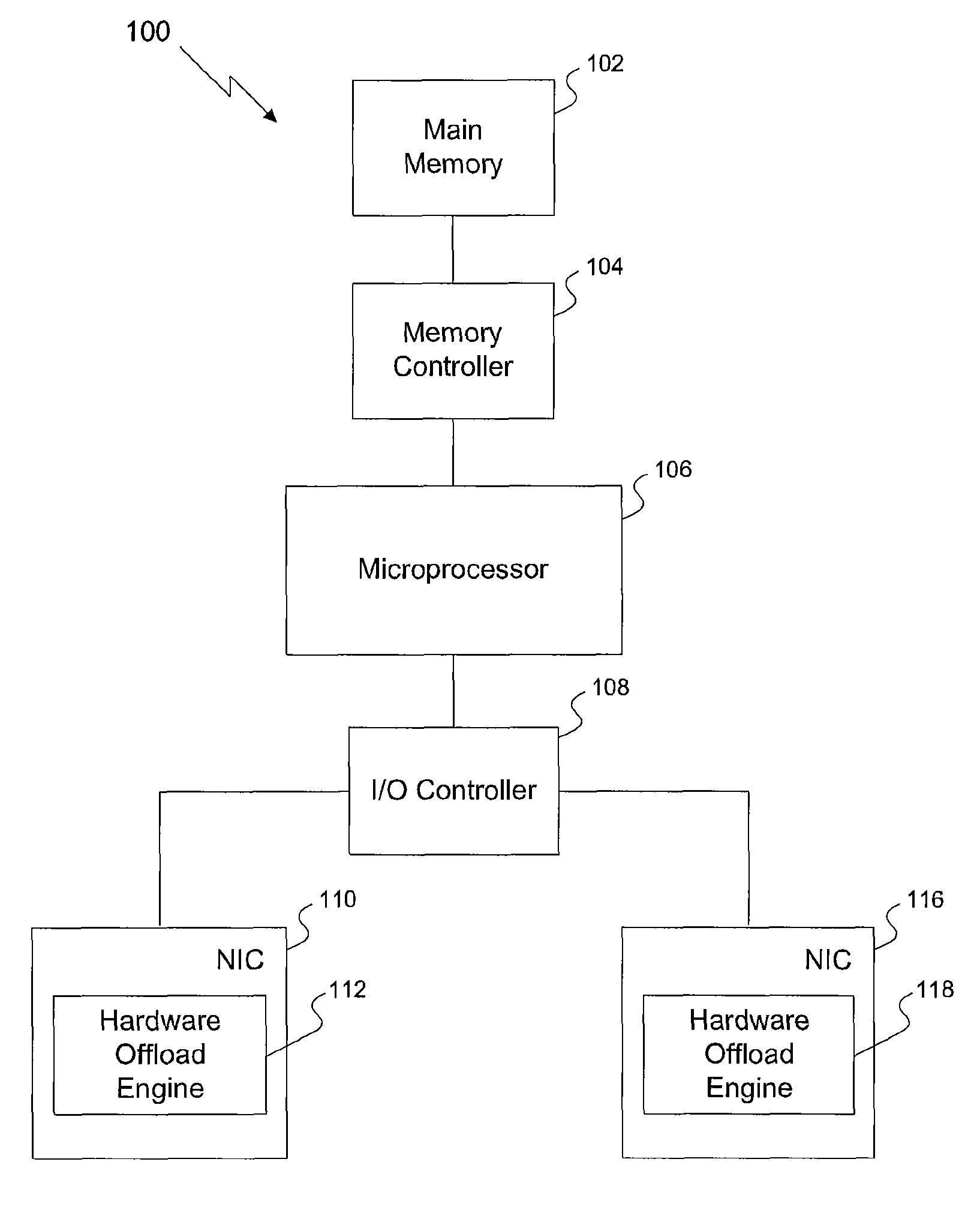

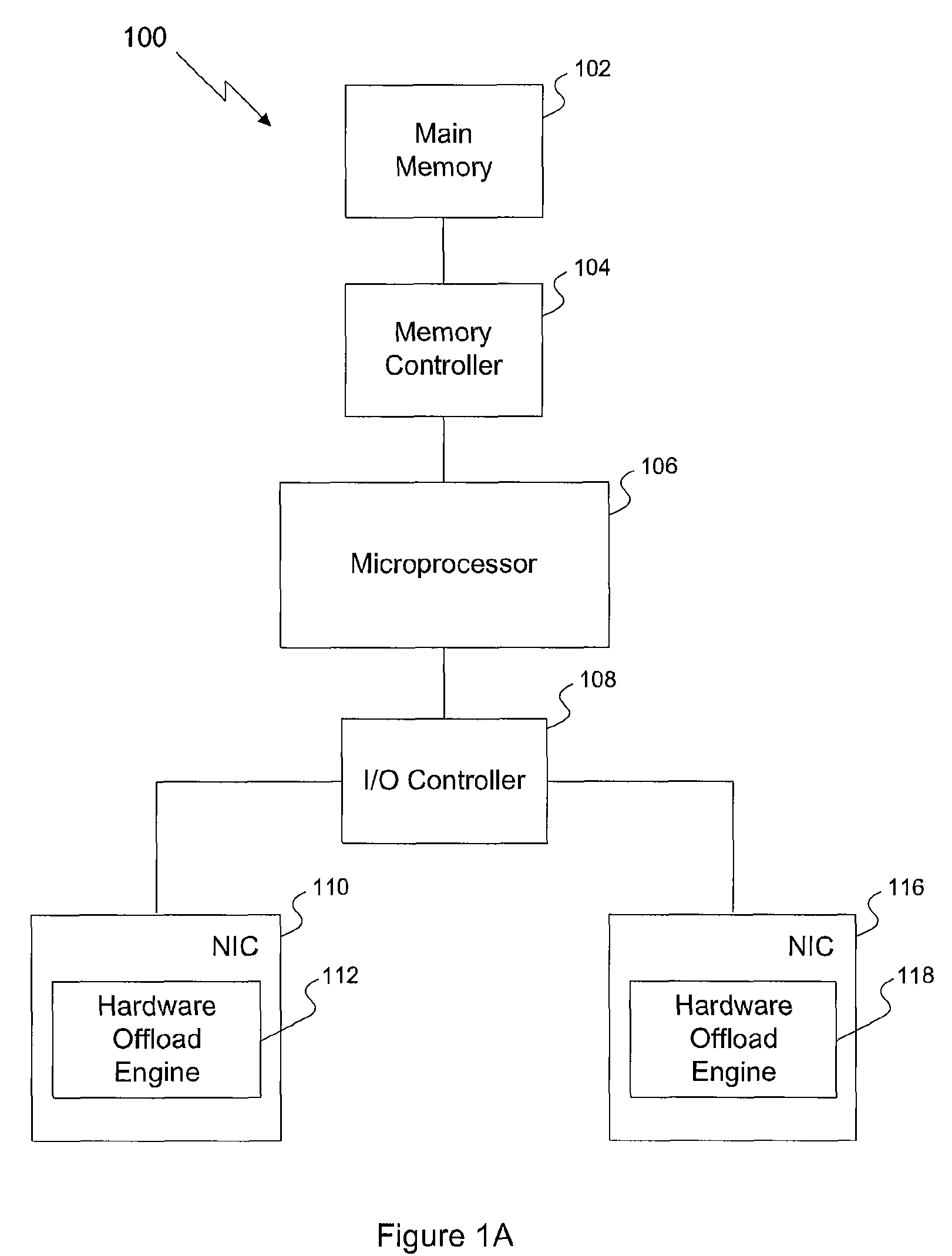

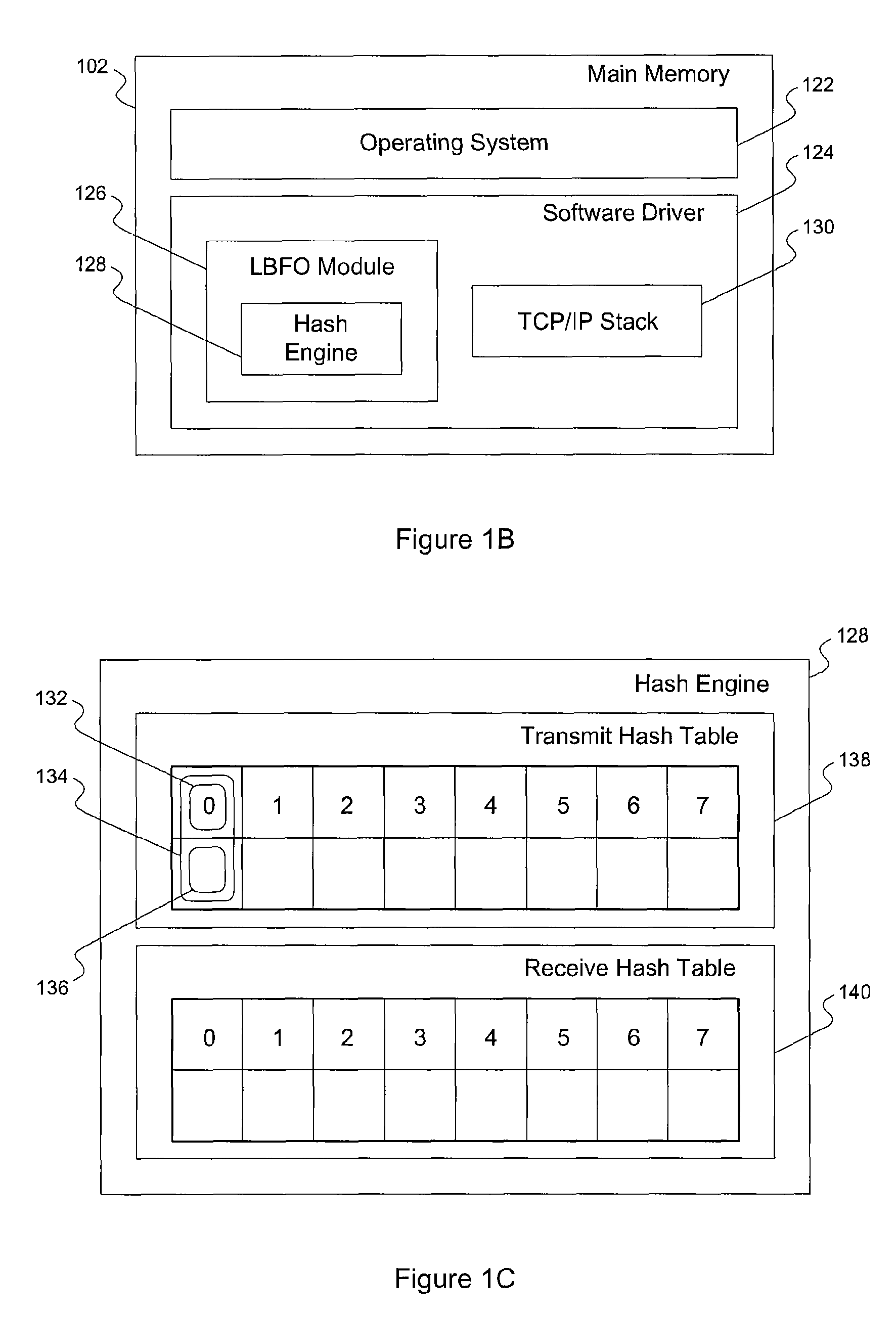

Intelligent load balancing and failover of network traffic

ActiveUS20080285553A1Improve network performanceEasily avoidedData switching by path configurationAddress Resolution ProtocolOperational system

A hash engine in a network device driver maintains data on the utilization and error rate for each network interface card (“NIC”) within a local computing device. From this data, the hash engine intelligently selects transmit NICs and receive NICs based on various networking parameters provided from a software driver program. Transmit packets sent from the operating system in a local computing device to a remote computing device are intercepted, modified and redirected to transmit NICs selected by the hash engine for transmission to remote computing devices. Similarly, address resolution protocol (“ARP”) response packets sent by the operating system in response to ARP request packets are intercepted, modified and redirected to receive NICs selected by the hash engine for transmission. By selecting receive NICs and transmit NICs in this fashion, the hash engine is able to intelligently load balance transmit and receive traffic in the local computing device, thereby improving overall network performance relative to prior art techniques.

Owner:NVIDIA CORP

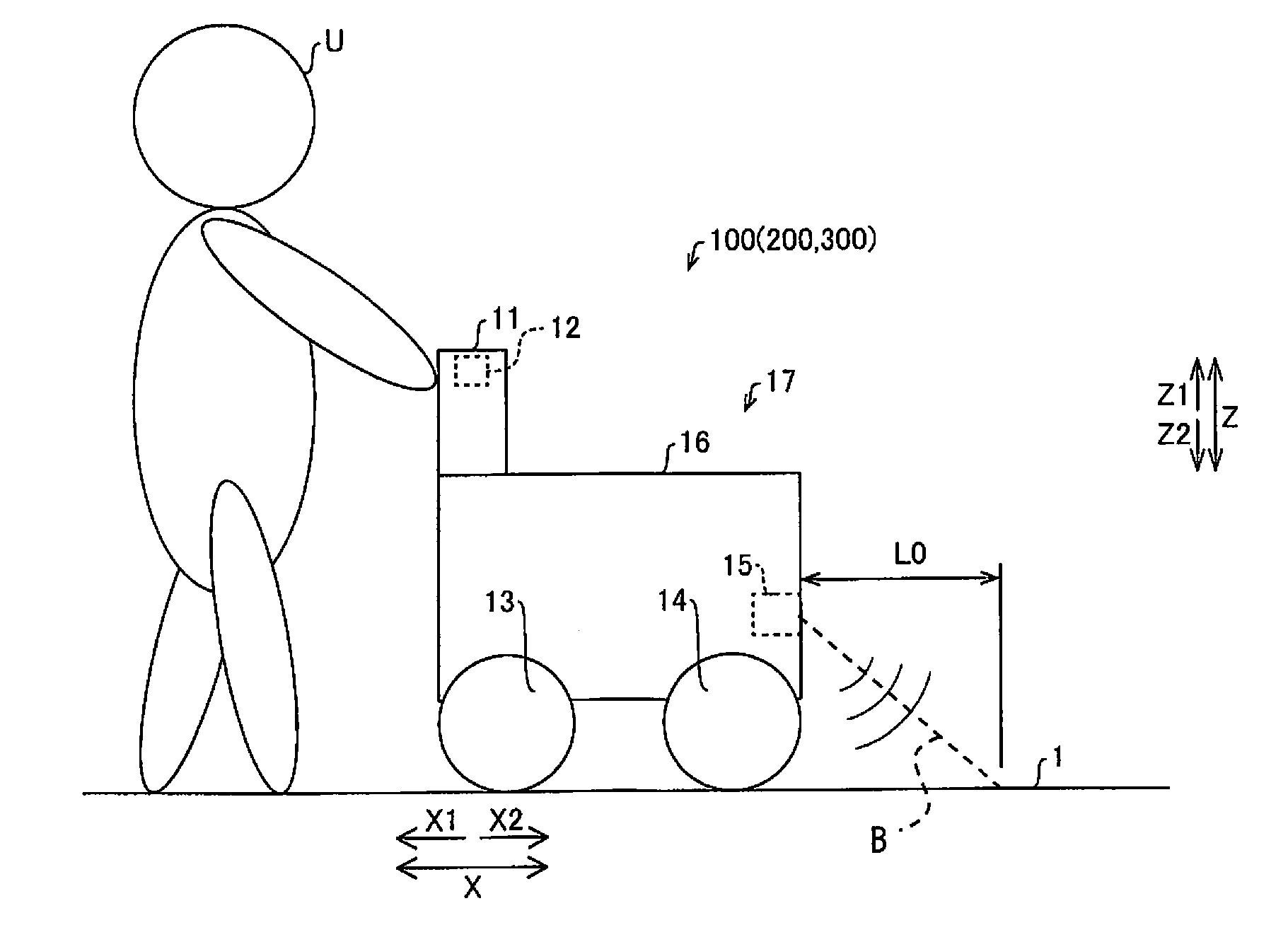

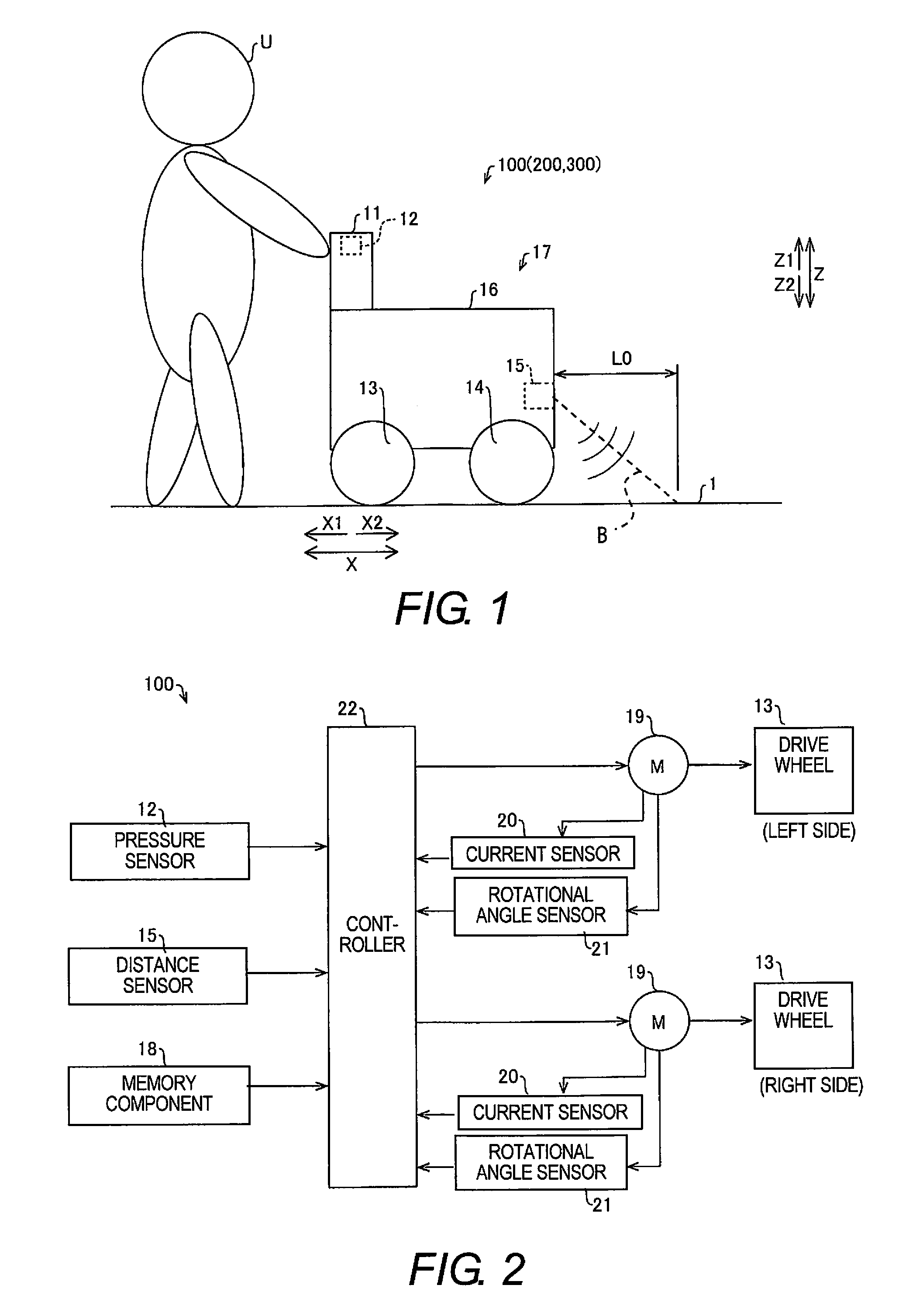

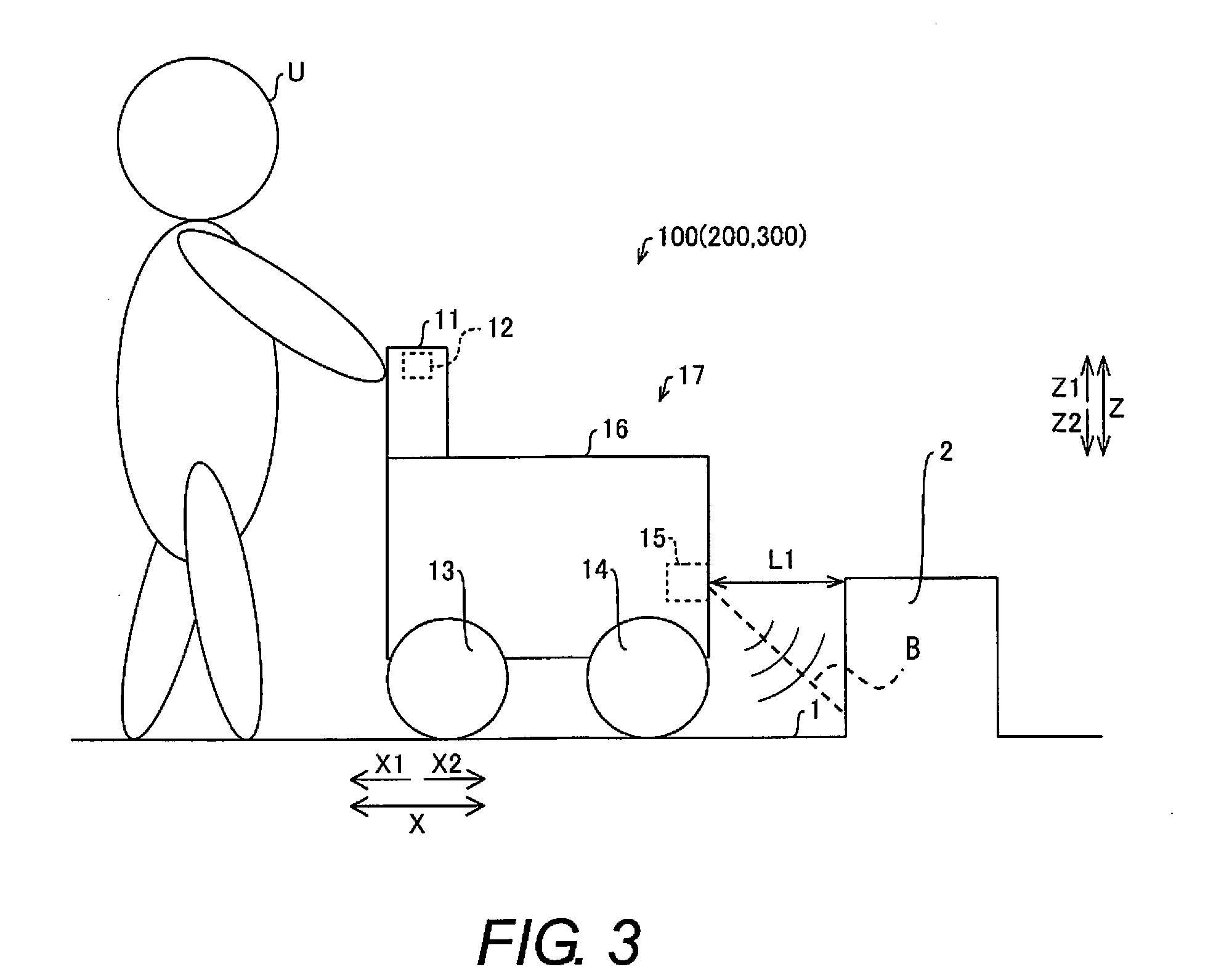

Walking assistance moving vehicle

InactiveUS20150066328A1Easily avoidedCarriage/perambulator accessoriesDigital data processing detailsMobile vehicleEngineering

