Sandproof integrated compound screening pipe and processing method thereof

A processing method and sand control technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of filter deformation, screen blockage, metal filter rupture, etc., and achieve the improvement of connection strength and increase The effect of increasing the leakage channel and the flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

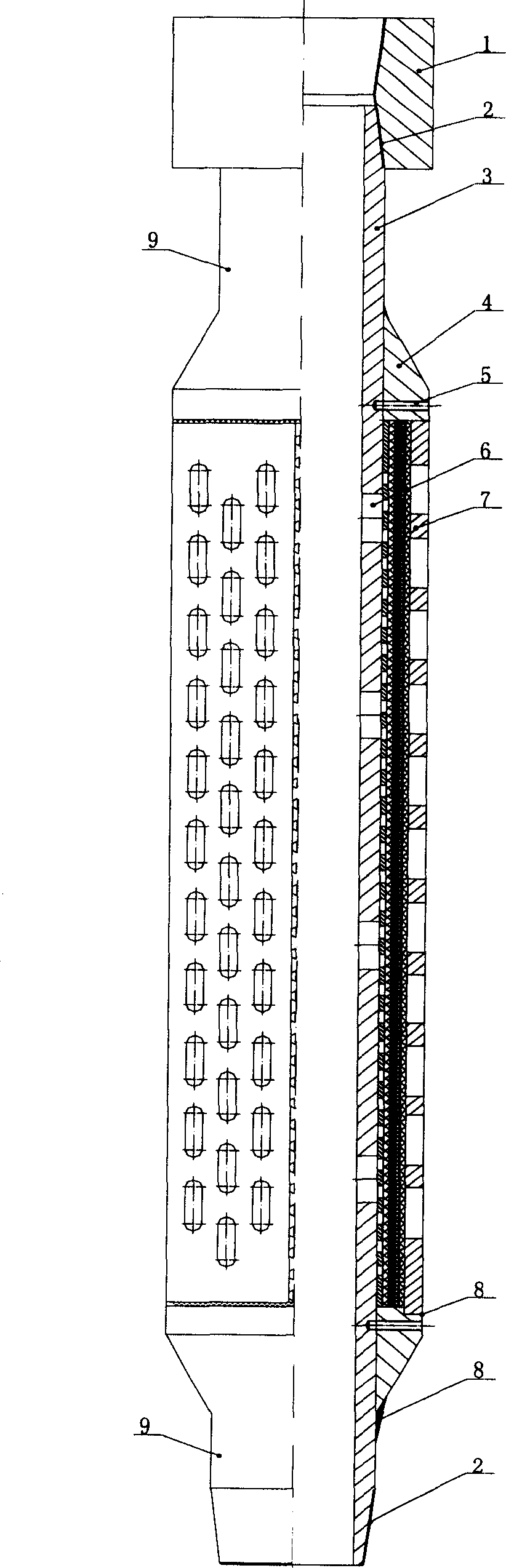

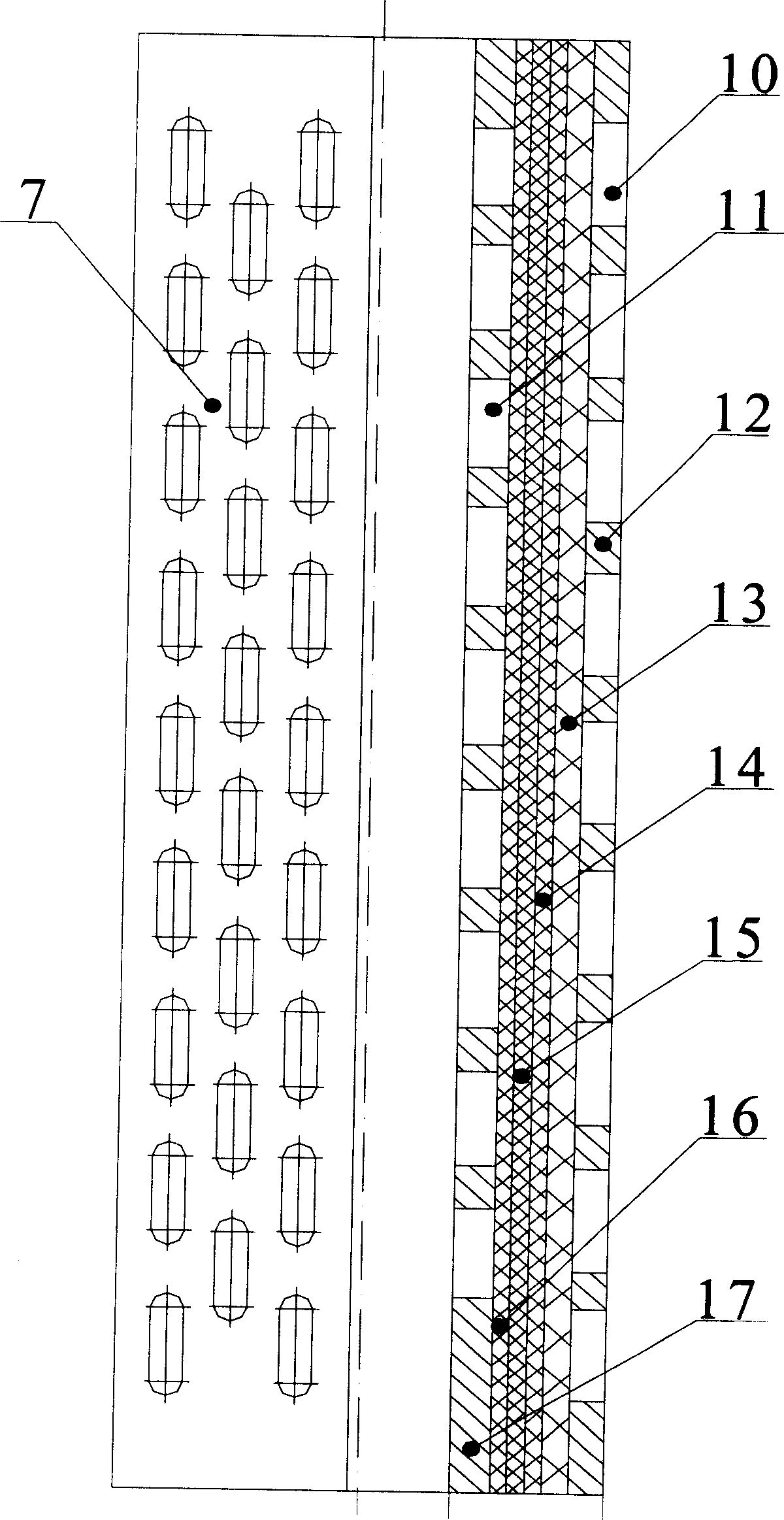

[0016] like figure 1 Shown: a sand control integrated composite screen of the present invention and its processing method: it mainly includes a center base pipe 3 with many flow holes 6 distributed on the pipe wall, and a center base pipe 3 with flow holes set on the center base pipe 3 The inner protective cover 17 of 11, the multi-layer sand control filter screen (13,14,15,16) outside the inner protective cover 17, is enclosed within the multi-layer sand control filter screen (13,14,15,16) The outer protective cover 12 of the orifice 10 and the support plate 4 used to connect the inner and outer protective covers (17, 12) and the multi-layer sand control filter screen (13, 14, 15, 16) to the central base pipe 3; Its characteristic is that its processing method is as follows: first roll the plates punched with flow holes (11, 10) into cylinders and weld them to form inner and outer protective sleeves (17, 12), and then put the multi-layer sand control filter screen (13 , 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com