Electronic equipment with foaming structure and producing method thereof

A technology of electronic equipment and manufacturing method, which is applied to the construction parts of electrical equipment, the installation of supporting structures, electrical components, etc., which can solve the problems of complex design and arrangement, increased difficulty, increased cost, etc., and achieve diversified appearance and simple process , The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

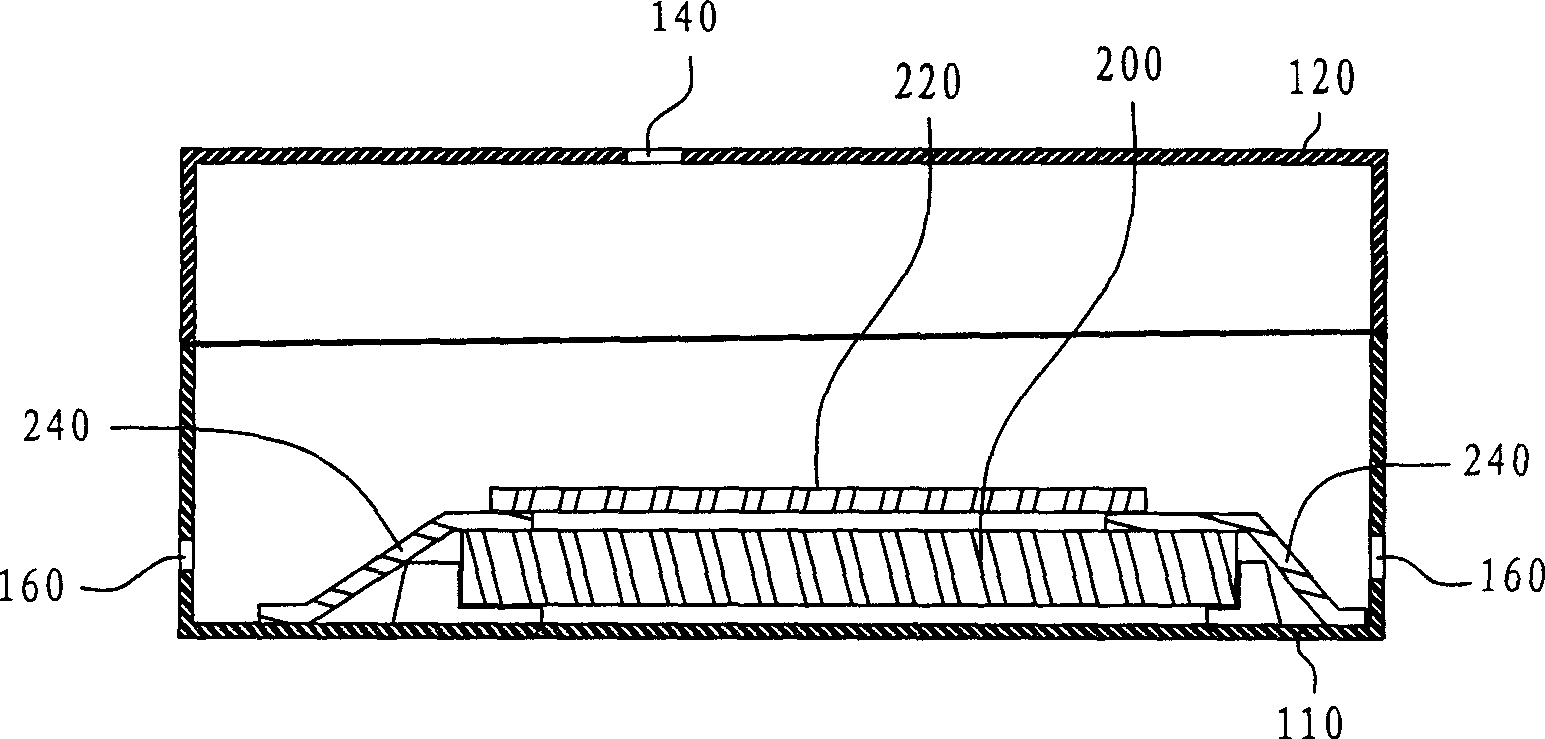