Owner:FUNAI ELECTRIC CO LTD

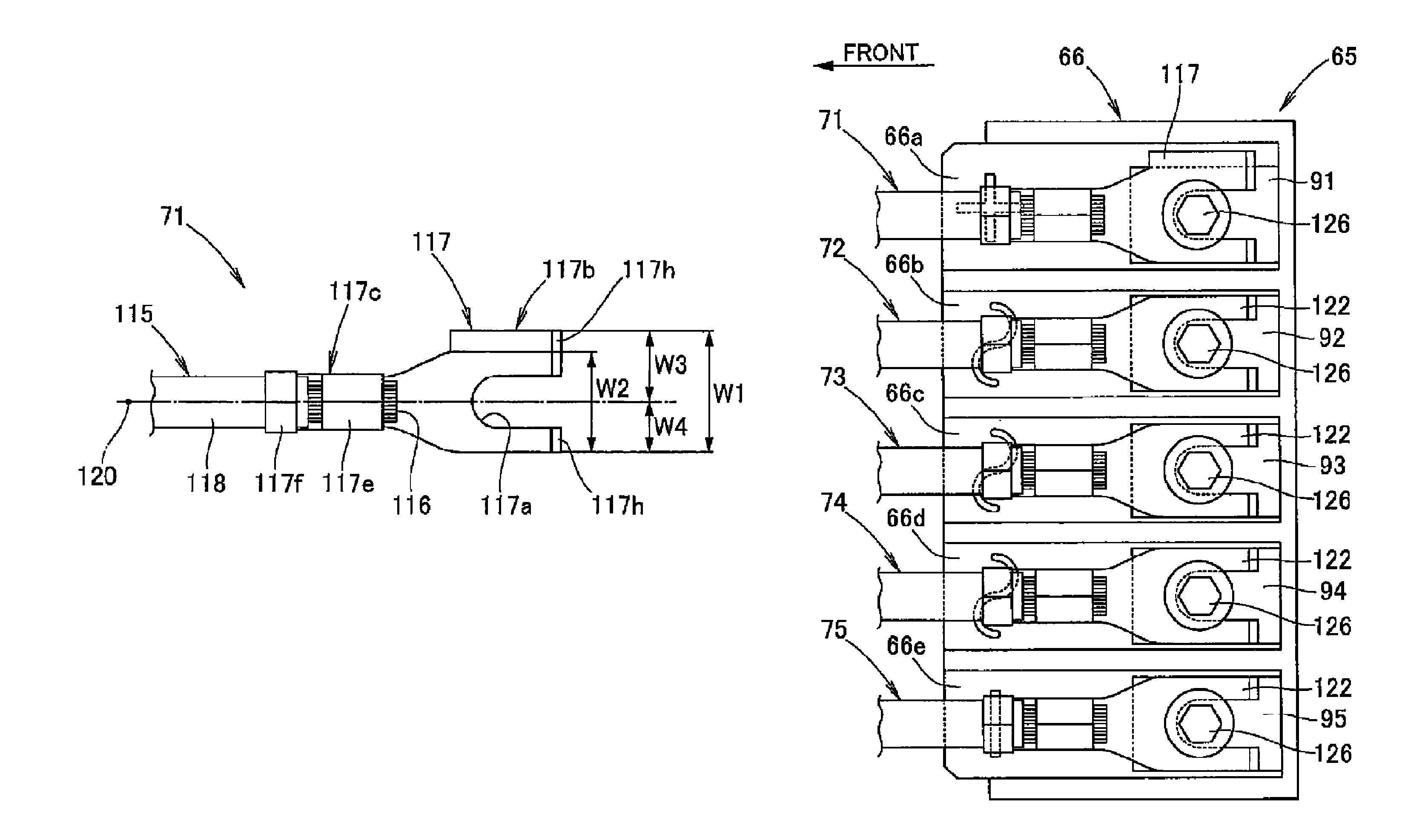

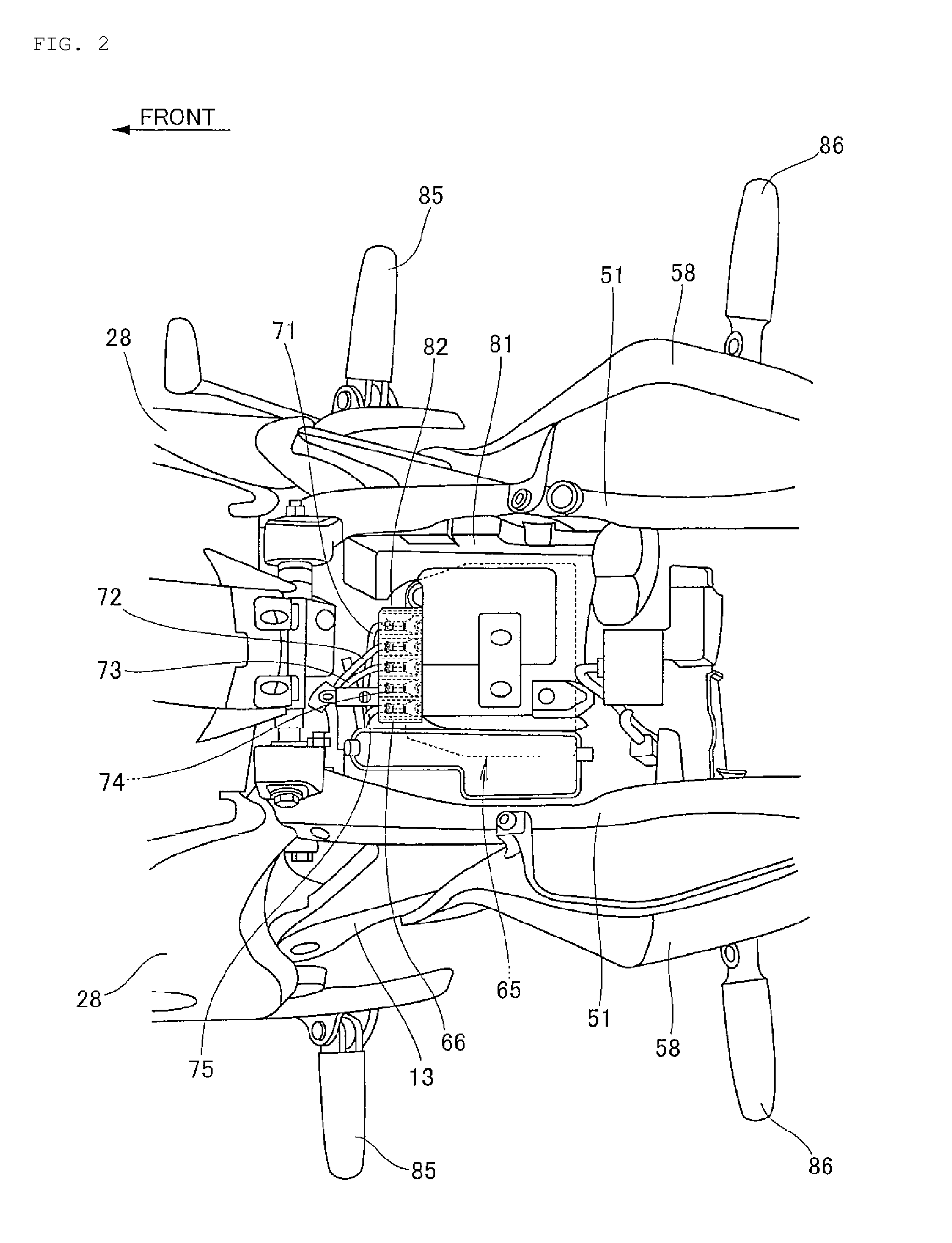

Terminal connector for a regulator

InactiveUS8226446B2Firmly connectedEasily identifiableVehicle connectorsContact member assembly/disassemblyEngineeringTerminal unit

A terminal connector for a regulator and a method for connecting an external terminal to the terminal connector are provided, whereby the regulator is configured to control an output of a generator provided to a motorcycle. The terminal connector is configured to connect the regulator and external terminals using bolts and nuts, and includes a plurality of terminal units. Each terminal unit is individually connected to an external terminal, and is configured in a width direction of the terminal connector. Each terminal unit is configured as a support base for screw-tightening, to which one of the external terminals is connected by screwing, and includes an identification mark. At least two of the terminal units have different widths.

Owner:HONDA MOTOR CO LTD

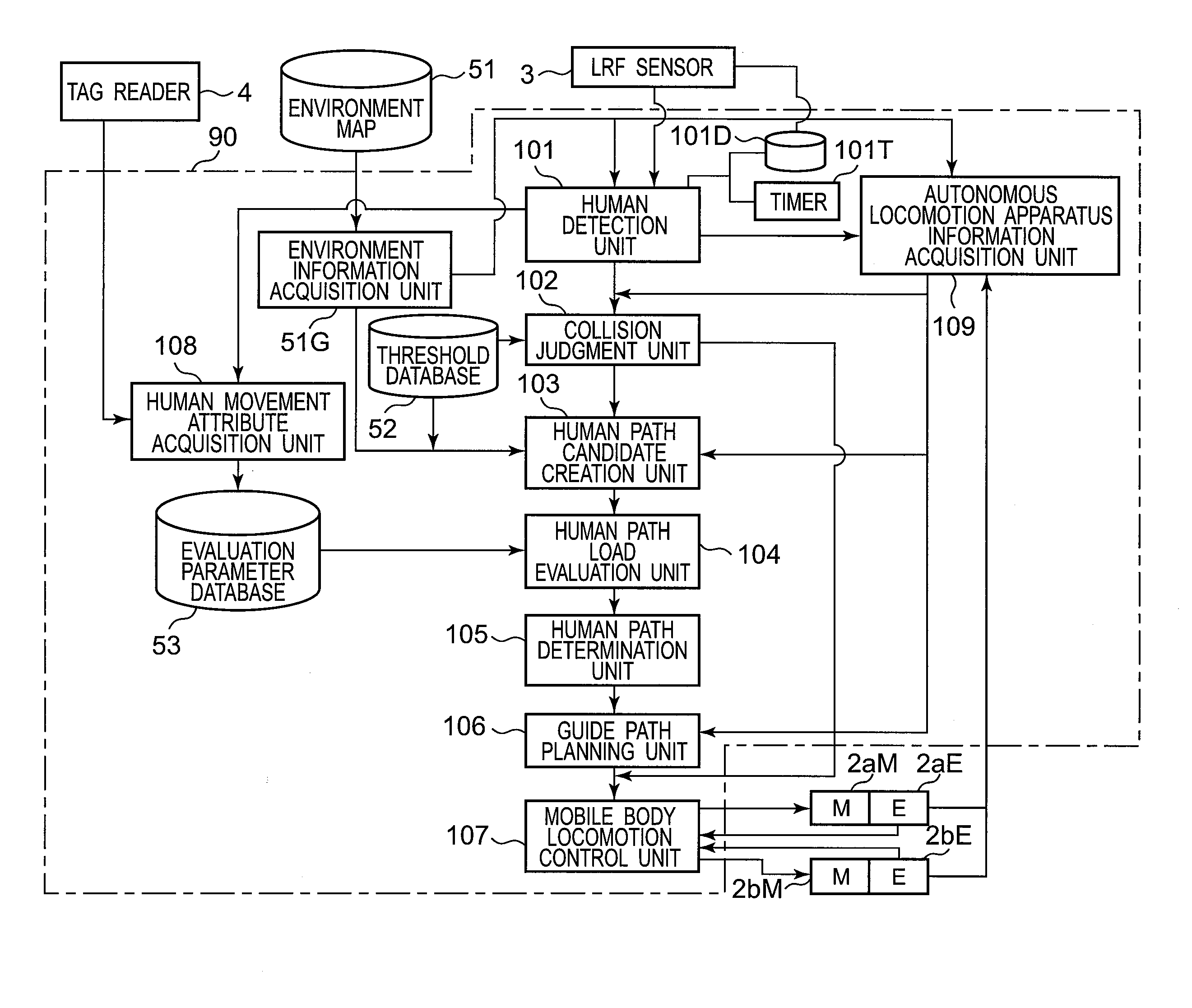

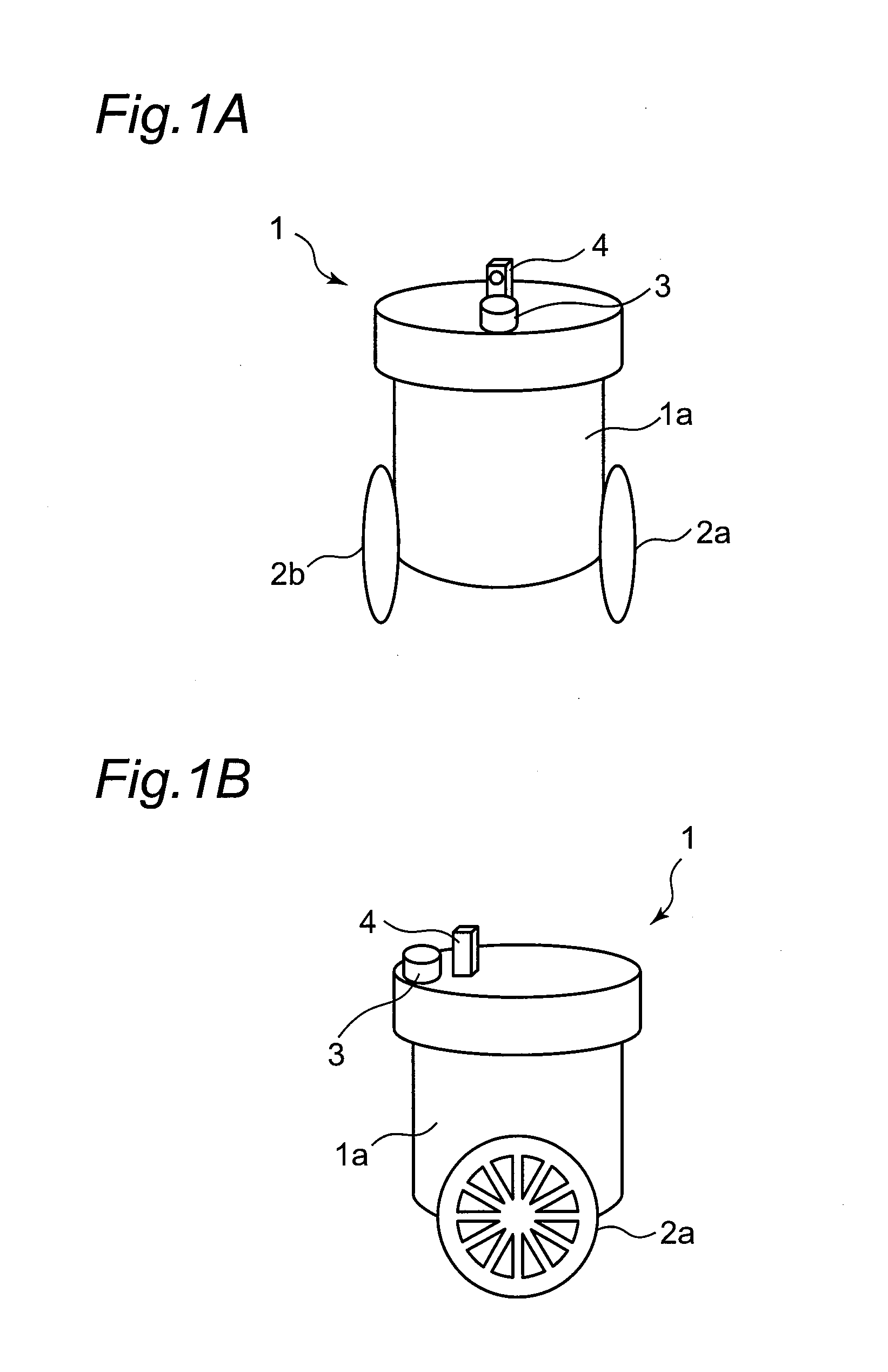

Autonomous locomotion apparatus, autonomous locomotion method, and program for autonomous locomotion apparatus

InactiveUS20140039676A1Low exercise loadEasily avoidedComputer controlSimulator controlPhysical medicine and rehabilitationSimulation

