Tilt drum washing machine with pulsation whell

A drum washing machine, tilting technology, applied to washing machines with containers, other washing machines, washing devices, etc., can solve the problems of difficult to obtain washing effect, inconvenient operation, etc., to improve washing effect, save water consumption, and improve satisfaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

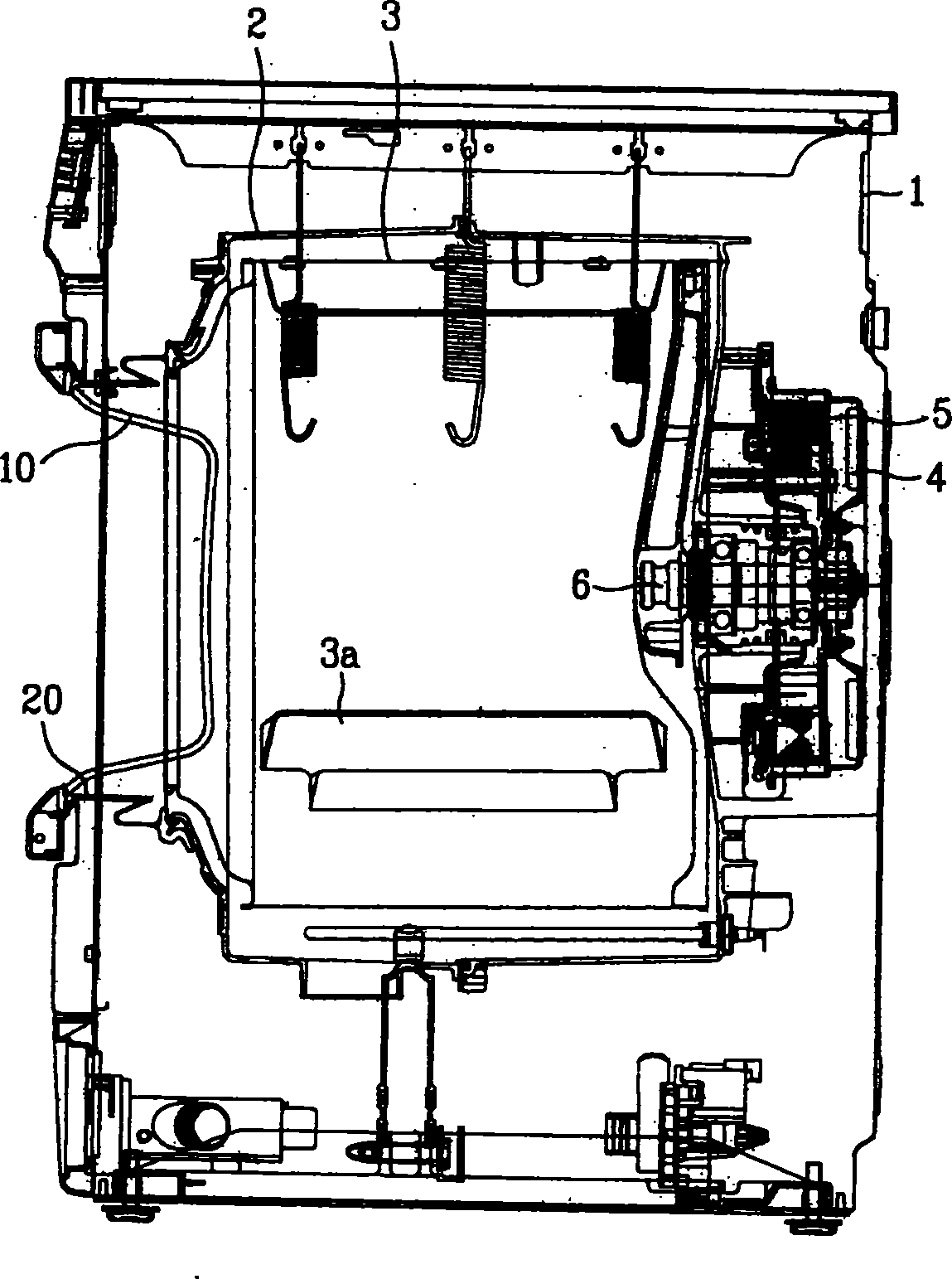

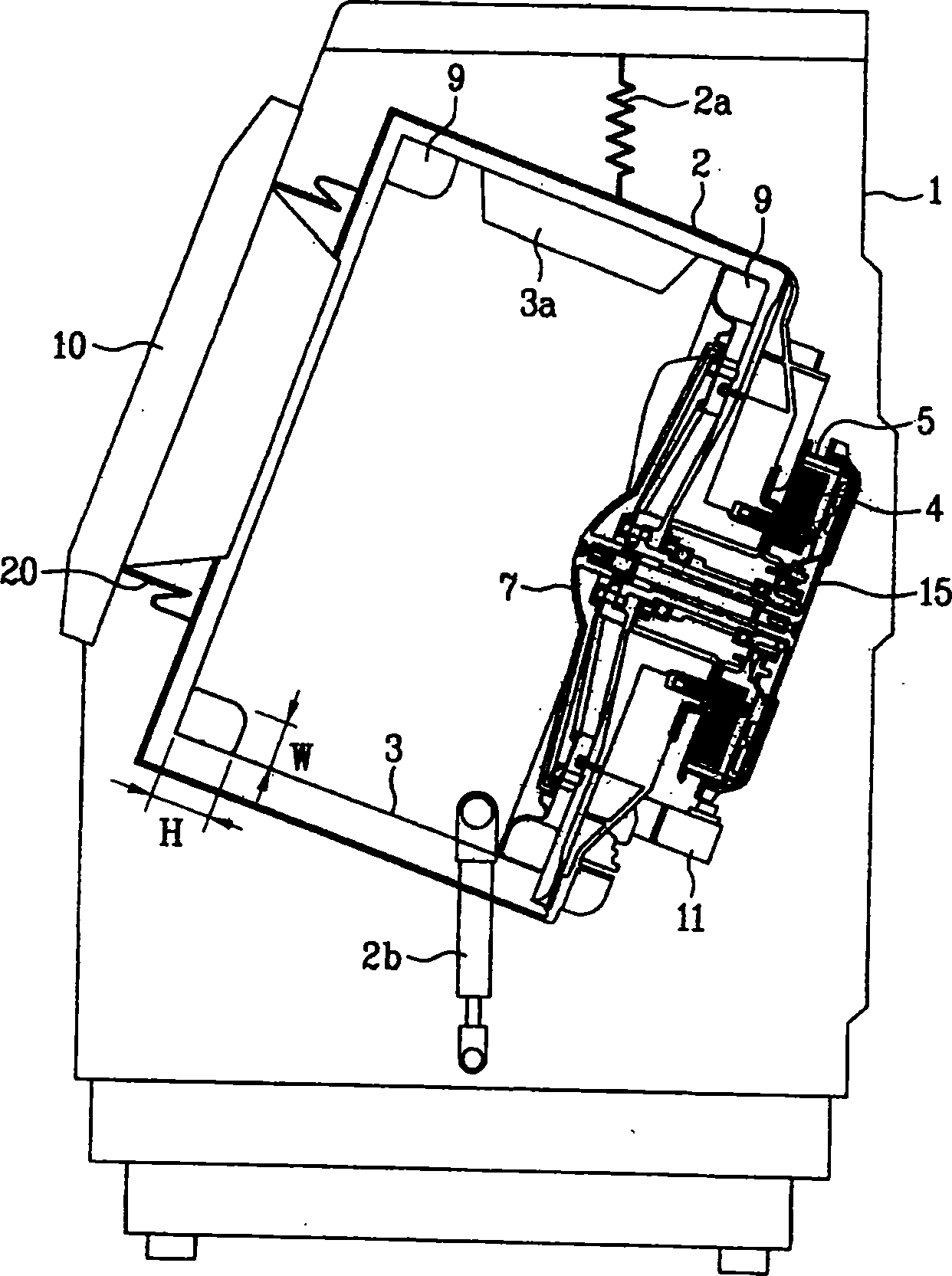

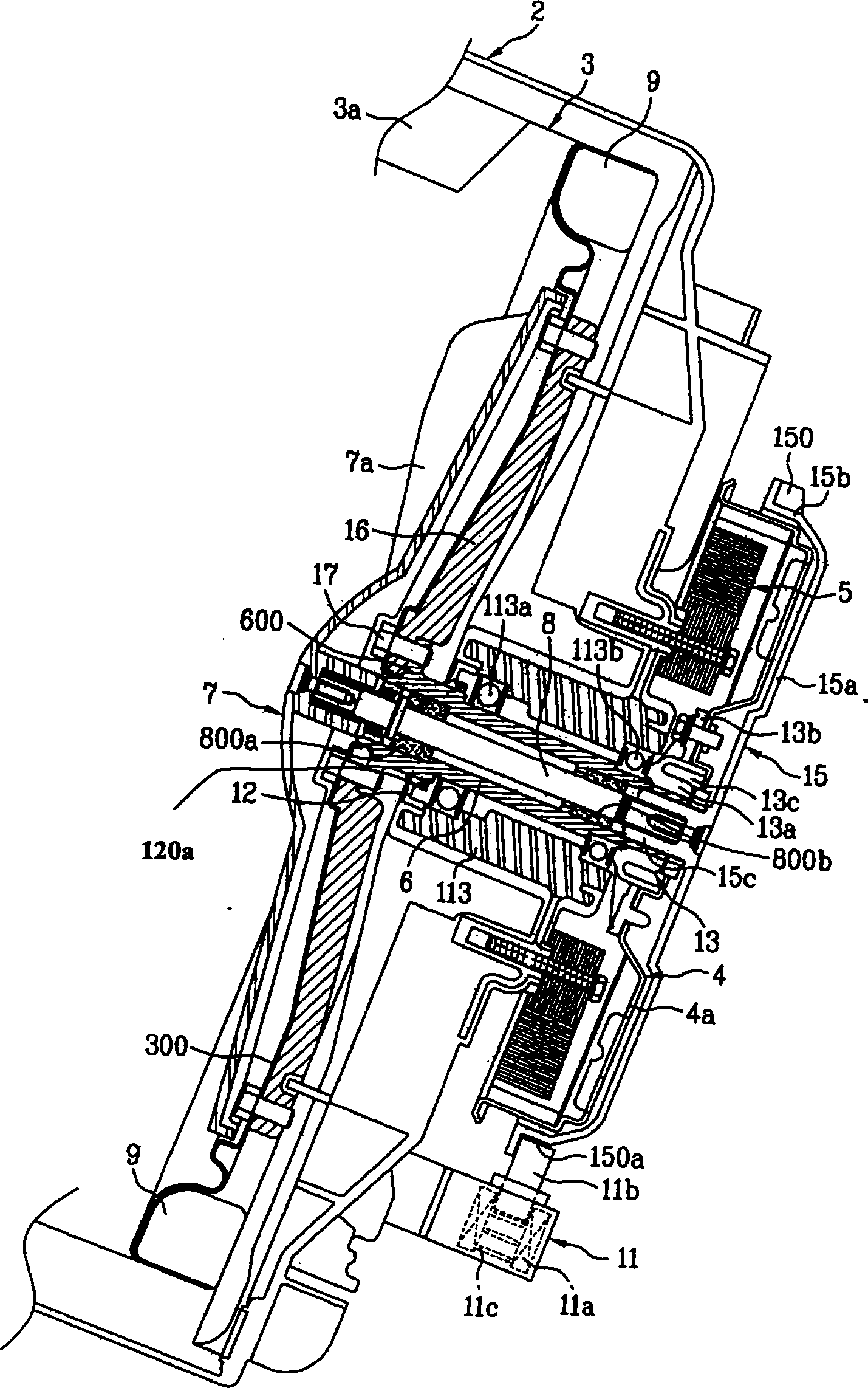

[0056] Such as Figure 2 to Figure 7 As shown, the inclined drum washing machine with a pulsator provided by the present invention includes: a plastic washing tub 2 with a side wall for storing washing water and assembling a driving part, and a certain inclination angle is formed between the front end and the bottom surface; The drum 3 is rotatably arranged inside the washing drum 2; the hollow drum shaft 6 that penetrates the washing drum 2 and is combined with the drum 3 in a shaft connection, so that the rotational power of the motor can be transmitted to the drum 3; can support the hollow drum More than one bearing 113a, 113b of the shaft 6; the bearing cover 113 capable of supporting the bearings 113a, 113b; the stator 5 assembled on the rear end face of the washing tub 2; The rotor 4 of the brush DC motor; it is rotatably arranged on the inner side of the drum 3, and its outer diameter is equivalent to the pulsator 7 of 50% to 80% of the inner diameter of the drum 3; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com