Aldehyde-free cement for wood-based panel

A technology of adhesives and wood-based panels, applied in the field of resin adhesives, can solve problems such as endangering the health of operators, high concentration of formaldehyde, irritating eyes and respiratory system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

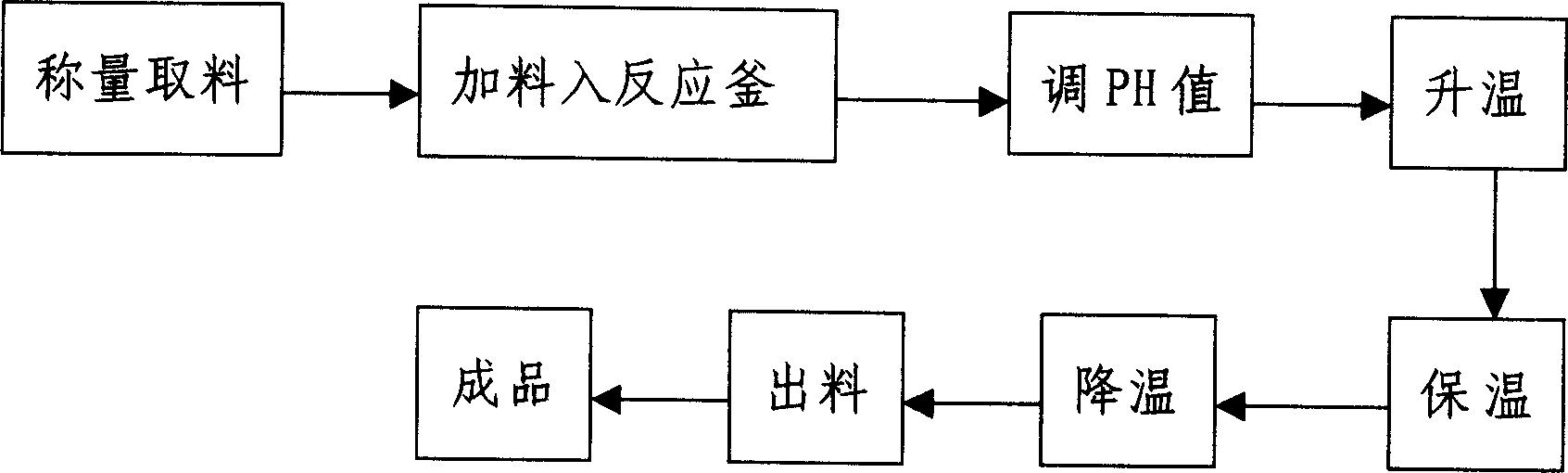

[0006] Refer to attached figure 1 5-15% of polyvinyl alcohol, 8-15% of YH-complexing agent, 15-20% of oxidized starch, 8-20% of BPA cross-linking agent and 45-60% of water are taken by weight. Add the measured water and polyvinyl alcohol into the reaction kettle, heat up and dissolve, keep it at 85-80°C for 1 hour, then lower it to 65°C, add oxidized starch and YH-1 complexing agent, and adjust the pH value to 5.0-6.0 , the temperature rises to 70-75°C for heat preservation reaction, about 0.5 hours to the end of the reaction, cools down to 50°C, adds BPA crosslinking agent, heats the reaction for 40 minutes, until it is completely emulsified, adjusts the pH value to 6.0-7.0, and the temperature drops to 40°C After discharging, the formaldehyde-free adhesive for wood-based panels of the present invention is obtained. Appearance of the present invention: pale yellow homogeneous liquid without impurities. The pH value is 7.0, the viscosity is 660cp, no free formaldehyde, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com