Cooling unit of gaseous discharge lamp in high pressure

A technology of cooling device and high-pressure gas, which is applied to components of gas discharge lamps, cooling/heating devices of lighting devices, lighting devices, etc., and can solve the problems of insufficient cooling capacity of reflector 3, difficult installation, and small size of air passages , to avoid thermal stress cracking, increase service life, and slow down the effect of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

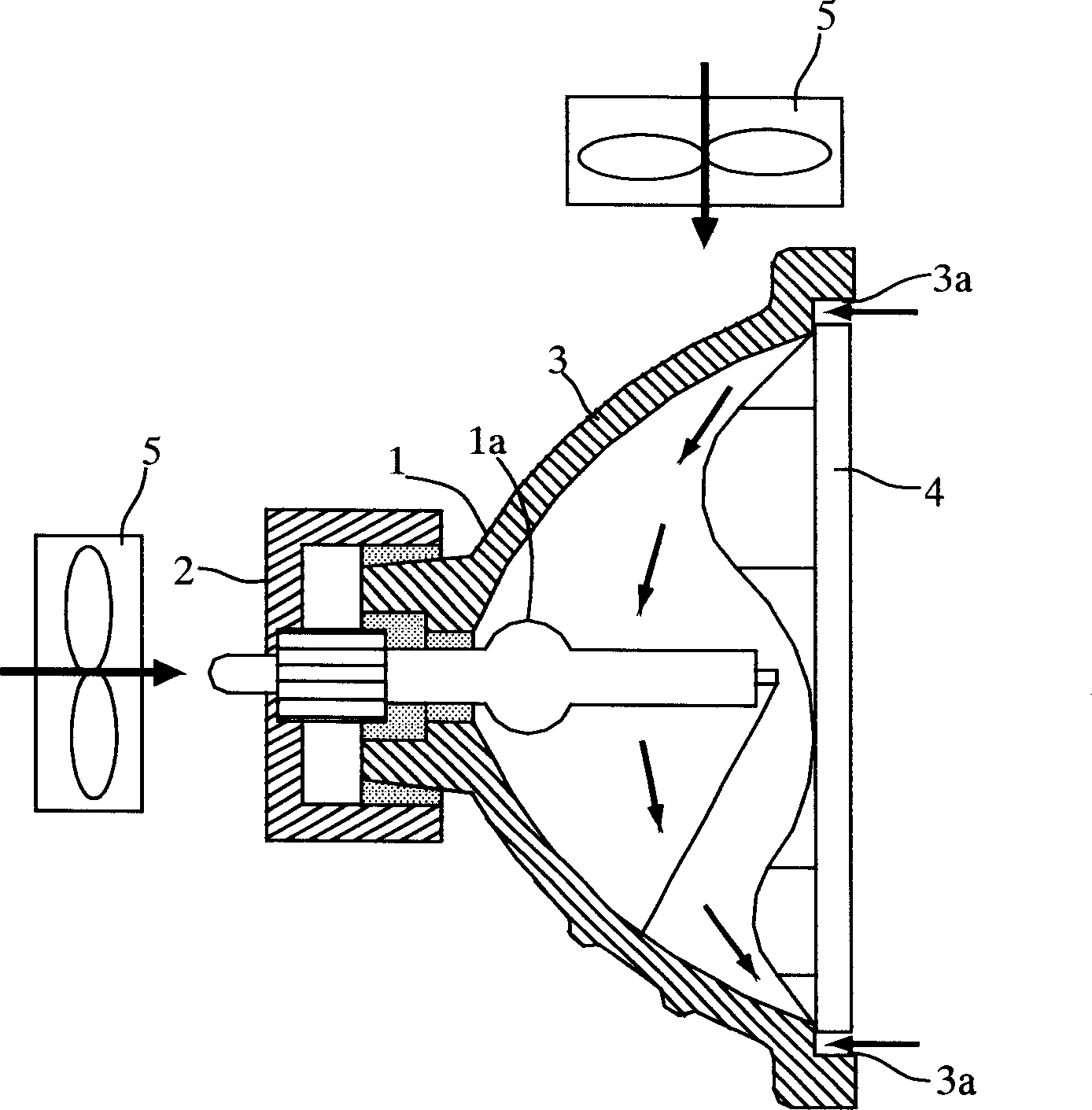

