Process for mechanized production of Yanpi (a traditional food) and dedicated equipment therefor

A meat swallow and process technology, applied in application, food preparation, food science and other directions, can solve the problems of lack of toughness and brittleness in taste, large gap between swallow skin, and the formation mechanism of swallow skin is not considered. The effect of short cycle and maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

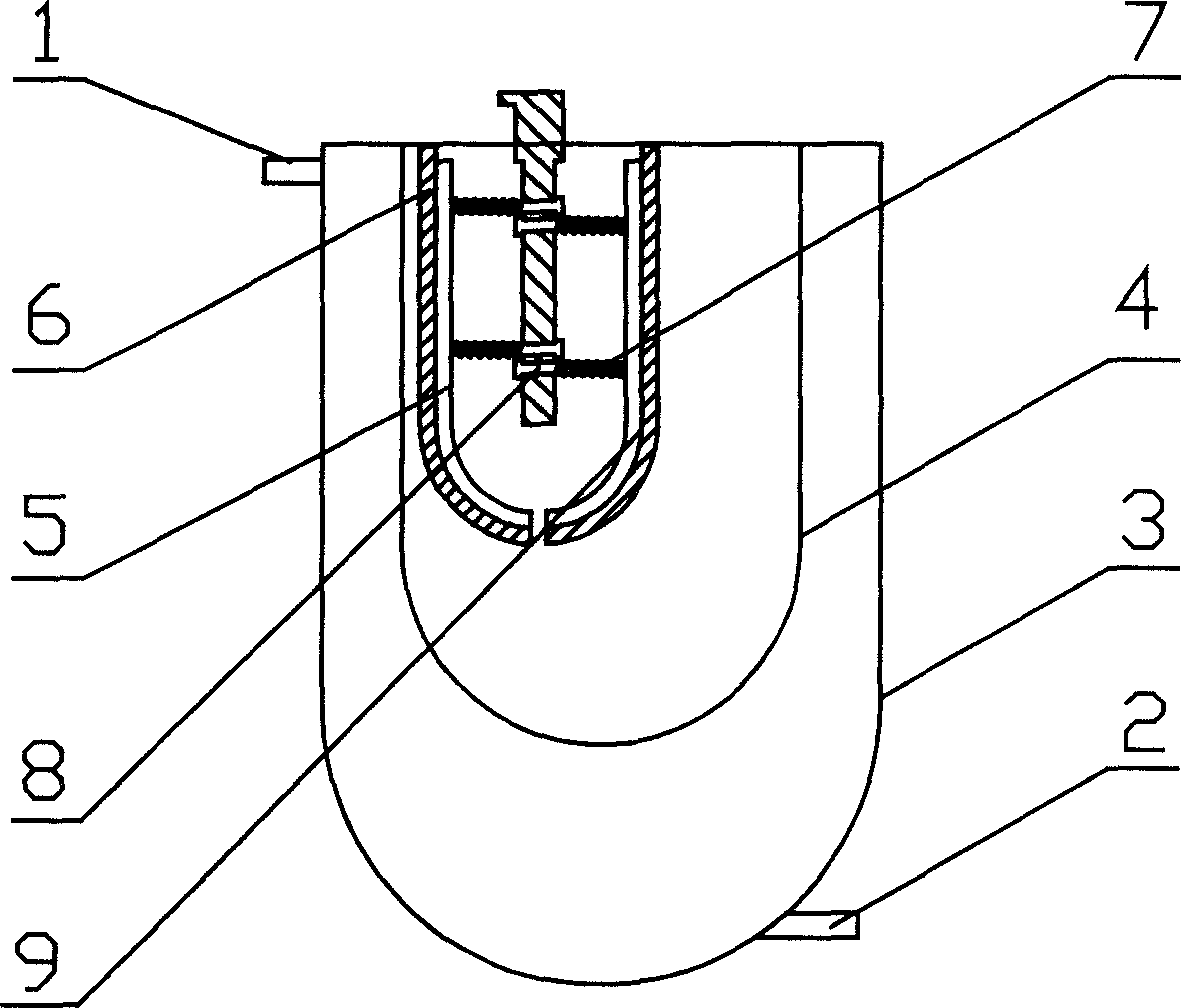

[0033] 1. Beating: Take 500g of fresh pork leg meat, put it in a grinding machine, beat it for 2 minutes at the speed of rotation 140r / min, revolution 35r / min, add 2% saturated potassium carbonate solution, and then change to rotation 300r / min , Revolution at a speed of 50r / min, continue to crush for 15 minutes, remove the tendons through a 2-mesh filter, and finally get fine muddy minced meat; the temperature during the entire crushing process is controlled below 25°C;

