Rotary electric container conveying flat bogie

A technology for flatbed trolleys and containers, applied in the direction of motor vehicles, goods transport vehicles, transported objects, etc., can solve the problems of inability to turn in place, reduce production costs, damage to the terminal environment, and achieve semi-automation and full automation. and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

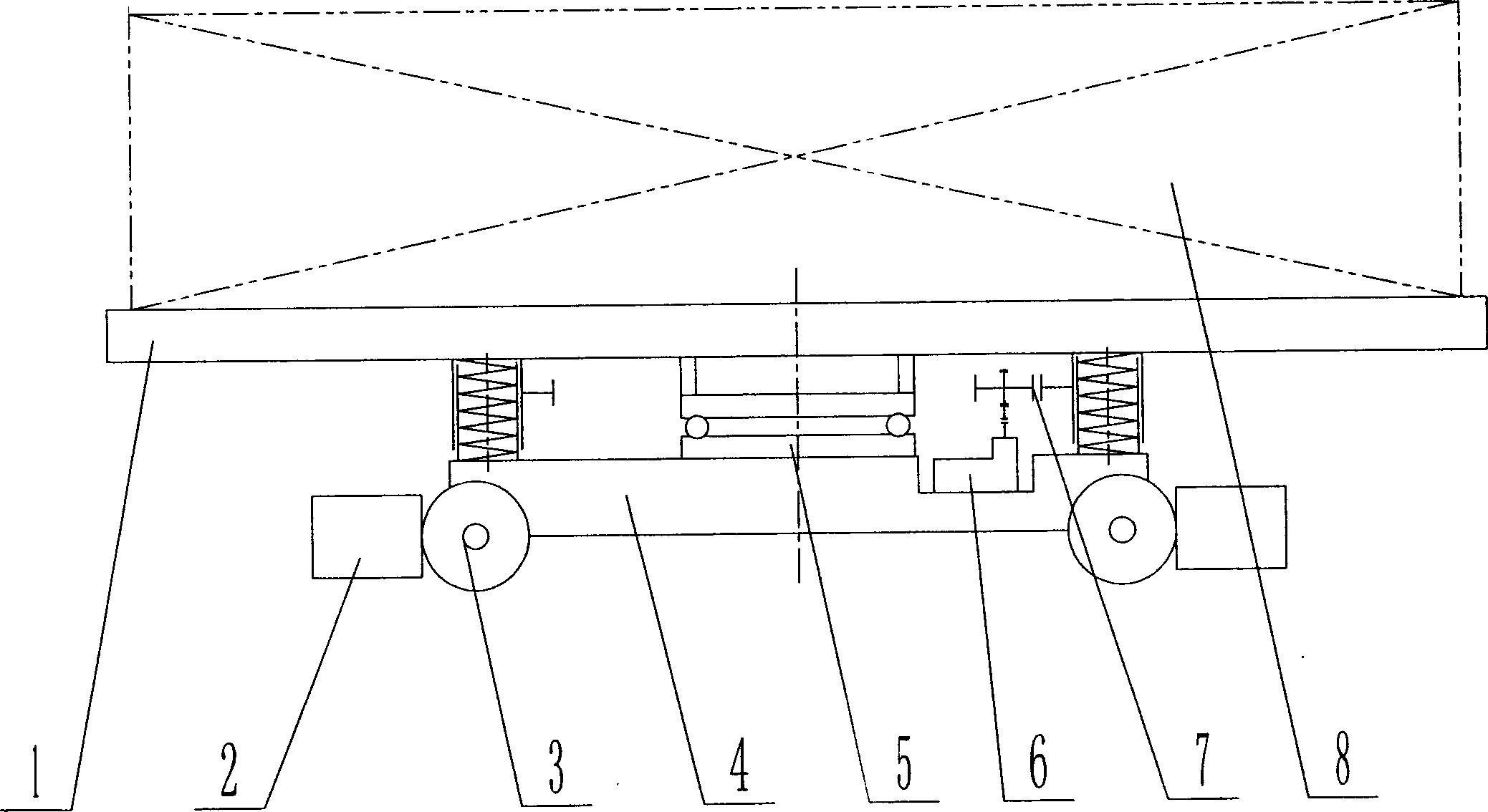

[0012] like figure 1 As shown, the rotary electric container conveying flat trolley of the present invention can run on the track, and its structure is as follows: an underframe 4 is provided, and the two sides of the underframe 4 are provided with wheel sets 3 that can slide on the track. The group 3 is provided with a wheel drive device 2 for driving the wheel group 3 to run. The slewing platform 1 is installed on the chassis 4 through the slewing support device 5. The slewing drive device 6 can drive the slewing mechanism 7, and the slewing mechanism 7 is connected to the slewing support device 5. And drive the operation of the slewing support device 5, so that the slewing platform 1 performs a slewing action on the underframe 4.

[0013] The slewing platform 1 is used to place containers 8. It can place single-row 20-inch containers, double 20-inch containers, 40-inch containers, and 45-inch containers. It can also place double-row 20-inch containers, double 20-inch contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com