Technique for preparing product of orthopedic shoes

A preparation technology and orthopedic technology, which is applied in the field of preparation technology of finished orthopedic shoes, can solve the problems of affecting the user's image, fixation stiffness, and different levels, and achieve the effects of avoiding poor orthopedic effects, reducing psychological burden, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 Foot varus deformity orthopedic shoe:

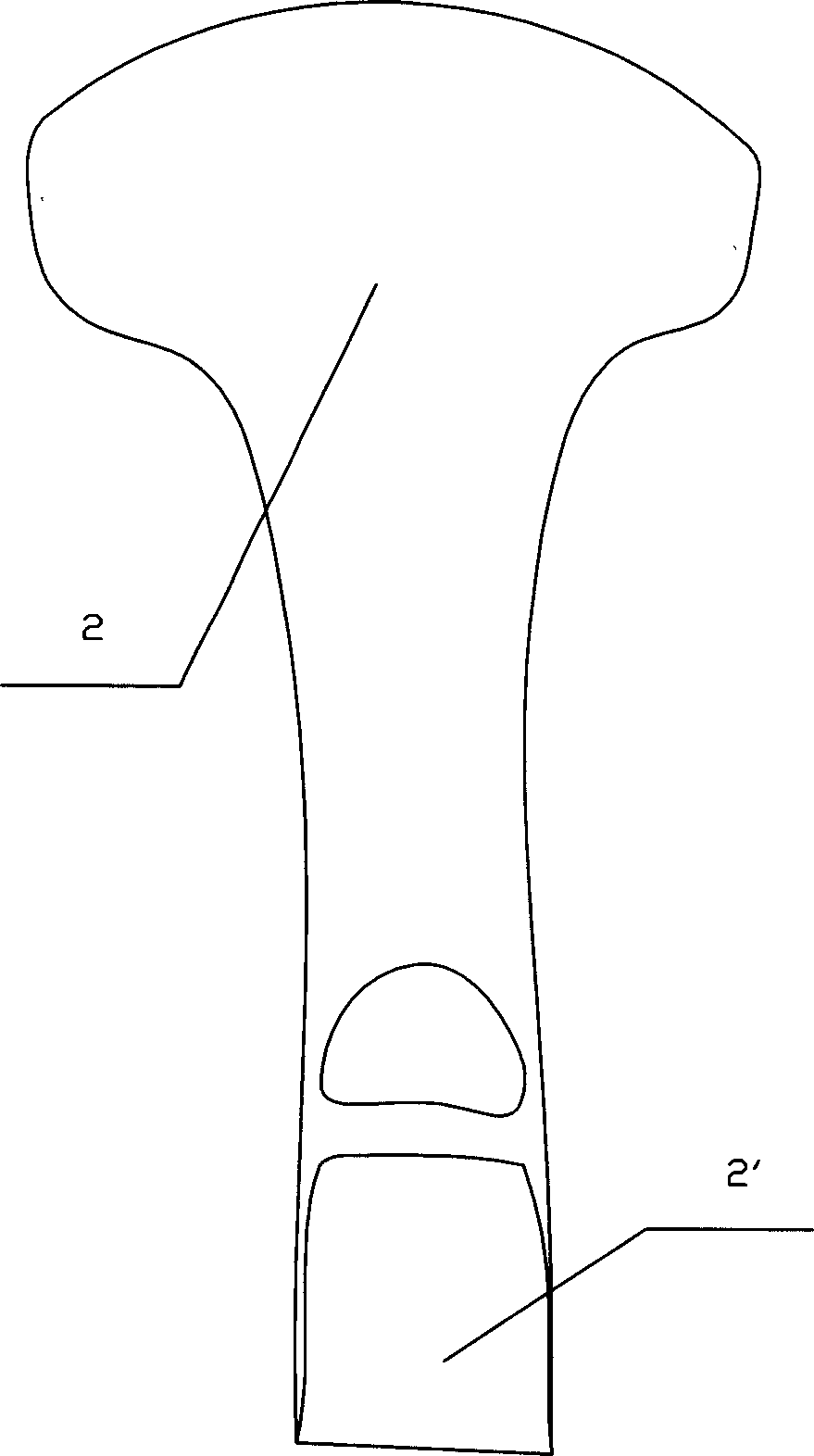

[0039] According to the user's gender, season, and ankle joint control, choose shoes: if the ankle joint is well controlled, choose shoes without AFO orthosis accessories, and only add FO orthosis accessories 1, such as Figure 5 As shown; if the ankle joint is poorly controlled, and there are pointed feet and spastic foot drop deformities, choose shoes with AFO orthotic accessories, and add ankle joint fixation straps to the ankle joint5.