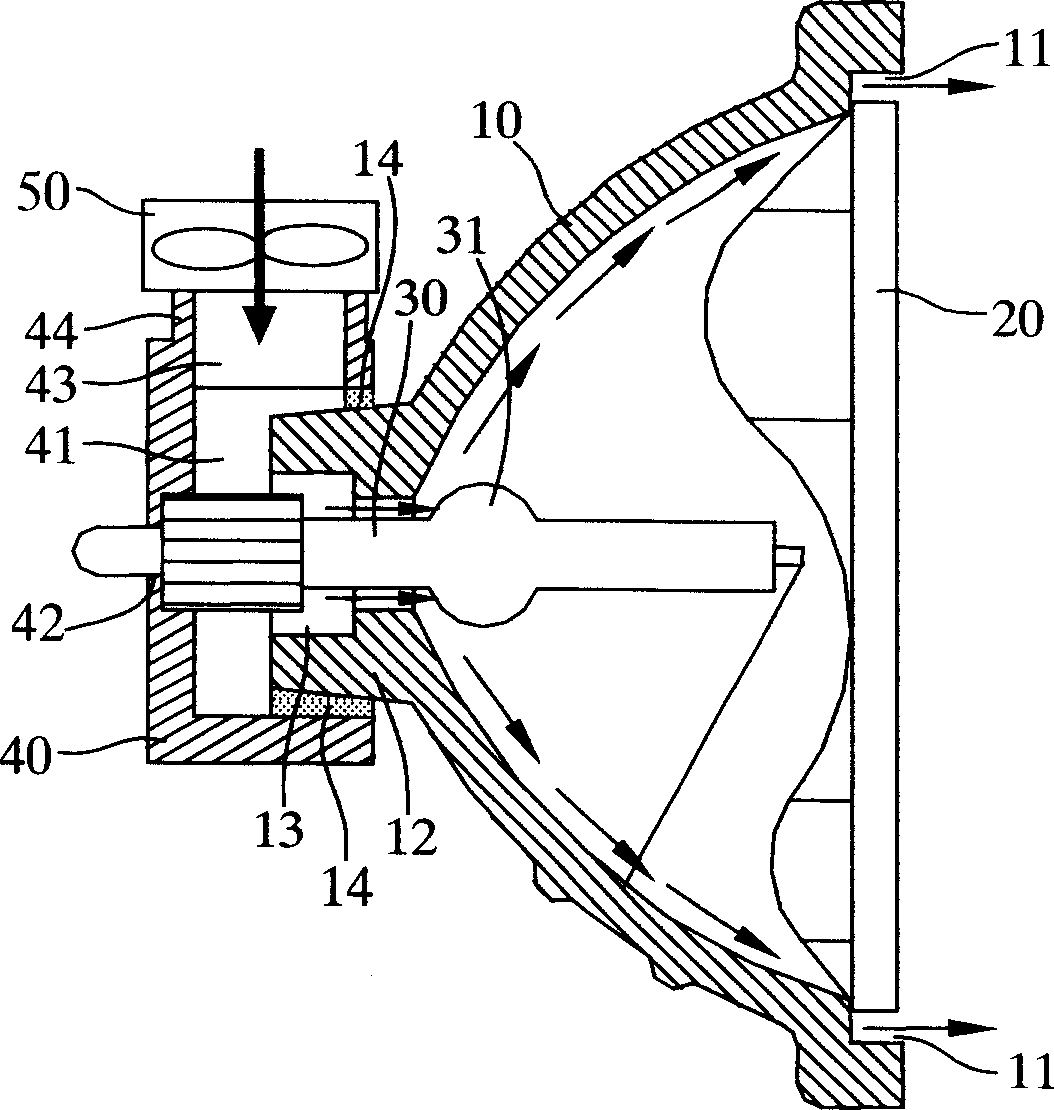

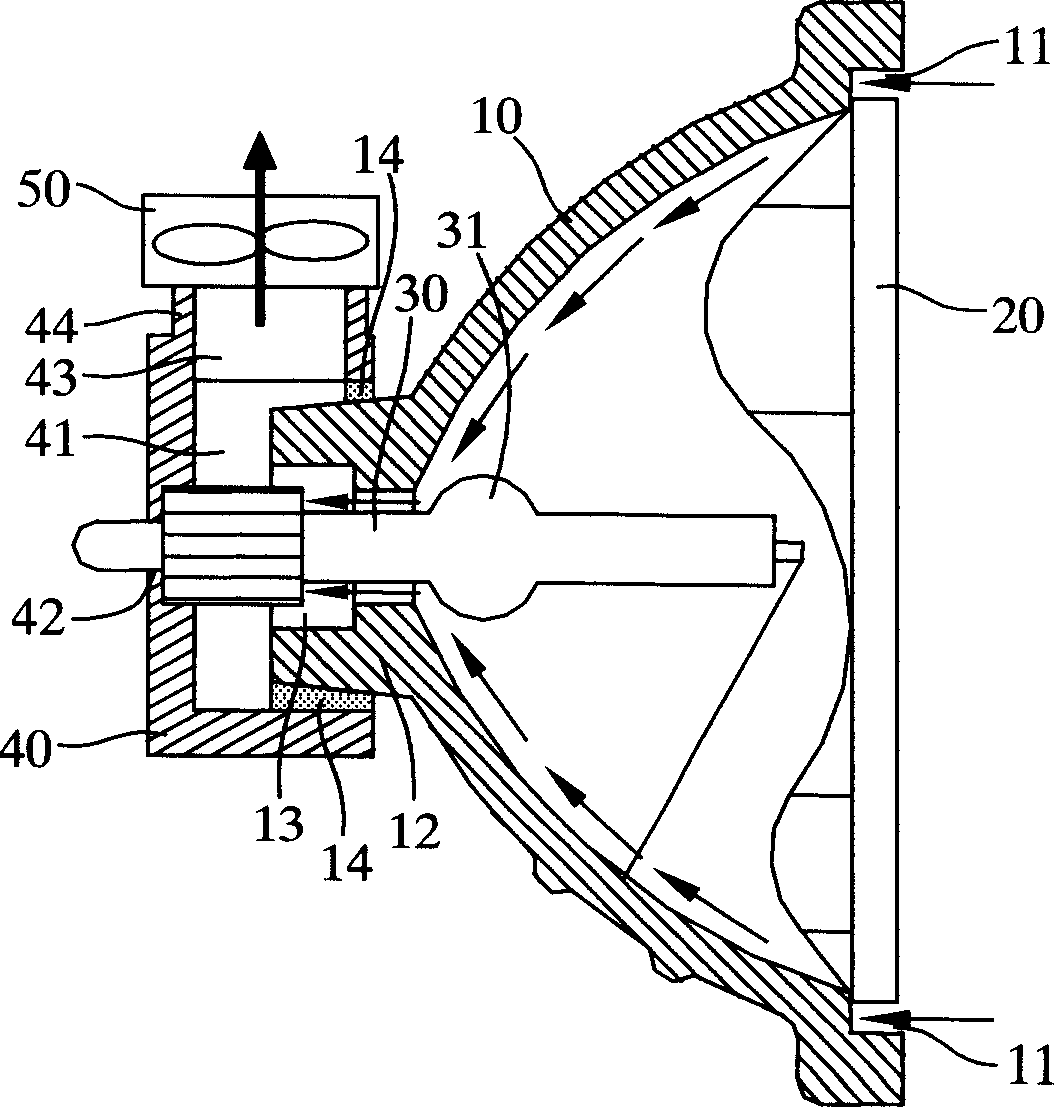

[0054] See figure 2 and image 3 As shown, a lighting device provided by the first preferred embodiment of the present invention includes a high-pressure gas discharge lamp group and a cooling device. The cooling device can control and continuously drive the cooling air flow to circulate inside and outside the high-pressure gas discharge lamp group. The temperature distribution inside the high-pressure gas discharge lamp group is controlled to operate in an appropriate temperature range, so that the high-pressure gas discharge lamp group has a better working life.

[0055] A common high-pressure gas discharge lamp group includes a reflector 10, a front lamp cover glass 20, and a discharge lamp tube 30. The reflector 10 usually presents a parabolic or elliptical shape, and the discharge lamp tube 30 has a spherical or elliptical discharge area 31, which is usually placed on the focus of the parabolic or elliptical surface of the reflector 10, and the discharge lamp 30 The electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com