Ultrasonic wave automatic defrosting device for refrigerator

An ultrasonic and refrigerator technology, which is applied in the field of ultrasonic automatic defrosting devices for refrigerators, can solve the problems of wasting electric energy, refrigerator temperature rise, and electricity consumption, and achieve the effects of improving heat exchange efficiency, maintaining freezing temperature, and ensuring freezing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

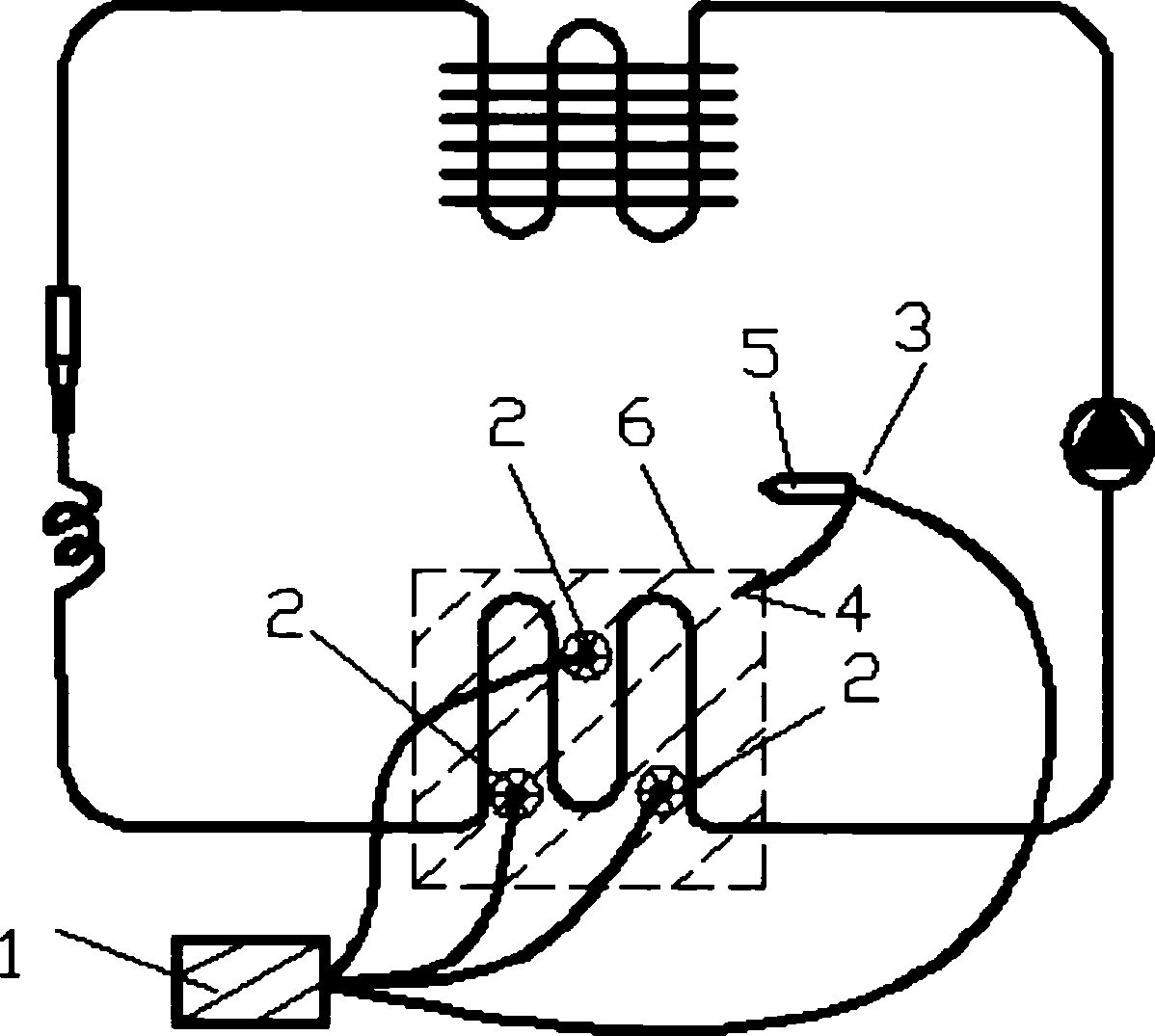

[0009] Such as figure 1 As shown, the present invention includes an ultrasonic generator 1, an ultrasonic transducer 2, and a frost sensor 3. The ultrasonic transducer 2 is glued to the side of the evaporator 6 close to the refrigerant pipeline. The ultrasonic generator 1 is placed next to the ultrasonic transducer 2 . Frost sensor 3 is installed in the refrigerator freezer close to evaporator 6 places.

[0010] The frost layer sensor 3 is composed of two probes, the first probe 4 is connected to the evaporator 6, and the second probe 5 has a gap with the evaporator, and the gap is the thickness of the frost layer during defrosting. When the frost layer reaches a certain thickness, the frost layer touches the second probe 5 . At this time, the power supply of the ultrasonic generator 1 is turned on, and the ultrasonic transducer 2 works. The ultrasonic transducer 2 converts electrical energy into acoustic energy, and the generated ultrasonic wave propagates in the evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com