Vehicle gearshifting cable connector and gear shifting rotary arm assembling structure

A technology for assembling structures and automobiles, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of time-consuming assembly, unfavorable work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

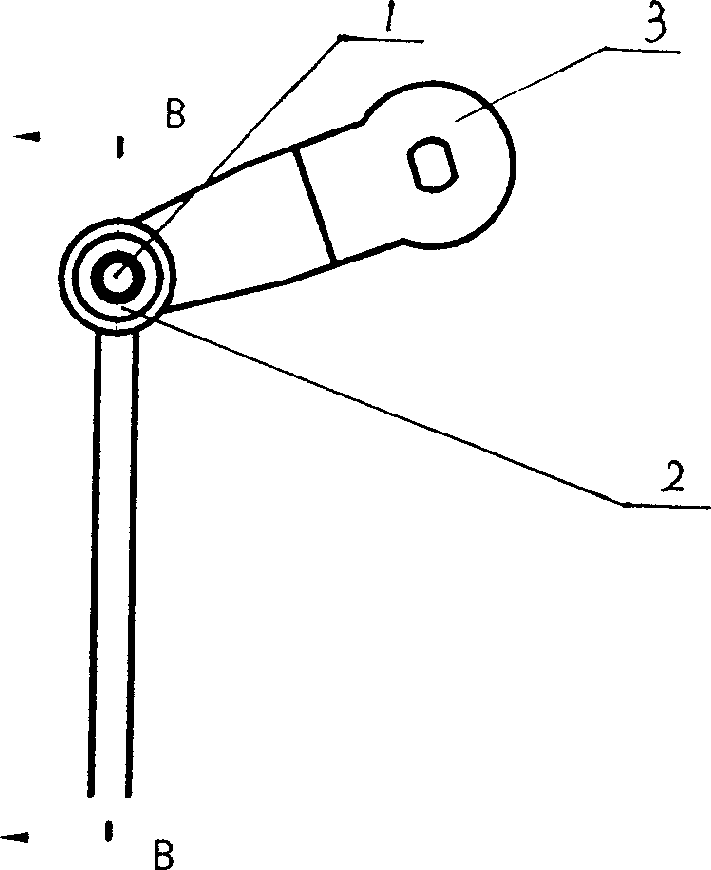

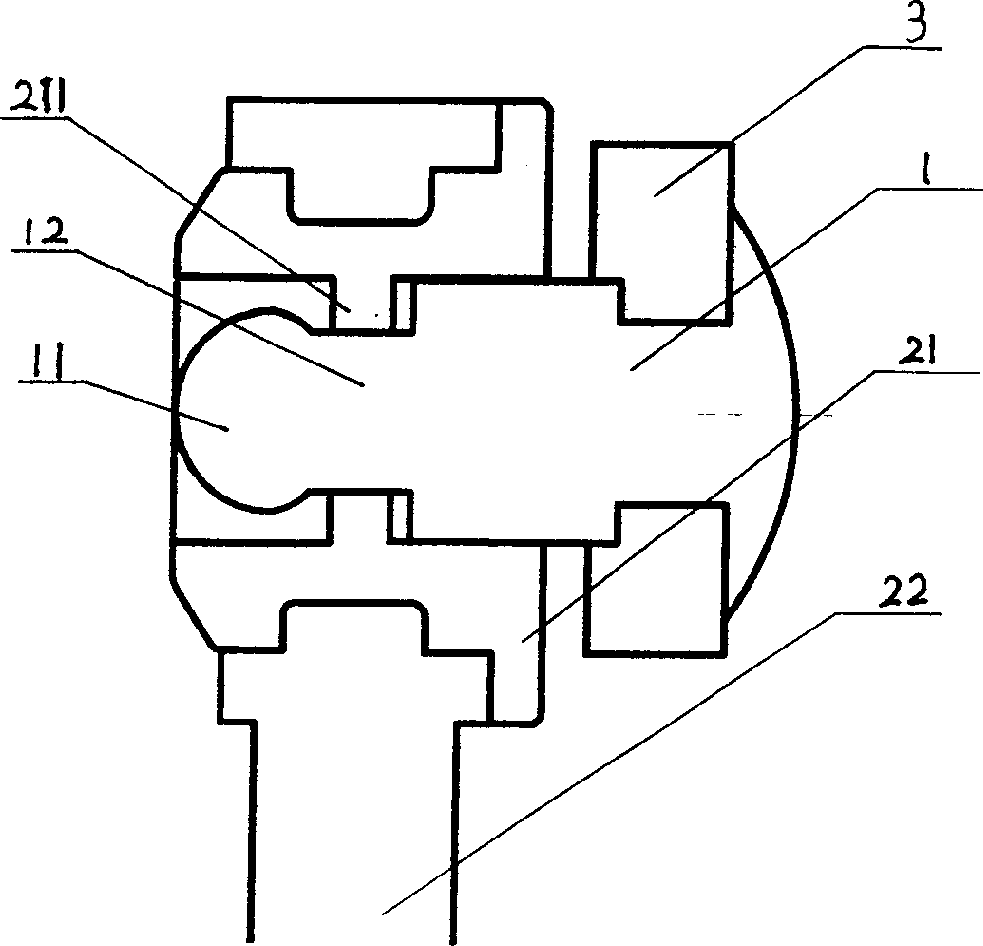

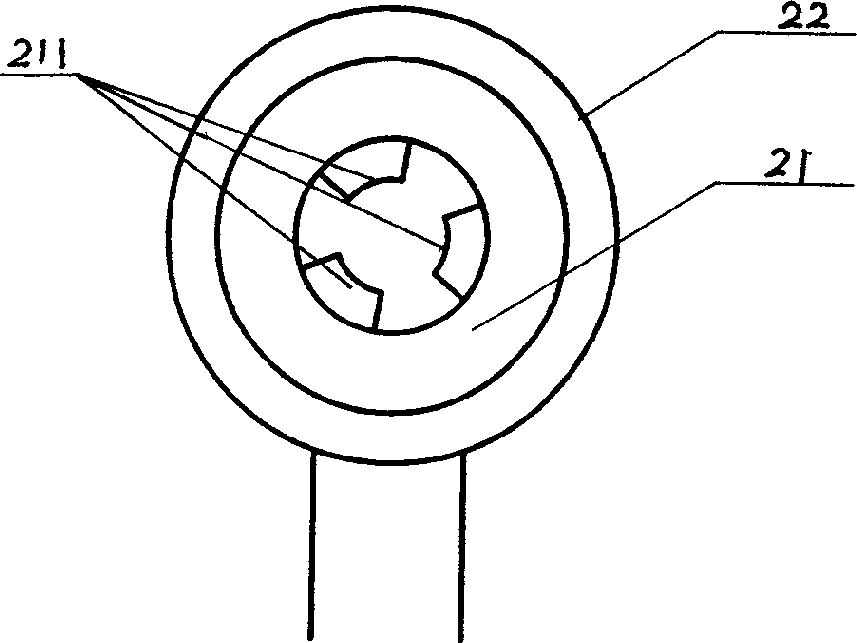

[0012] see figure 1 , the assembly structure of the shift cable joint and the shift arm is composed of a rotating pin 1, a cable joint 2 and a shift arm 3, combined figure 2 It can be seen that the rotating pin 1 is riveted on the shift arm 3 , and the cable joint 2 and the rotating pin 1 are clamped. Rotating pin 1 end is a hemisphere 11, and the center is a cylindrical neck 12, and the neck diameter is smaller than the hemisphere diameter. The cable joint 2 is composed of a rubber bush 21, a metal ring and a rod welding assembly 22. The inner ring of the rubber bush 21 has three protruding clips 211 with optimized shapes. The shape of the rubber bush 21 adopts a tapered buckle shape. The elasticity of the rubber, the rubber bushing 21 is pressed into the metal ring and the rod welding assembly 22, and the combination is very reliable, so that the whole ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com