Inclined rotary drum washing and drying machine with pulsative wheel

A drum washing machine, tilting technology, applied in the field of drum washing machines, can solve the problems of inconvenient operation and difficulty in obtaining washing performance, and achieve the effects of saving water consumption, improving drying efficiency and drying performance, and improving laundry performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

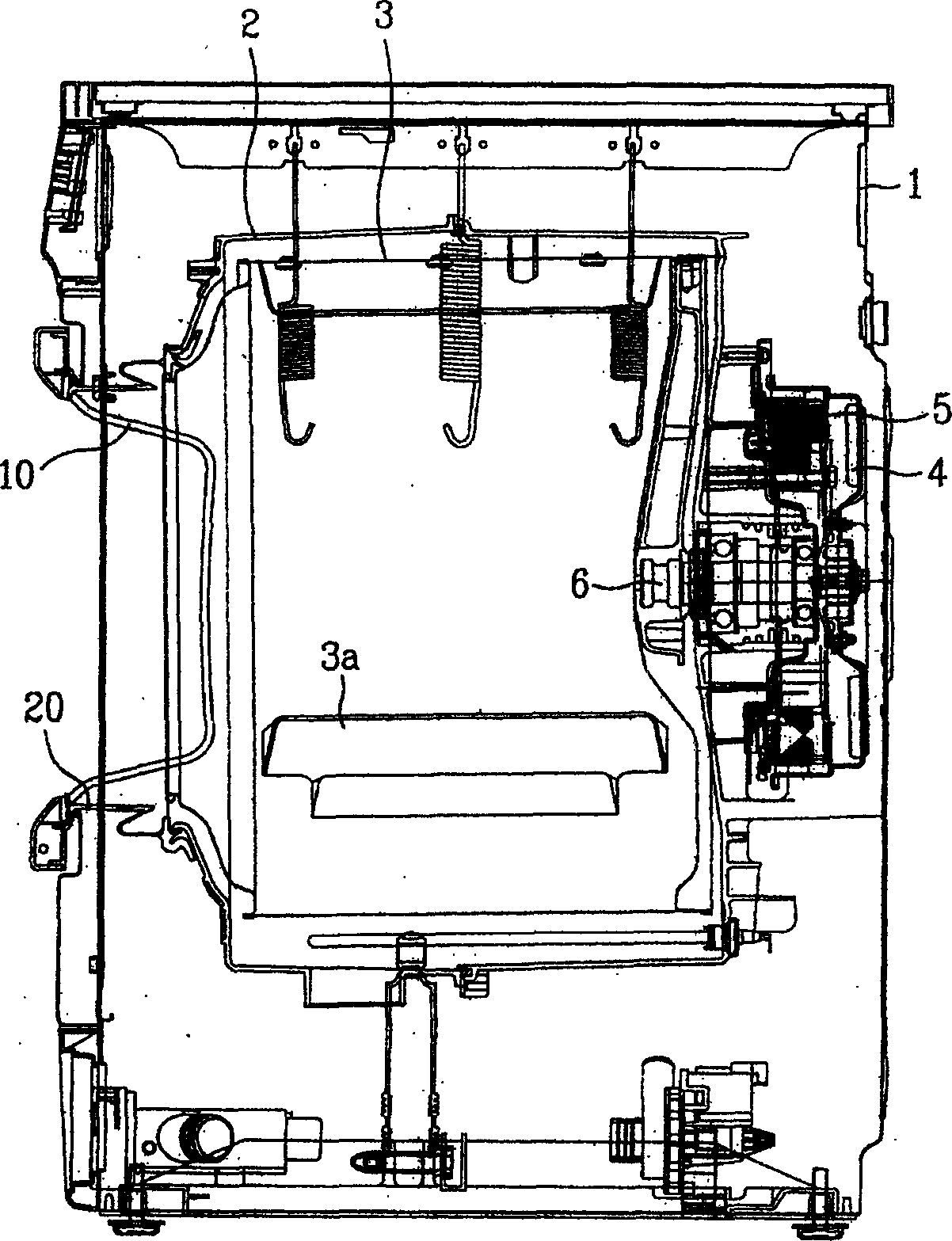

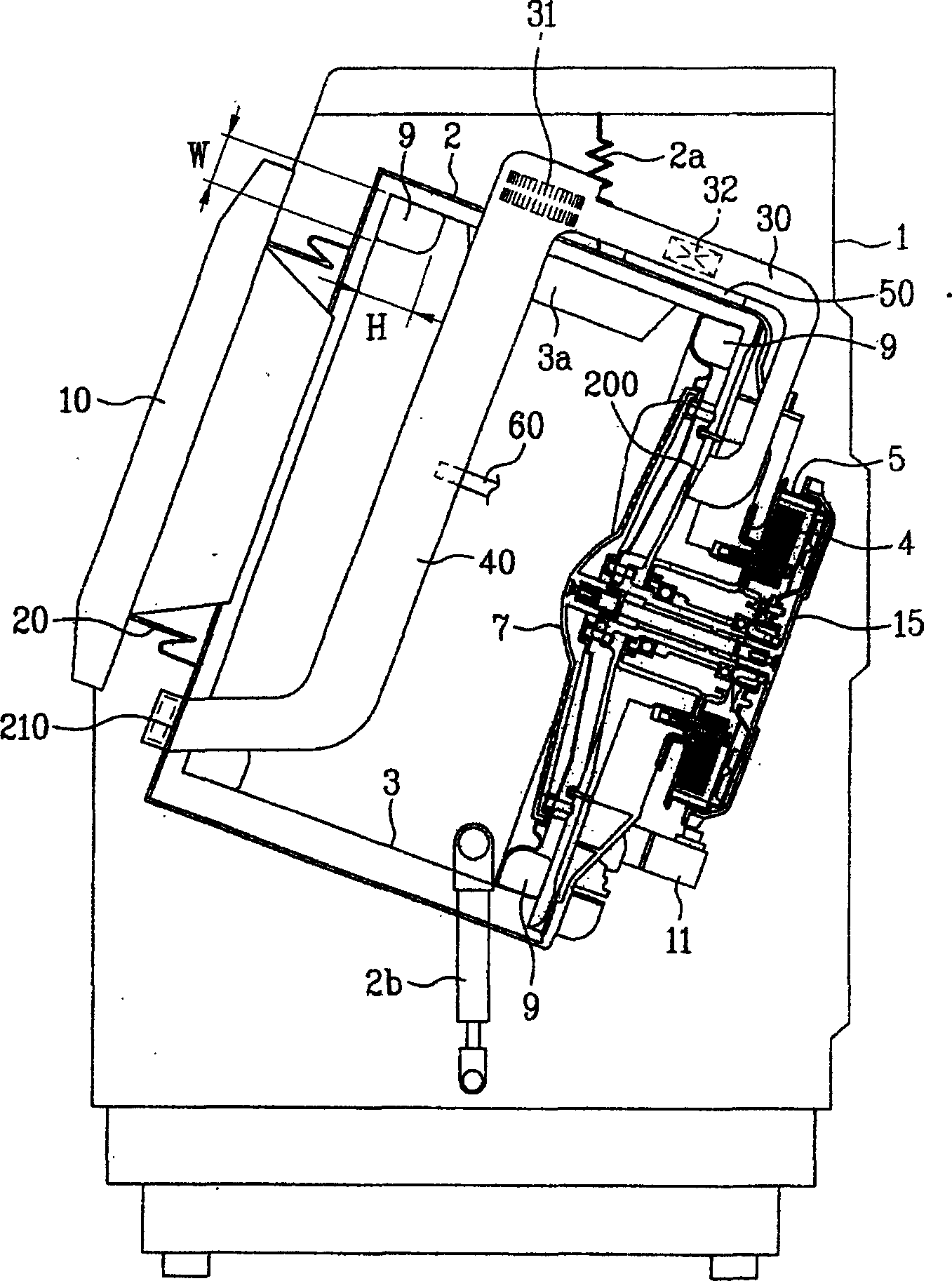

