Method for load limitation in drive systems for a high lift system for aeroplanes

A driving system and load technology, which is applied to indicate the direction of the aircraft's movable elements, aircraft parts, aircraft indicating devices, etc., and can solve the problems of increased mass, operating costs, and complex structures of the aircraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

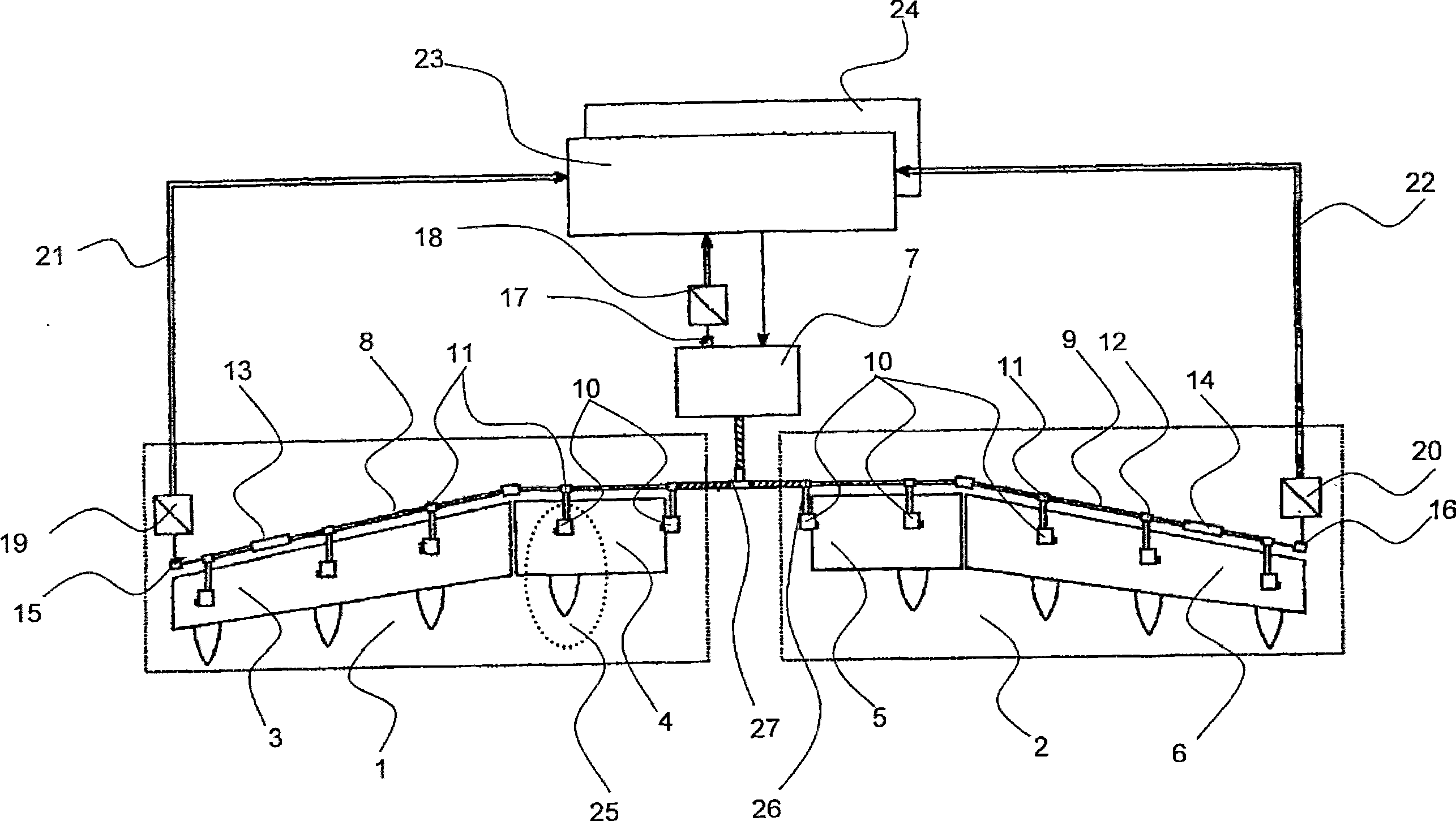

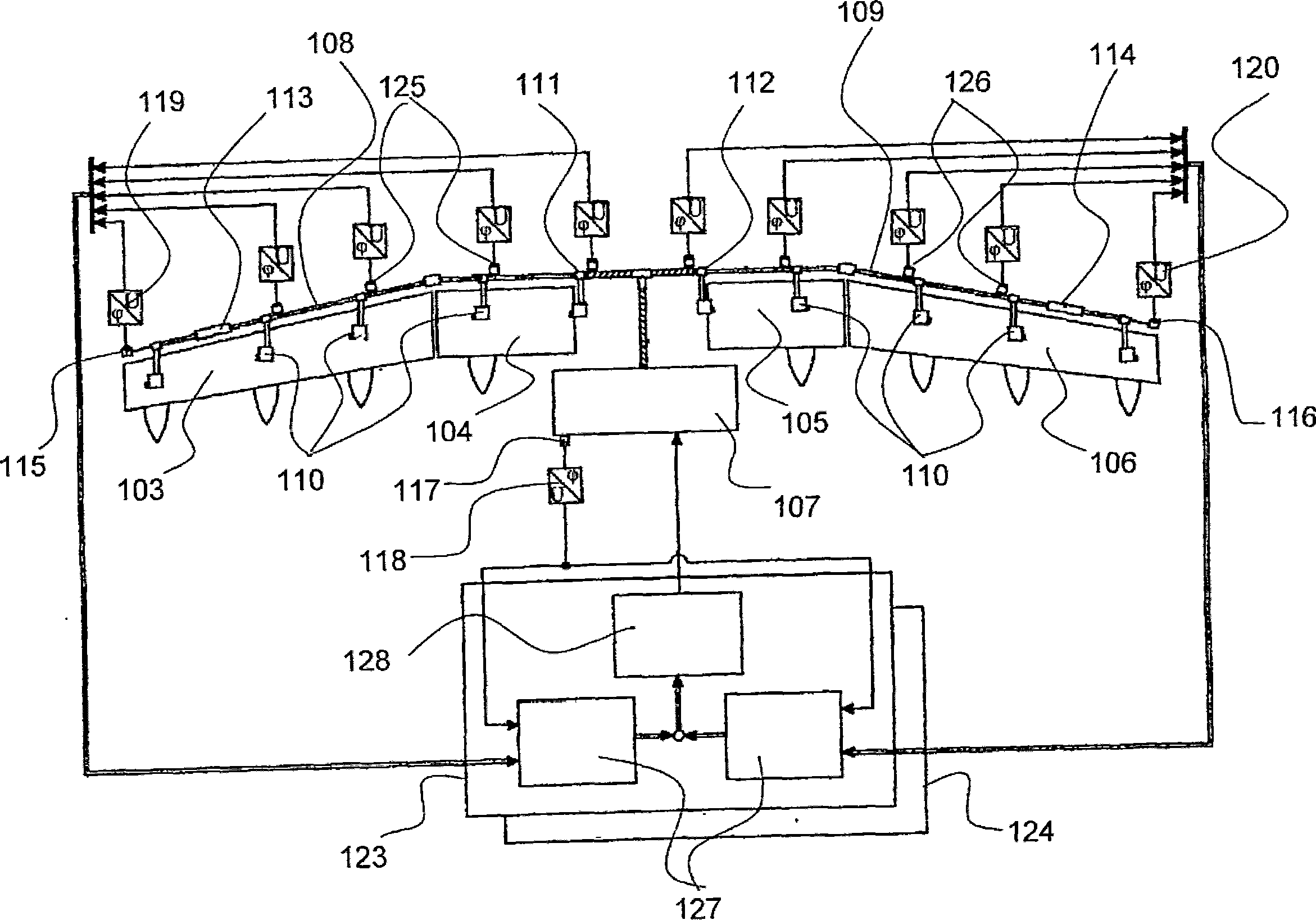

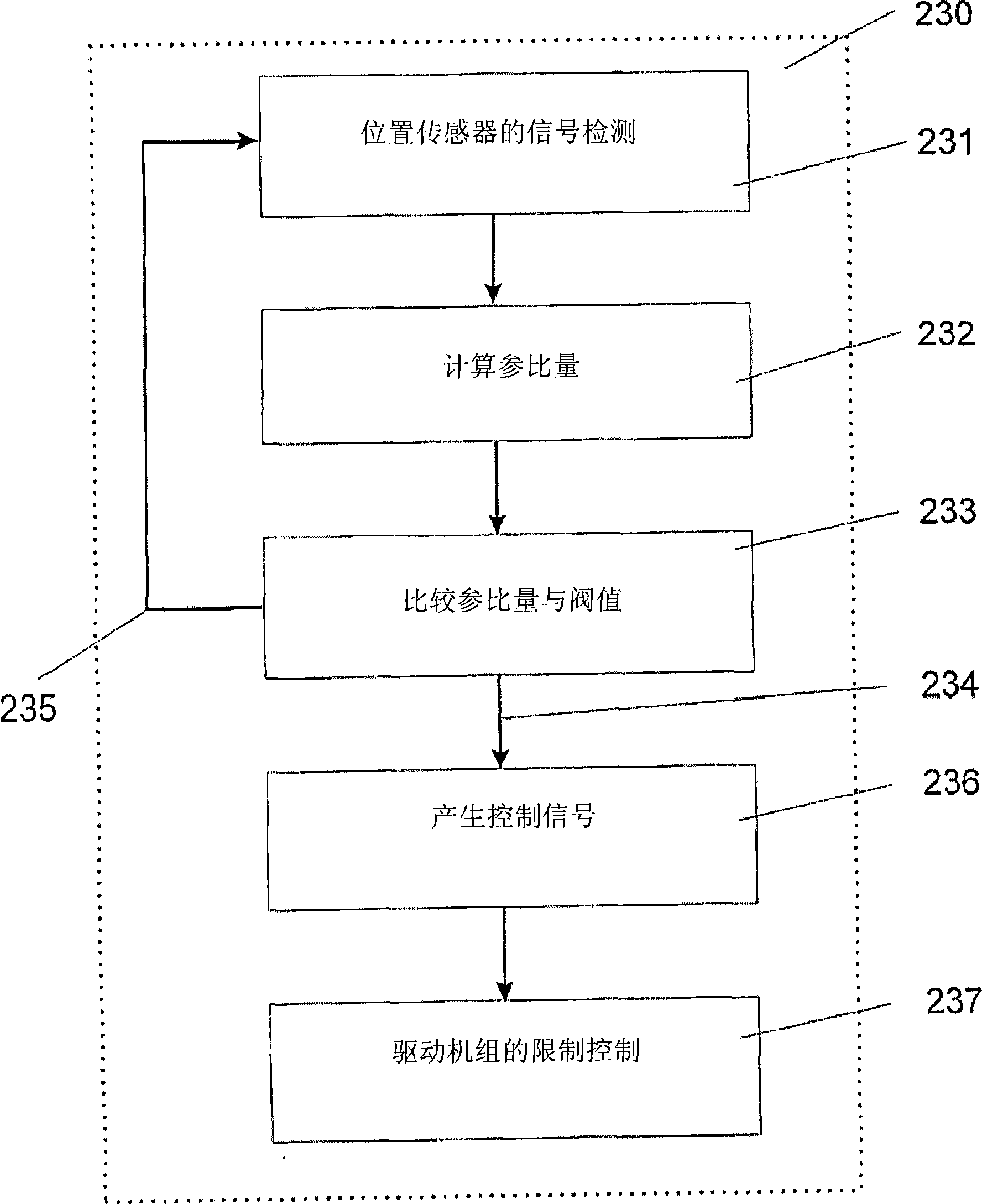

[0012] figure 1 The landing flap actuation system shown is equipped with an electronically adjustable overload protector instead of a conventional mechanical load limiter. Here, the drive system comprises left and right wing subsystems 1, 2, which are respectively used to drive two high-lift flaps 3, 4 and 5, 6, which are arranged on the rear edge of the wing. The structures of the two subsystems 1 and 2 here are symmetrical to each other. The mechanical power necessary to position the flaps 3 to 6 is provided by the central drive unit 7 and transmitted to a series of mechanical actuators 10 in the two wings via drive chains 8, 9, respectively, wherein the central drive unit 7 Power can be controlled in a highly dynamic manner.

[0013] They each also include branch transmissions 11 , 12 . Each drive station 25 is connected to the drive chain 8 through its respectively configured branch transmission mechanism 11 . Furthermore, hydraulically actuated brakes 13 , 14 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com