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

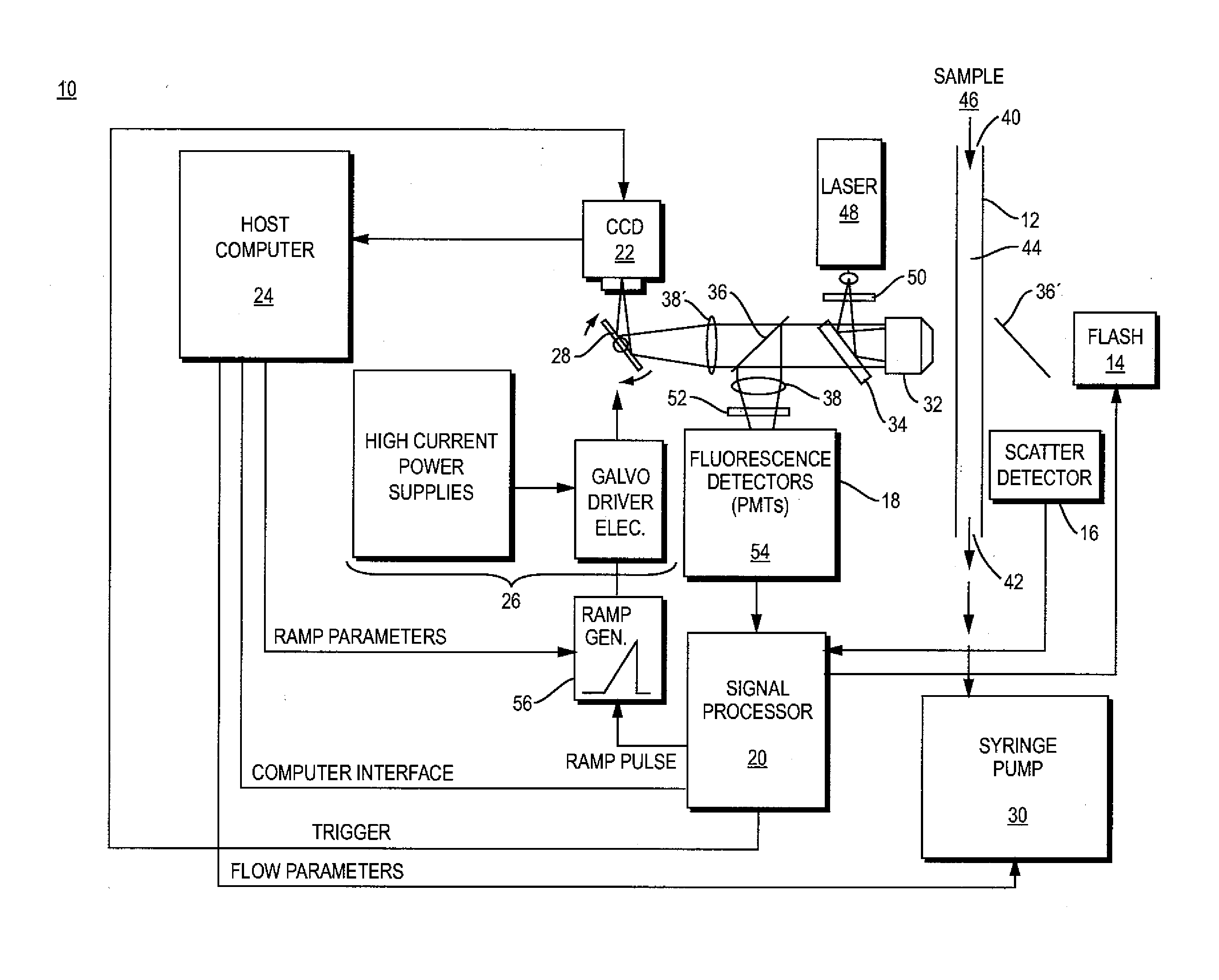

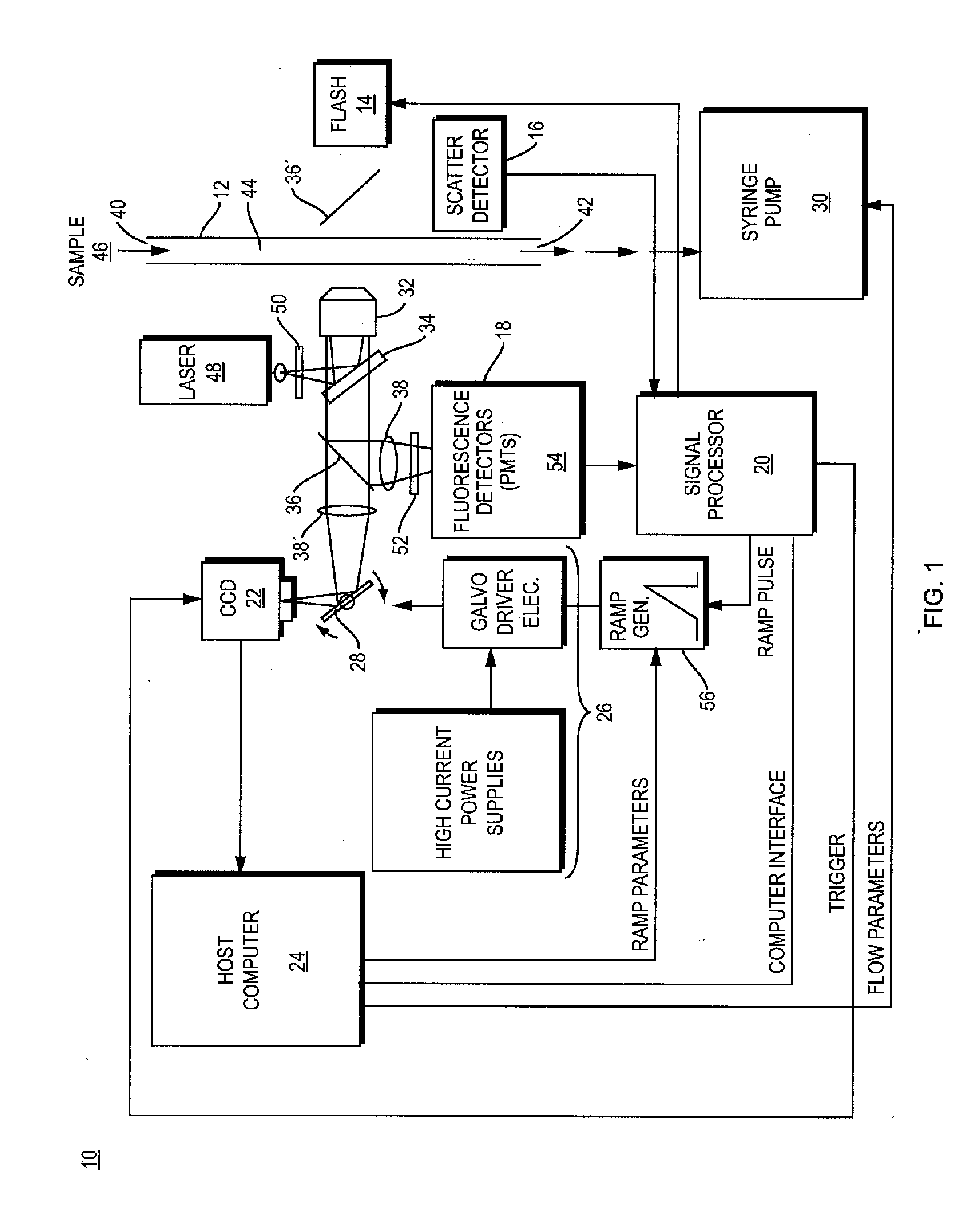

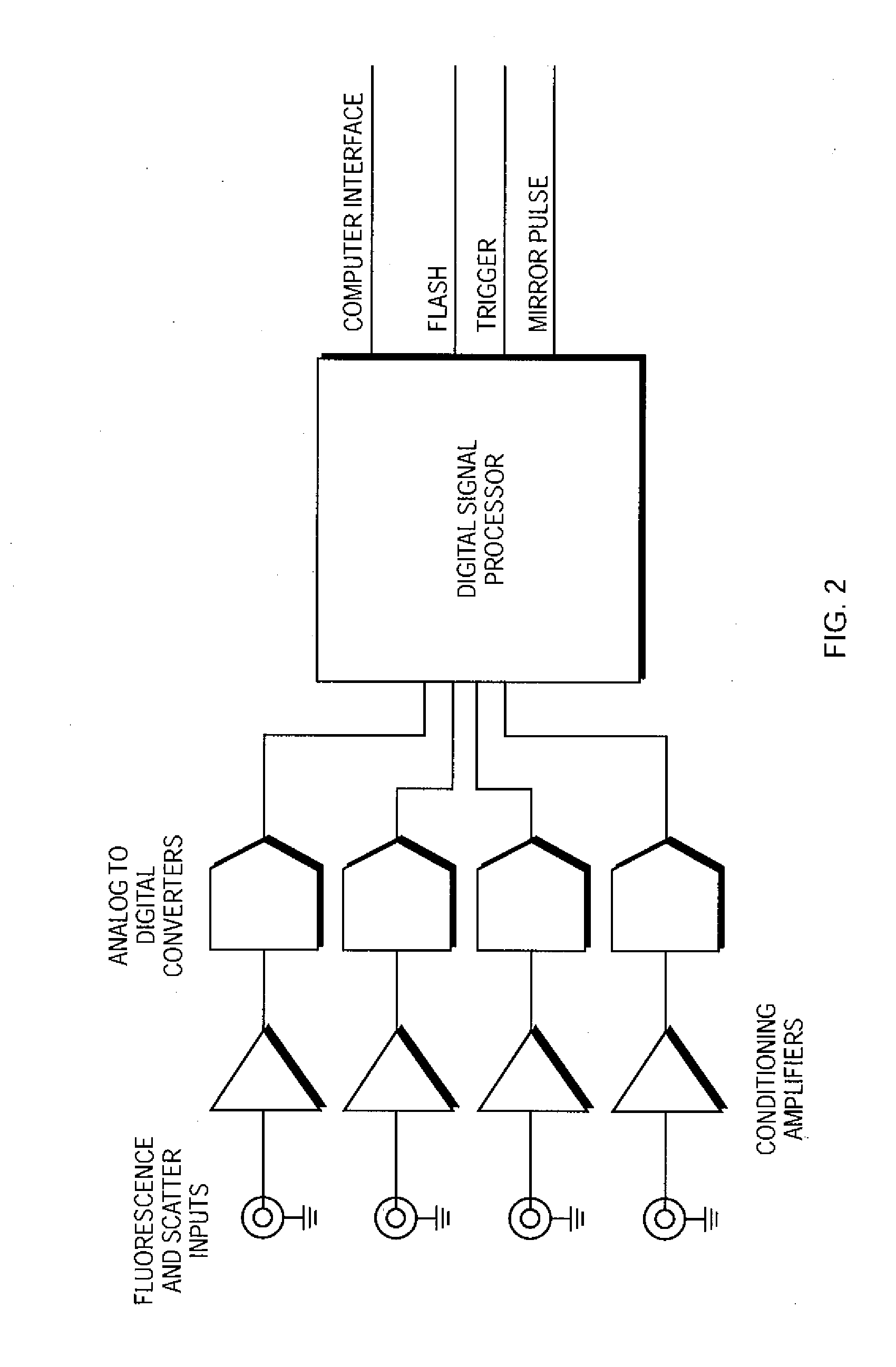

System and method for sweeping mirror enhanced imaging flow cytometry

InactiveUS20120002029A1Improved sample fluid flow rateReduce blurMaterial analysis by optical meansColor television detailsPhysicsHigh rate

An imaging flow cytometry system and method which includes a flow chamber, tracking mirror, microscope and imaging optics, image capturing system, device to regulate fluid flow through the chamber, and backlighting generator. The tracking mirror moves at a rate matched to the particle velocity in the flow chamber so as to enhance the sample flow rates possible with the system while maintaining clear and accurate imaging. The backlighting generator passes through the flow chamber and the objective before being focused on the image capturing system. Detected scatter events initiate tracking by the mirror, resulting in imaging with reduced motion blur even at high rates of flow.

Owner:FLUID IMAGING TECH

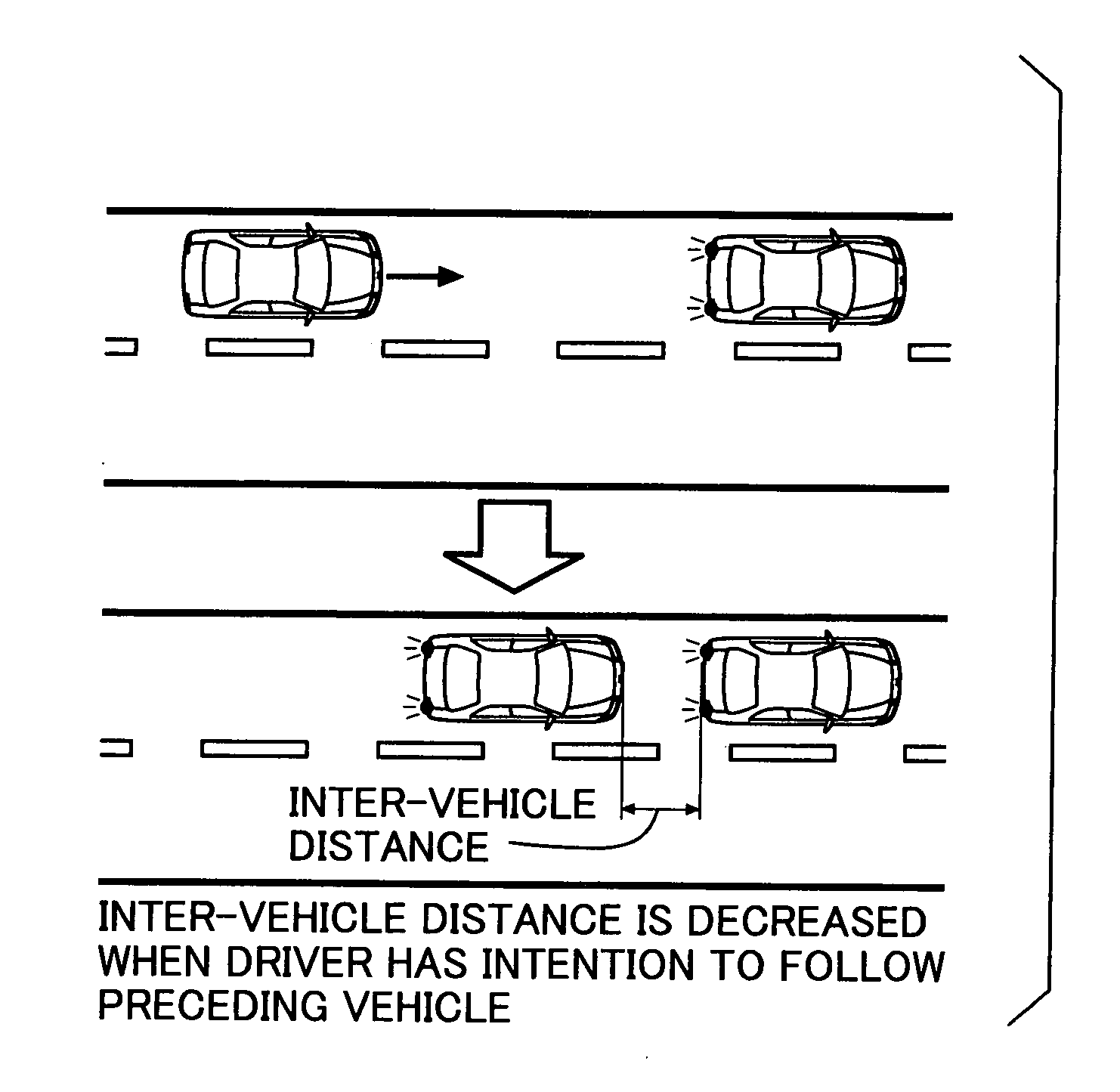

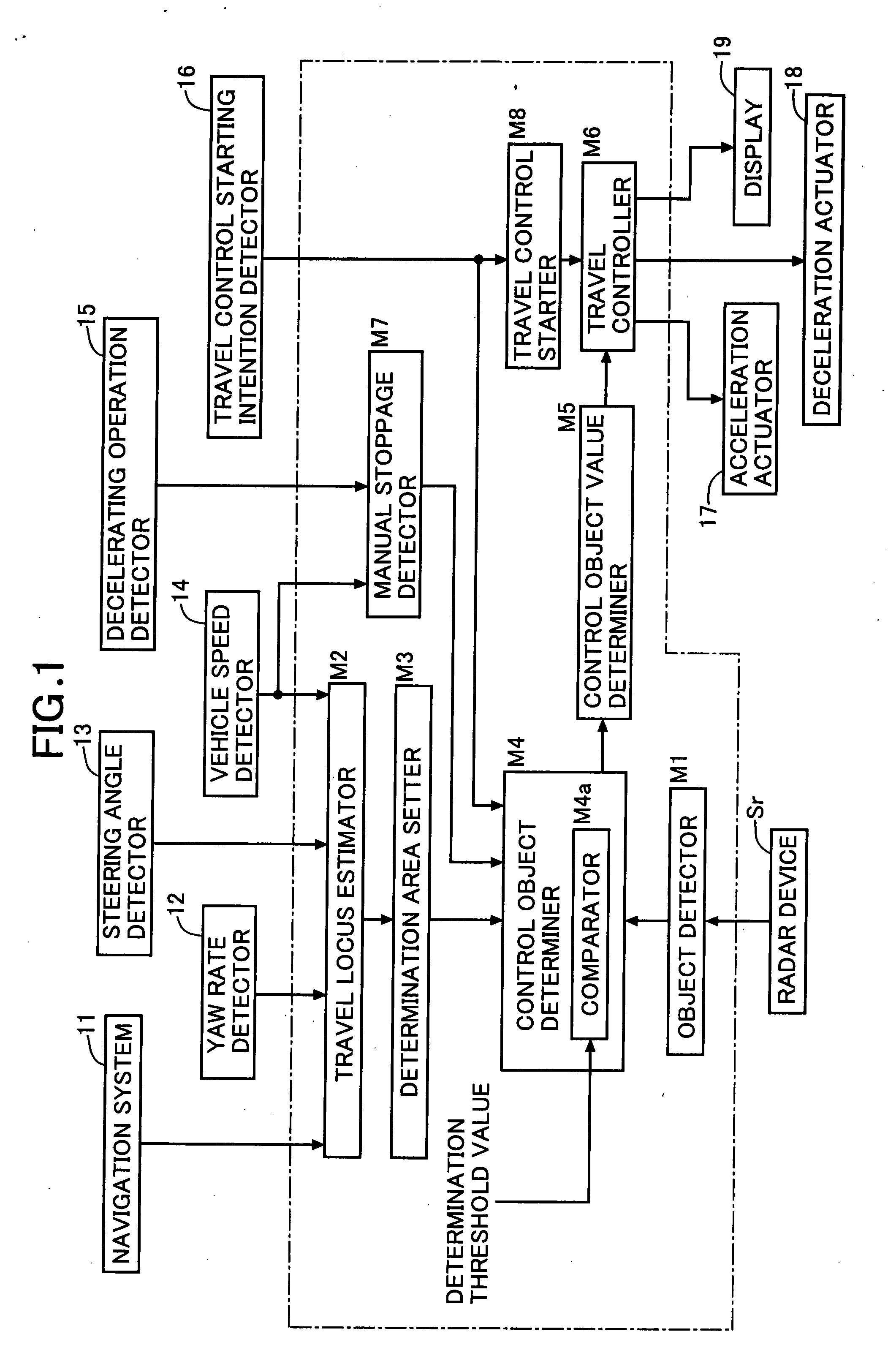

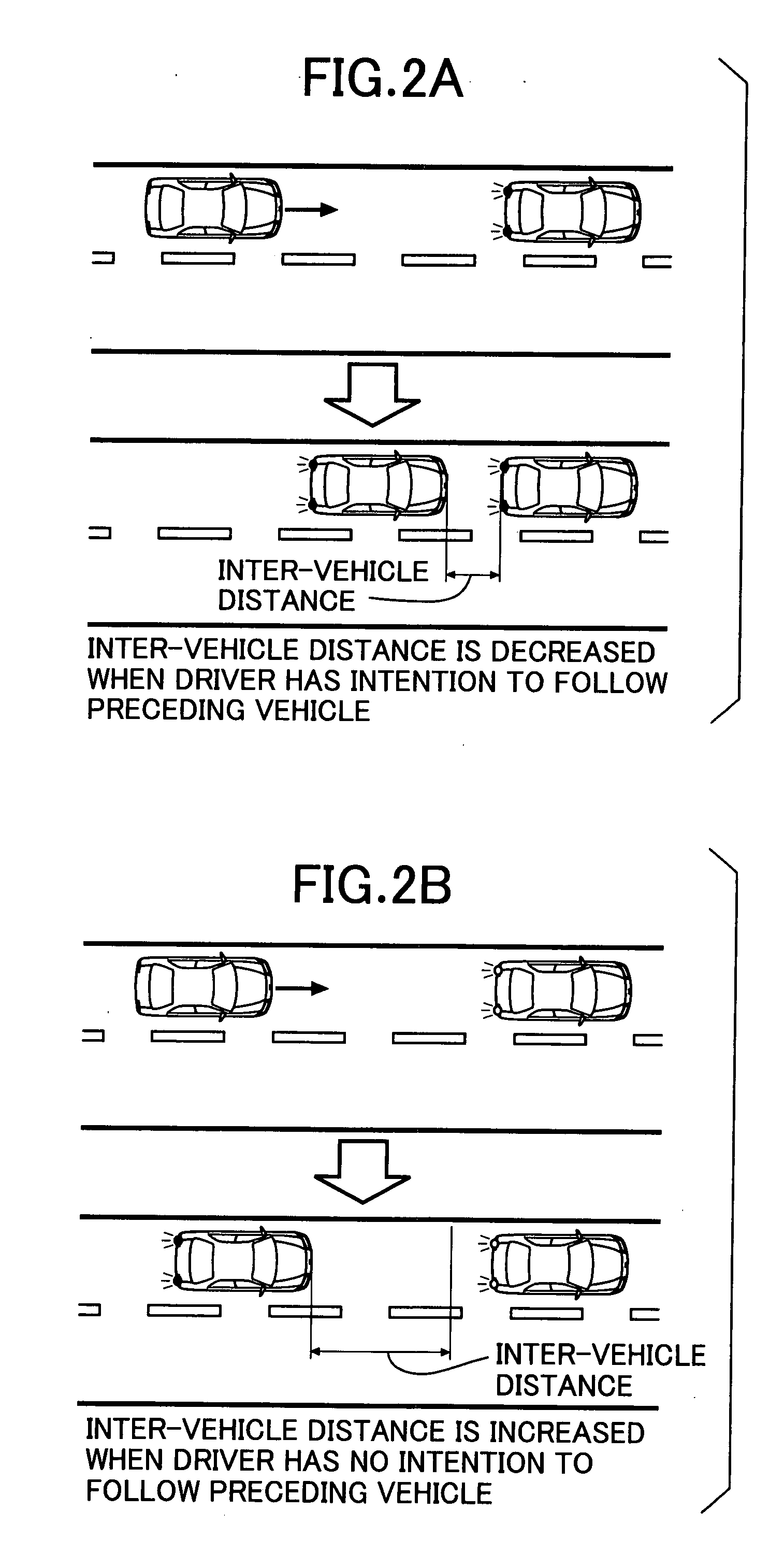

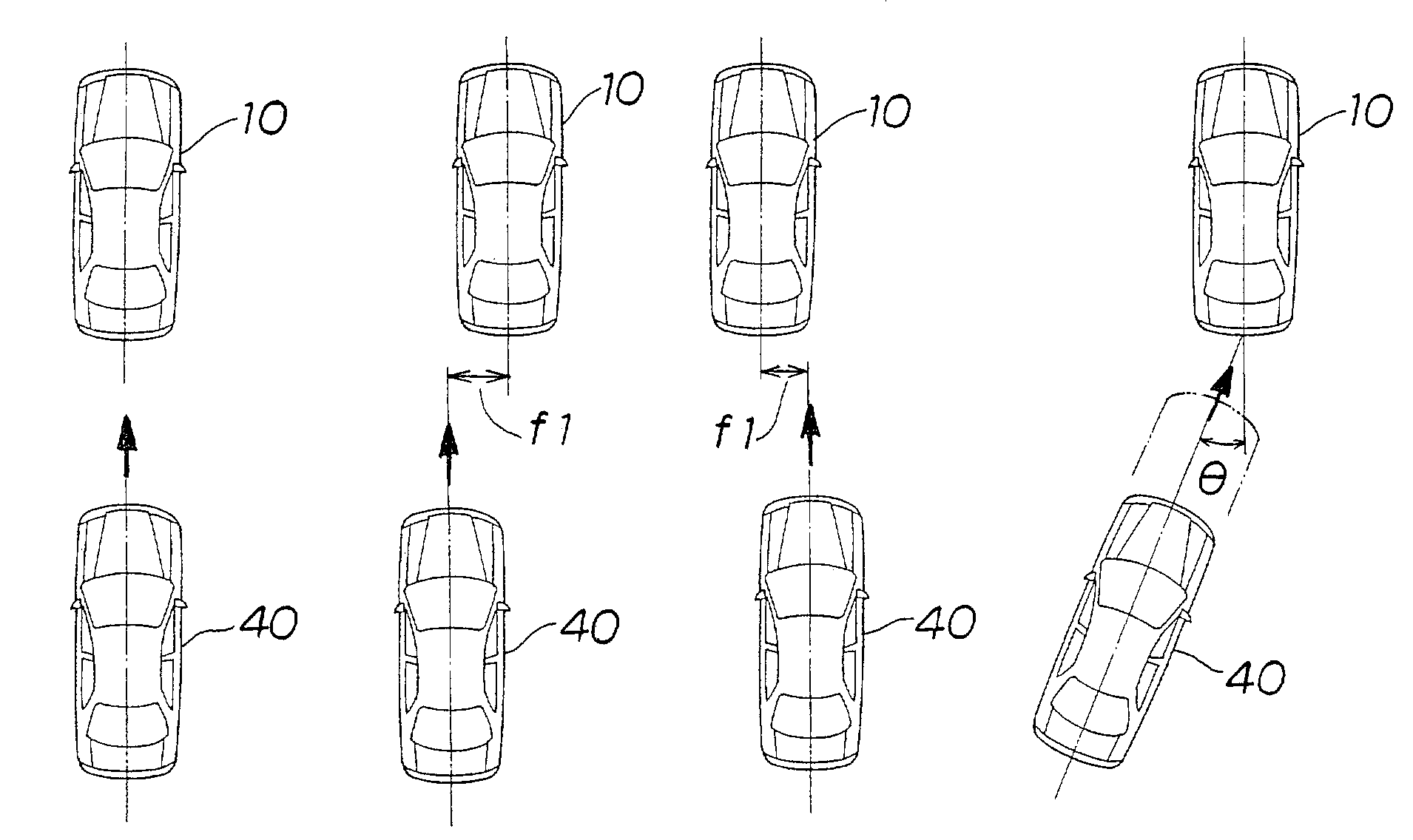

Travel control system for vehicle

InactiveUS20080109120A1Uncomfortable feelingRaise the thresholdVehicle fittingsAnalogue computers for trafficControl systemEngineering

A travel controller which controls the travel of a subject vehicle based on a distance to and a relative speed with respect to a control object determined by a control object determiner. If stoppage of the subject vehicle by a decelerating operation of a driver is detected by a manual stoppage detector and a comparator determines that a distance to the object in or on a travel locus is equal to or larger than a determination threshold value, the comparator excludes the object from being considered as a control object.