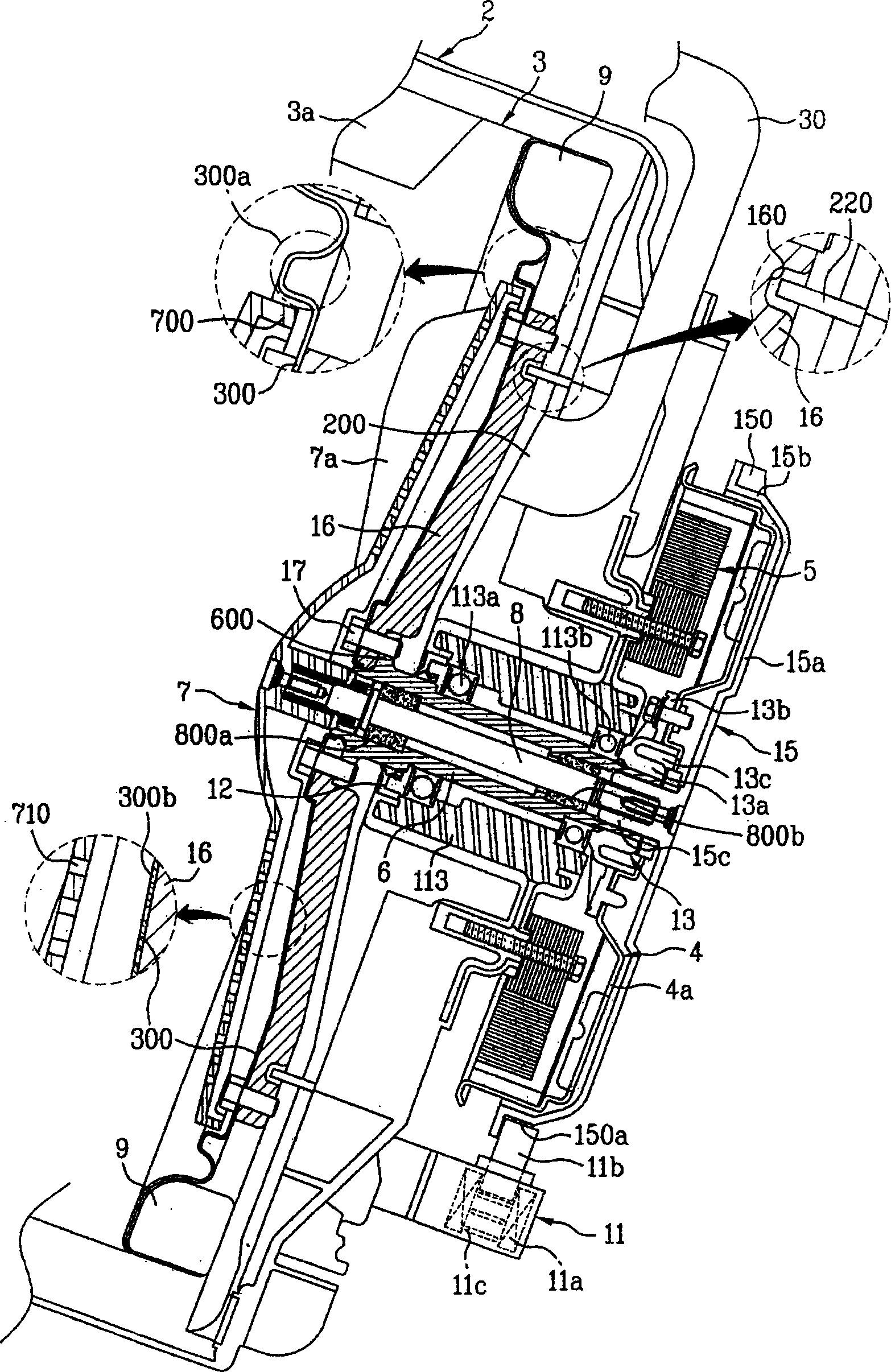

[0059] Below, refer to Figure 2 to Figure 7 , to describe the embodiments of the present invention in more detail.

[0060] For reference, in the description of the present invention, the parts that are the same as those in the conventional technology use the same names and refer to the same reference symbols.

[0061] figure 2 It is a schematic diagram of the internal structure of the drum washing machine of the present invention; Figure 3a yes figure 2 Schematic diagram of the partially enlarged structure of the important parts of the fixed state of the wave wheel; Figure 3b yes figure 2 Schematic diagram of the partially enlarged structure of the important parts of the rotation state of the middle wave wheel.

[0062] Figure 4 It is a structural schematic diagram of the pulsator of the present invention; Figure 5 is a schematic diagram of the pulley structure of the present invention; Image 6 yes Figure 5 schematic diagram of the back; Figure 7 yes Fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap