Cast-in-situ reinforced concrete soundproof floors and construction method thereof

A technology of reinforced concrete and cast-in-place floor slabs, which is applied in the direction of sound insulation, floor slabs, floors, etc., can solve problems such as the inability to meet the requirements of floor slab sound insulation, and achieve the effects of shortening the construction period, reducing costs, and reasonable reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

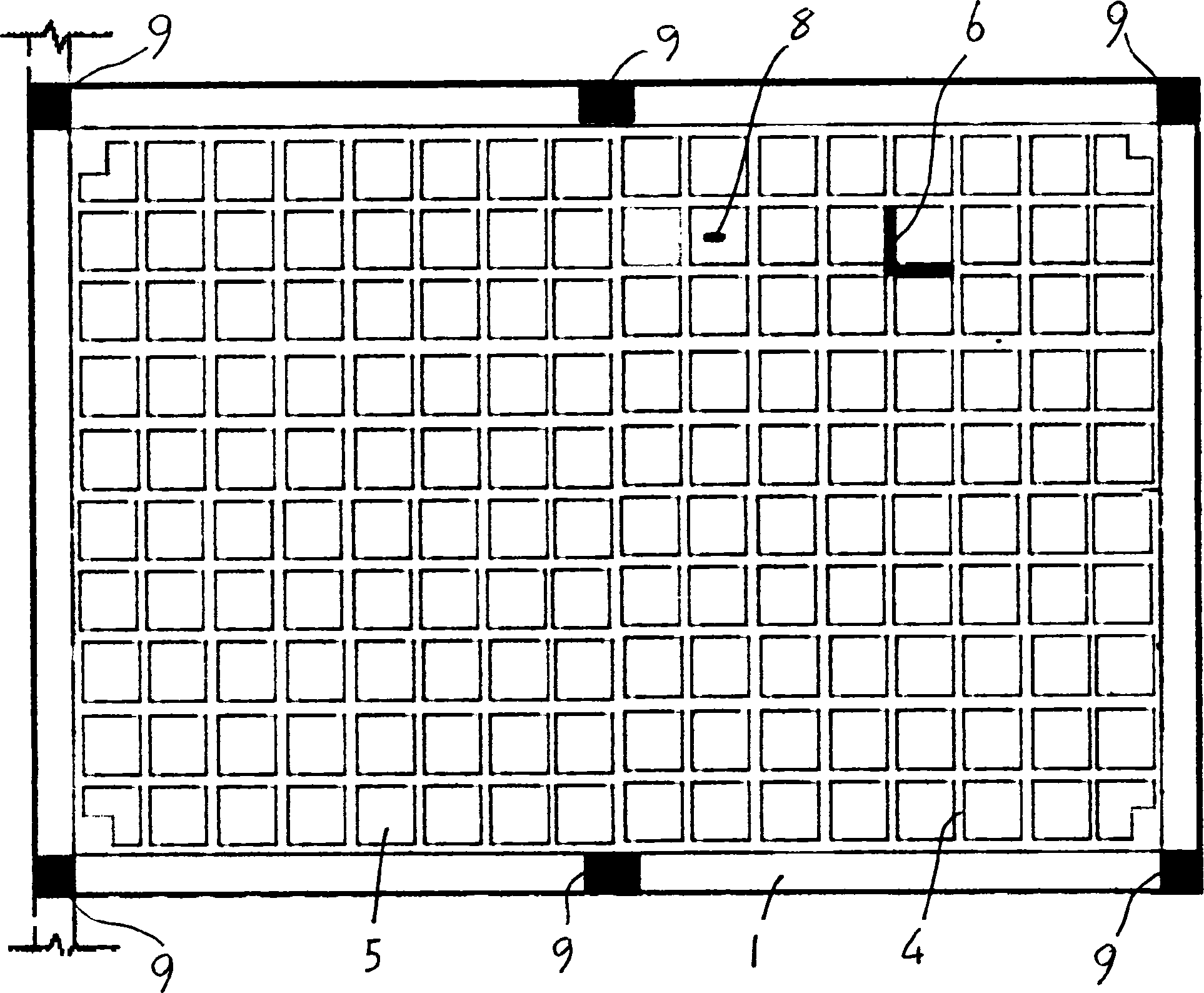

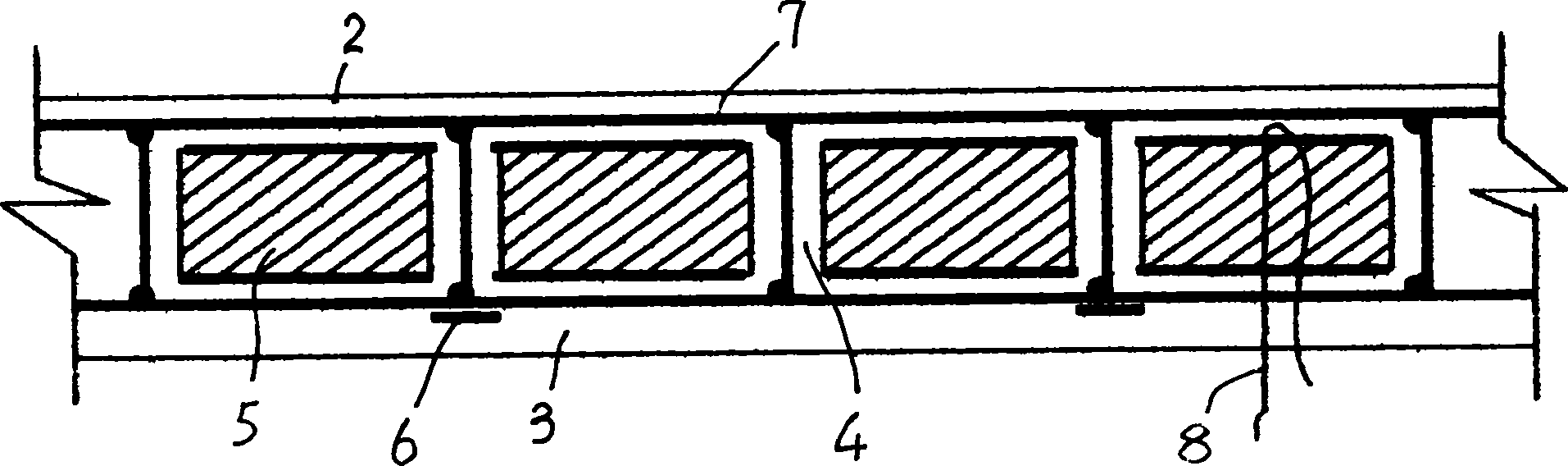

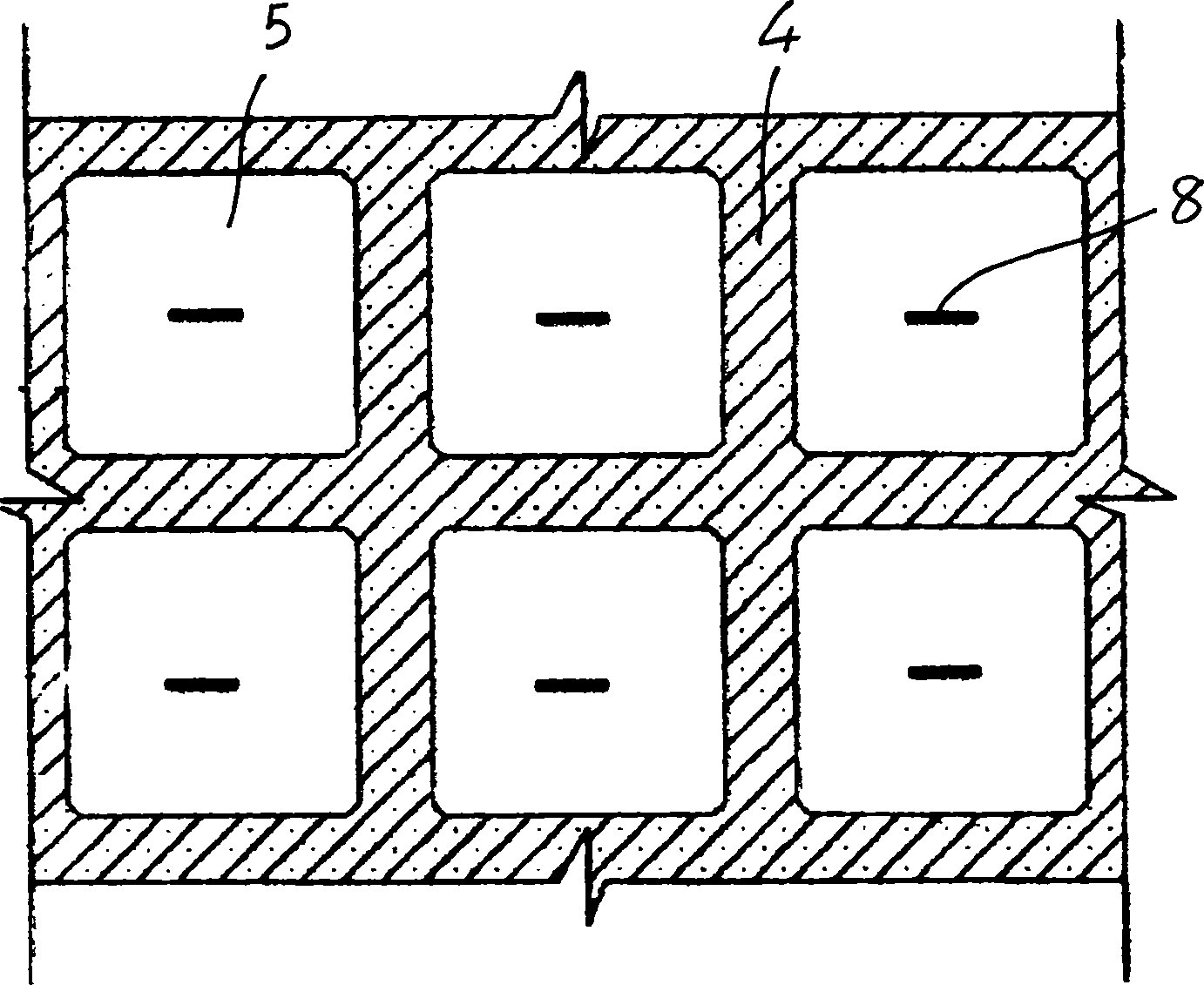

[0029] see figure 1 , in this embodiment, the cast-in-place floor slab is set, which is a box-shaped body with hollow cavities composed of ring beam 1, cover plate 2 and bottom plate 3. The hollow cavities are independently arranged in a matrix, and adjacent hollow cavities are connected in The support ribs 4 between the cover plate 2 and the bottom plate 3, the support ribs 4 are in a cross array;

[0030] figure 1 , figure 2 and image 3 As shown, the floor sound insulation core material 5 is set in the hollow cavity, the floor sound insulation core material 5 is a lightweight elastic embedded part, and the hollow cavity uses the pre-embedded floor sound insulation core material 5 as the forming mold; the ring beam 1 and the support rib 4 The sound insulation layer 6 is set on any plane at the position.

[0031] In the specific implementation, the volume of the sound-insulating core material 5 of the floor slab accounts for 26-55% of the volume of the cast-in-place floo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap