Integrated oily mud wastewater pipe bundle coagulation and separation reactor

A technology for reactors and wastewater, applied in liquid separation, separation methods, flocculation/sedimentation water/sewage treatment, etc., to achieve the effects of low energy consumption, convenient installation and use, and less land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

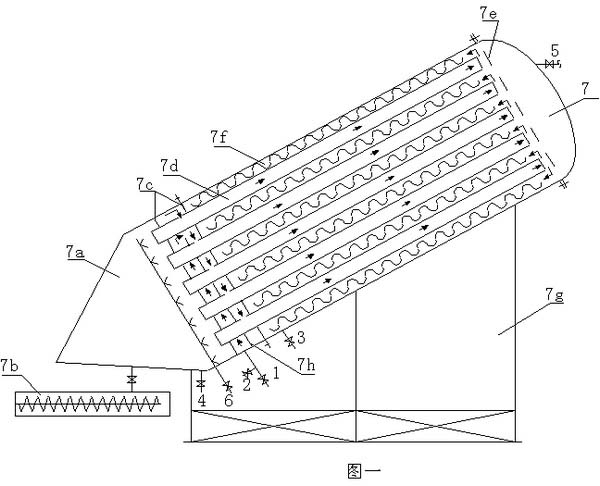

[0032] The present invention will be described in detail below with reference to the accompanying drawings.

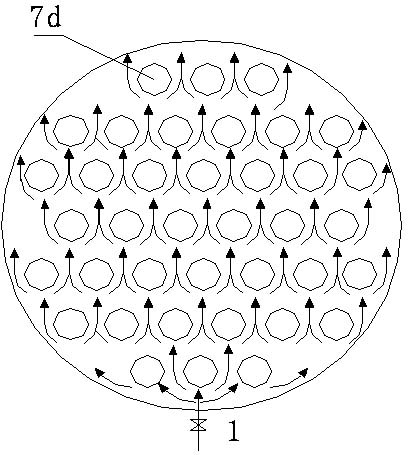

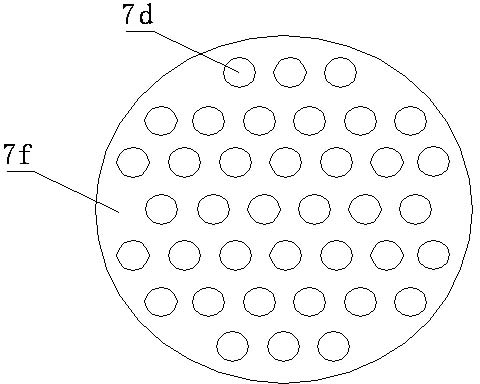

[0033] Integrated coagulation and separation reactor of oily sludge wastewater tube bundle, including reactor main body 7, water inlet pipe 1, dosing pipe 2, water outlet pipe 3, emptying pipe 4, oil collection pipe 5, and compressed air purge pipe 6 arranged on the main body The interior of the reactor mainly includes a mud storage area 7a, a screw conveying mud discharge device 7b, a water retaining plate 7c, a tube bundle sedimentation area 7d, a water distribution plate 7e, a fiber bundle coagulation coarse-graining area 7f, a bracket 7g, and a water baffle 7h, like figure 1 shown.

[0034] The specific working principle is as follows. Wastewater containing mud, sand and oil enters the reactor main body 7 through the water inlet pipe 1. The sewage is blocked by the water baffles 7c at the upper and lower ends. Enter the tube bundle sedimentation zone 7d, during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com