High purity hafnium, target and thin film comprising said high purity hafnium, and method for producing high purity hafnium

A manufacturing method and high-purity technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problem of difficult to effectively remove impurities, no effective and stable high-purity hafnium material manufacturing technology, no separation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

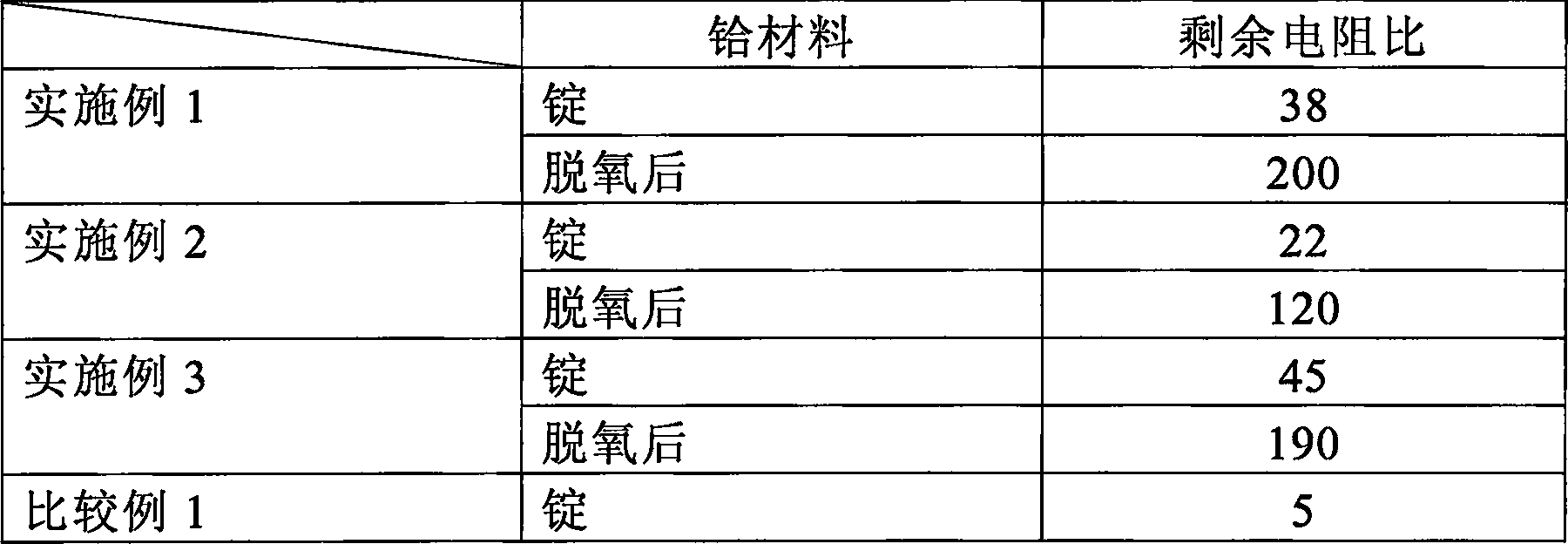

Embodiment 1

[0038] Commercially available hafnium tetrachloride (HfCl) of purity 3N containing about 5000 ppm by weight of zirconium as shown in Table 1 was used. 4 ) 100kg as a raw material, it was dissolved in 1L of pure water to make a nitric acid solution.

[0039] as HfCl 4 The main impurities in the raw material contain iron, chromium and nickel at 500 ppm by weight, 40 ppm by weight and 1000 ppm by weight, respectively.

[0040] Then, the hafnium raw material (nitric acid solution) was extracted with a 4-stage organic solvent using TBP organic solvent, and neutralized to obtain hafnium oxide (HfO 2 ).

[0041] In addition, the hafnium oxide is chlorinated to obtain high-purity hafnium tetrachloride (HfCl 4 ), followed by magnesium reduction to obtain hafnium sponge as a raw material. The hafnium sponge contained 300 ppm by weight of zirconium, and the total content of other impurities was reduced to 300 ppm by weight.

[0042] Then, using the obtained hafnium sponge as a raw m...

Embodiment 2

[0049] 100 kg of zirconium metal raw material (zirconium content 2% by weight) shown in Table 2 was used and dissolved in nitric acid-hydrofluoric acid. As main impurities of the raw material, the raw material contained 15000 ppm by weight, 8000 ppm by weight and 5000 ppm by weight of iron, chromium and nickel, respectively.

[0050] Then, use TBP organic solvent to carry out 10 stages of organic solvent extraction on the hafnium raw material, and carry out neutralization treatment to obtain hafnium oxide (HfO 2 ).

[0051] In addition, the hafnium oxide is chlorinated to obtain high-purity hafnium tetrachloride (HfCl 4 ), followed by calcium reduction to obtain hafnium sponge. The hafnium sponge contained 1500 ppm by weight of zirconium, and the total content of other impurities was reduced to 1000 ppm by weight.

[0052] Then, using the obtained hafnium sponge as a raw material, further two-stage melting was performed by furnace melting and ingot melting using an electron...

Embodiment 3

[0058] Zirconia (HfO 2 ) raw material (3N level) 100kg and dissolved in nitric acid-hydrofluoric acid. As main impurities of the raw material, the raw material contained 15000 ppm by weight, 8000 ppm by weight and 5000 ppm by weight of iron, chromium and nickel, respectively.

[0059] Alternatively, the hafnium oxide raw material is chlorinated and purified by at least 10 stages of distillation followed by sodium reduction.

[0060] Then, using the obtained hafnium as a raw material, further two-stage melting is performed by furnace melting and ingot melting using an electron beam to remove volatile elements, gas components, and the like. Due to the above process, as shown in Table 3, Zr: 500 wtppm, O: 100 wtppm, C: 100 wtppm, N: 20 wtppm, S: 10 wtppm, P: 10 wtppm, others: 30 ppm by weight.

[0061] Then, using Ca and CaCl 2 The hafnium thus obtained was deoxidized at 1250° C. under argon pressure (4 atm) for 10 hours. Reductions were achieved where O, C, N, S, P < 10 wtp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com