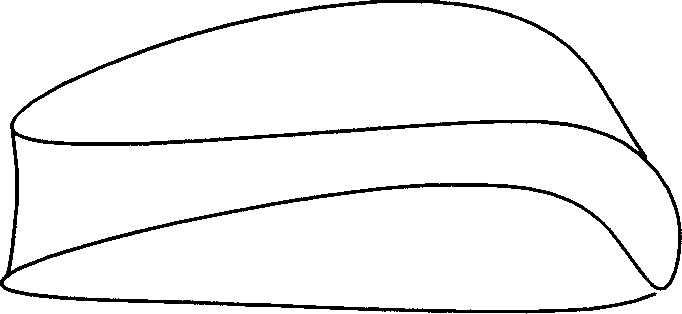

[0040] Choose a prostheses corrective shoe last: the head shape of the shoe last is straight last or reverse last.

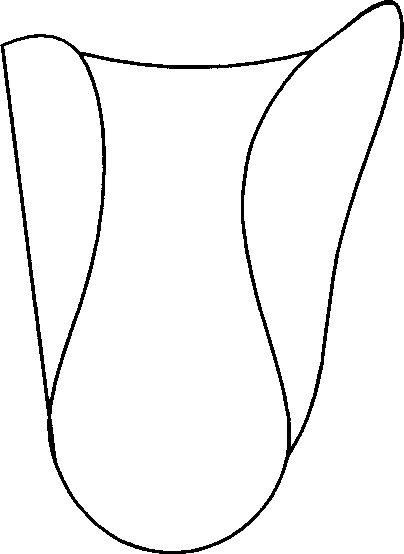

[0041] Choose the built-in varus FO orthosis accessories: conform to the varus orthopedic shoe last shape, its medial edge is slightly longer than the lateral edge, beyond the metatarsophalangeal joint of the big toe, and the lateral edge is located at the fifth metatarsophalangeal joint. The FO orthosis accessory 1 is built into the reserved interlayer of the shoe...

Embodiment 2

[0045] Embodiment 2 Valgus flat foot orthopedic shoe:

[0046] According to the user's gender, season, and ankle joint control, choose shoes: if the ankle joint is well controlled, choose a shoe that does not add AFO orthosis accessories, but only adds FO orthosis accessory 1; For foot and spastic foot drop deformity, choose shoes with AFO orthosis accessories, and add ankle joint fixation belt 5 at the ankle joint.

[0047] Choose a foot eversion correction shoe last: the head shape of the shoe last is a positive last or an internal rotation last.

[0048] Choose the built-in valgus FO orthotic accessories: it conforms to the valgus correction shoe last shape, its lateral edge is slightly longer than the medial edge, slightly beyond the fifth metatarsophalangeal joint, and the medial edge is located at the hallux toe joint.

[0049] According to the situation of ankle joint control, AFO orthosis accessories are selected, and its fixation and placement methods are the same as...

Embodiment 3

[0051] Embodiment 3 hemiplegic foot drop orthopedic shoes:

[0052] According to the user's gender, season, and ankle joint control, choose shoes: the side with good ankle joint control, choose not to add AFO orthosis accessories; the side with poor ankle joint control, and foot drop deformity, choose to add AFO orthosis accessories, and Choose whether to add ankle joint fixation belt 5 at the ankle joint according to the degree of spasm.

[0053] Choose a shoe last, and choose a special last that reserves the position of the orthosis in advance on the side where the AFO support is added.

[0054] According to the control of the left and right ankle joints, choose AFO orthosis accessories, and the fixation and placement methods are the same as

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com