Owner:HONDA MOTOR CO LTD

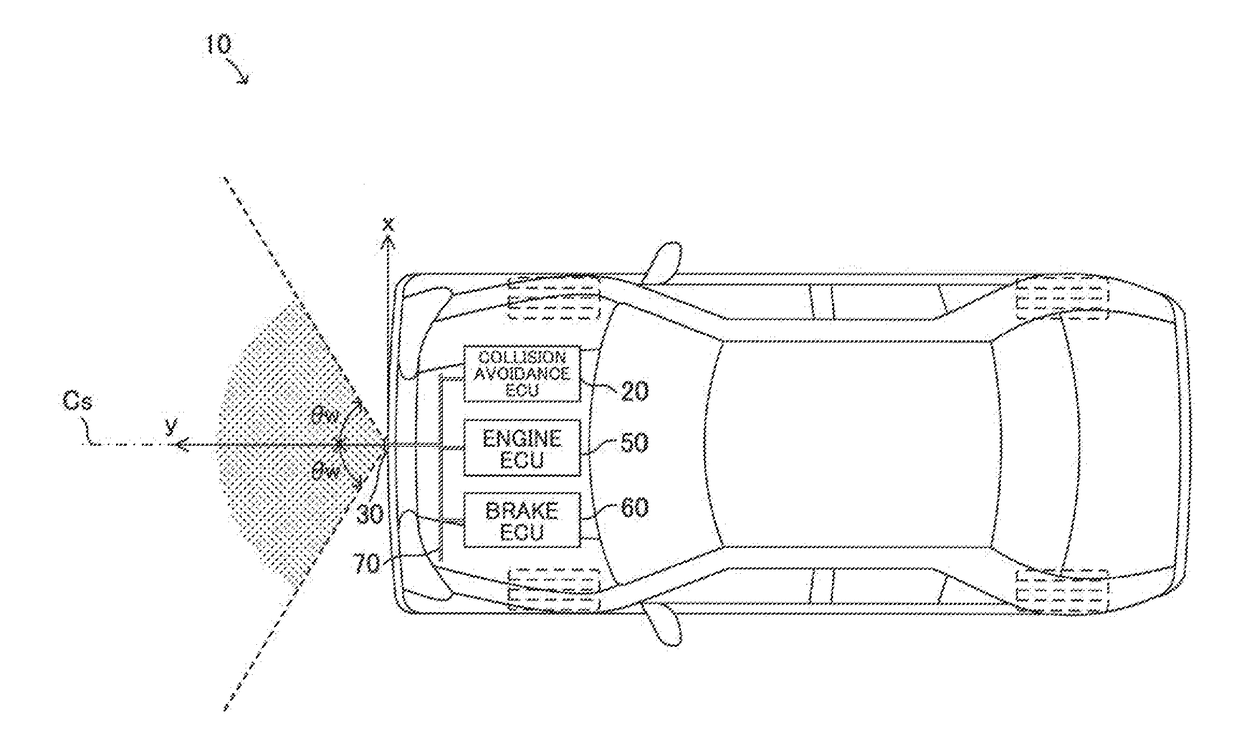

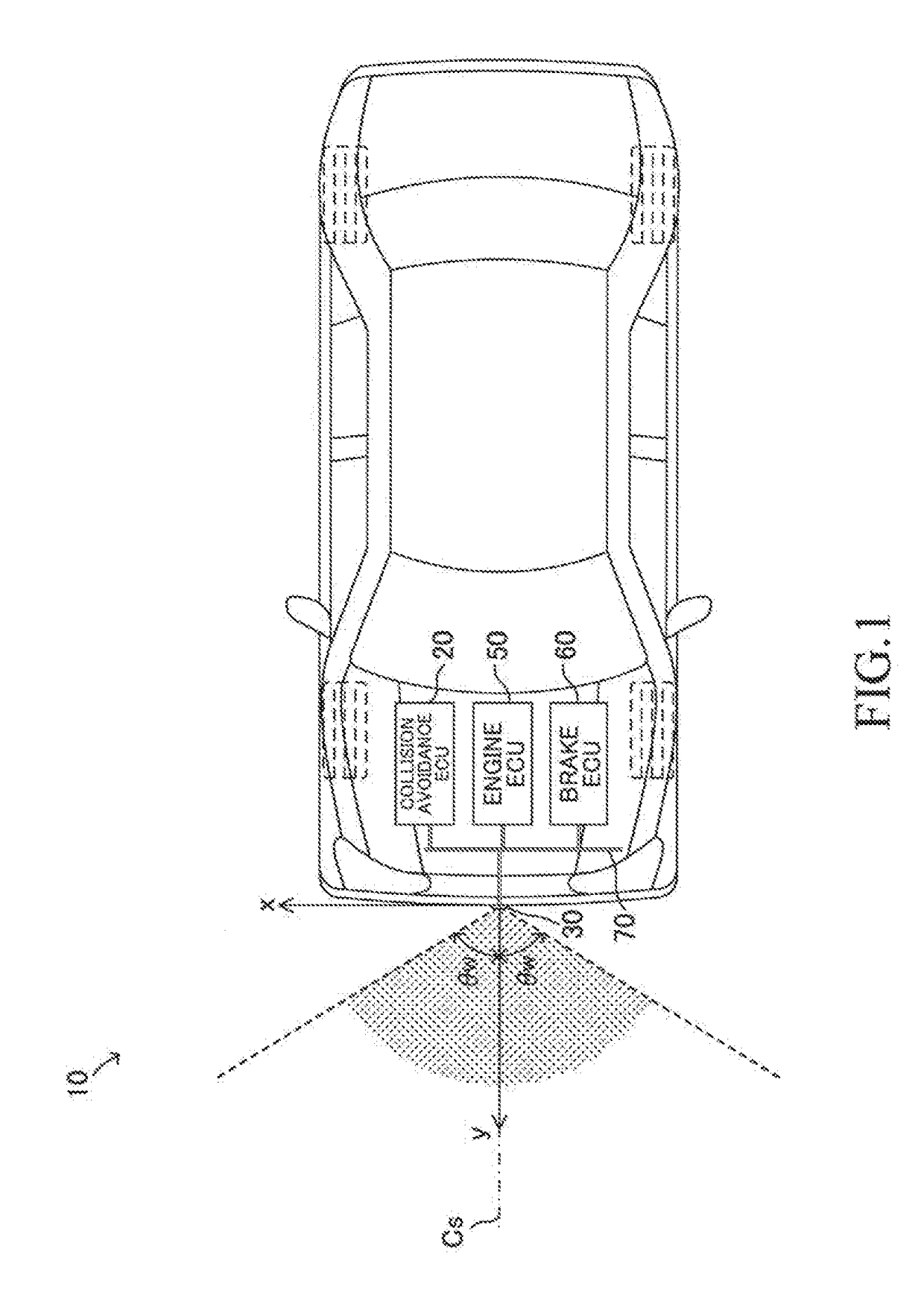

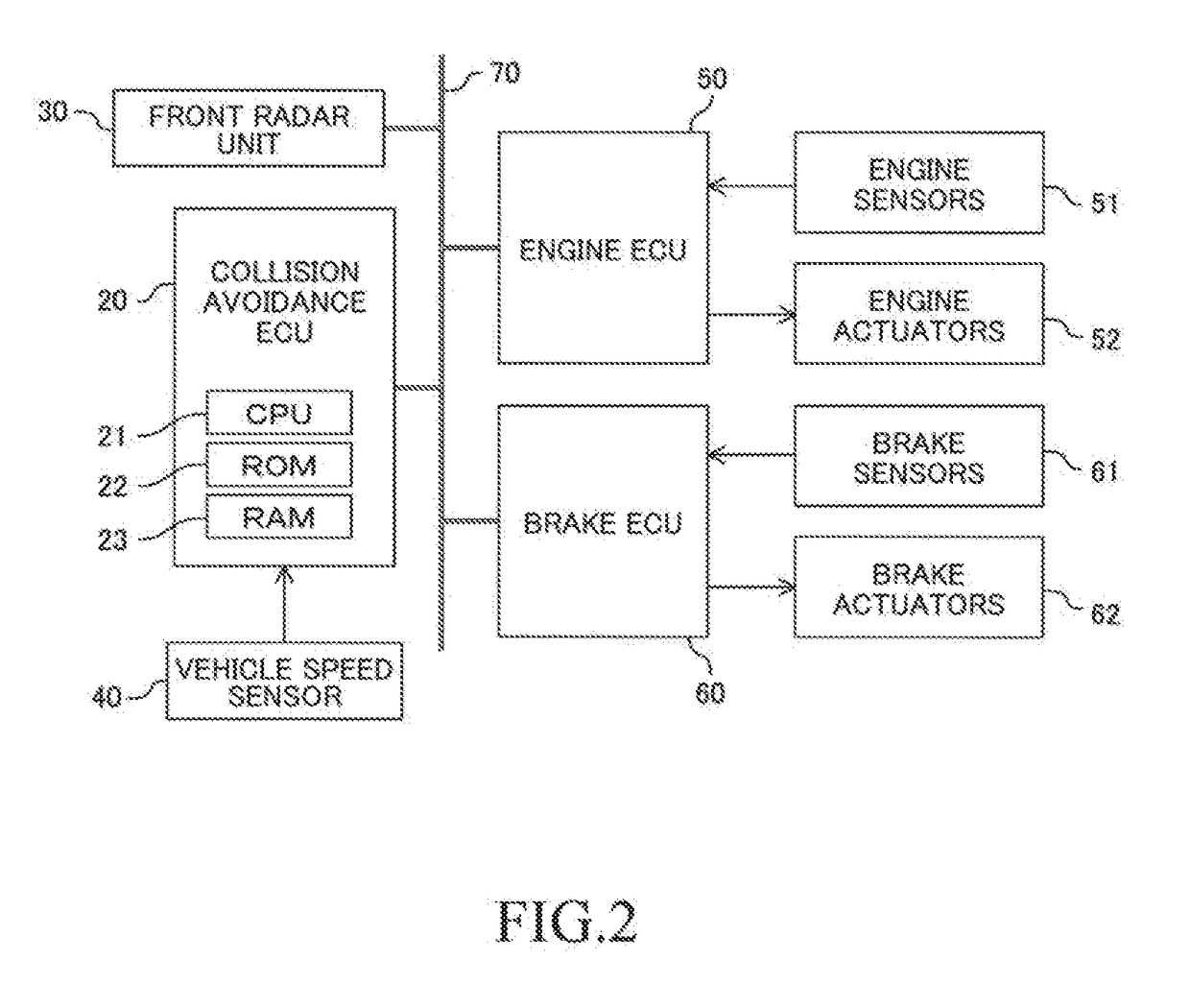

Collision avoidance apparatus

ActiveUS20170369054A1Reduce the possibilityRaise the possibilityExternal condition input parametersEngineering

A collision avoidance apparatus includes an obstacle detection section for detecting an obstacle, a collision avoidance section which performs collision avoidance assist control, and an avoidance processing start section for causing the collision avoidance section to start the collision avoidance assist control. In the case where the obstacle is a continuous obstacle, the timing of starting the collision avoidance assist control is delayed as compared with the case where the obstacle is not a continuous obstacle. Further, the greater the degree of gentleness of the inclination of the continuous obstacle, the greater the amount by which the timing of starting the collision avoidance assist control is delayed.

Owner:TOYOTA JIDOSHA KK

Method and apparatus for discoverable input of symbols on a reduced keypad

InactiveUS7761175B2Laborious multipleEasily avoidedInput/output for user-computer interactionComputer controlDiscoverabilityTheoretical computer science

We discovered that a) a single key can support a multiplicity of ordered groups, b) only a subset of each group needs to be visually represented on the face of a key, c) either multi-tap or predictive methods, or both, can be used to input members of each of the groups, and d) auxiliary keys are a convenient, effective and user-discoverable method to select ordered groups, and to perform the multi-tap function. The objects of: limiting multi-tap depth, reducing keystrokes per symbol, unifying focus, increasing discoverability, graduated discoverability, power, compact presentation, and seamless integration of multi-tap and predictive text methods, can all be achieved by exploiting these discoveries.

Owner:EATONI ERGONOMICS INC

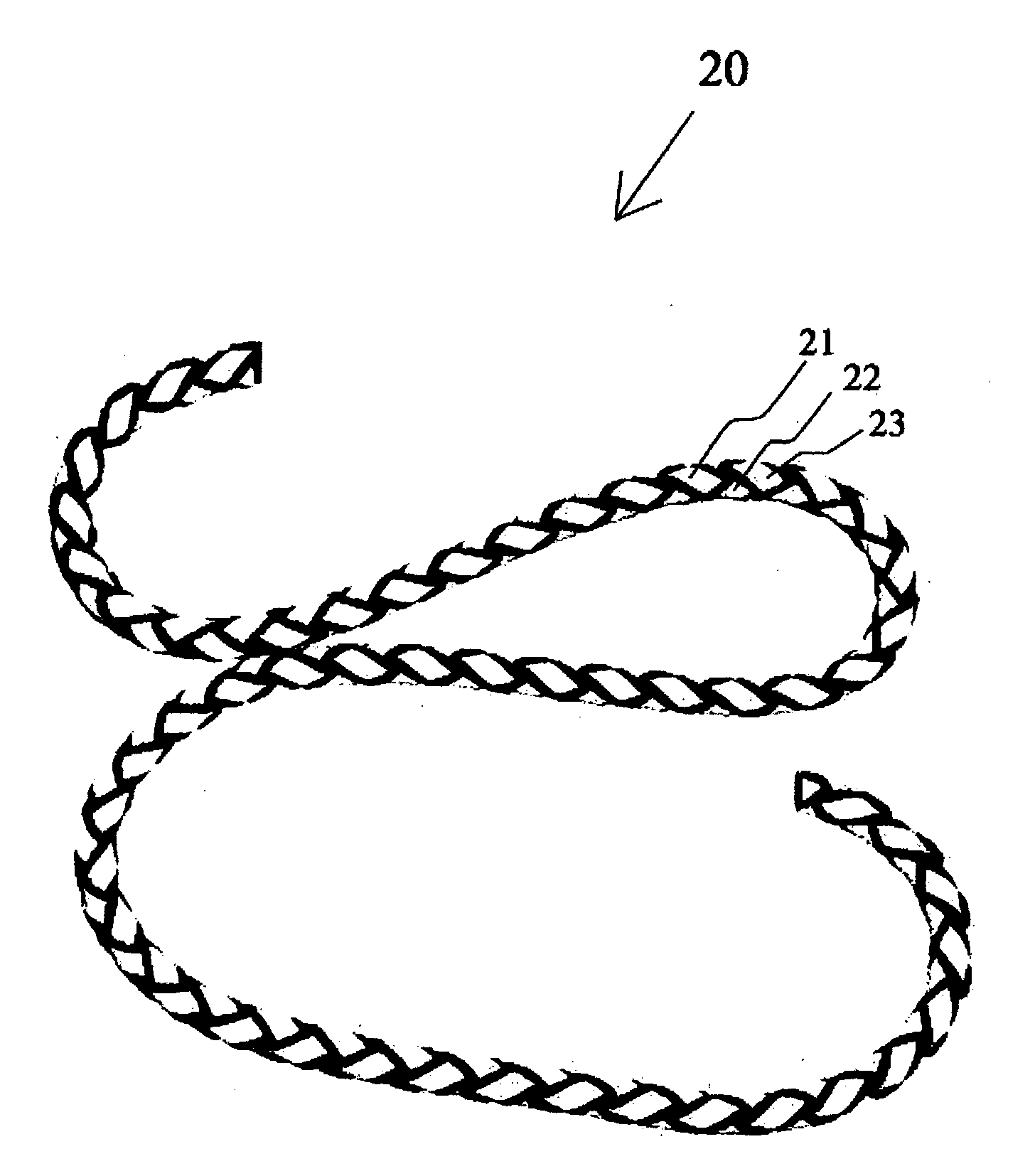

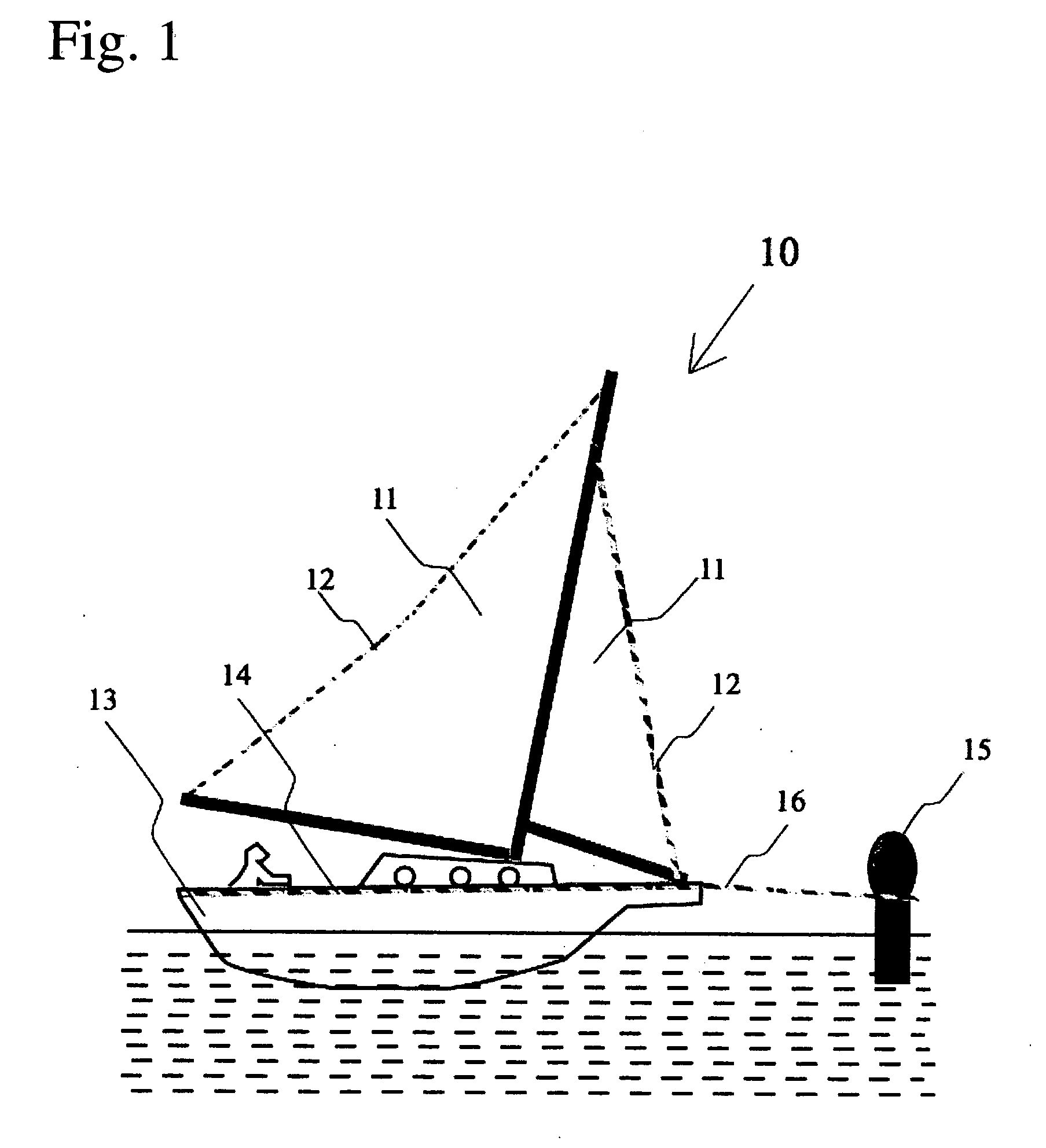

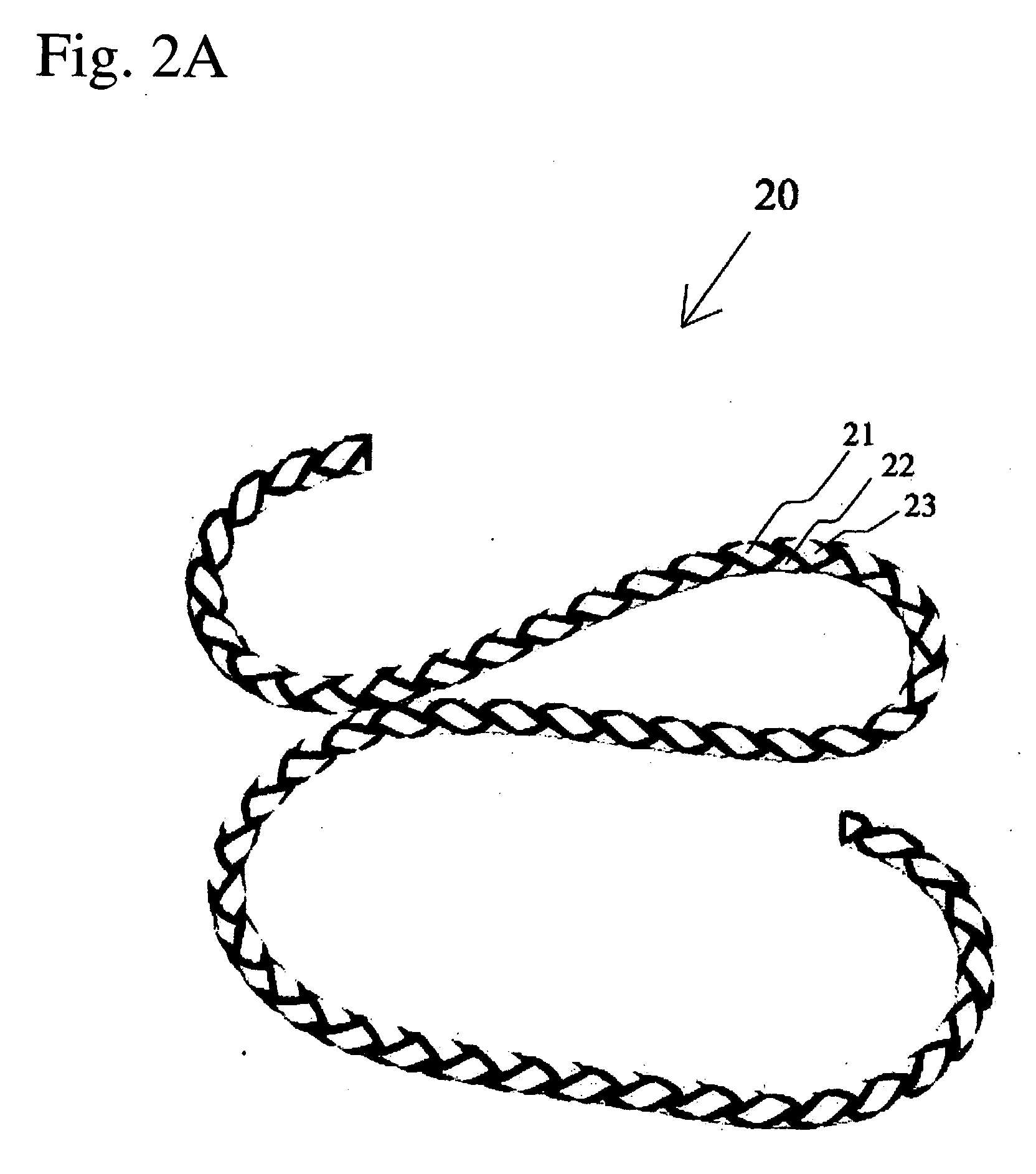

Abrasion resistant omnidirectionally reflective rope

InactiveUS20070062433A1Increase awarenessEasy to seeSafety beltsVessel safetyNylon materialMicrosphere

A flexible abrasion resistant omnidirectionally reflective rope has a central braided high strength core comprising gel fiber or p-aramid fibers that is surrounded by cylindrically braided sleeve of reflective strips composed of narrow width reflective strips that comprise a woven or knitted narrow width strip and a flexible nylon retroreflective sheet sewn thereon and covered with abrasion resistant coating. The flexible retroreflective sheet is formed by thermally bonding corner cube, microsphere retroreflectors, or wide angle exposed retroreflective lenses to a flexible polymeric sheet. Due to its braided construction, the reflective rope reflects light omnidirectionally over a large angle of acceptance, thereby providing an improved measure of safety in the marine craft environment. The reflected light beam provides accurate illumination of the marine craft gunnels, sail edges, mooring lines, railings and the like when the omnidirectionally reflective rope is used during dusk, fog or nighttime hours.

Owner:NITE GLOW INDS

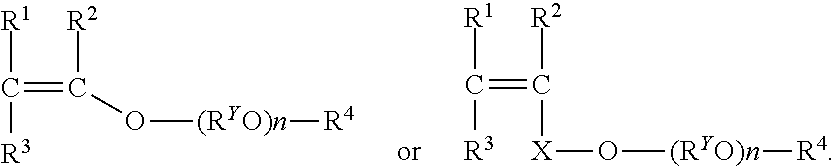

Synthesis method of polycarboxylic acid water-reducing agent

InactiveUS20130172505A1Easily avoidedProduction capacity can be enlarged easily.Acid waterSynthesis methods

A method for synthesizing concrete polycarboxylic acid water-reducing agent at room temperature under non-stirring situation is disclosed, which comprises dissolving reactive materials, initiator, chain transfer agent and promoter into a solvent, reacting on standing at 0-50° C.; then adding neutralizing agent at the end of reaction. The method makes use of oxidation-reduction system reacting at low temperature, and can adapt to a variety of reactive material monomers. It does not need to control feeding speed or provide extra heating, does not need to stir during the reaction, and remarkably simplifies operation steps in traditional process, which makes it possible to not only produce in large scale, but also produce in small scale in concrete construction site at any moment.

