Mouth fixed section flue of gasification cooling flue for steel-making converter

A technology for vaporizing cooling flues and steelmaking converters, which is applied in the manufacture of converters, etc., can solve the problems of cracking and leakage of fillet welds, pipe burst accidents, deterioration of water circulation, etc. Optimizing the effect of the water cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

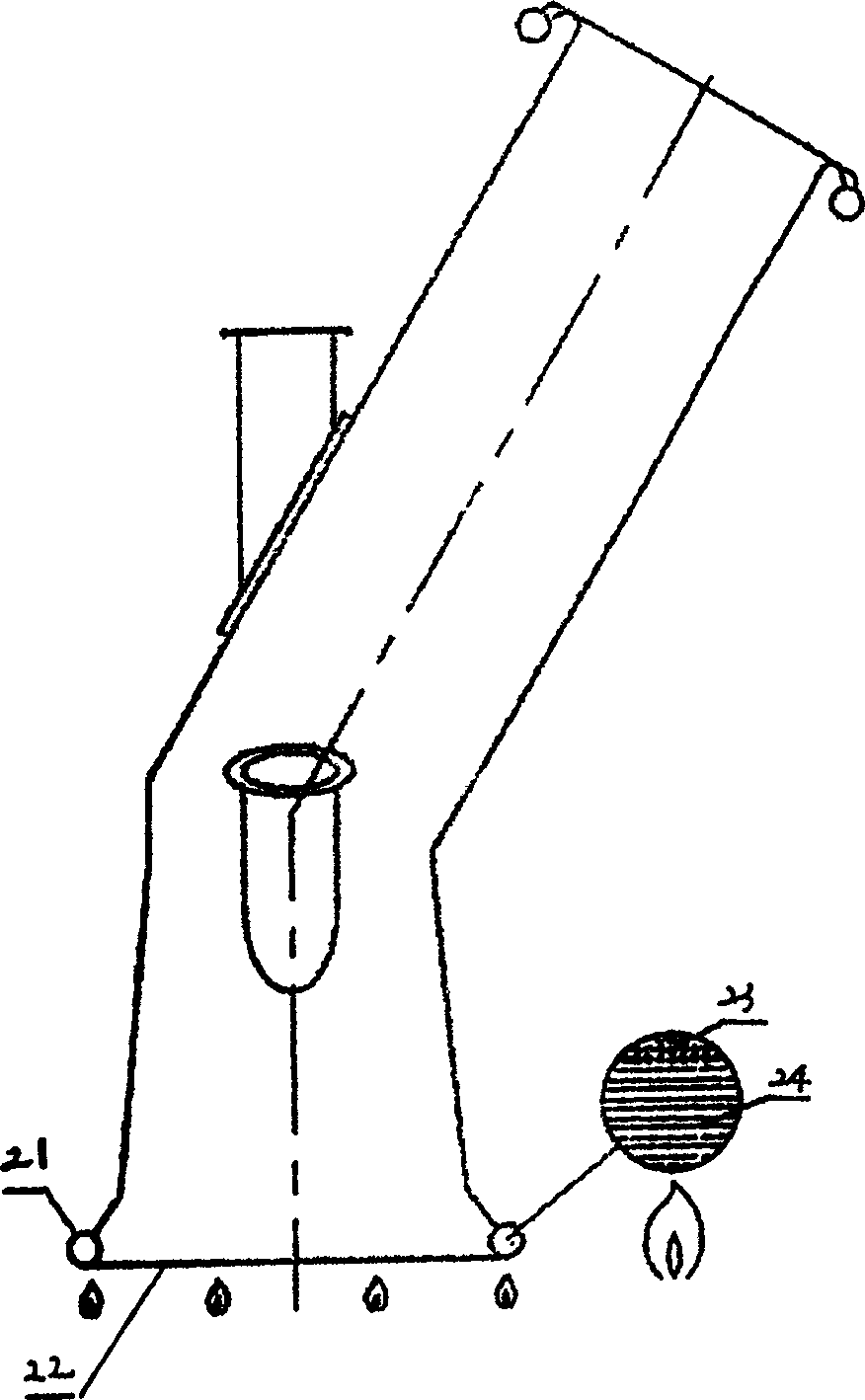

[0033] see Figure 9 , the furnace mouth fixed section flue of the gasification cooling flue used in the steelmaking converter of the present invention comprises a lower header 21, and the lower header 21 is connected with the water inlet of the flue heat receiving pipe of the furnace mouth fixed section, and the lower header 21 is arranged at the distance from the flue The bottom end 22 is slightly farther away.

[0034] see Figure 10 , the furnace mouth fixed section flue of the gasification cooling flue used in the steelmaking converter of the present invention, the furnace mouth fixed section flue is provided with an oxygen gun port and a feeding port, and the heating tubes 28 of the feeding port and the oxygen gun port are arranged as direct stacked pipes Mode.

[0035] see Figure 11, the fixed-section flue of the gasification cooling flue for the steelmaking converter of the present invention, the heating tube 28 of the charging port and the oxygen gun port is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com