Atmospheric corrosion sensor and manufacturing method thereof

A technology for atmospheric corrosion and sensors, applied in weather resistance/light resistance/corrosion resistance, instruments, scientific instruments, etc., can solve problems such as excessive spacing, lack of high-sensitivity atmospheric corrosion sensors, poor sensitivity, etc., to prolong life and avoid crossover Contamination, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

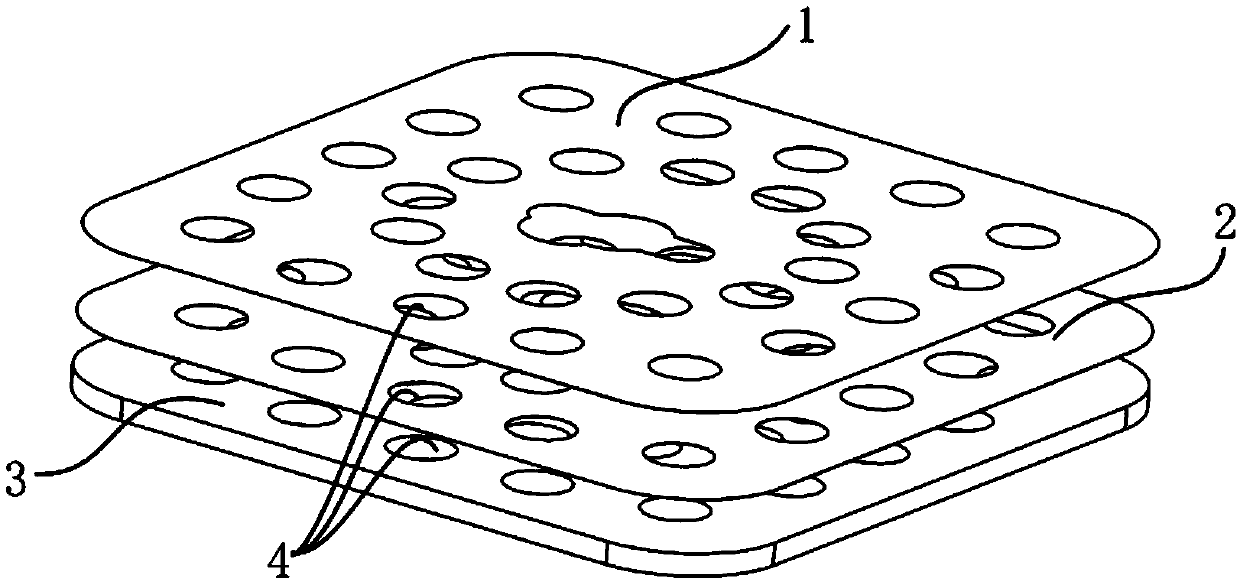

[0052] The anode material layer is a thin sheet made of metal zinc with a purity of more than 99.95%, with a thickness of 1mm.

[0053] The cathode material layer is a thin sheet made of metallic platinum with a purity of more than 99.9%, with a thickness of 50 μm.

[0054] The insulating material layer is a PET film with glue on the front and back sides with a total thickness of 10 μm. Wherein, the PET film is a polyethylene terephthalate film with a thickness of 5 μm, and acrylic glue with a thickness of 2.5 μm is respectively arranged on the front and back sides of the PET film, so that the total thickness of the insulating film is 10 μm. The main components of acrylic glue include acrylic acid with a mass fraction of 30%, sodium lauryl sulfate with a mass fraction of 15%, ethyl acetate with a mass fraction of 10%, and dibenzoyl peroxide with a mass fraction of 25%. And butyl acrylate with a mass fraction of 20%.

[0055] The above-mentioned cathode material layer, insula...

Embodiment 2

[0061] The anode material layer is a sheet made of metal copper with a purity of more than 99.9%, with a thickness of 1.5mm.

[0062] The cathode material layer is a thin sheet made of metal gold with a purity of more than 99.9%, and the thickness is 30 μm.

[0063] The insulating material layer is a PET film with glue on the front and back sides with a total thickness of 5 μm. Wherein, the PET film is a polyethylene terephthalate film with a thickness of 2.5 μm, and acrylate glue with a thickness of 1.25 μm is arranged on the front and back sides respectively, so that the total thickness of the insulating film is 5 μm. The main components of acrylic glue include acrylic acid with a mass fraction of 30%, sodium lauryl sulfate with a mass fraction of 15%, ethyl acetate with a mass fraction of 10%, and dibenzoyl peroxide with a mass fraction of 25%. And butyl acrylate with a mass fraction of 20%.

[0064] The above-mentioned cathode material layer, insulating material layer an...

Embodiment 3

[0070] The anode material layer is a thin sheet made of metallic zinc with a purity of more than 99.95%, with a thickness of 2mm.

[0071] The cathode material layer is a thin sheet made of metallic platinum with a purity of more than 99.9%, with a thickness of 50 μm.

[0072]The insulating material layer is a PET film with glue on the front and back sides with a total thickness of 30 μm. Wherein, the PET film is a polyethylene terephthalate film with a thickness of 15 μm, and acrylic glue with a thickness of 7.5 μm is arranged on the front and back sides of the PET film, so that the total thickness of the insulating film is 30 μm. The main components of acrylic glue include acrylic acid with a mass fraction of 30%, sodium lauryl sulfate with a mass fraction of 15%, ethyl acetate with a mass fraction of 10%, and dibenzoyl peroxide with a mass fraction of 25%. And butyl acrylate with a mass fraction of 20%.

[0073] In this embodiment, the above materials are used to manufact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com