Owner:SHANGHAI TAIJIE CHEM

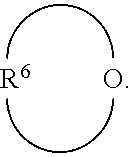

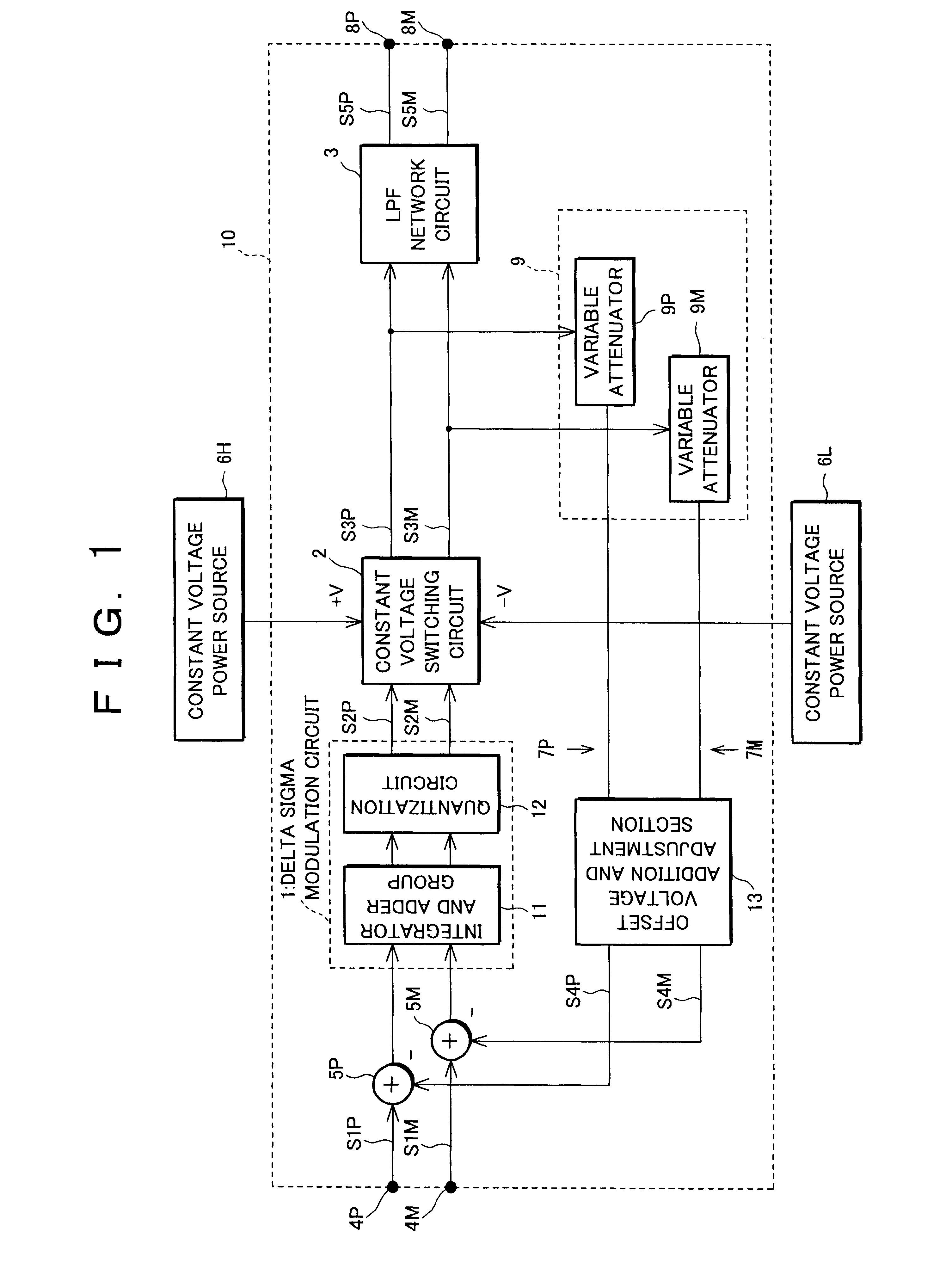

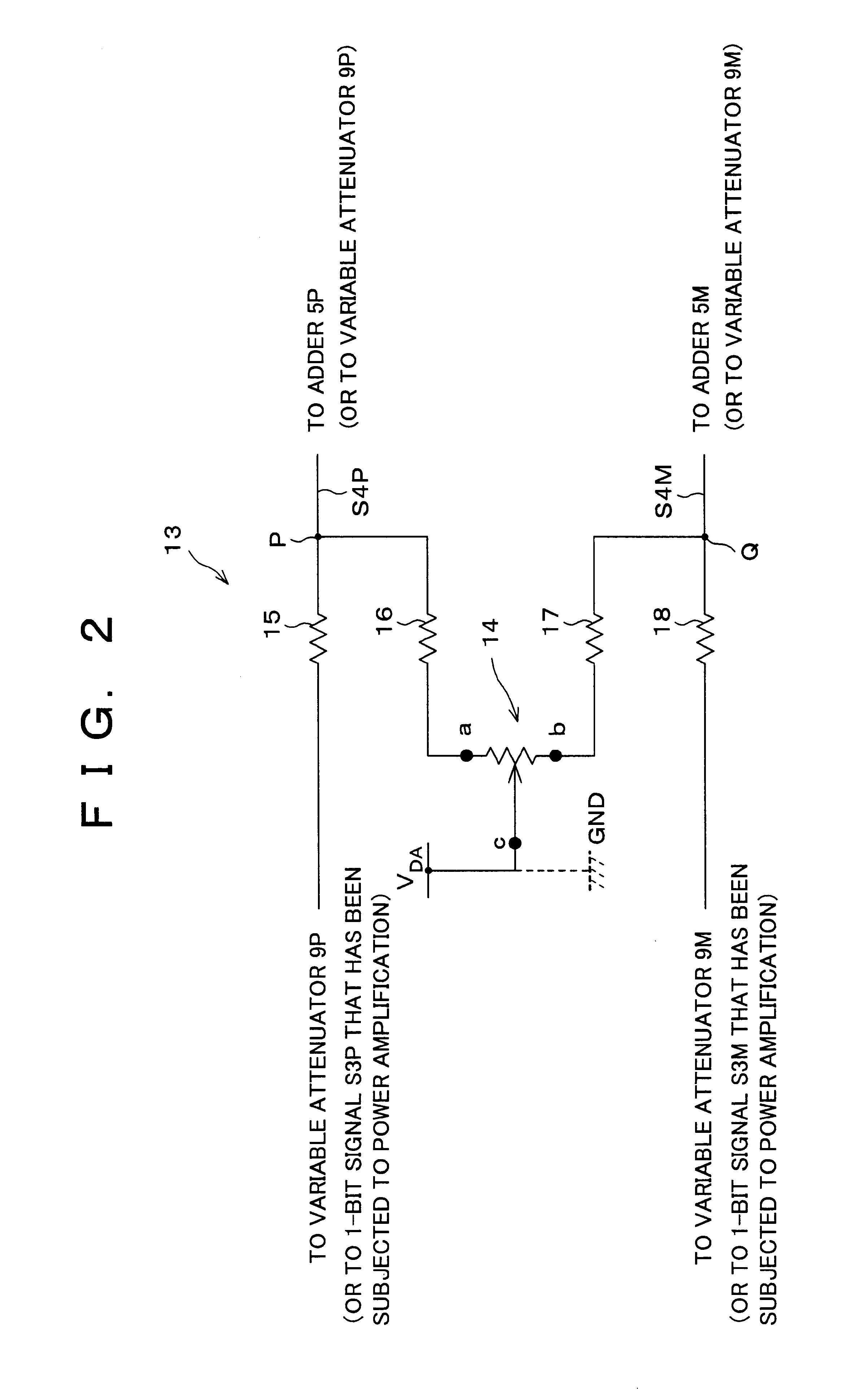

Digital switching amplifier

InactiveUS6700518B2Avoid noiseReduce the ratioElectric signal transmission systemsPower amplifiersNegative feedbackUltrasound attenuation

A digital switching amplifier is provided with attenuation sections that attenuate respective 1-bit signals that have been subjected to the power amplification. Also, an offset voltage addition and adjustment section adds adjustment voltages to output signals of the respective attenuation sections so that a D.C. voltage level difference between negative feedback signals which return to a delta sigma modulation circuit becomes substantially zero. This function ensures that the digital switching amplifier can avoid the gain with respect to positive and negative input signals change and easily avoid the noise that occurs in the lower frequency band due to an offset voltage.

Owner:SHARP KK

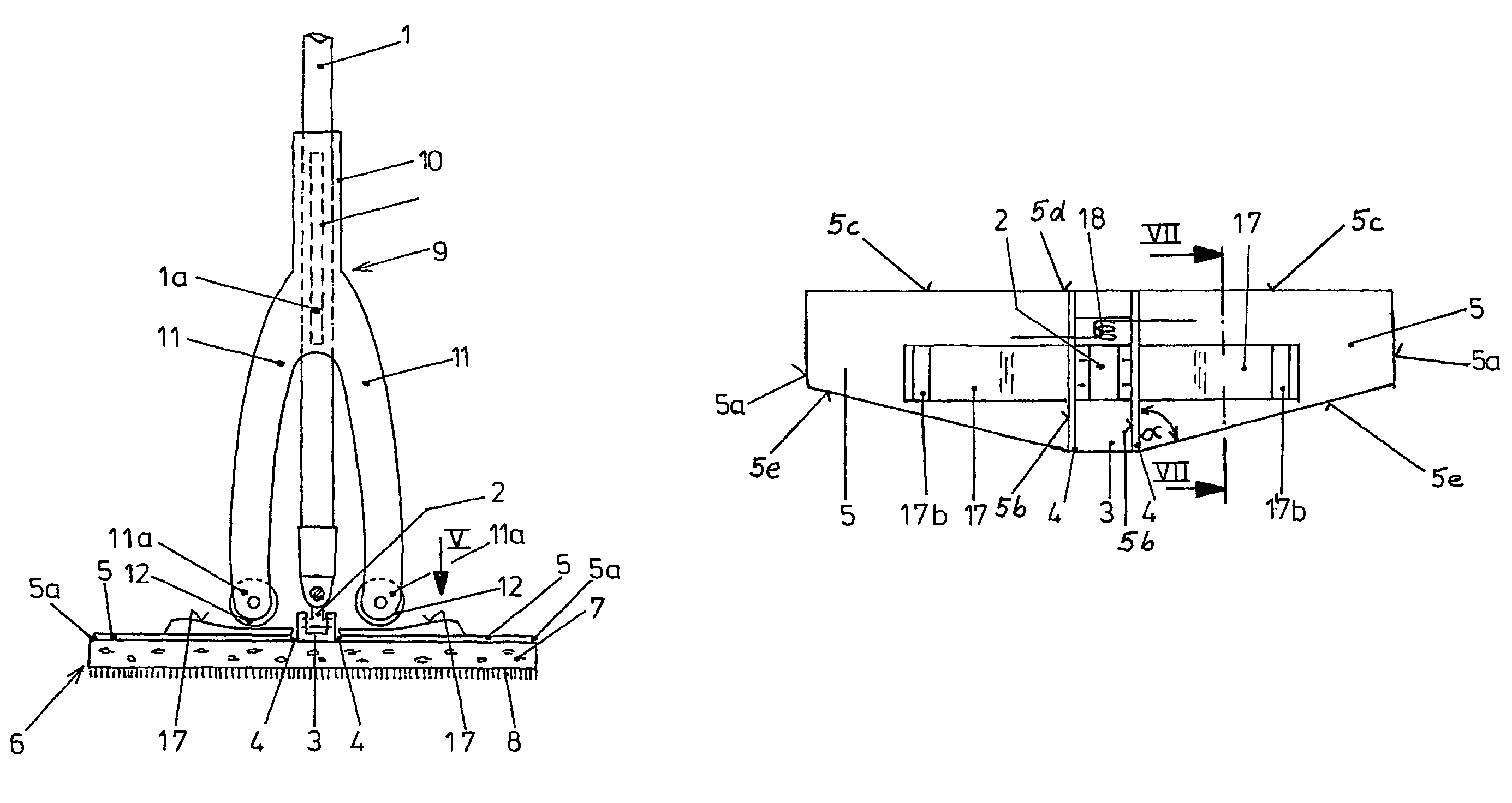

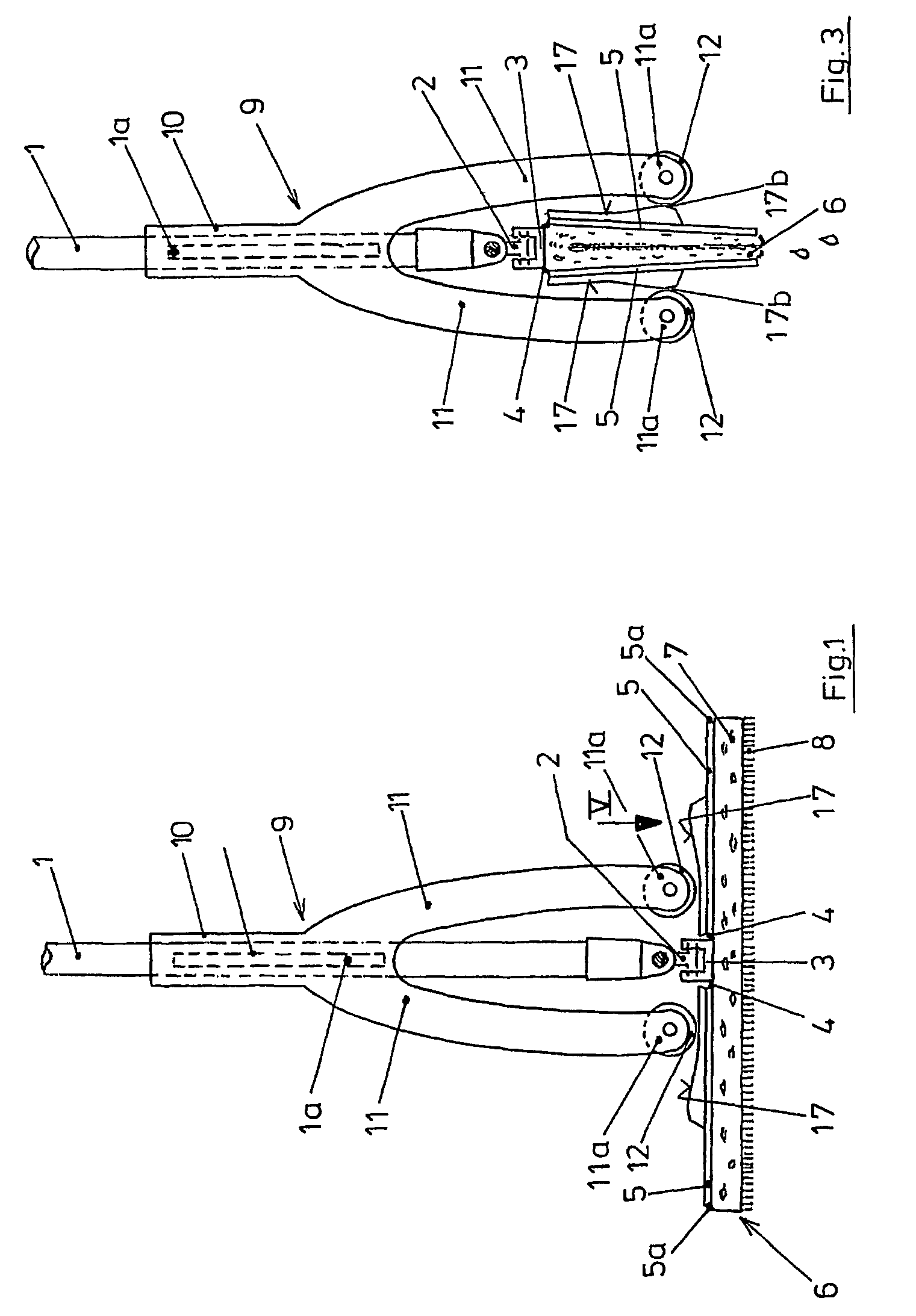

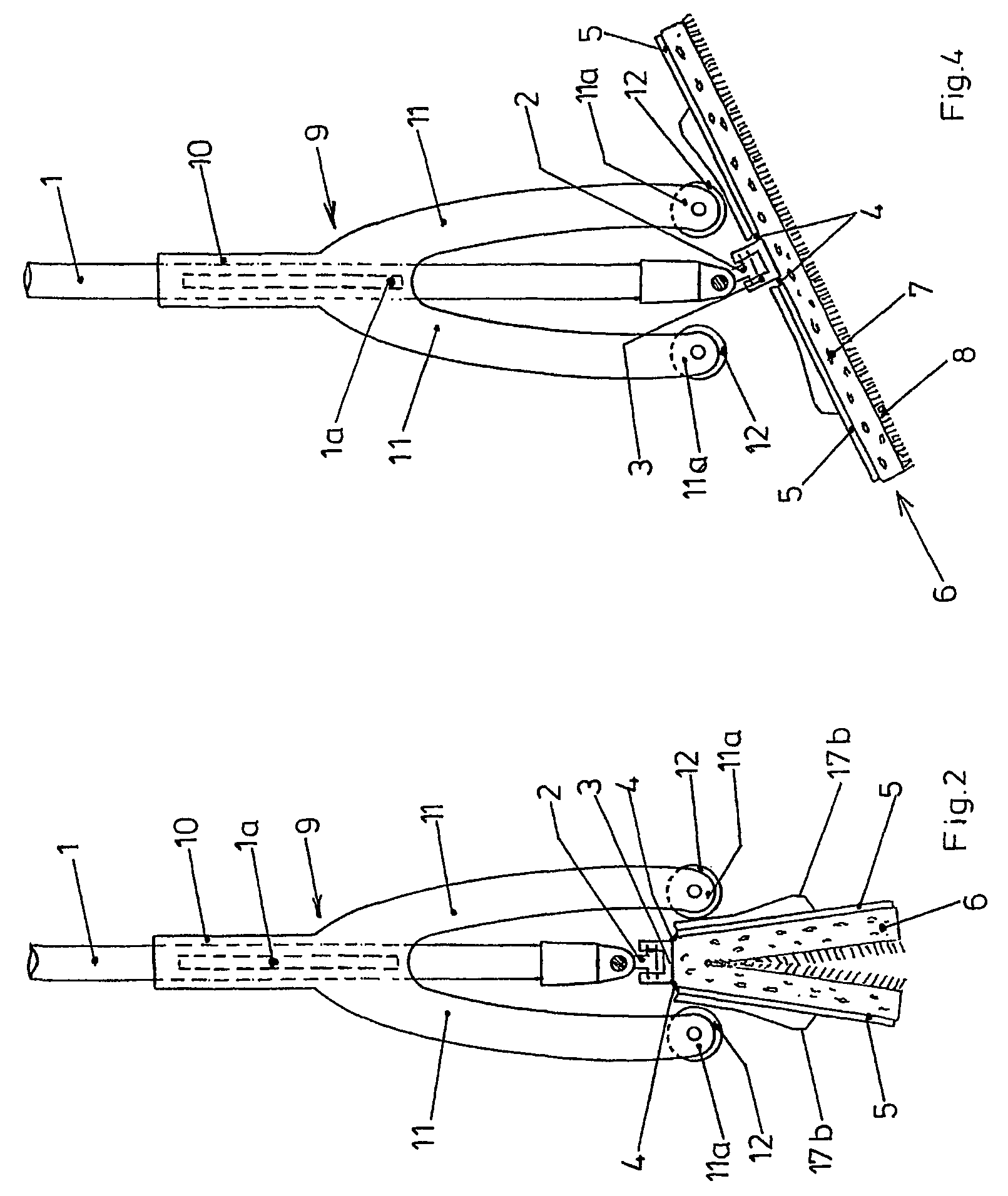

Floor mop

A floor mop has two mop supporting wings, which carry an absorbent mop layer and are hinge-connected to a common supporting centerpiece. A mop handle is hinge-mounted to the supporting centerpiece via a Cardan joint. A squeezing slider, which is displaceable along the mop handle and is guided non-rotatably, has two rigid squeezing arms whose ends can each be brought into engagement with a guide surface on the upper side of the respectively assigned mop supporting wings via rollers. Each mop supporting wing forms a rectangular trapezium or triangle. The edges running at right angles to the hinge edge of each mop supporting wing form a common straight continuous front edge.

Owner:CARL FREUDENBERG KG

Intelligent load balancing and failover of network traffic

ActiveUS20080285441A1Improve network performanceEasily avoidedError preventionFrequency-division multiplex detailsAddress Resolution ProtocolTraffic capacity

A hash engine in a network device driver maintains data on the utilization and error rate for each network interface card (“NIC”) within a local computing device. From this data, the hash engine intelligently selects transmit NICs and receive NICs based on various networking parameters provided from a software driver program. Transmit packets sent from the operating system in a local computing device to a remote computing device are intercepted, modified and redirected to transmit NICs selected by the hash engine for transmission to remote computing devices. Similarly, address resolution protocol (“ARP”) response packets sent by the operating system in response to ARP request packets are intercepted, modified and redirected to receive NICs selected by the hash engine for transmission. By selecting receive NICs and transmit NICs in this fashion, the hash engine is able to intelligently load balance transmit and receive traffic in the local computing device, thereby improving overall network performance relative to prior art techniques.

