Sheet feeder and printer

a feeder and printer technology, applied in the field of paper feeders and printers, can solve the problems of increasing the size of the paper feeding apparatus, unable to transmit the paper feeding force to the sheets, and sheets becoming wrinkled, etc., and achieves the effects of low rigidity, easy paper jams, and high rigidity of sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

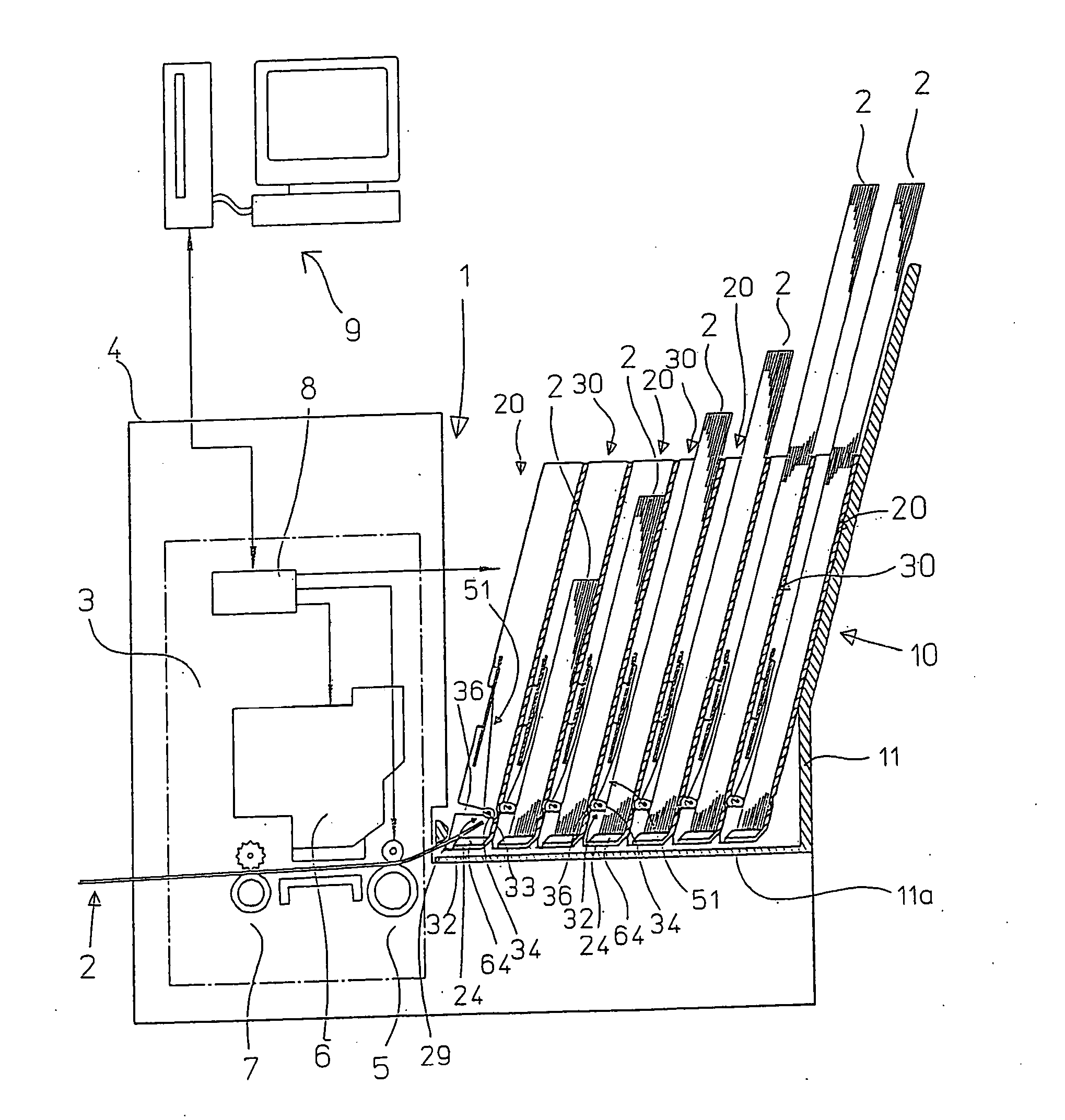

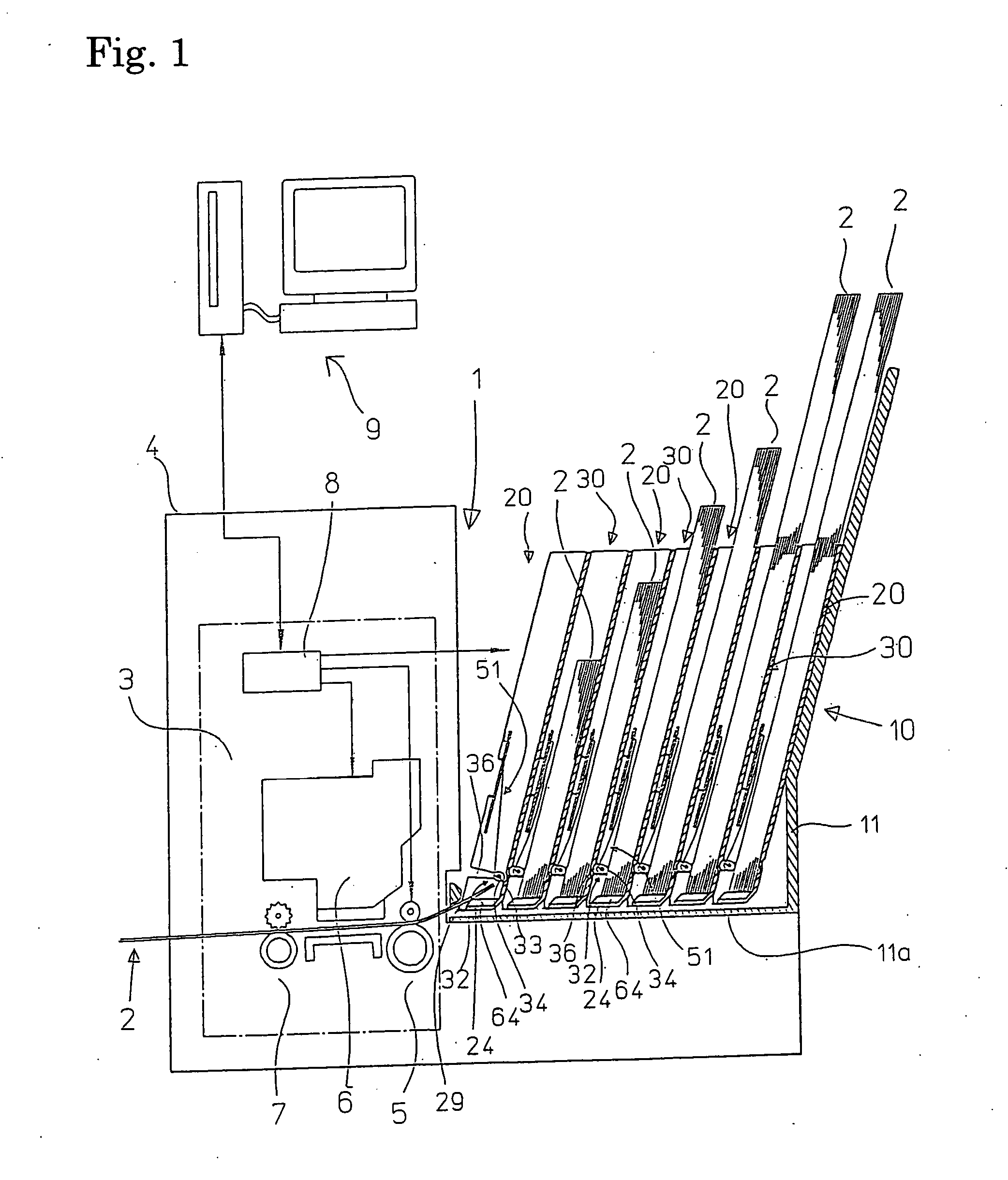

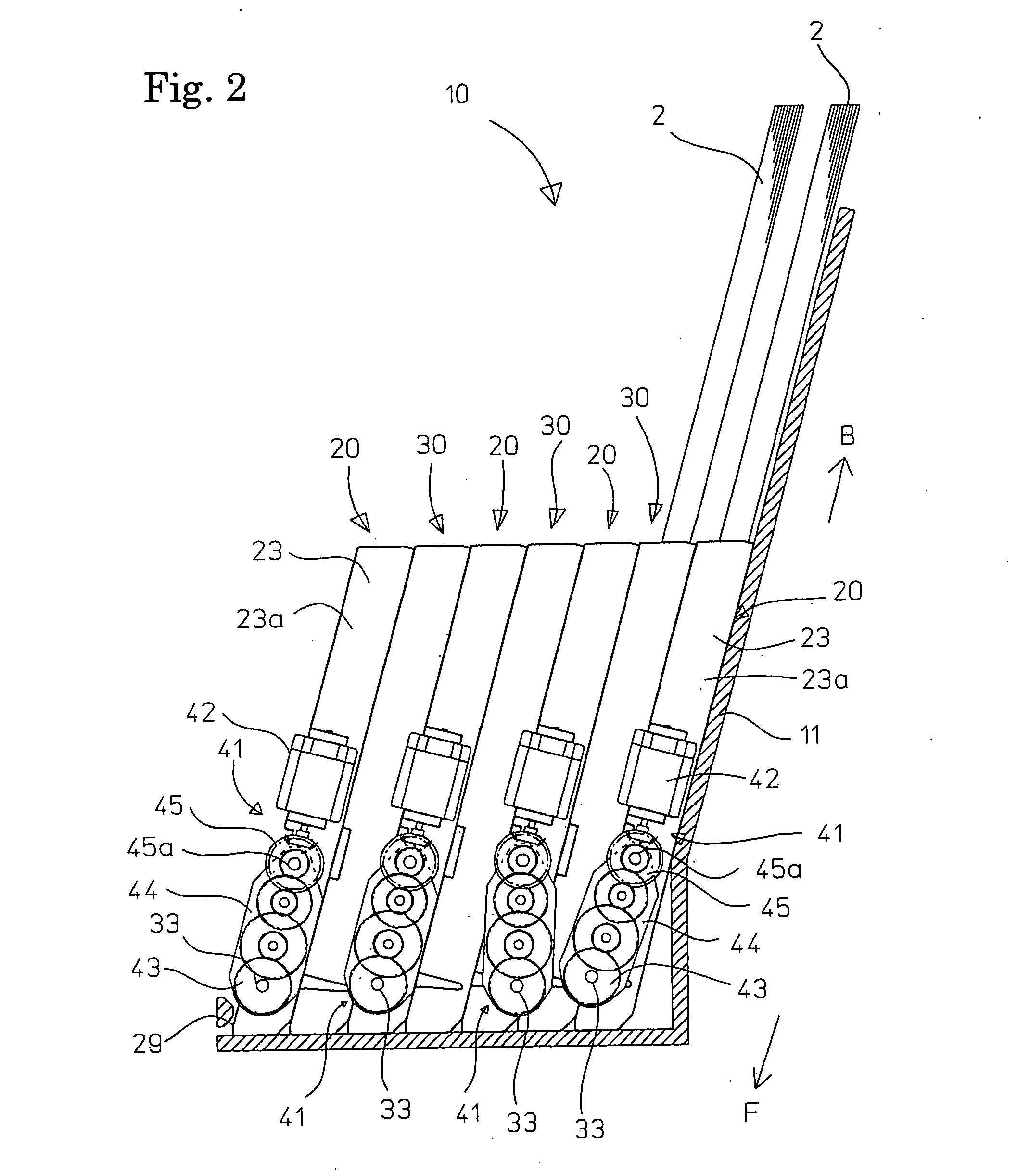

[0053] The present invention is described in more detail below with reference to the attached drawings. FIG. 1 schematically shows a printer with a multiple paper feeding apparatus, that is, a multitray including paper feeding apparatuses according to the present invention. The printer 1 includes a multitray 10 in which two types of paper feeding apparatuses 20 and 30 are alternately stacked on seven levels, with the respective paper feeding apparatuses 20 and 30 being capable of storing a plurality of sheet like papers (sheets), that is, cut sheets 2. The printer 1 also has a printing unit 3 that prints on the cut sheets 2 supplied from the multitray 10. The printing unit 3 includes a paper feeder 5, an ink jet-type printing head 6, and a discharge feeder 7. The printing unit 3 also includes a control unit 8 that receives print data and commands from a computer 9 that is a host, and controls the printing head 6, the feeders 5 and 7, and the multitray 10 based on the received inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com