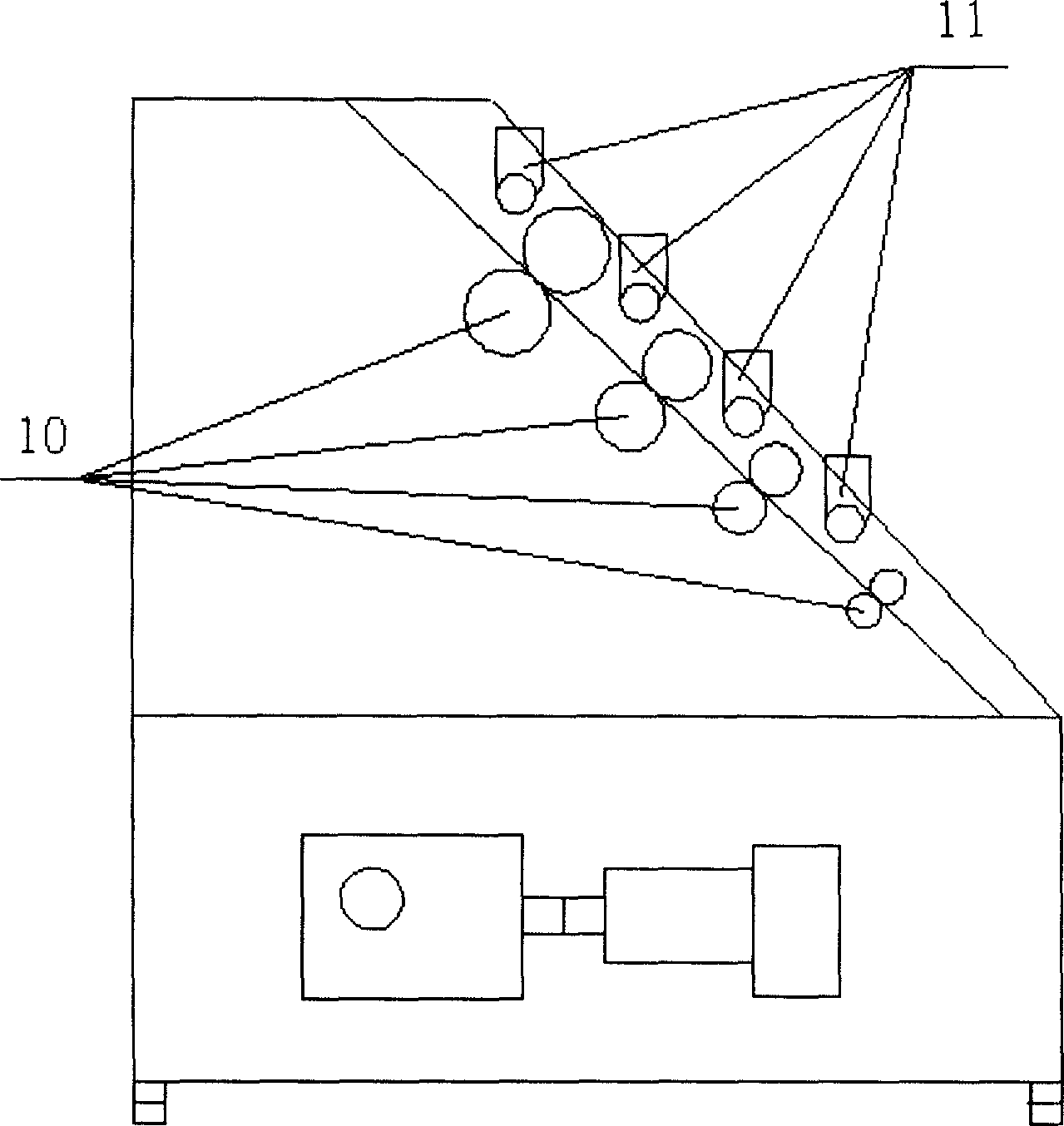

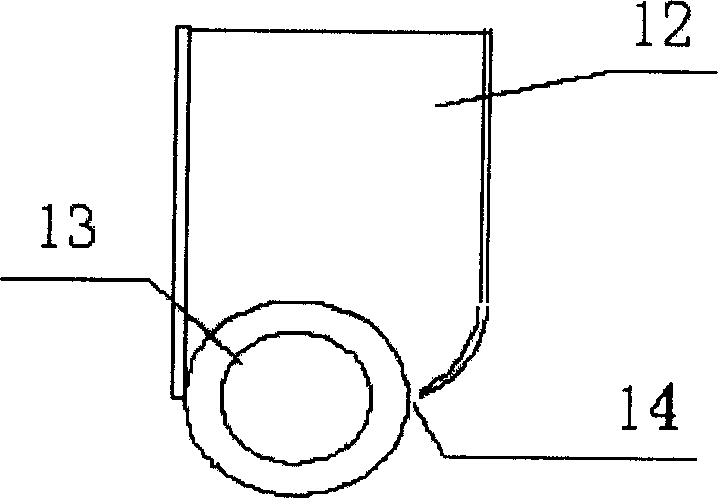

[0034]2. Calendering: Take out the minced meat, sprinkle sweet potato powder on top, put it in the noodle press, adjust the distance between each roller: 4mm, 2.5mm, 1.5mm, 0.8mm; the speed of the first roller is 180cm / min. Finally, a white paper-like product is obtained.

Embodiment 2

[0036] 1. Grinding: Take 1000g of fresh pork leg meat, put it in the grinding machine, grind it at the speed of rotation 160r / min, revolution 40r / min for 3min, and then change it to the speed of rotation 340r / min, revolution 60r / min Knead for 2 minutes, add 3% of saturated potassium carbonate solution, continue to grind for 10 minutes at a speed of 340r / min in rotation and 60r / min in revolution, and remove tendons through a 4-mesh filter screen to finally obtain fine muddy minced meat; the temperature of the whole grinding process is controlled at Below 25℃;

[0037] 2. Rolling: Take out the minced meat, sprinkle cassava flour on top, place it in the noodle press, adjust the distance between each roller: 4.5mm, 3.5mm, 2.5mm, 1.8mm, 0.6mm; the speed of the first roller is 200cm / min. Finally, a white paper-like product is obtained.

Embodiment 3

[0039] 1. Grinding: Take 2000g of fresh pork leg, put it in a grinding machine, grind it for 2 minutes at the speed of rotation 140r / min and revolution 35r / min, add 2% saturated potassium carbonate solution, and then change to rotation 320r / min , Revolution at a speed of 55r / min, continue to crush for 16 minutes, remove the ribs through a 3-mesh filter, and finally obtain fine muddy minced meat; the temperature during the entire crushing process is controlled below 25°C;

[0040] 2. Calendering: Take out the minced meat, sprinkle cornstarch on it, put it in a noodle press, and adjust the distance between each roller: 3mm, 2mm, 1mm, 0.5mm; the speed of the first roller is 240cm / min. Finally, a white paper-like product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com