Owner:NVIDIA CORP

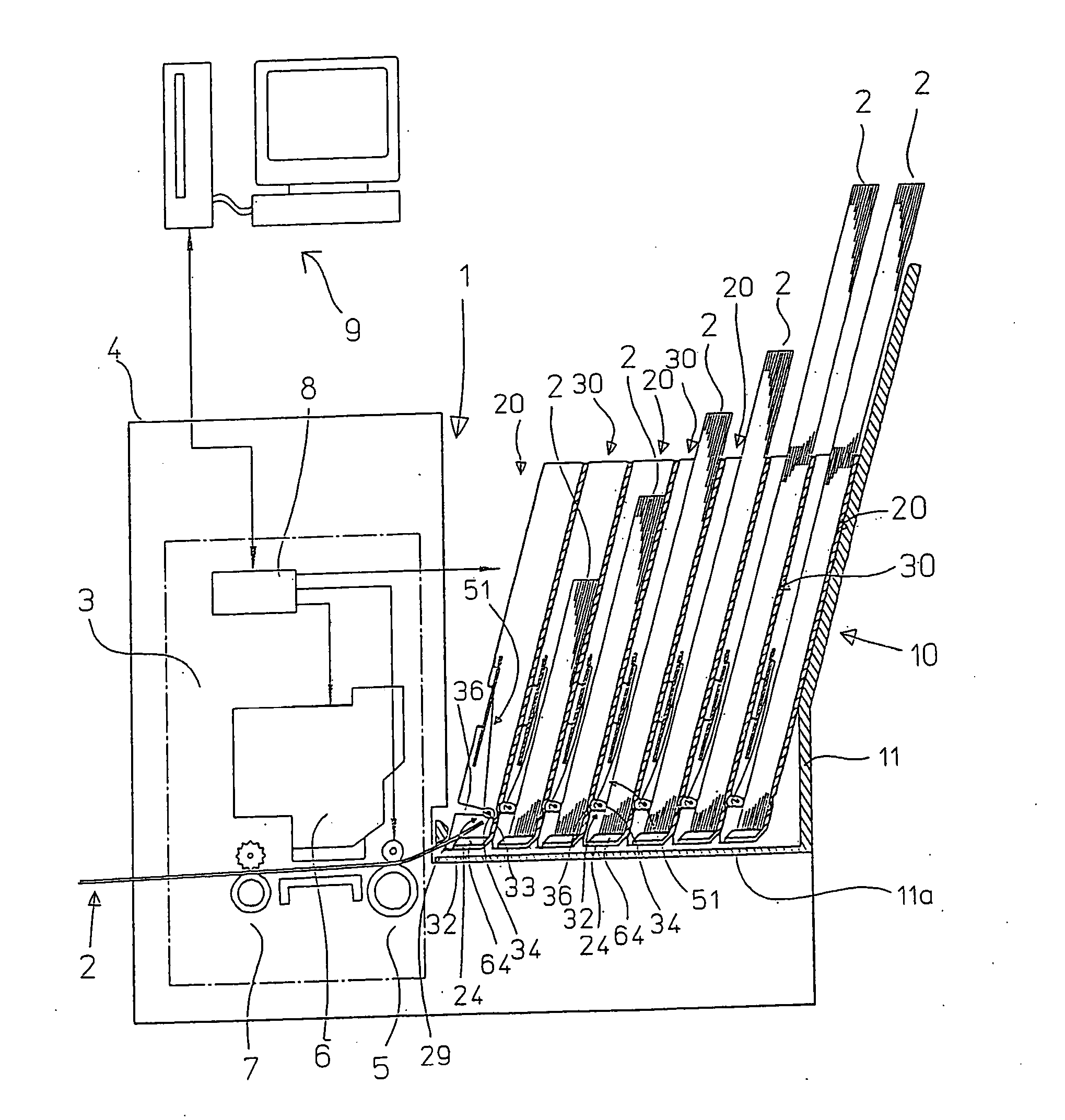

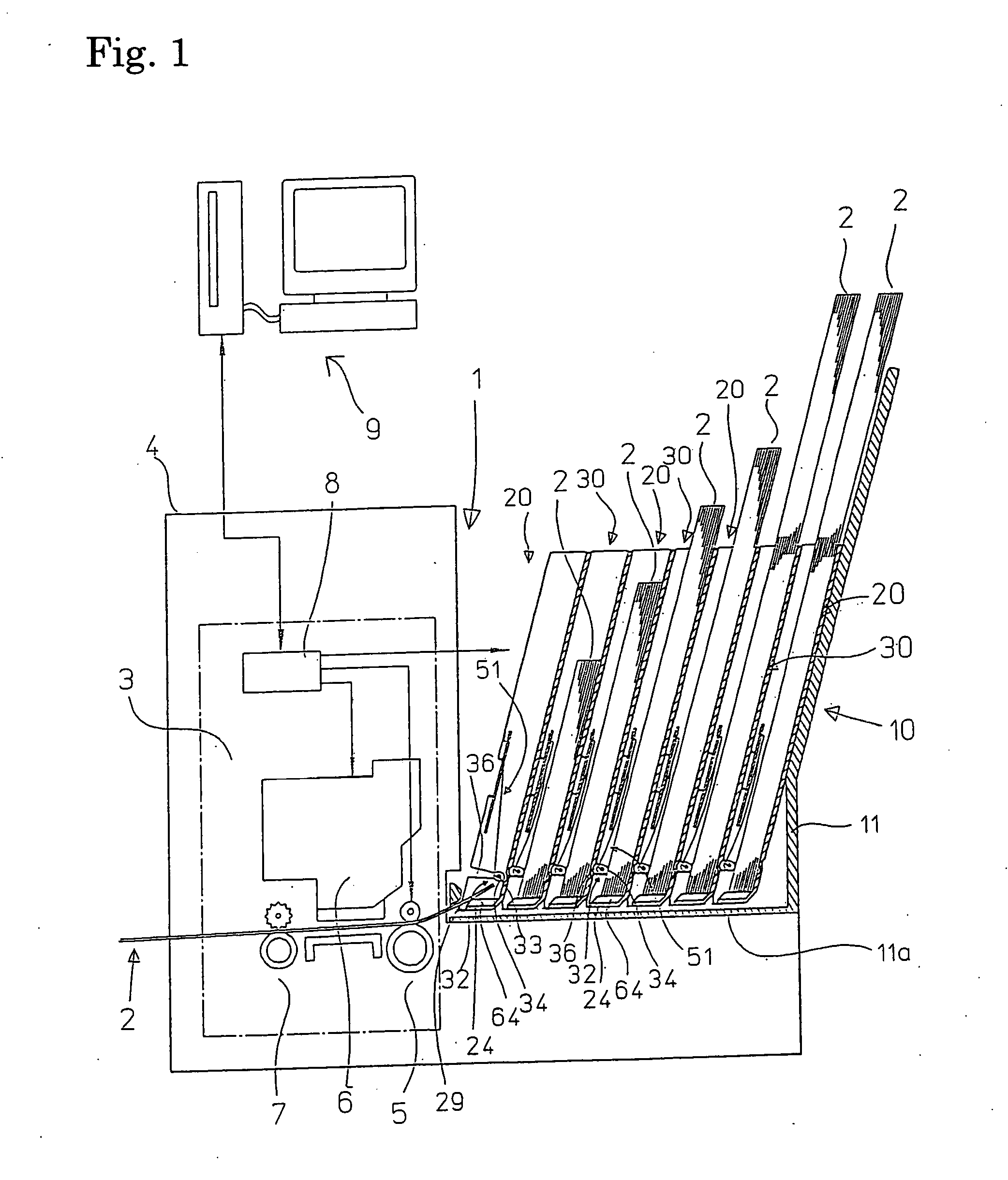

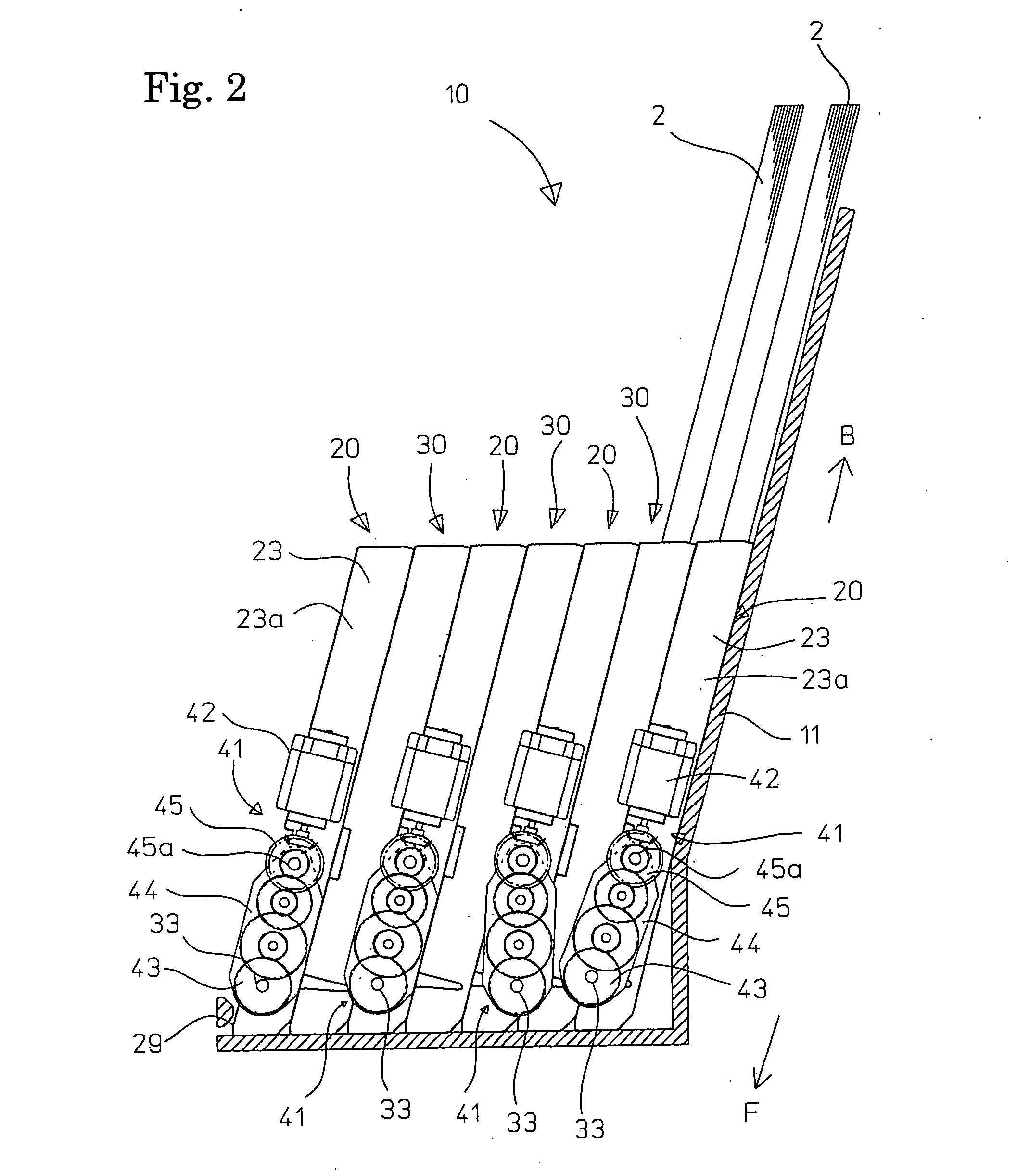

Sheet feeder and printer

InactiveUS20050140078A1Improve reliabilityEradicate skewingFunction indicatorsArticle feedersDrive shaftComputer printing

A paper feeding apparatus according to the present invention has a pickup roller, which includes a drive shaft disposed so as to cross a sheet tray and a plurality of roller parts intermittently attached to the drive shaft, and elastic supporting means, which substantially independently supports a plurality of exposed parts of the drive shaft so as to apply pressure towards a base plate of the sheet tray. In the paper feeding apparatus, respective exposed parts of the drive shaft, which has a narrow diameter and being flexible, are independently pressurized towards the sheet tray of the base plate, so that the respective roller parts contact tightly with the sheets substantially independently. Accordingly, sheets can be fed with high reliability by making the most of the flexibility of the drive shaft. The extremely slim and highly reliable paper feeding apparatus with the extremely slim pickup roller is provided. By stacking a plurality of these paper feeding apparatuses, a compact multitray can be provided.

Owner:F&F

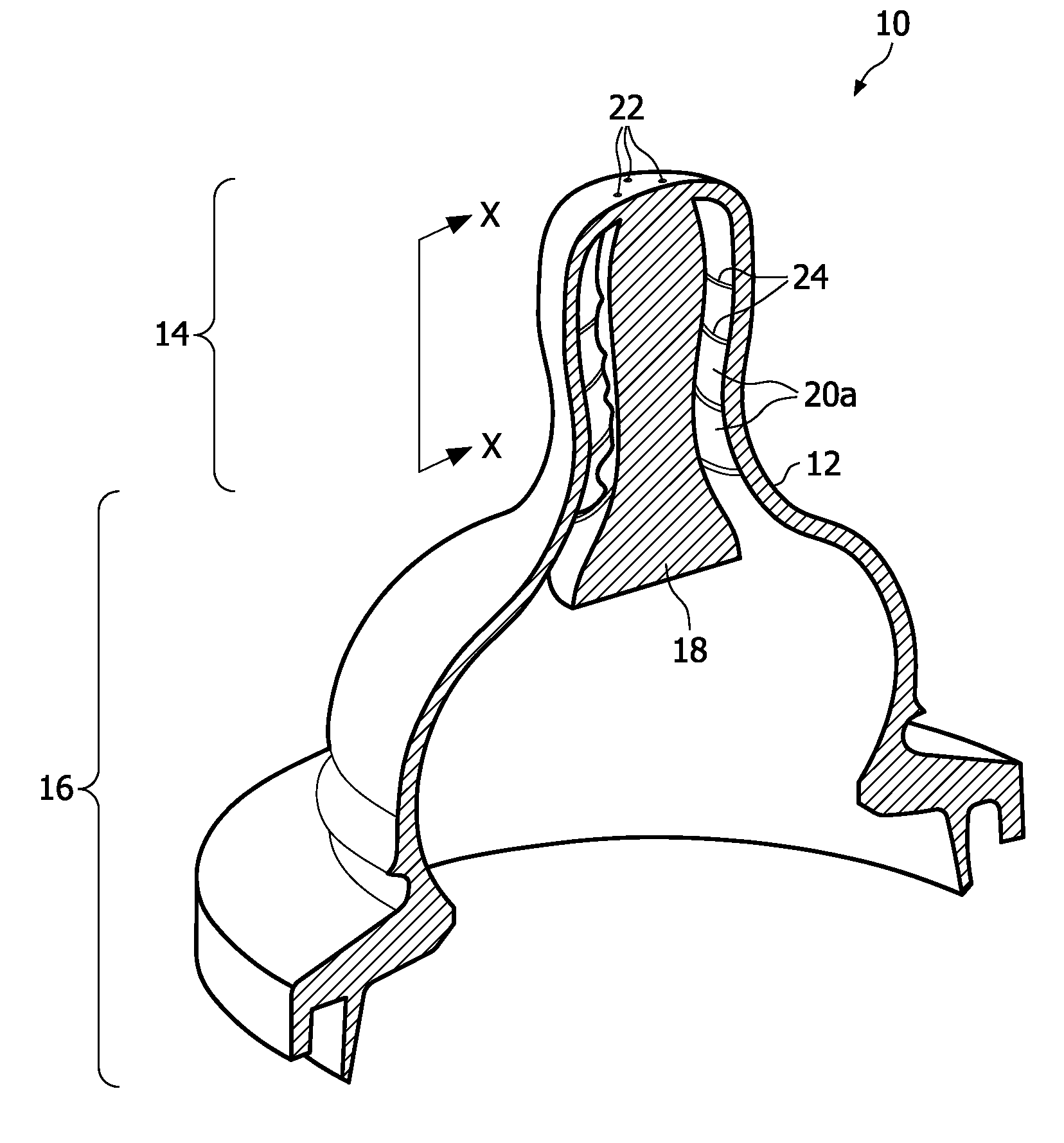

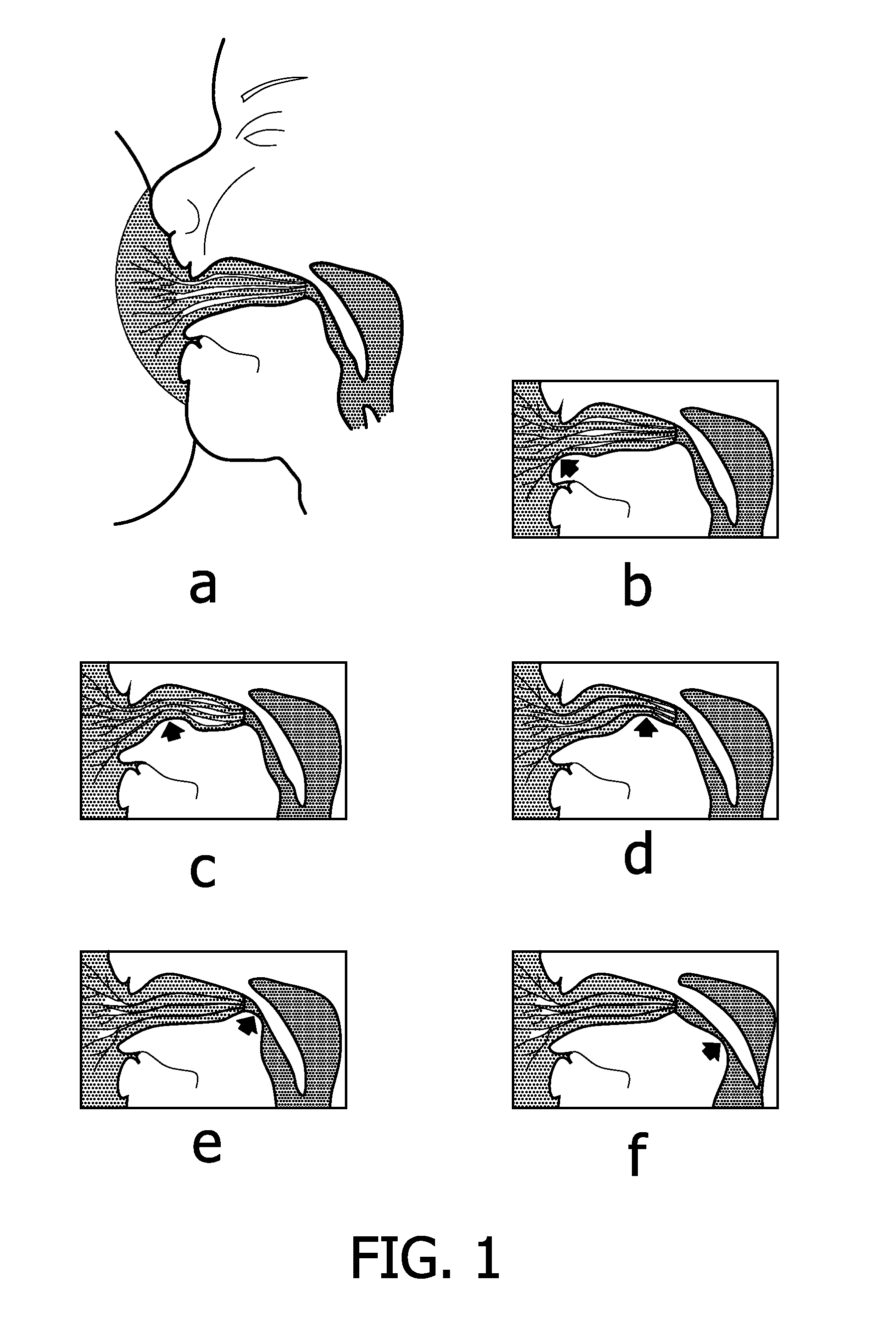

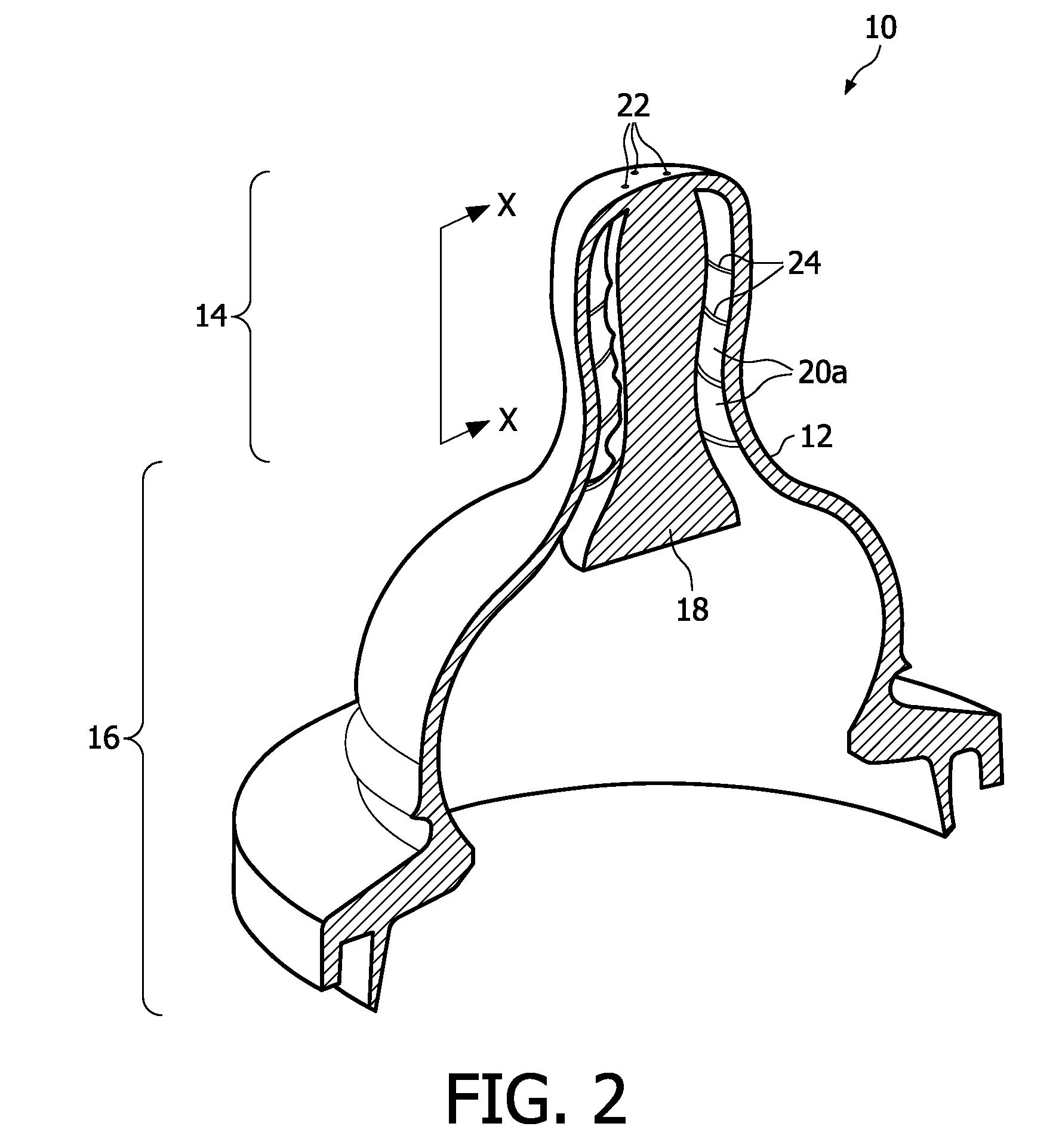

Peristaltic teat

The peristaltic teat is a cleanable teat which rewards the baby for making the same natural peristaltic tongue movement it makes at the mother's breast. The reward is that the baby gets (more) milk when making the correct movement. The consequence is that the baby will use the same drinking mechanism as at the breast. Hence bottle feeding will become closer to breast feeding which makes the combination of bottle feeding and breast feeding easier.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Sanitary Diaper Changing Kit

InactiveUS20080108965A1Avoid spreadingEasy procedureContainer/bottle contructionBaby linensWhite petrolatumEngineering

A sanitary diaper changing kit includes a package, a pair of disposable gloves in the package, and a re-sealable disposal bag in the package. Alternatively, the kit may include other materials such as small single-use package of moist wipes or towelettes, a small single-use package of antiseptic wipes, a small single use package of petroleum jelly and a small single-use package of powder. The sanitary diaper changing kit may be packaged and sold with a disposable diaper, or may be sold separately from diapers to be used in conjunction with a disposable diaper. The kit allows the person changing the diaper to be isolated from the contaminated diaper during the diaper changing operation and provides a convenient means by which the soiled diaper and other used or soiled materials may be disposed of in a sanitary procedure and diaper wearer remains isolated from care giver.