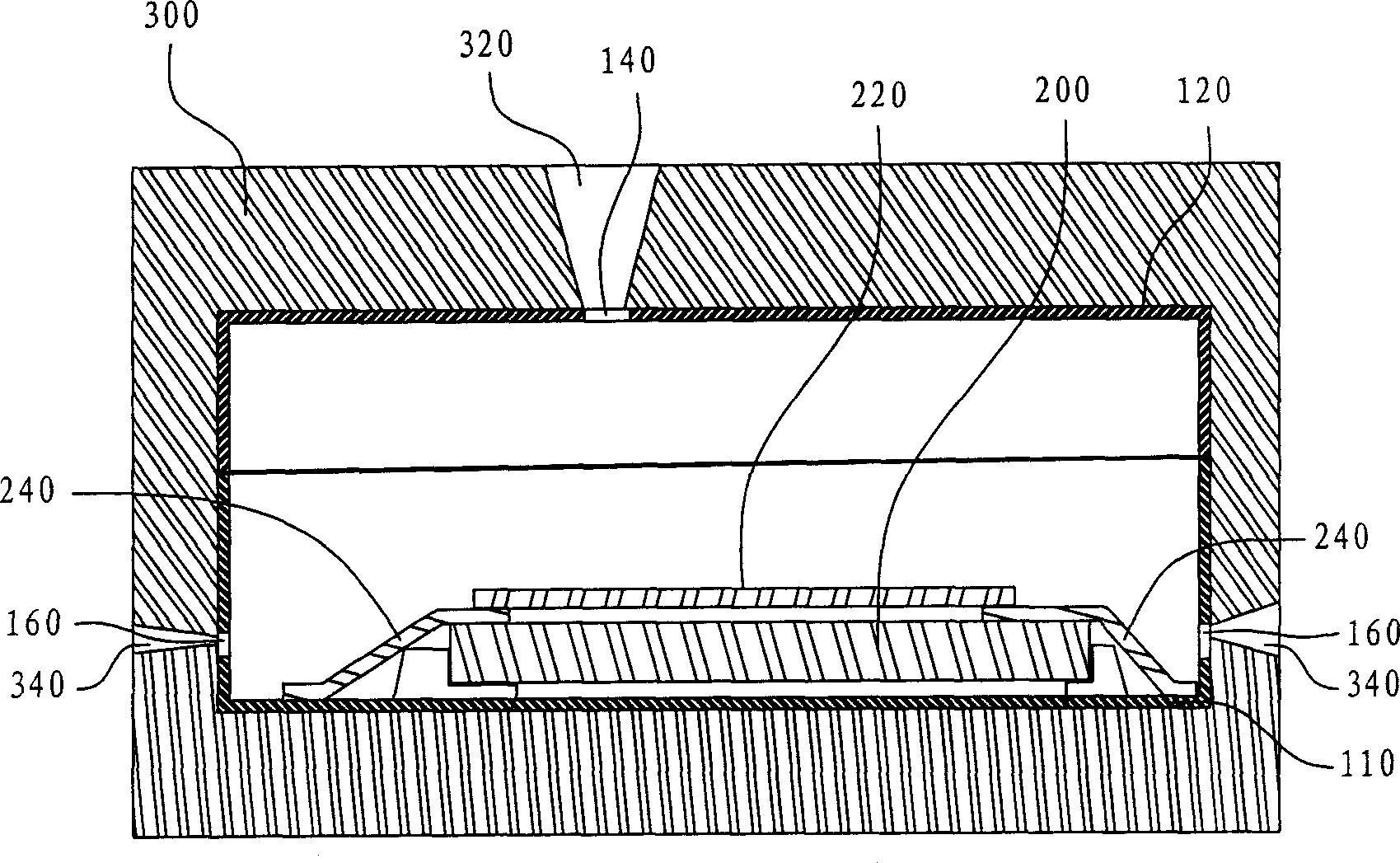

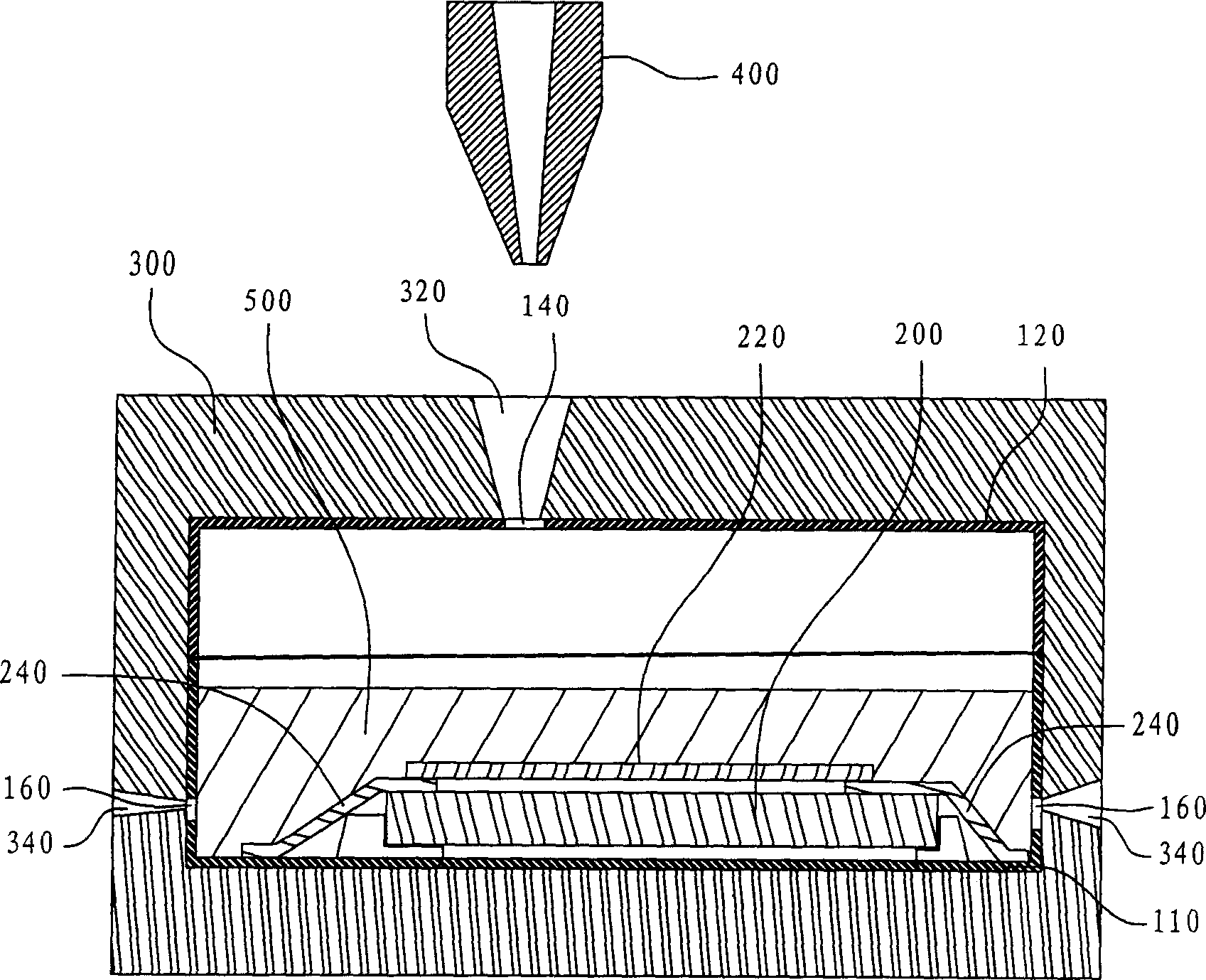

[0021] A preferred embodiment of the present invention discloses a method for forming a foamed structural reinforcement, which is suitable for manufacturing electronic equipment. The foam structure is used to cover or wrap the electronic components to protect the electronic components from damage caused by external impact. In addition, because the foam structure has the characteristics of light weight, electronic products can still maintain the characteristics of lightness, thinness, shortness and smallness. Furthermore, because the method of forming the foamed structural reinforcing material is simple, the electronic product applying the present invention can have the characteristics of low cost and various appearances. The embodiments of the present invention can be used in various fields without limiting the patent scope of the present invention.

[0022] refer to Figure 1-6 , which is a cross-sectional view of a manufacturing process of a method for forming a foamed stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com