Plumbing pipe fitting cutting device

A technology of cutting device and pipe fittings, which is applied in the field of plumbing, can solve the problems of short service life of blades, waste of raw materials, and inability to dissipate heat, and achieve the effects of speeding up work efficiency, improving product quality, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

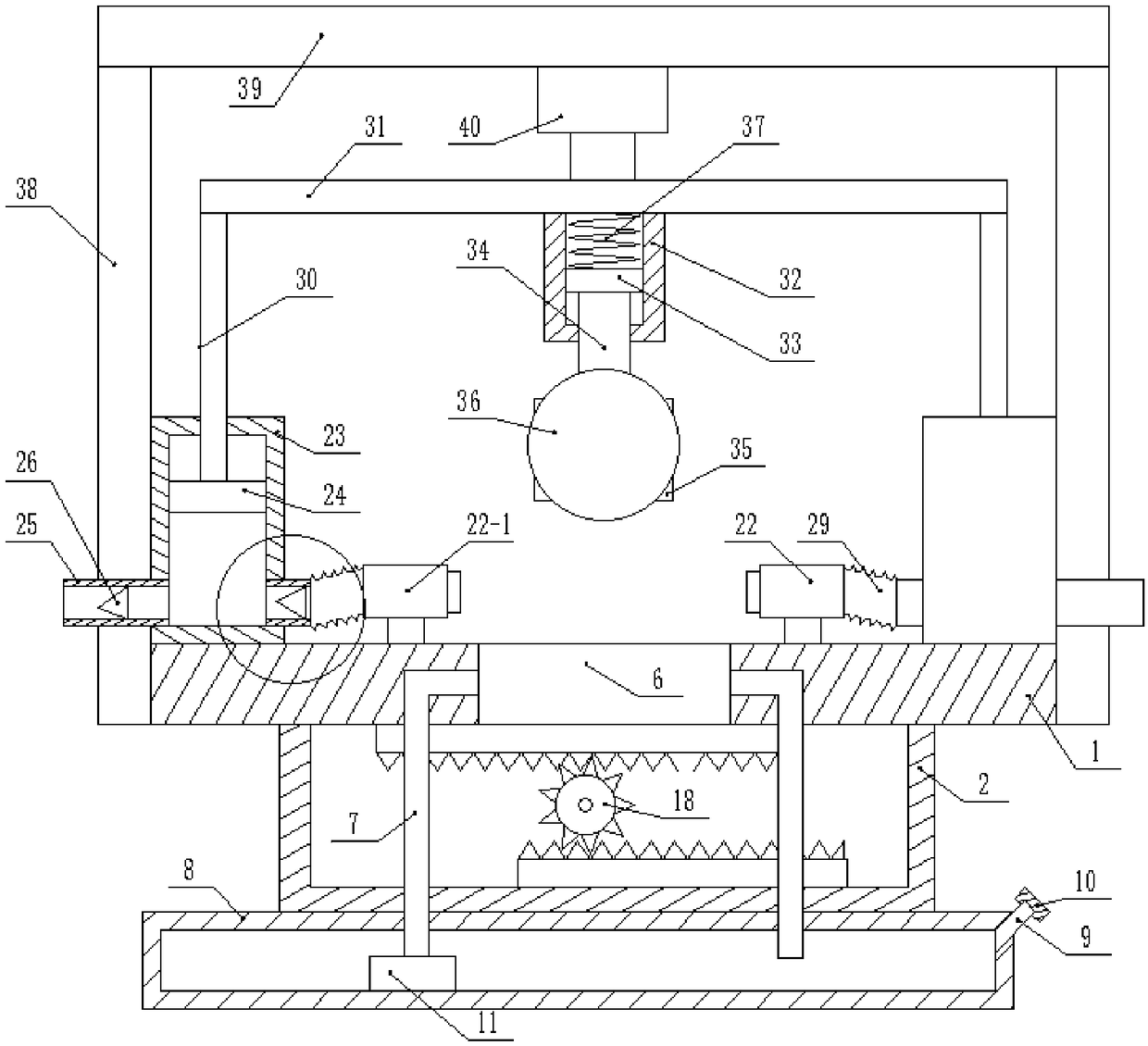

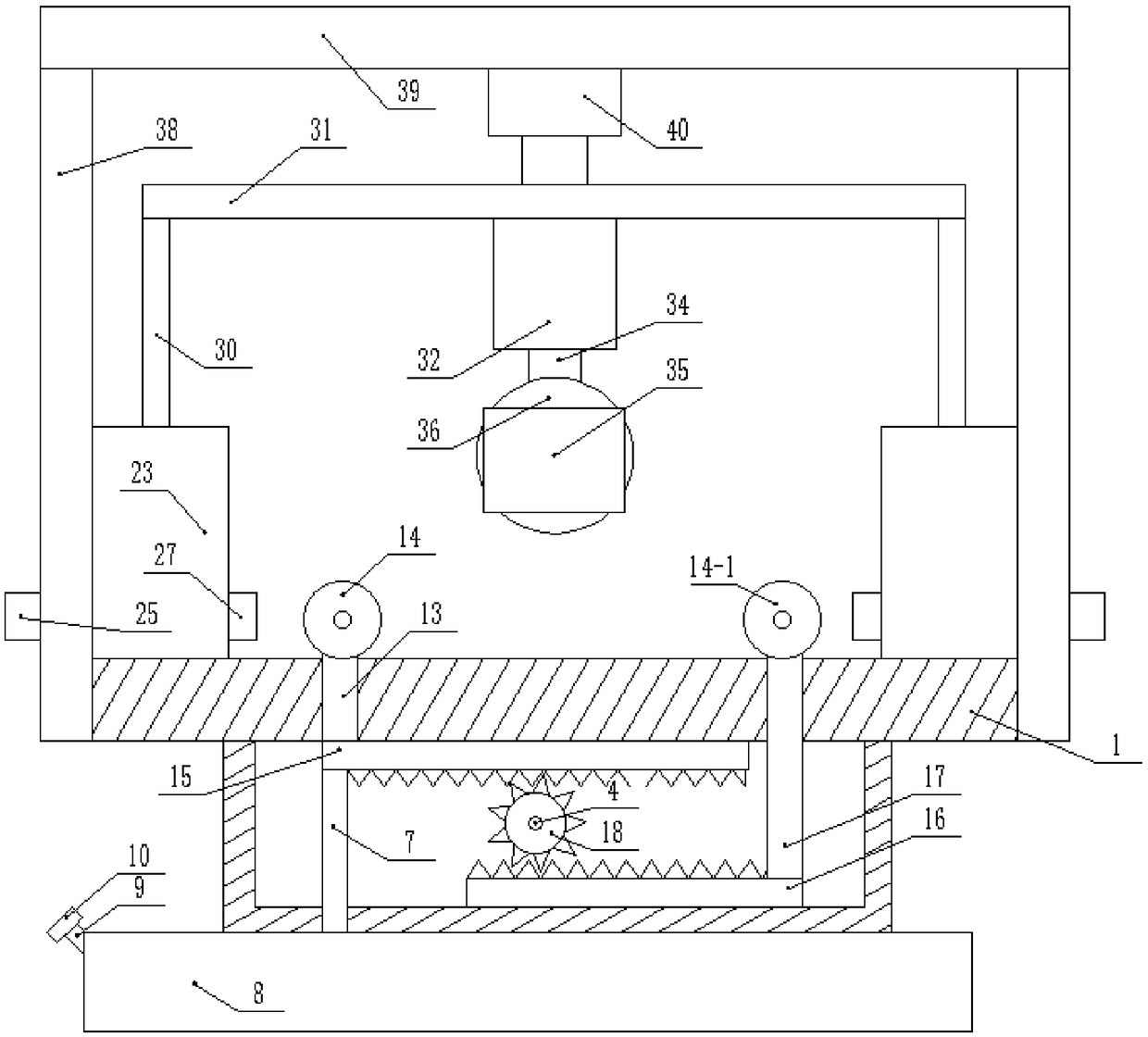

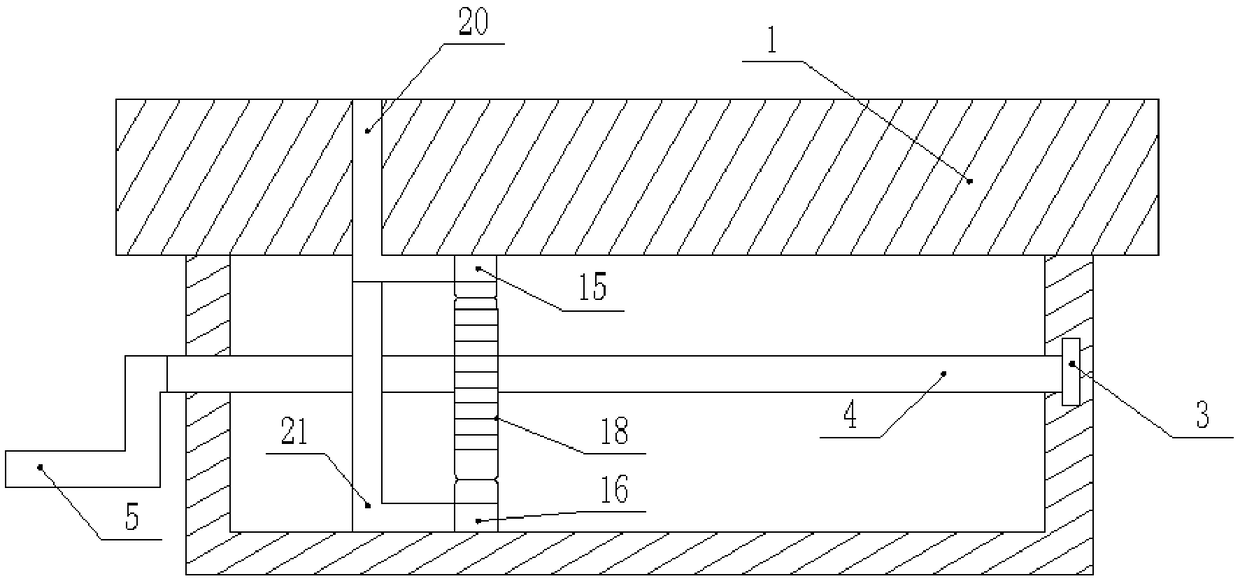

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a plumbing pipe fitting cutting device includes a workbench 1, a cover body 2 is fixedly connected to the ground of the workbench 1, and a rotating block 3 is embedded in a side wall of the cover body 2, and the rotating block 3 and the cover body 2 rotating connection, the side wall of the rotating block 3 is fixedly connected with a rotating rod 4, the other end of the rotating rod 4 penetrates the cover body 2 and then goes out of the cover body 2 and is fixedly connected with a handle 5, the top surface of the workbench 1 A cutting box 6 is fixedly embedded, and the top surface of the cutting box 6 is on the same plane as the workbench 1. The cutting box 6 and the two side walls are fixed and symmetrically connected with water pipes 7, and the bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com