Owner:CHRISTENSEN WILLIAM MICHAEL +1

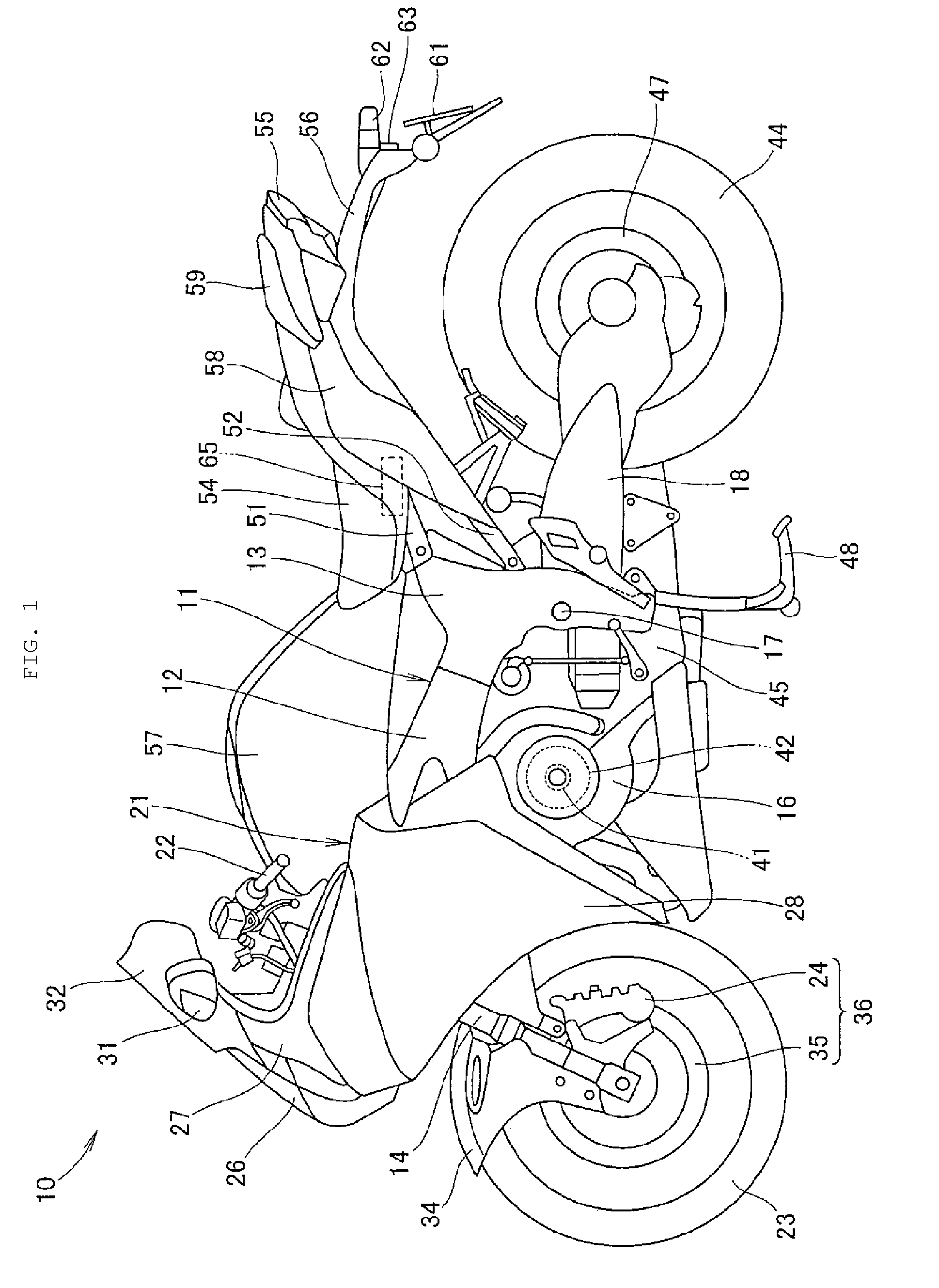

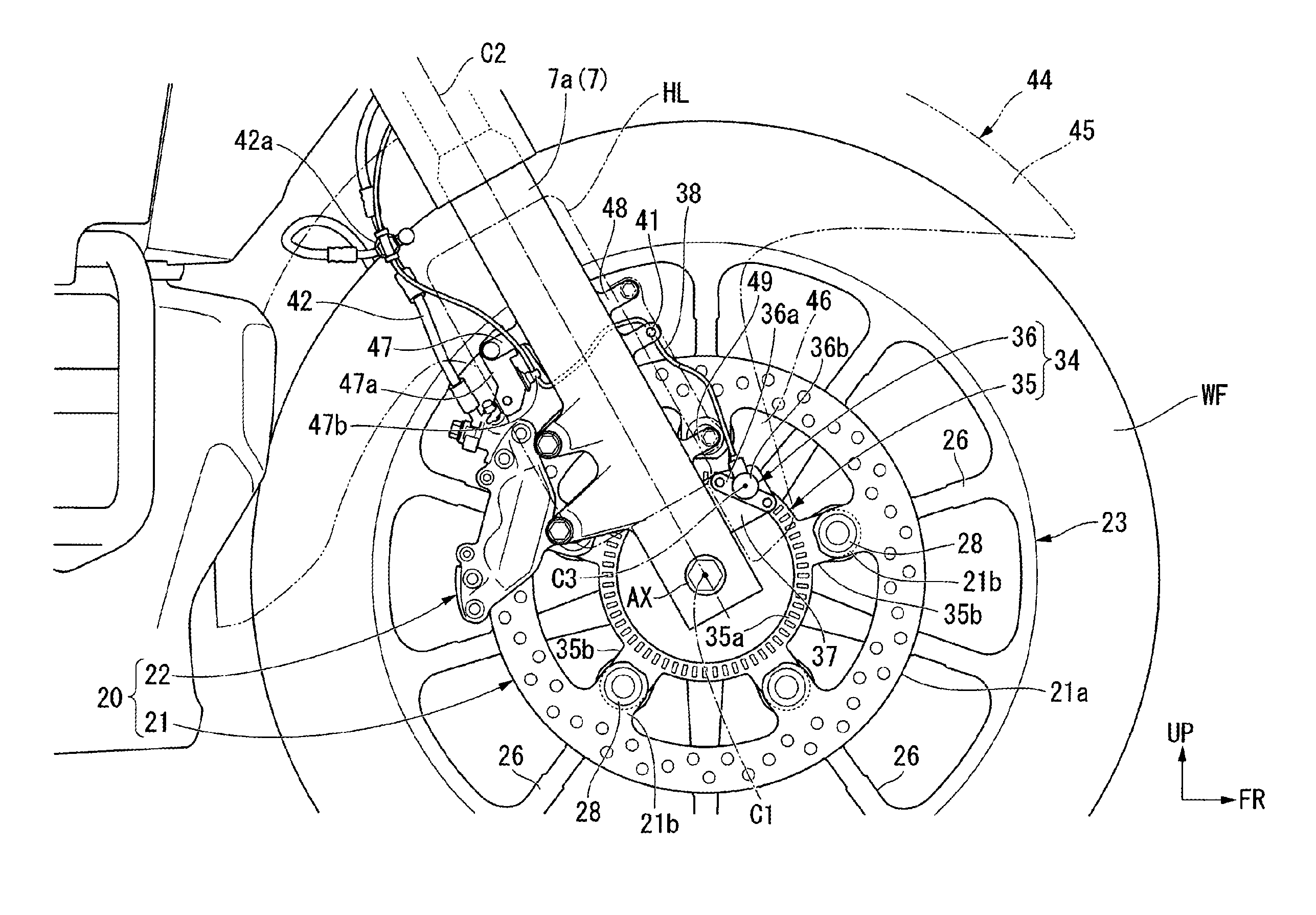

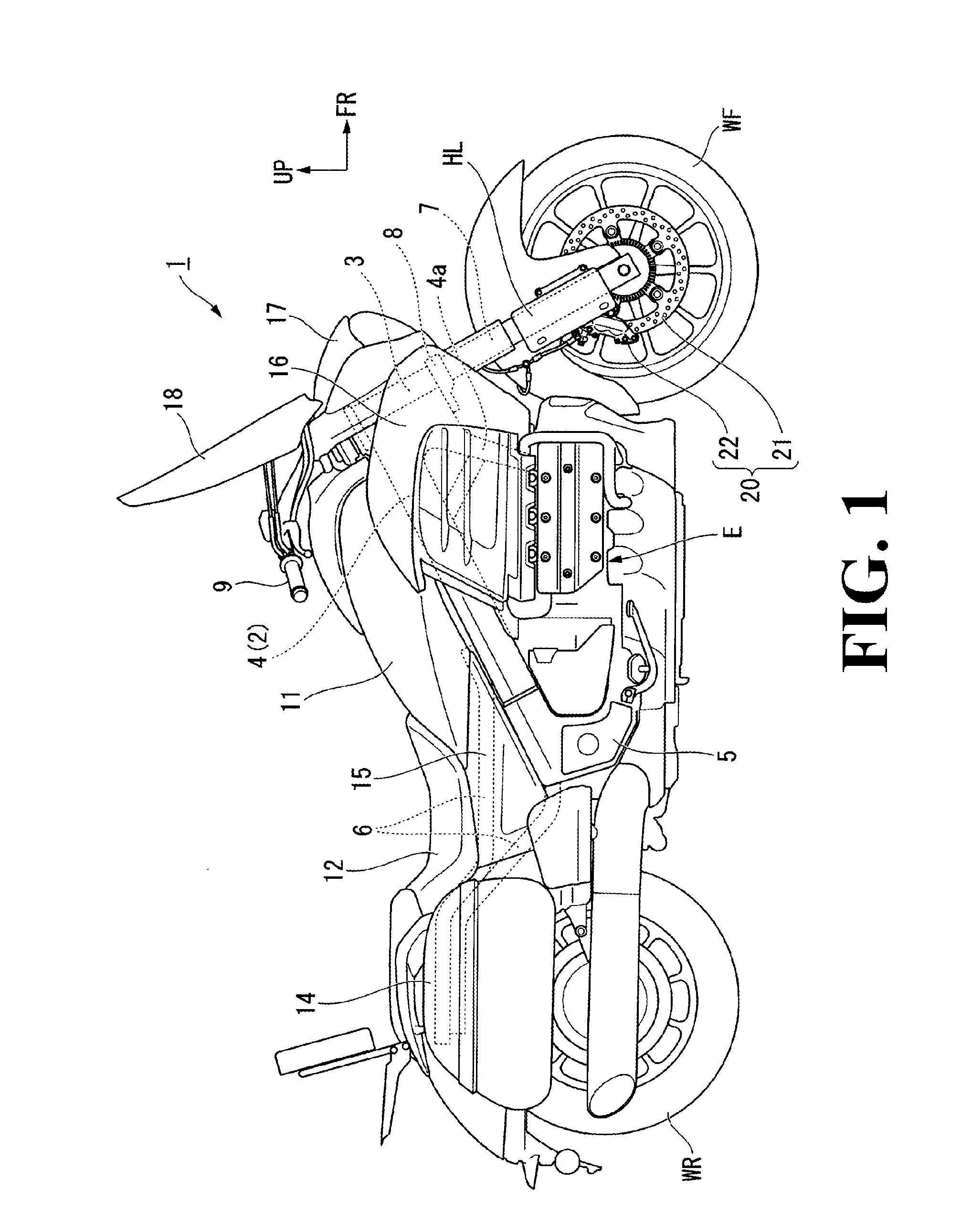

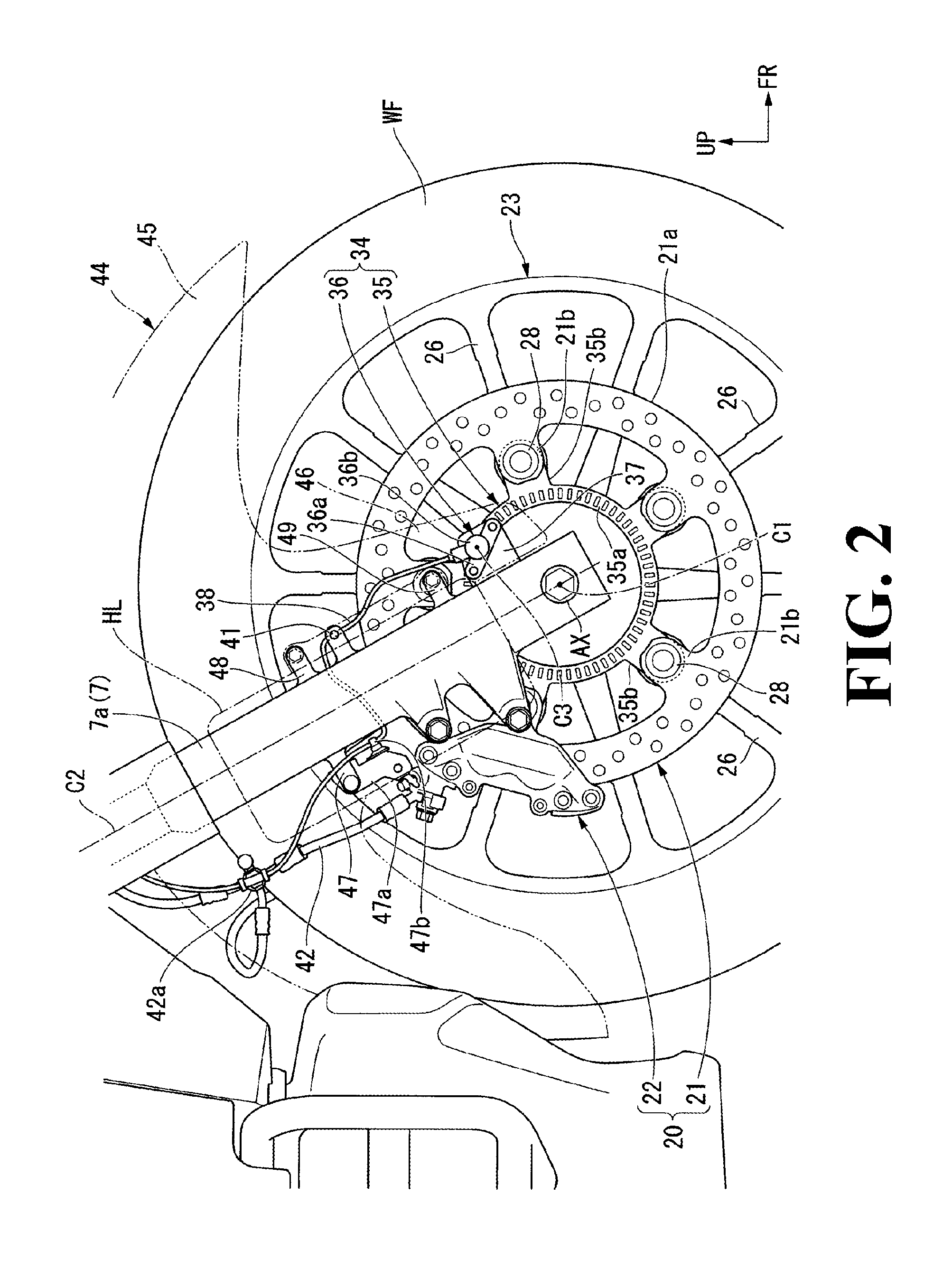

Saddle-type vehicle

ActiveUS20150042062A1Suppress interferenceEasy to assembleFoot-driven leversWheel based transmissionWheel speed sensorEngineering

A wheel speed sensor is provided between a front wheel and a front fork. The wheel speed sensor includes a sensor body to be supported by the front side of the front fork. A front fender includes a downward extending portion extending downward along the front side of the front fork. The downward extending portion covers the sensor body. As such, the influence of an arrangement of a sensor body on the design in a saddle-type vehicle provided with a wheel speed sensor between a front fork and a wheel is suppressed.

Owner:HONDA MOTOR CO LTD

Image signal processing apparatus, image signal processing method and camera using the image signal processing apparatus

InactiveUS7750955B2Easily avoidedSuppress errorTelevision system detailsColor signal processing circuitsComputer scienceImage signal

When clamping a signal from a solid state image sensor, float of an optical black pixel output due to incoming of infrared light avoids a malfunction of a clamp from occurring. When clamping a signal from the solid state image sensor, the difference between the optical black pixel output and a clamp target level is output as a difference output, the difference output is compared with a comparison level to integrate the number of times larger than the comparison level every horizontal line. When the number of times is equal to or more than a certain rate (⅔) from the number of optical black pixels on the horizontal line, an optical black float state is determined and clamping operation is performed in accordance with a held value immediately before.

Owner:CANON KK

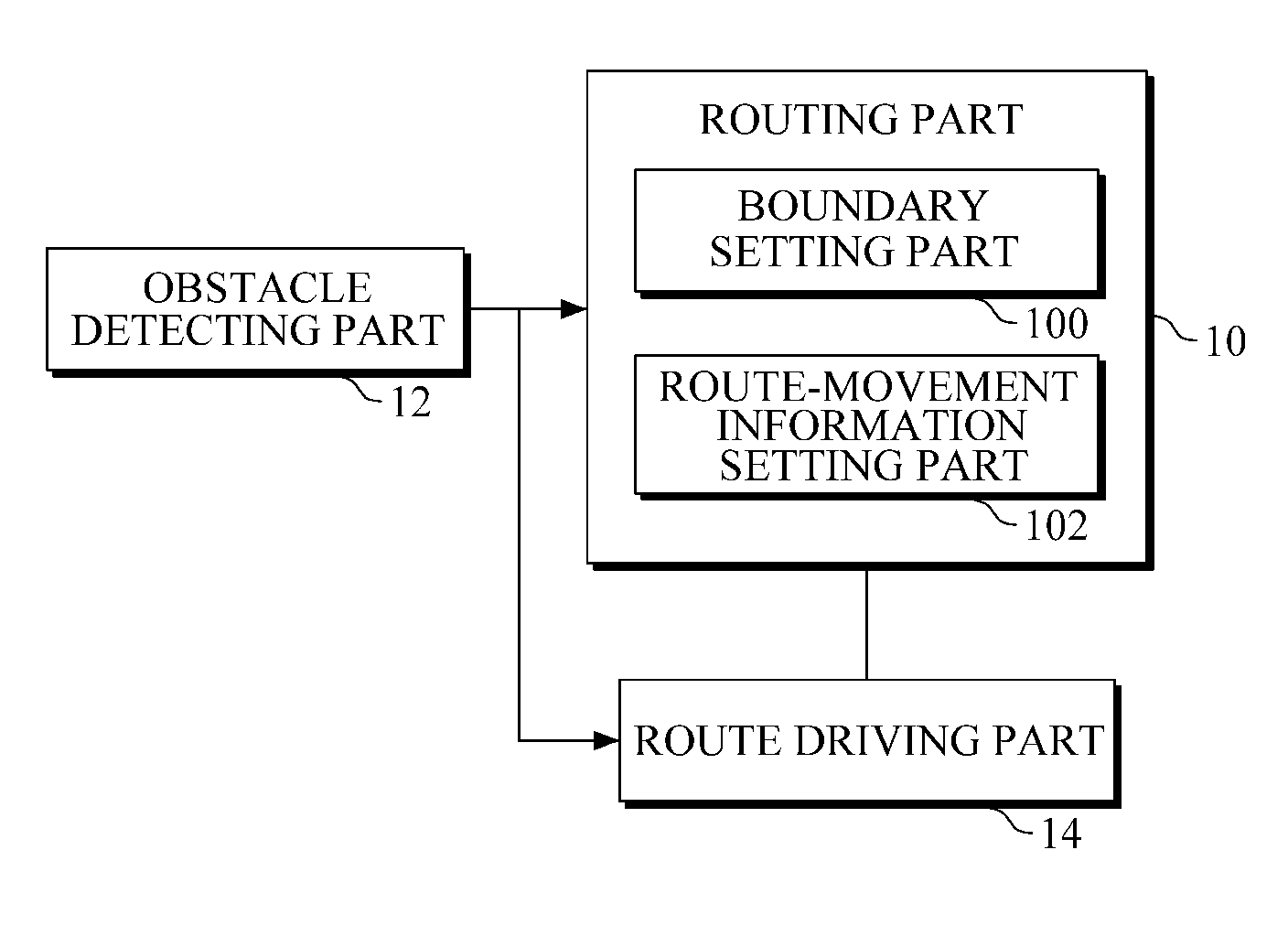

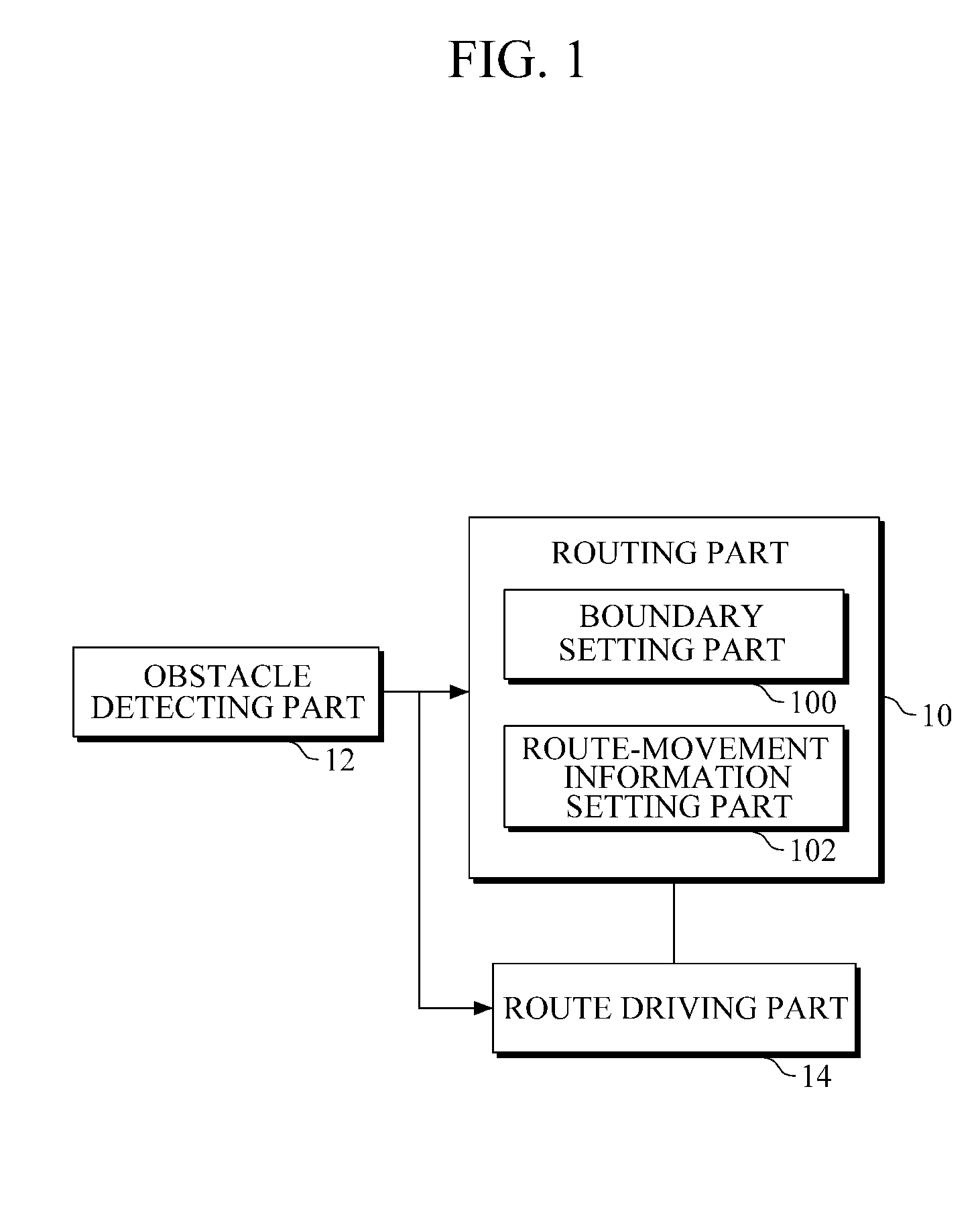

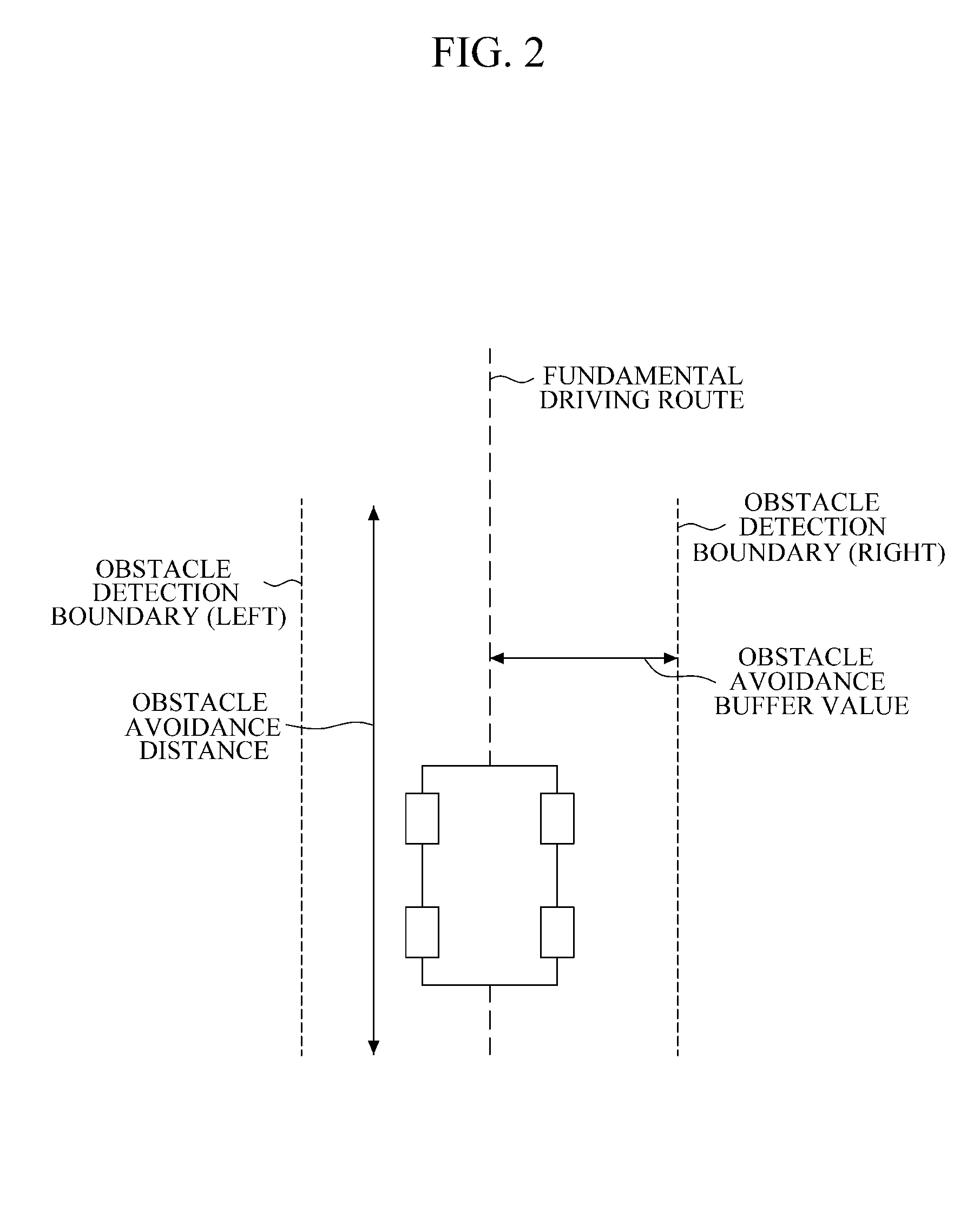

Unmanned vehicle driving apparatus and method for obstacle avoidance

InactiveUS20150336576A1Easily avoidedInstruments for road network navigationExternal condition input parametersObstacle avoidanceEngineering

An unmanned vehicle driving apparatus which allows obstacle avoidance and the method of it is commenced. The unmanned vehicle driving apparatus according to an exemplary embodiment include: a routing part which generates or receives a vehicle's fundamental driving route and generates a moved-driving route by adding or subtracting a route changing value to the fundamental driving route to avoid obstacles while driving; an obstacle detecting part which detects obstacles while driving; and a route driving part which drives the vehicle on the fundamental driving route and when an obstacle is detected, drives the vehicle on the moved-driving route to avoid it.

