High Cr series stainless steel jointless oil well tube and its production method

A production method and technology for oil well pipes, which are applied in the field of stainless steel oil well pipes and their manufacturing, can solve problems such as difficulty in achieving results, reduced material toughness, etc., and achieve the effects of low manufacturing cost, easy operation, and good CO2 corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

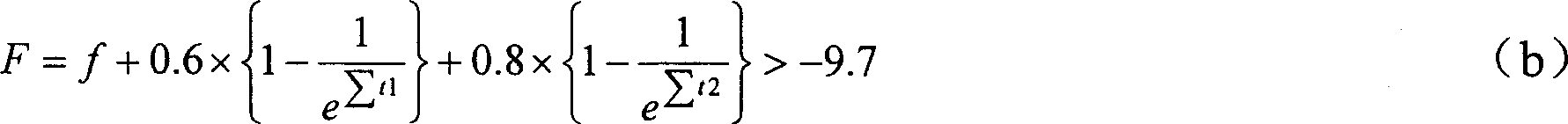

Method used

Image

Examples

Embodiment 1

[0027] Φ139.7×9.17mm WSP13Cr casing of 110KSI steel grade.

[0028] ①The steel composition (mass percentage) of the tubing is: C 0.02-0.05, Si 0.3-0.5, Mn0.25-1.0, Cr 12.0-14.0, S<0.010, P<0.015, Ni 3.0-6.0, Mo 1.0- 2.0, Cu≤0.25, Al 0.02-0.04, Ti 0.01-0.06, Nb 0.01-0.04, V≤0.06, and the rest is Fe.

[0029] ② The molten steel containing the above components is decarburized and refined to make a steel billet. The seamless steel pipe is hot rolled into a seamless steel pipe by a limited mandrel rolling mill. No lubricant is used between the rolling head and the billet during rolling, but the material used in the rolling head is (mass percentage): C 0.30, Si 0.30, Mn 0.40, Cr 0.40 , Ni 1.00, Nb 0.45, Mo 1.20, W 5.00, Co 1.20, and the rest is Fe.

[0030] ③ No lubricant is used between the roll and the billet during rolling. In order to overcome the gnawing phenomenon caused by sliding between the perforated roll and the rolled material, an anti-slip agent is required. The anti...

Embodiment 2

[0034] 95KSI steel grade Φ177.8×11.51mm WSP13Cr casing.

[0035] The steel composition (mass percentage) of the bushing is: C 0.15-0.20, Si 0.3-0.6, Mn 0.4-0.75, Cr 12.0-14.0, S<0.010, P<0.015, Ni 3.0-4.0, Cu≤0.25, Al 0.02-0.04, Ti0.01-0.06, V≤0.06, and the rest is Fe.

[0036] Except for ingredients, other manufacturing steps and methods are the same as in Example 1.

[0037] The 95 steel grade WSP13Cr bushing produced by the method has a yield strength of 655-758Mpa, a tensile strength greater than 724Mpa, and a strength index meeting API requirements for C95 / T95 steel grade bushings. This bushing can meet CO 2 The exploitation needs of oil fields and natural gas fields of gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com