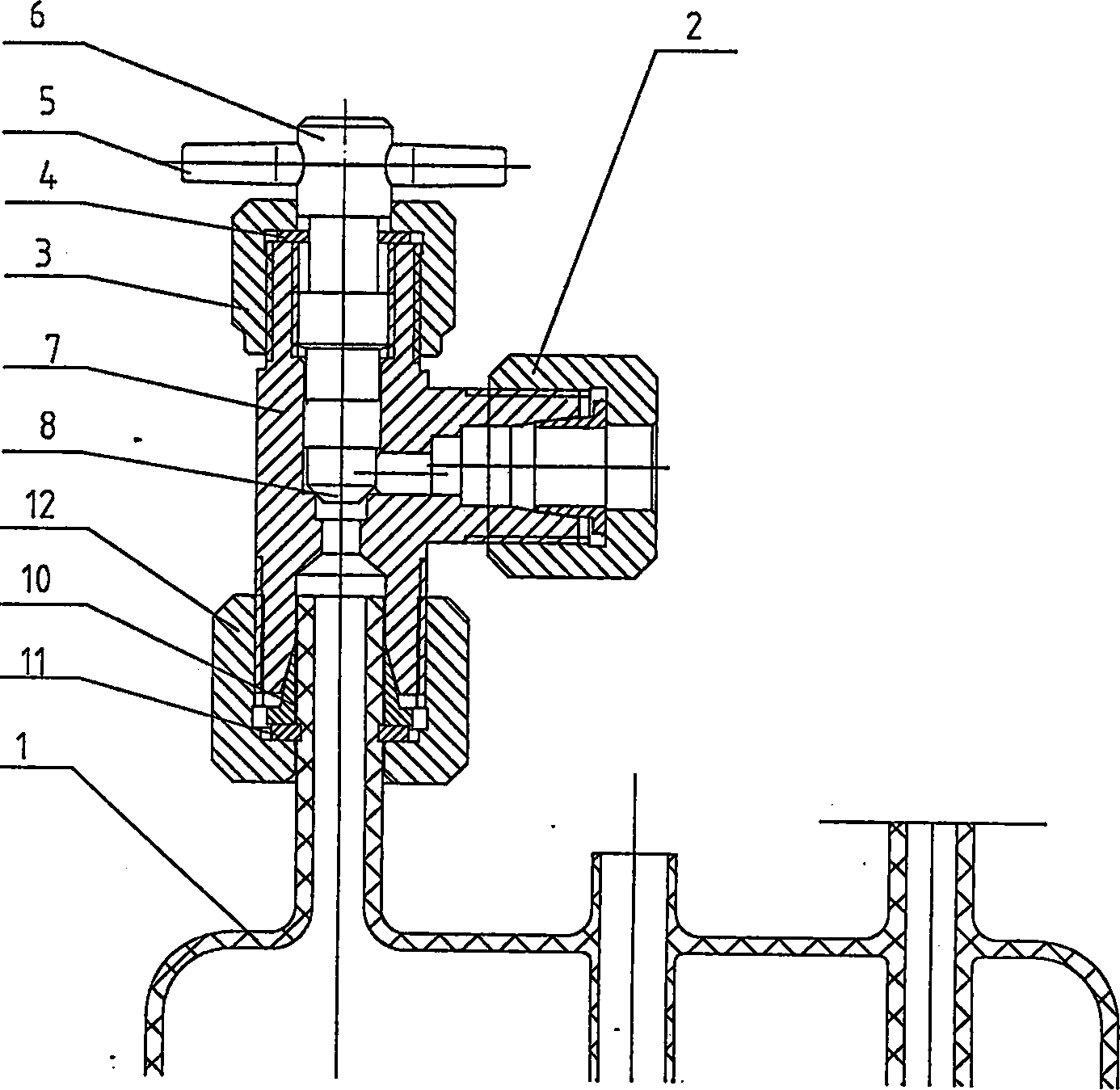

Valve piece of dedicated composite tubing for source bottle

A combined tube and source bottle technology, which is applied to the structural improvement of the combined tube and valve parts for source bottles, and in the field of special combined tube and valve parts, can solve the problems of complex process and unsatisfactory anti-drawing performance, and achieve the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