Owner:ELECTRONICS & TELECOMM RES INST

Intelligent load balancing and failover of network traffic

ActiveUS7995465B2Easily avoidedImprove network performanceError preventionFrequency-division multiplex detailsFailoverAddress Resolution Protocol

A hash engine in a network device driver maintains data on the utilization and error rate for each network interface card (“NIC”) within a local computing device. From this data, the hash engine intelligently selects transmit NICs and receive NICs based on various networking parameters provided from a software driver program. Transmit packets sent from the operating system in a local computing device to a remote computing device are intercepted, modified and redirected to transmit NICs selected by the hash engine for transmission to remote computing devices. Similarly, address resolution protocol (“ARP”) response packets sent by the operating system in response to ARP request packets are intercepted, modified and redirected to receive NICs selected by the hash engine for transmission. By selecting receive NICs and transmit NICs in this fashion, the hash engine is able to intelligently load balance transmit and receive traffic in the local computing device, thereby improving overall network performance relative to prior art techniques.

Owner:NVIDIA CORP

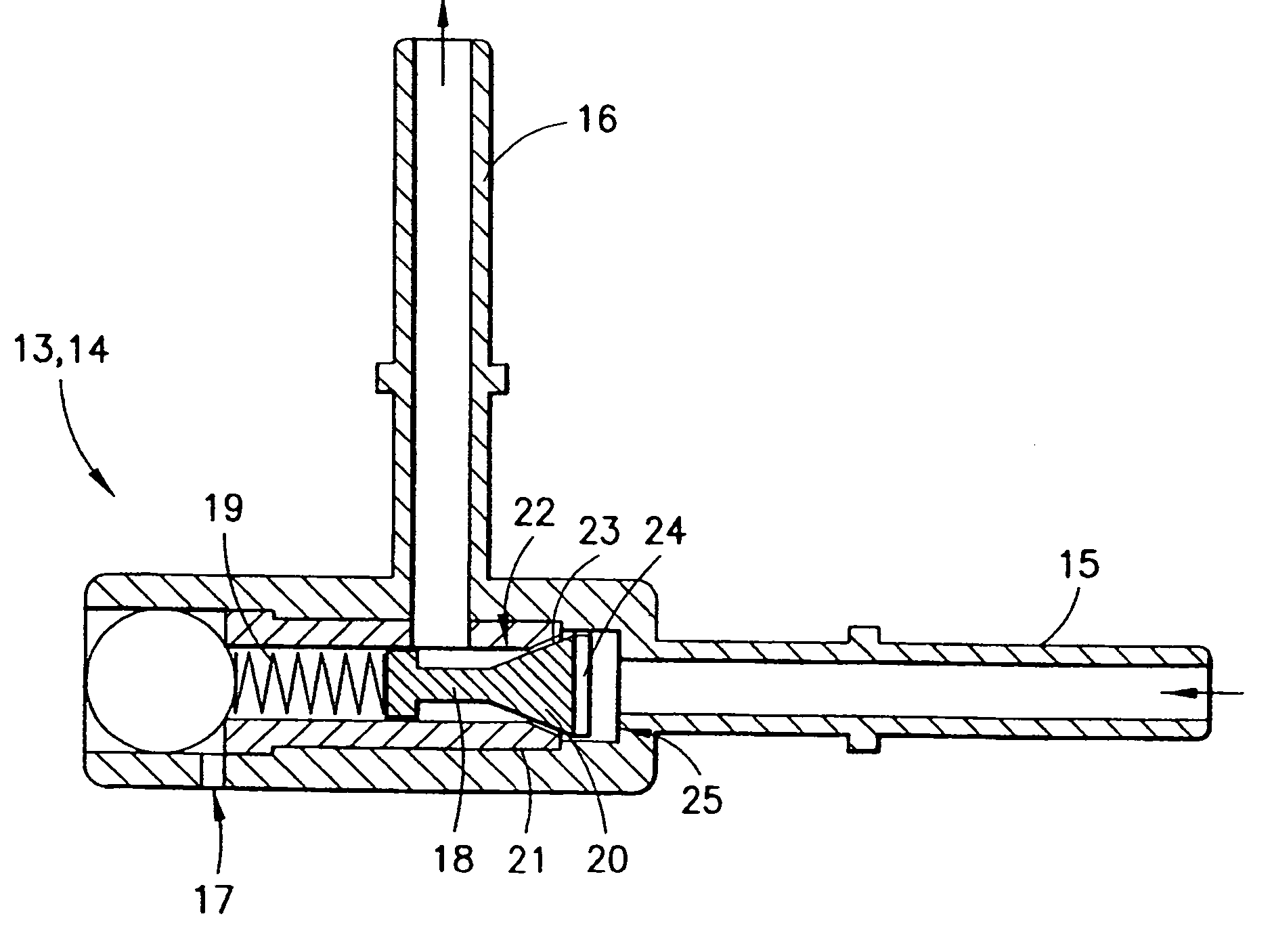

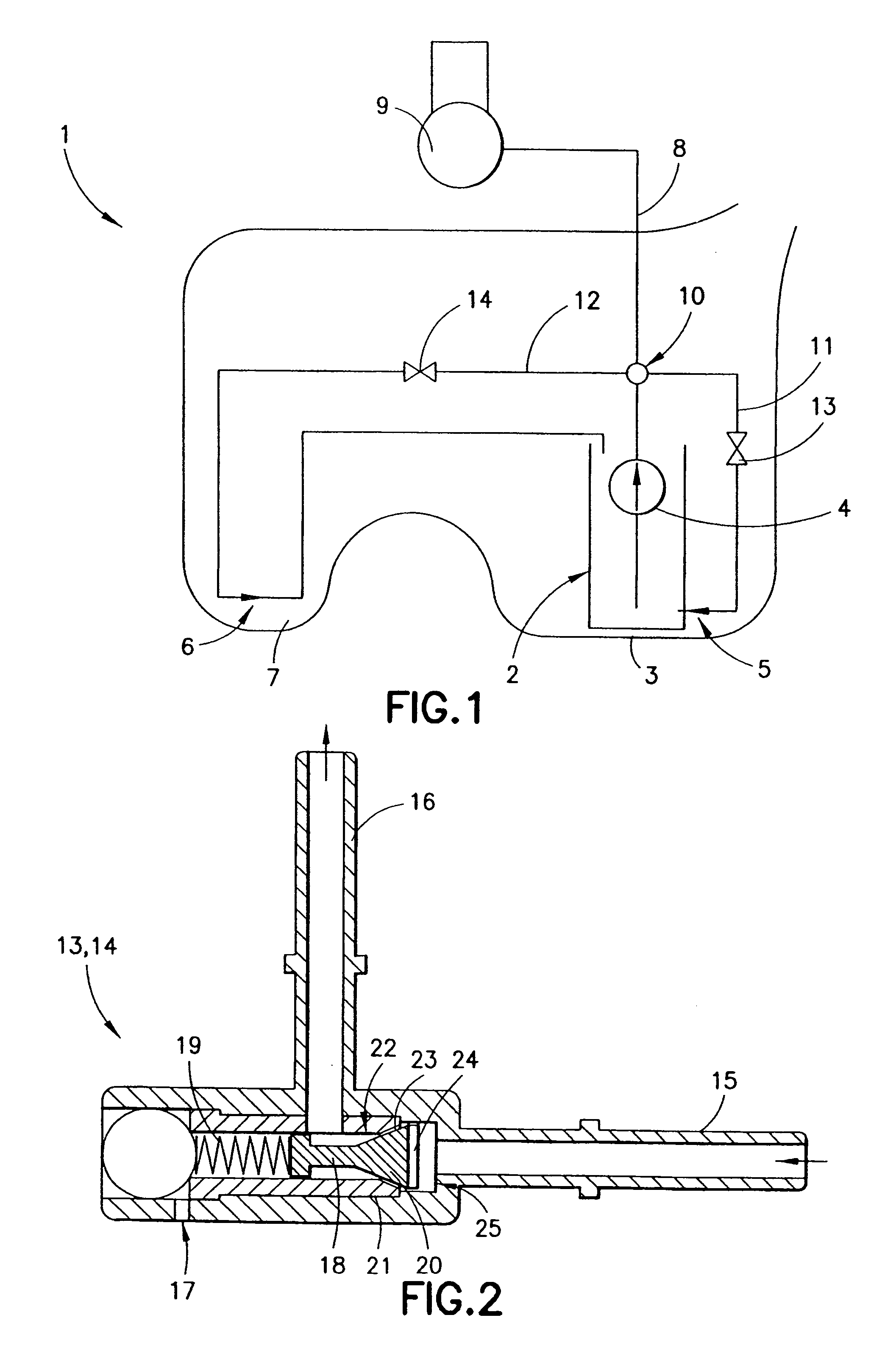

Fuel feed unit

InactiveUS7370640B2Low fuel pump delivery capacityCompact designMachines/enginesLiquid fuel feedersEngineeringVolume rate

The invention relates to a fuel feed unit (2) for a motor vehicle, comprising a volume flow reducing valve (13, 14) that is mounted in a pump fluid line (11, 12) leading to a suction jet pump (5, 6). Said volume flow reducing valve (13, 14) reduces the fuel volume flow supplied to the suction jet pump (5, 6) when the feed pressure of the fuel pump (4) increases, thereby avoiding unnecessary feed of fuel to the suction jet pump (5, 6).

Owner:SIEMENS AG

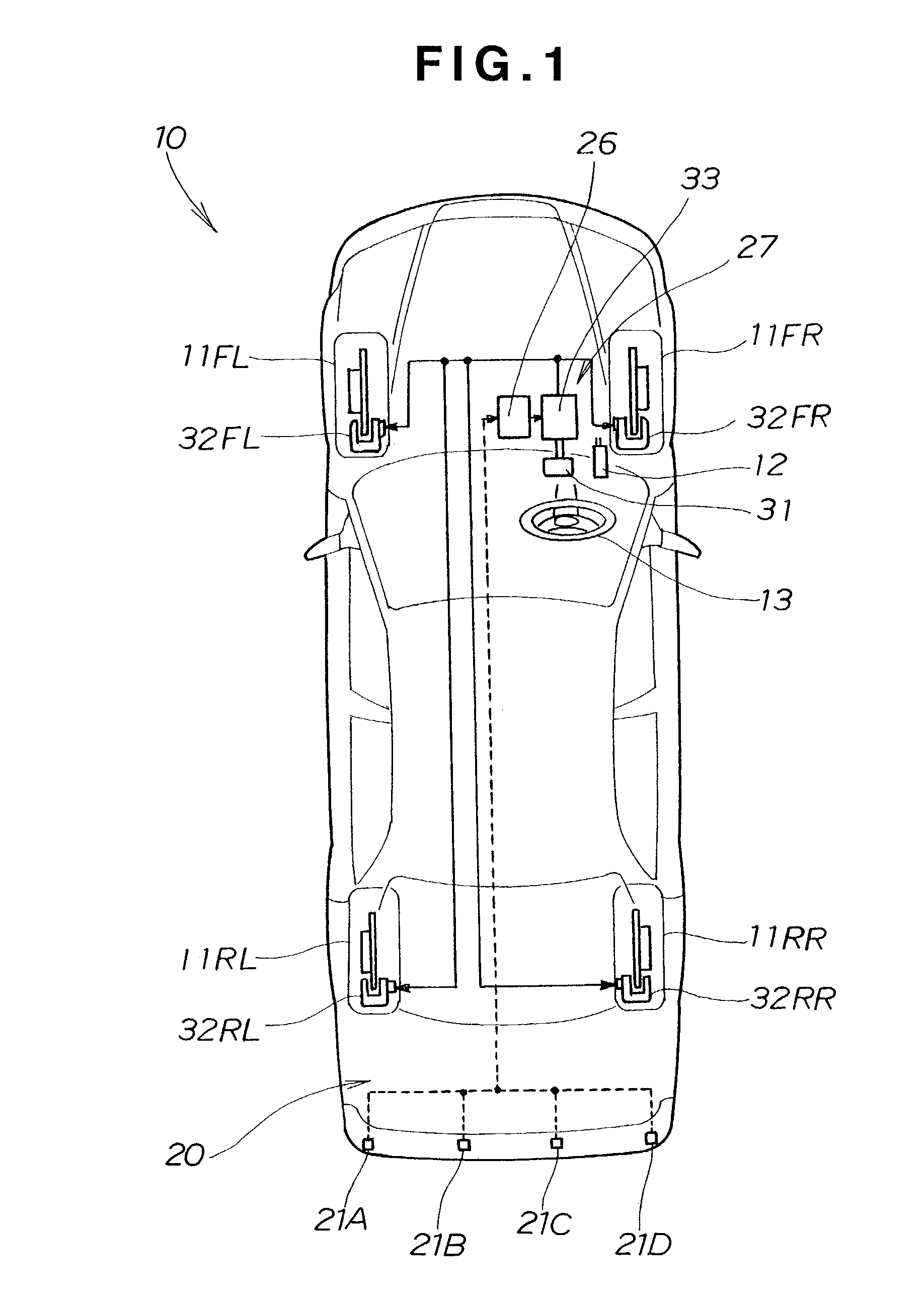

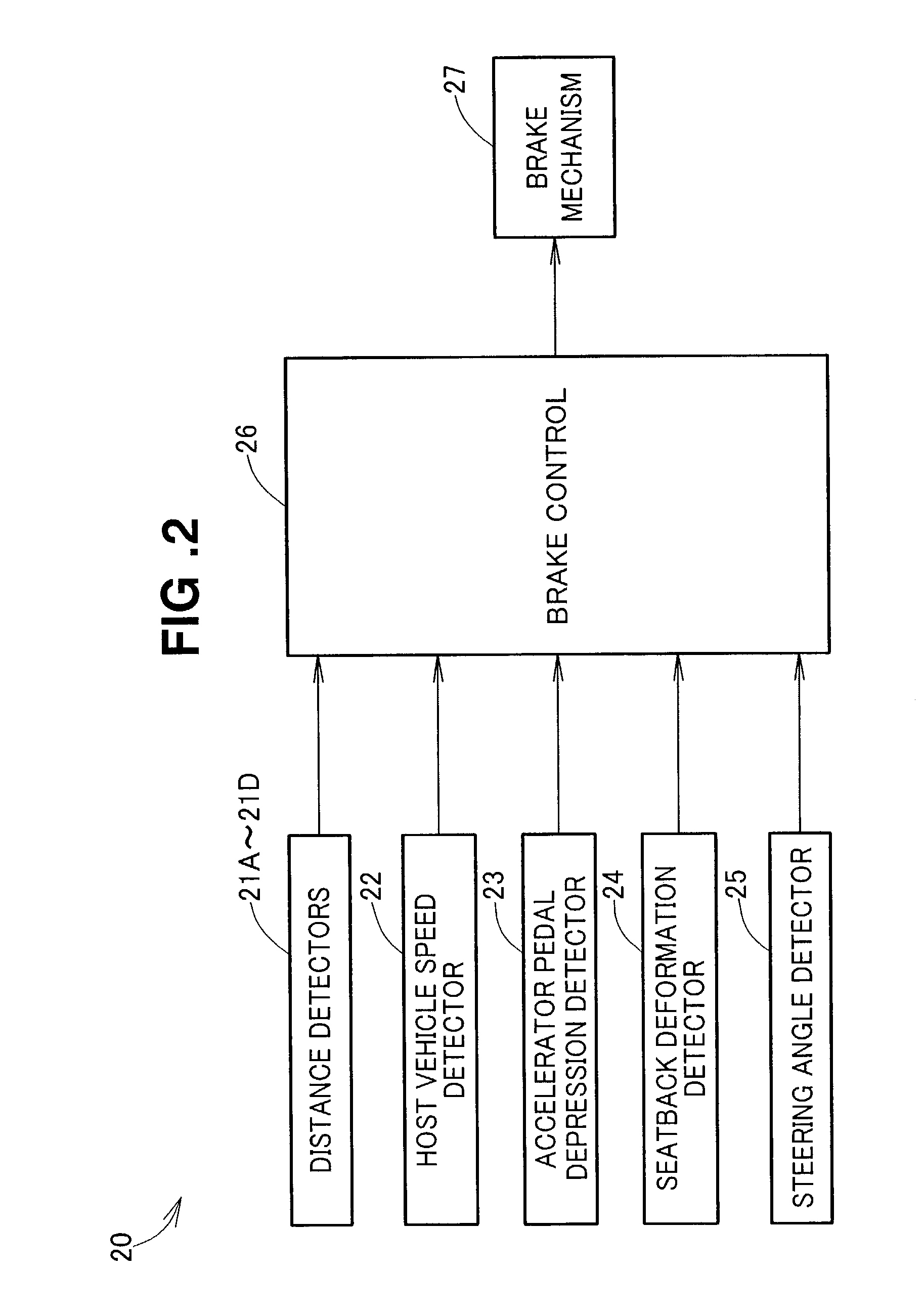

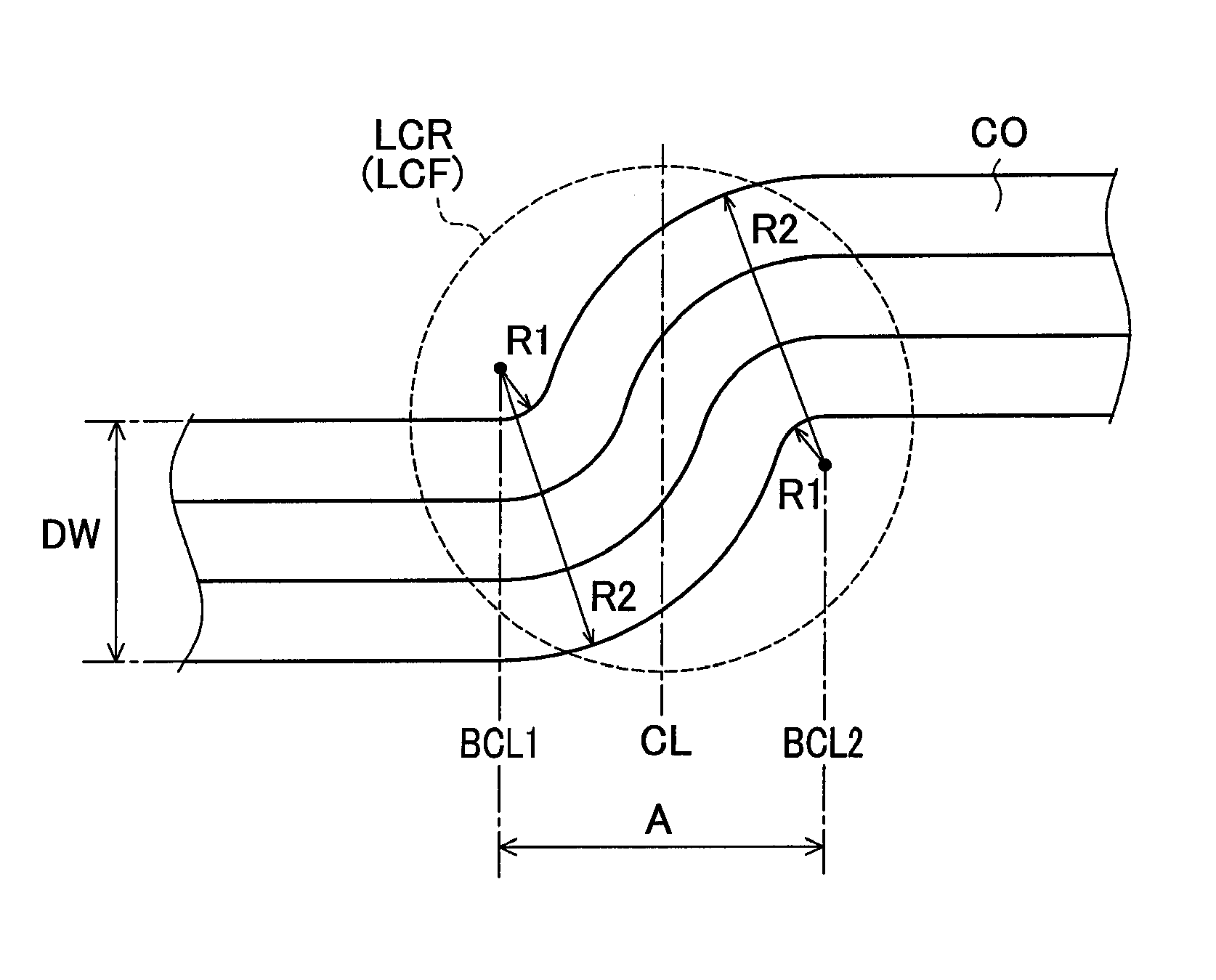

Vehicle brake system

InactiveUS6971727B2Avoid turningAvoid relative motionPedestrian/occupant safety arrangementAutomatic initiationsControl theoryOblique collision

A vehicle brake system includes a brake mechanism for individually braking wheels, and a brake controller for controlling the brake mechanism against an oblique collision from behind or an offset collision with a host vehicle. The controller includes a collision predictor, a collision direction detector, and a colliding object speed detector. In accordance with a prediction signal transmitted from the collision predictor, a detection signal transmitted from the collision direction detector and a detection signal transmitted from the colliding object speed detector, the controller controls the operation of the brake mechanism to allocate braking forces to the respective wheels so as to prevent the turning of the host vehicle in a collision.

Owner:HONDA MOTOR CO LTD

Stator

ActiveUS8427024B2Avoid interferenceEasily avoidedSynchronous generatorsMagnetic circuitElectrical conductorPhysics

To provide a stator capable of achieving downsizing and high output power and a stator manufacturing method, a stator comprises a split stator core and slots formed between the teeth, and protrusion-formed coils each being made of a flat rectangular conductor and placed in the slots. Each protrusion-formed coil has a shape including, in a coil end portion, a lead-side protrusion or a non-lead-side protrusion formed to protrude upward in an axial direction of the stator core from a first oblique side portion, a second oblique side portion, a third oblique side portion, and a fourth oblique side portion, and a first oblique side portion, a second oblique side portion, a third oblique side portion, and a fourth oblique side portion. The lead-side protrusion or the non-lead-side protrusion is designed with a height to avoid interference between the protrusion-formed coils placed in the stator core.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com