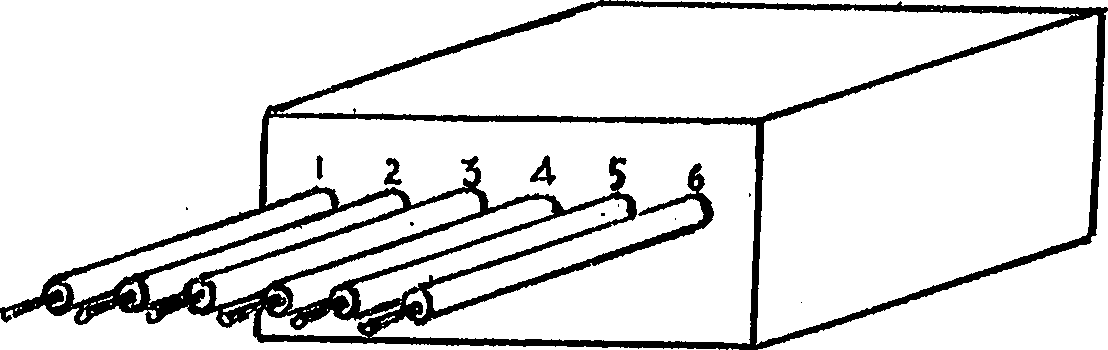

Self-braking electronic module of electric tools

A technology of automatic braking and electronic modules, applied in the direction of motor generator control, electric motor/converter plug, AC motor deceleration device, etc., can solve the problems of complex structure, unsafe, inconvenient, etc., and achieve small size, Low cost and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

