Lifting type valve mechanism for motorcycle engine

A gas distribution mechanism and engine technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of increasing engine noise, adding engine noise and vibration, affecting engine power, etc., and achieving the effect of increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

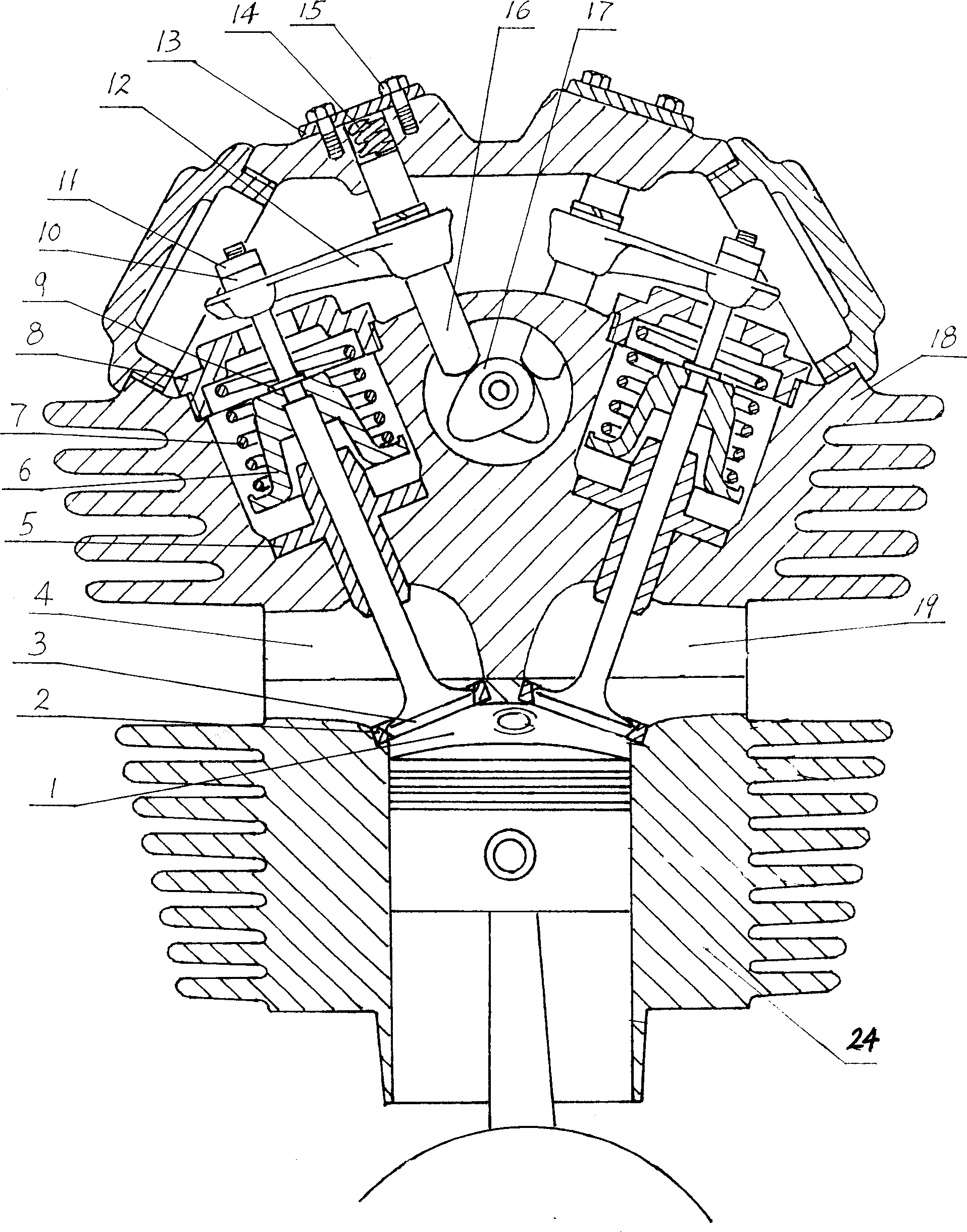

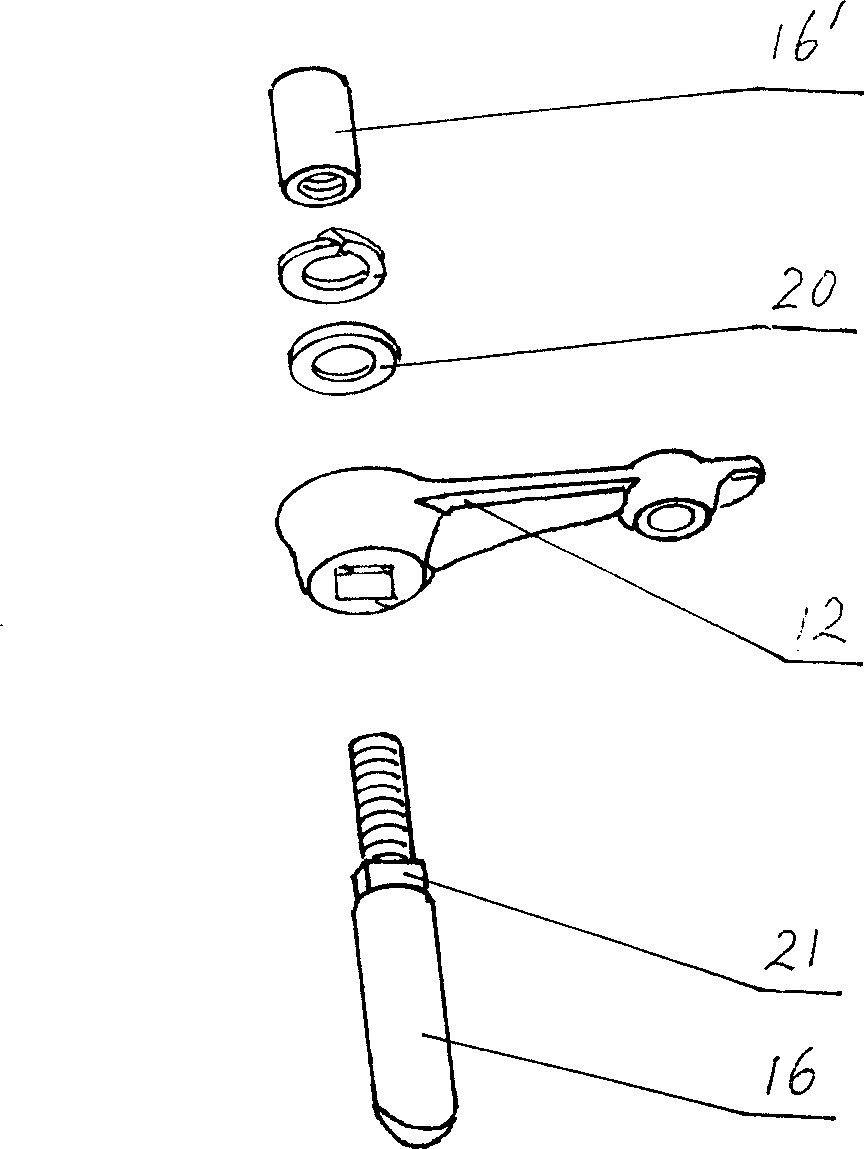

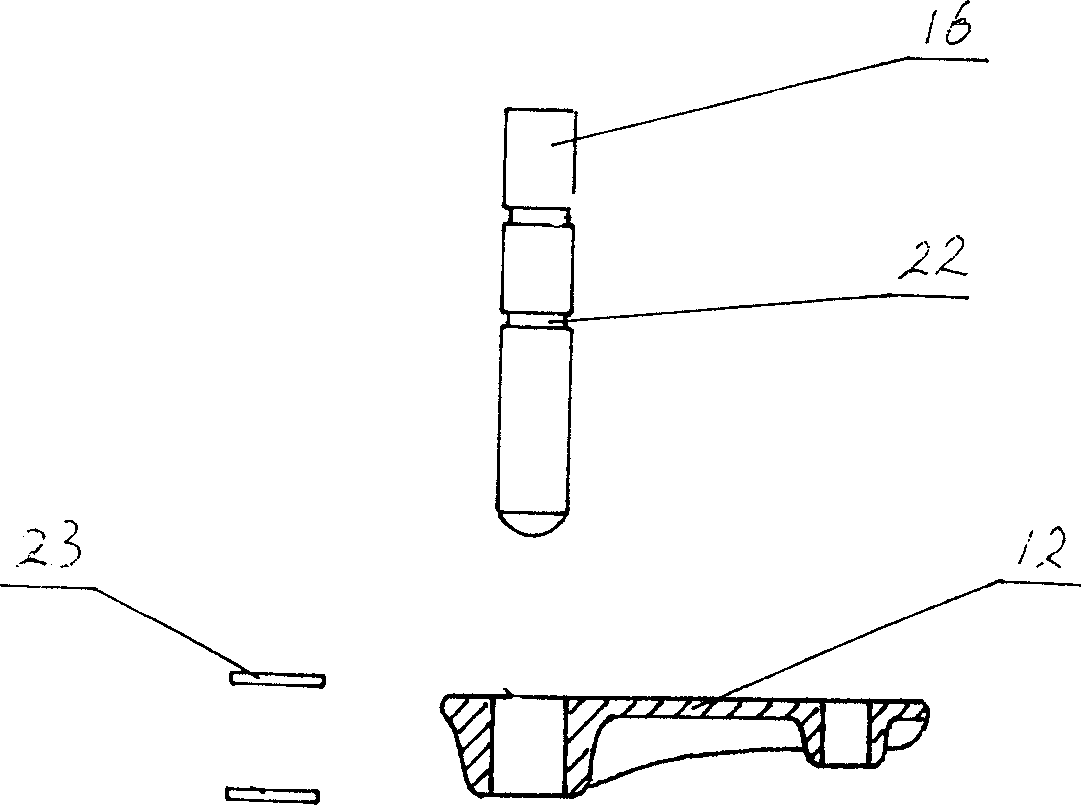

[0016] see figure 1 , This embodiment is an embodiment in which the valve train is installed on the cylinder where the junction between the cylinder head 18 and the cylinder block 24 is located at the intake and exhaust passages. The rod portion of the valve 3 is reasonably clearance-fitted in the valve sleeve 5 that is press-fitted on the cylinder head 18, and the valve cone angle and the circumference of the lower end of the valve 3 head are fitted in the intake and exhaust ports of the combustion chamber 1 by interference. The working slope of the valve seat 2 of the mouth cooperates to form a seal, and the working slope of the valve seat 2 that cooperates with the valve is located at the intake and exhaust passages 4,19 one side. The upper part of the stem of the valve 3 is provided with a step and a ring groove, the spring bushing 6 is set on the stem of the valve 3, and is axially positioned on the stem of the valve 3 through the step and the retaining spring 9, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com