Process for the purification of compressed air and cartridge therefore

A technology for compressed air and filter cartridges, which is applied in the methods of reacting gas medium with gas medium, chemical instruments and methods, separation methods, etc., can solve the problems of fiber mesh filter pollution and reduced filtration effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

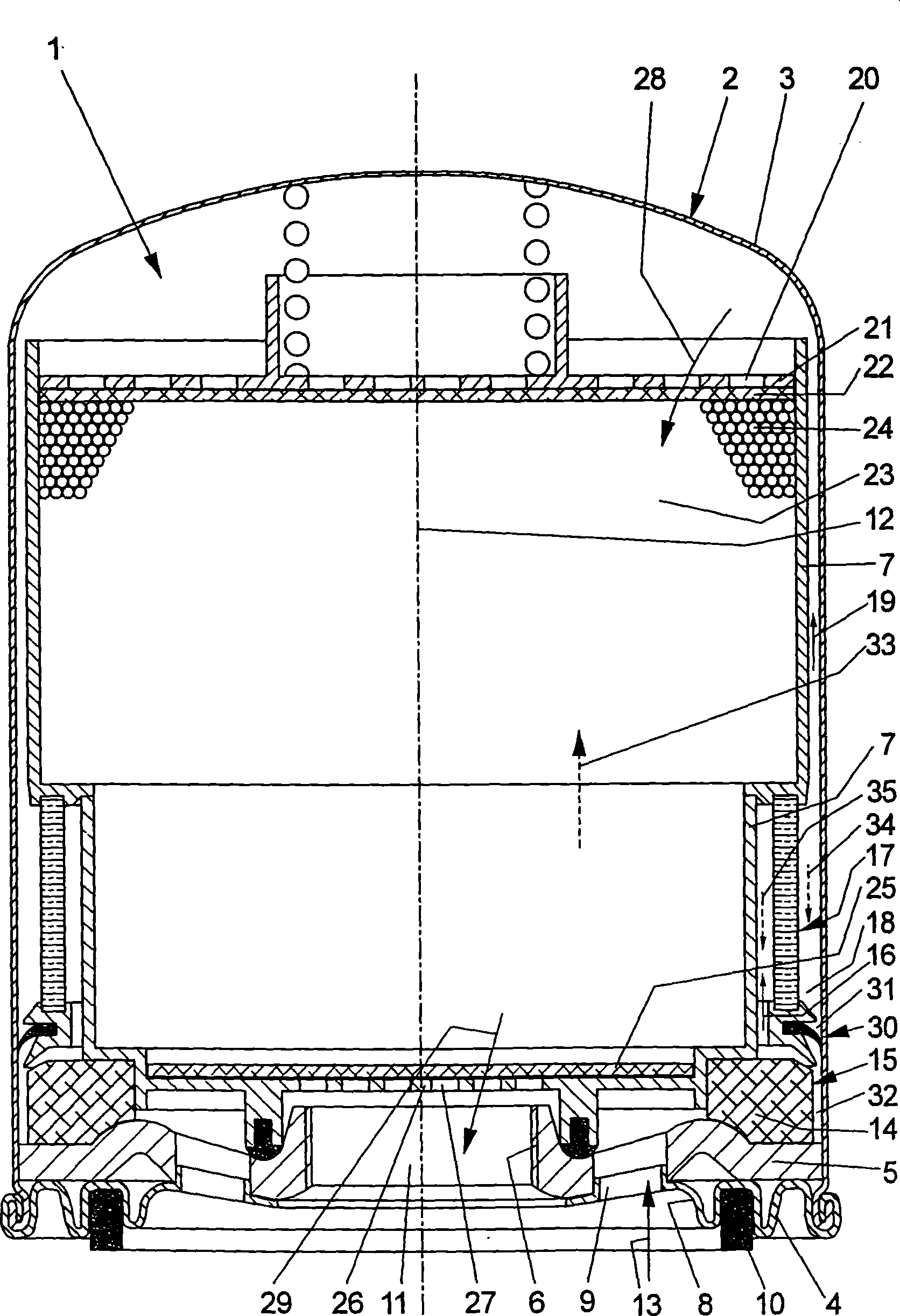

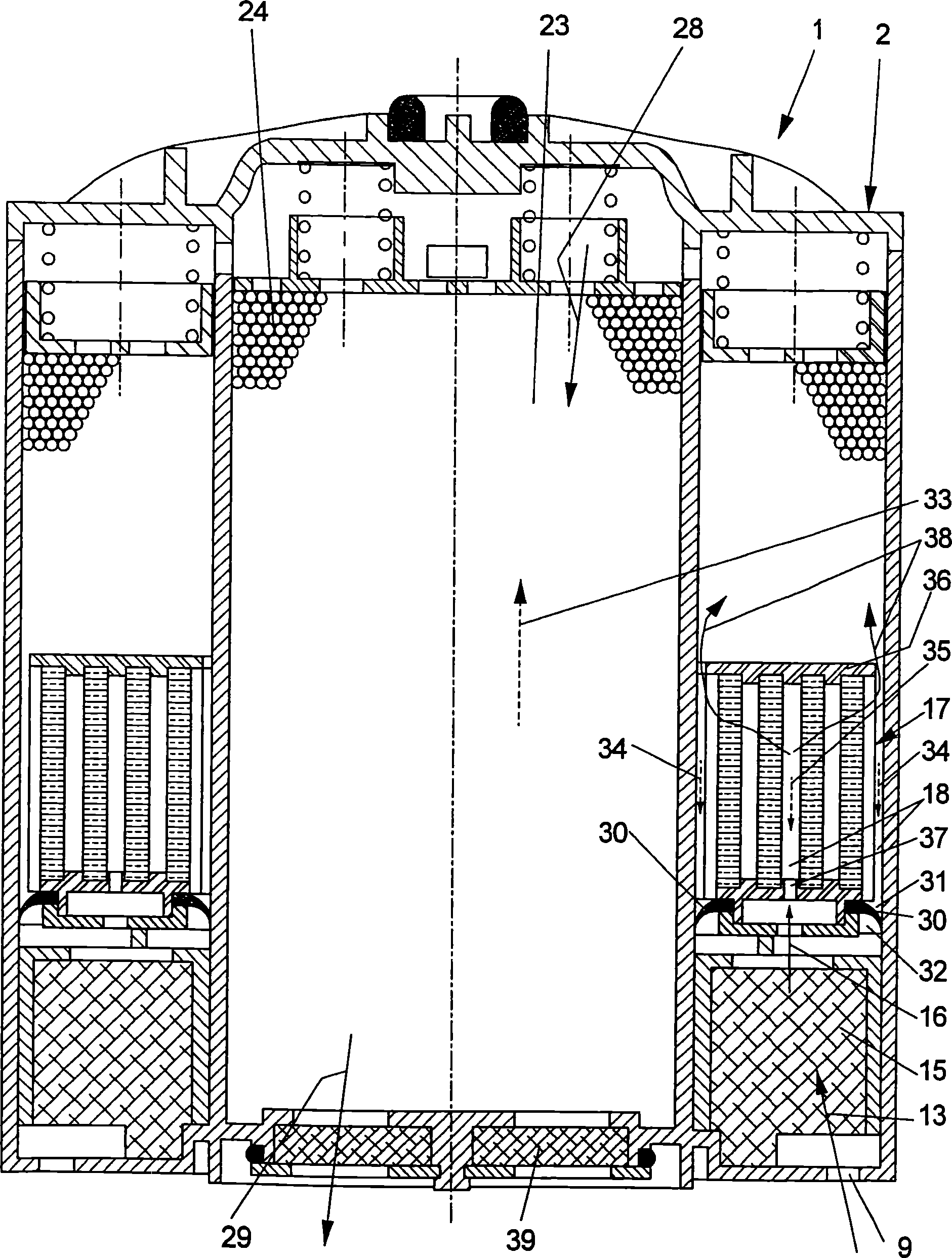

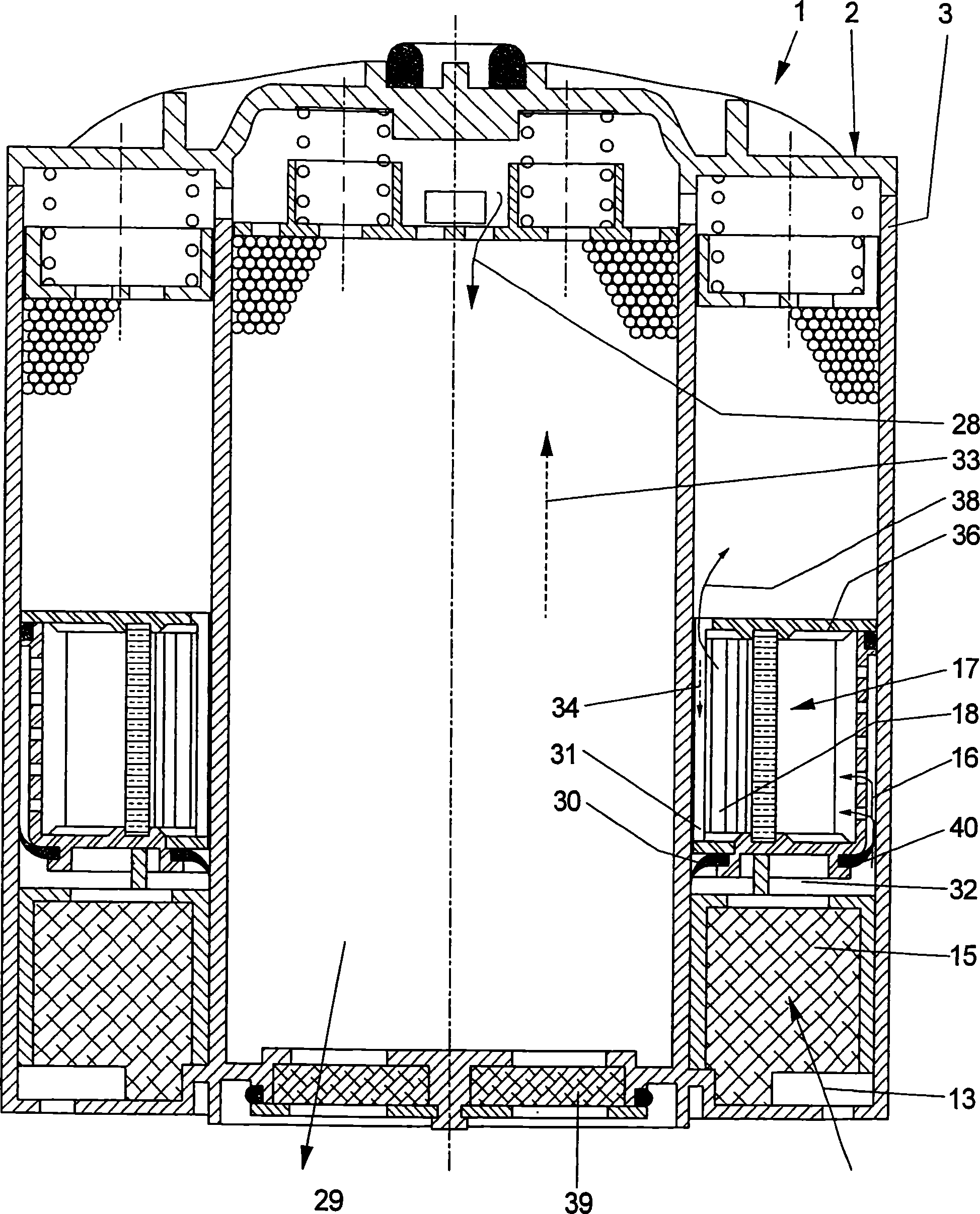

[0026] figure 1 A filter cartridge 1 is shown, which is engaged as an exchangeable part with a not shown base part. The filter cartridge 1 has a housing 2 composed of several parts. The housing 2 has an outer shell consisting of sheet metal parts 3 , 4 connected by rolling, in which a connecting cover 5 of a screw connection 6 is arranged. A stepped inner wall 7 is arranged in the housing 2 . In the lower region, the end wall 8 with a perforation 9 surrounds the connection cover 5 . The end wall 8 carries a seal 10 which rests against the base part when the filter cartridge 1 is screwed on via the screw connection 6 . The perforations 9 on the connection cover 5 are arranged distributed on the circumference. The screw connection 6 surrounds a perforation 11 . The filter cartridge 1 is substantially rotationally symmetrical with respect to the center axis 12 . Compressed air to be cleaned from a compressor (not shown) flows in according to arrow 13 through the perforatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com