Process for producing barium sulfide

A technology of barium sulfide and a new method, applied in the direction of magnesium/calcium/strontium/barium sulfide/polysulfide, etc., can solve the problems of difficult close contact, large distance between each other, poor heat preservation effect of converter, etc., to achieve reduction The atmosphere is easy to control, the temperature is easy to control, and the heat preservation effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

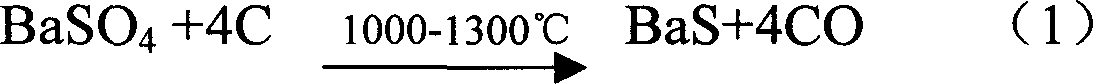

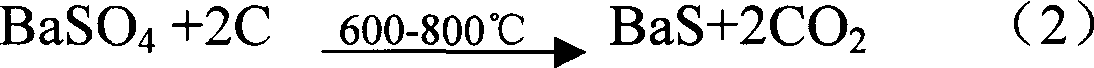

Method used

Image

Examples

Embodiment 1

[0025] Implement raw material selection:

[0026] Barite: BaSO 4 The content is 98%, the loss on ignition is 0.1%, and the barite raw material collection point is Xifeng County, Guizhou Province.

[0027] Coal: The carbon (C) content is 62%, the ash content is 20%, and the raw coal collection point is Jinsha County, Guizhou Province.

Embodiment approach

[0029] First crush the barite to a particle size below _30mm, mix 120 tons of barite and 30 tons of coal in a weight ratio of 1:0.25, mix well, grind to 80 mesh with a ball mill, and the sieve residue is less than 2%. Add 14% water to make a block of 60×120×240mm, stack the block on the tunnel kiln car, push it into the tunnel kiln for calcination, the highest temperature in the high temperature zone is 950°C, and the retention time of the block in the high temperature zone is 2 Hour.

[0030] Implementation results:

[0031] The obtained crude barium sulfide (black ash) product was 92.37 tons, and the BaS content was 90.6% through analysis and testing. BaSO 4 The conversion rate is 98.3%, and the total coal consumption per ton of black ash (raw coal plus kiln coal) is 420kg.

Embodiment 2

[0033] Implement raw materials:

[0034] Barite: BaSO 4 The content is 90%, the loss on ignition is 2.5%, and the barite raw material collection point is Tianzhu County, Guizhou Province.

[0035] Coal: The carbon (C) content is 62%, the ash content is 20%, and the raw coal collection point is Jinsha County, Guizhou Province.

[0036] method of execution:

[0037] First crush the barite to a particle size below _30mm, mix 150 tons of barite and 30 tons of raw coal in a weight ratio of 1:0.20, mix well, grind to 80 mesh with a ball mill, and the sieve residue is less than 2%. Add 14% water to the material to make a 60×120×240mm material block, stack the material block on the tunnel kiln car, and push it into the tunnel kiln for calcination. The highest temperature in the high temperature zone of the tunnel kiln is 950°C, and the retention time for 2 hours.

[0038] Implementation results:

[0039] The obtained crude barium sulfide (black ash) product was 115 tons, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com