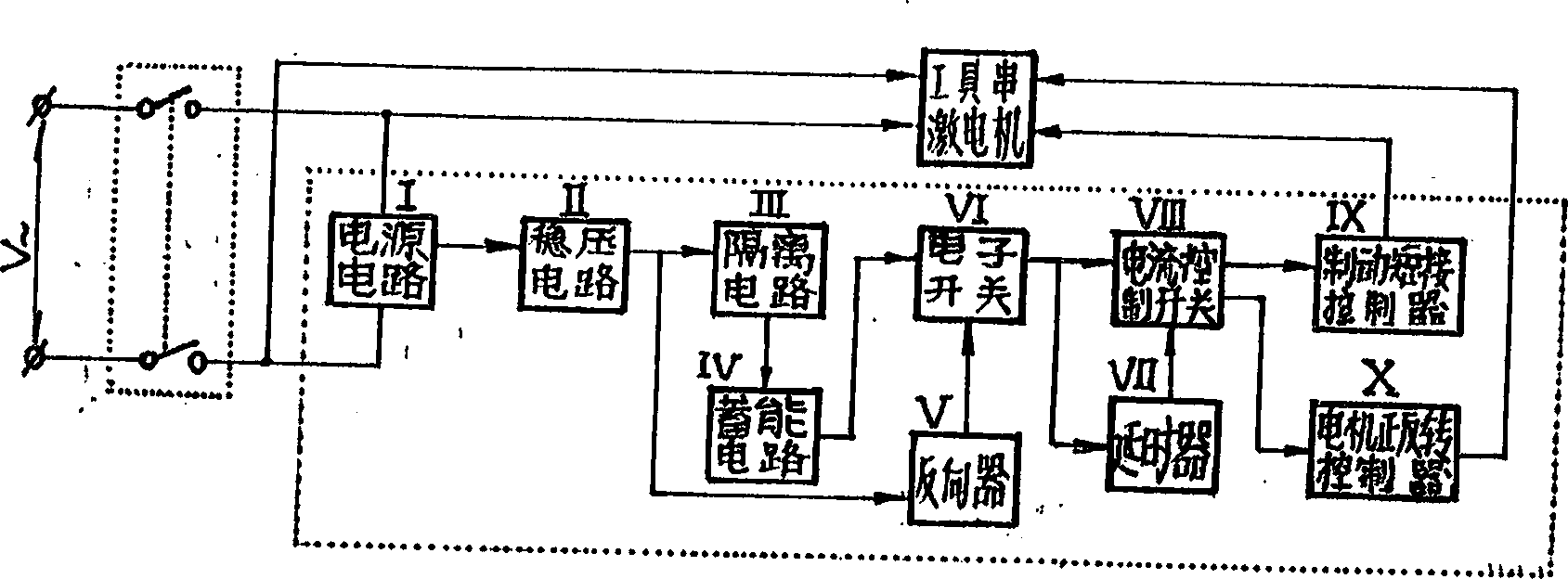

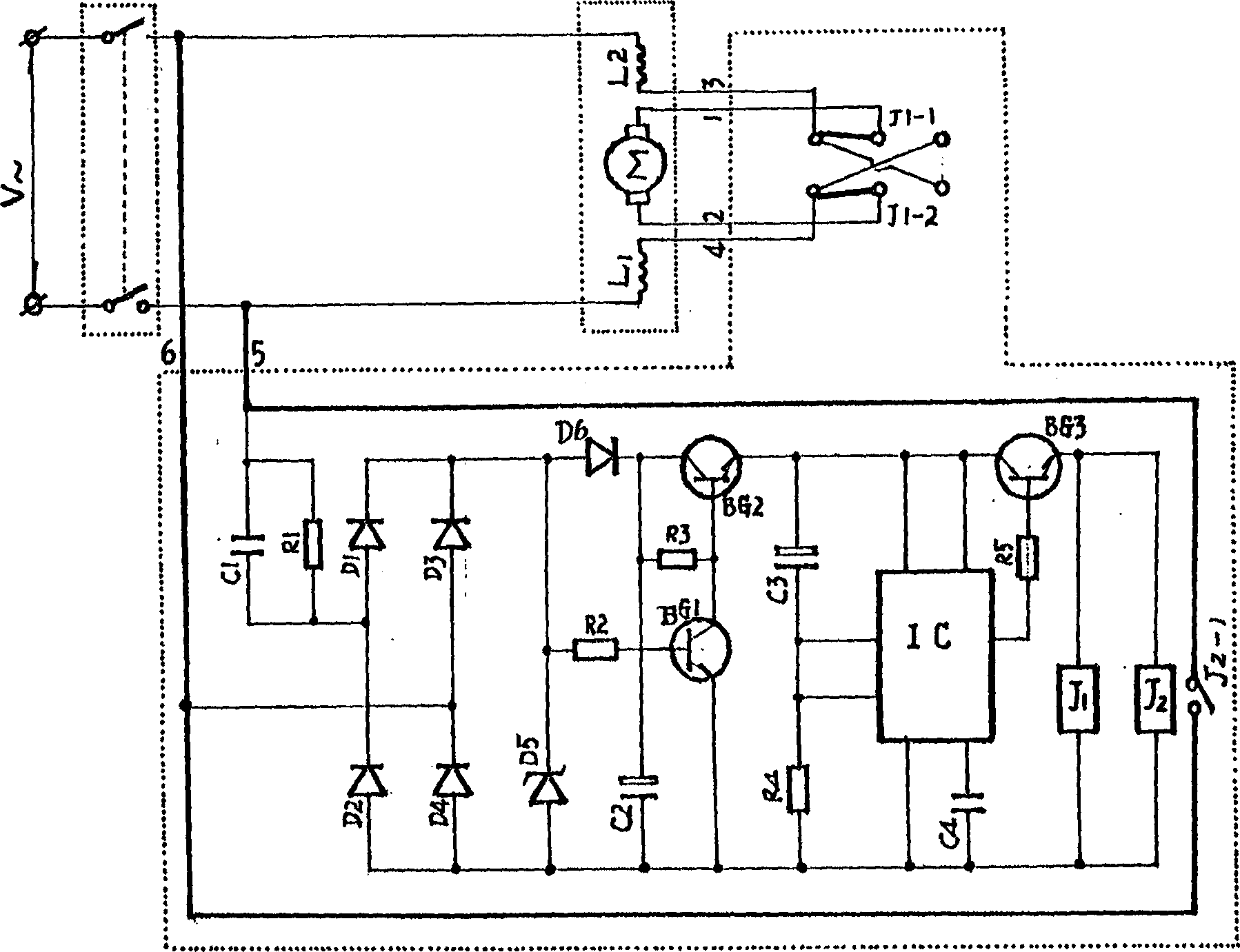

[0009] Now, the present invention will be described in detail in conjunction with the embodiments shown in the accompanying drawings.

[0010] like figure 2 , 3 As shown, the power supply circuit I consists of a step-down capacitor C 1 Parallel resistance R 1 and by the rectifier diode D 1 -D 4 connected into a rectifier consisting of a C 1 , R 1 Connect one end of the parallel branch to the first input of the rectifier, C 1 , R 1 The other end of the parallel connection branch and the other input end of the rectifier are AC power input ends 5 and 6 respectively. The voltage stabilizing circuit II consists of a voltage stabilizing diode D connected in parallel to the output terminal of the rectifier 5 constitute. Isolation circuit III consists of diode D 6 Composition, D 6 Positive connection D 5 negative electrode. The energy storage circuit IV consists of a capacitor C 2 Composition, C 2 Positive connection D 6 Negative pole, negative pole connection D 5 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com