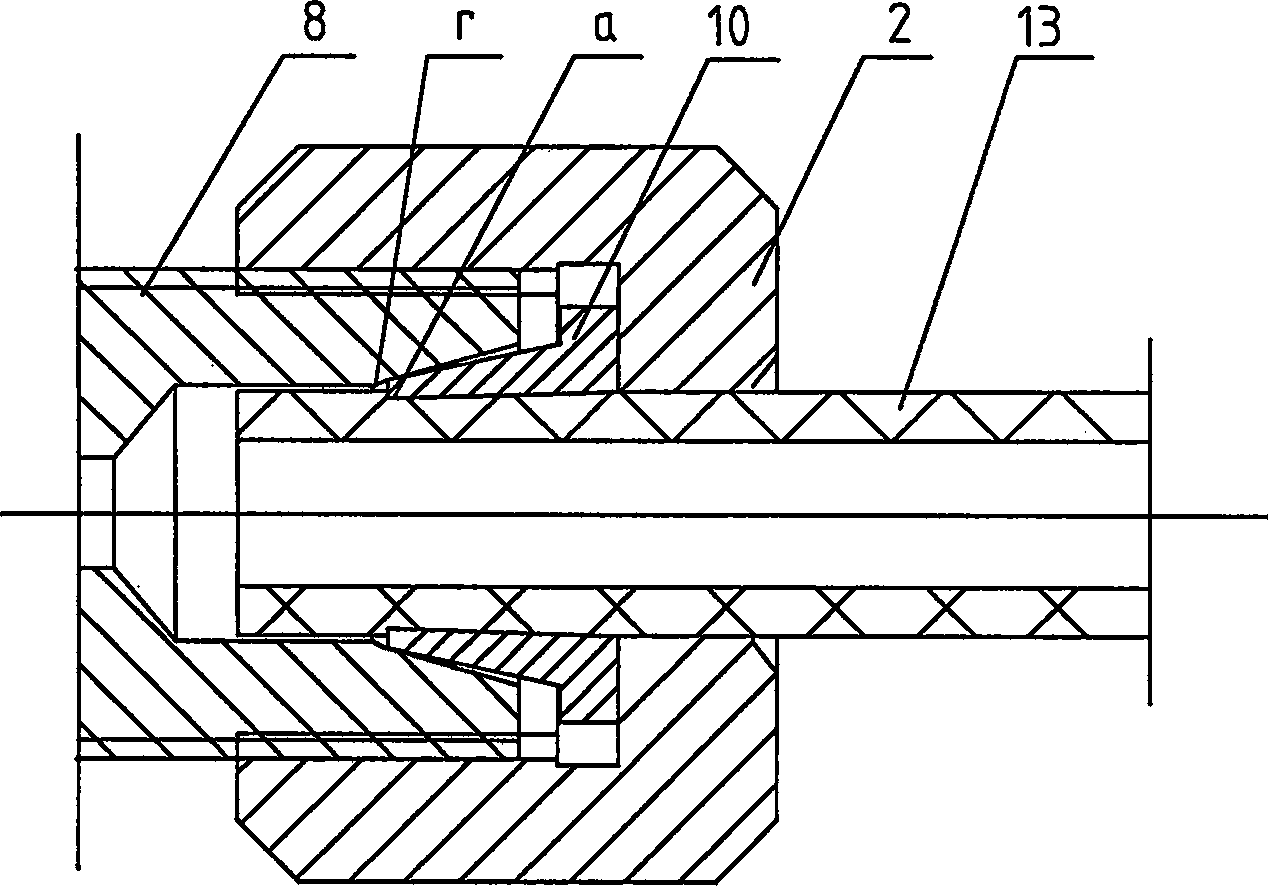

[0016] This embodiment is a special combination pipe valve part for the phosphorus oxychloride source bottle. Phosphorus oxychloride is a colorless, transparent, corrosive and toxic liquid. If inhaled, it will irritate mucous membranes and lungs, and cause severe burns if in contact with skin. Because phosphorus oxychloride is highly toxic and highly corrosive, the source bottle is made of quartz glass, and all pipes and valves are made of polytetrafluoroethylene plastic. At this time, the gas pipe and pipe valve parts of the source bottle cannot be directly threaded. Practice has proved that due to the excellent lubricating properties of polytetrafluoroethylene plastics, the ideal pull-out resistance cannot be obtained when the pipe valve parts of the prior art are used-when the pipe valve parts, especially the external hose, are subjected to pulling force, It is relatively easy to disengage from the gas pipe of the source bottle or the side port of the valve body, so there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com