Bearing device for wheel

A bearing device and wheel technology, applied in the directions of axles, wheels, roller bearings, etc., can solve the problems of complicated assembly and large number of parts, and achieve the effects of low cost, improved durability, and increased bearing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

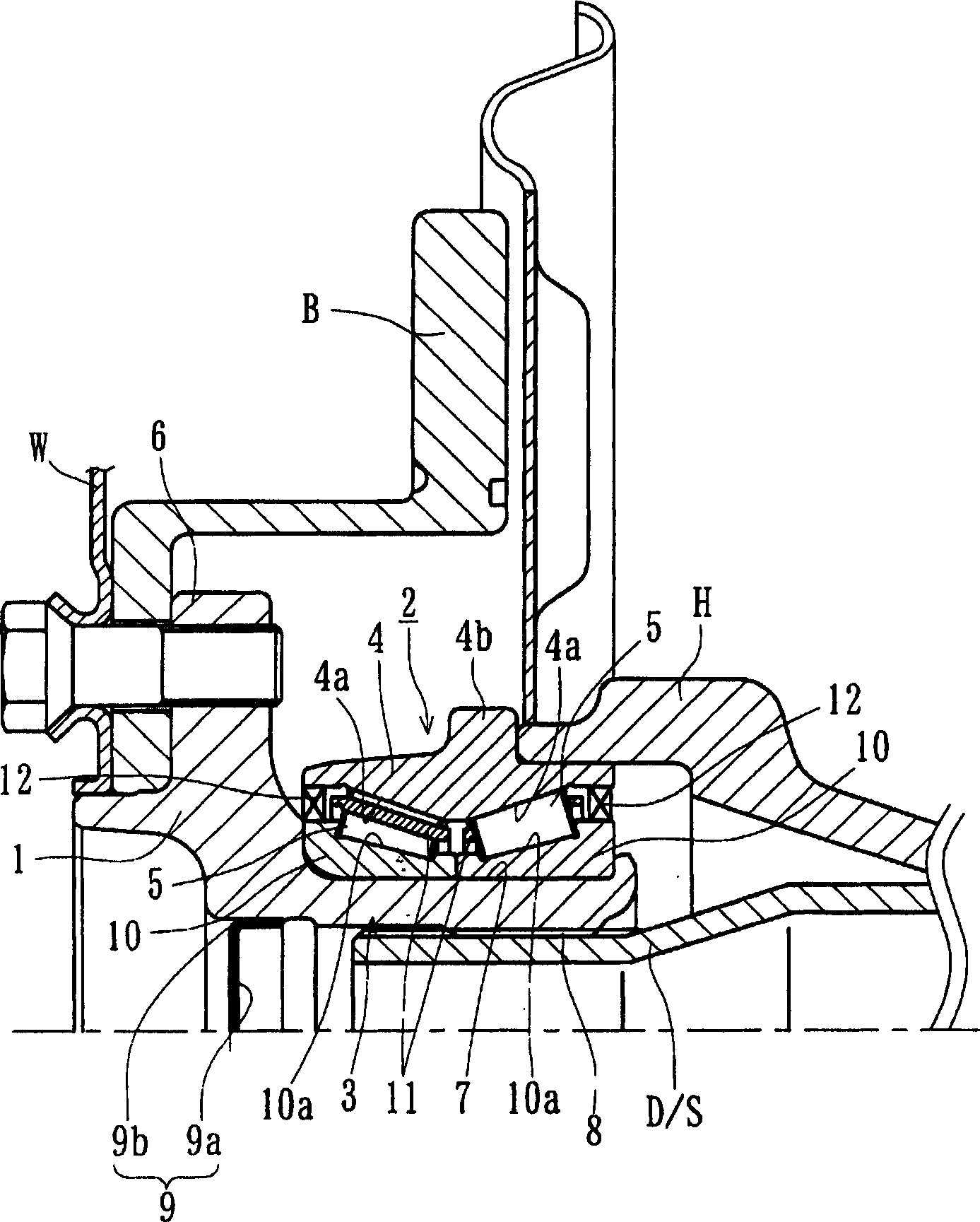

[0036] figure 1 It is a longitudinal sectional view showing the first embodiment of the wheel bearing device according to the present invention, figure 2 It is a longitudinal sectional view showing the wheel bearing. In addition, in the following description, in the state mounted on the vehicle, the side closer to the vehicle outer side is referred to as the vehicle outer side (left side in the figure), and the side closer to the center is referred to as the vehicle inner side (right side in the figure). ).

[0037] The wheel bearing device is composed of a wheel hub 1 and a multi-row rolling bearing 2 and is connected to the drive shaft D / S. The multi-row rolling bearing 2 has an inner member 3 , an outer member 4 , and multi-row rolling elements (tapered rollers) 5 , 5 rotatably housed between the two members 3 , 4 . Here, the inner member 3 refers to ...

Embodiment 2

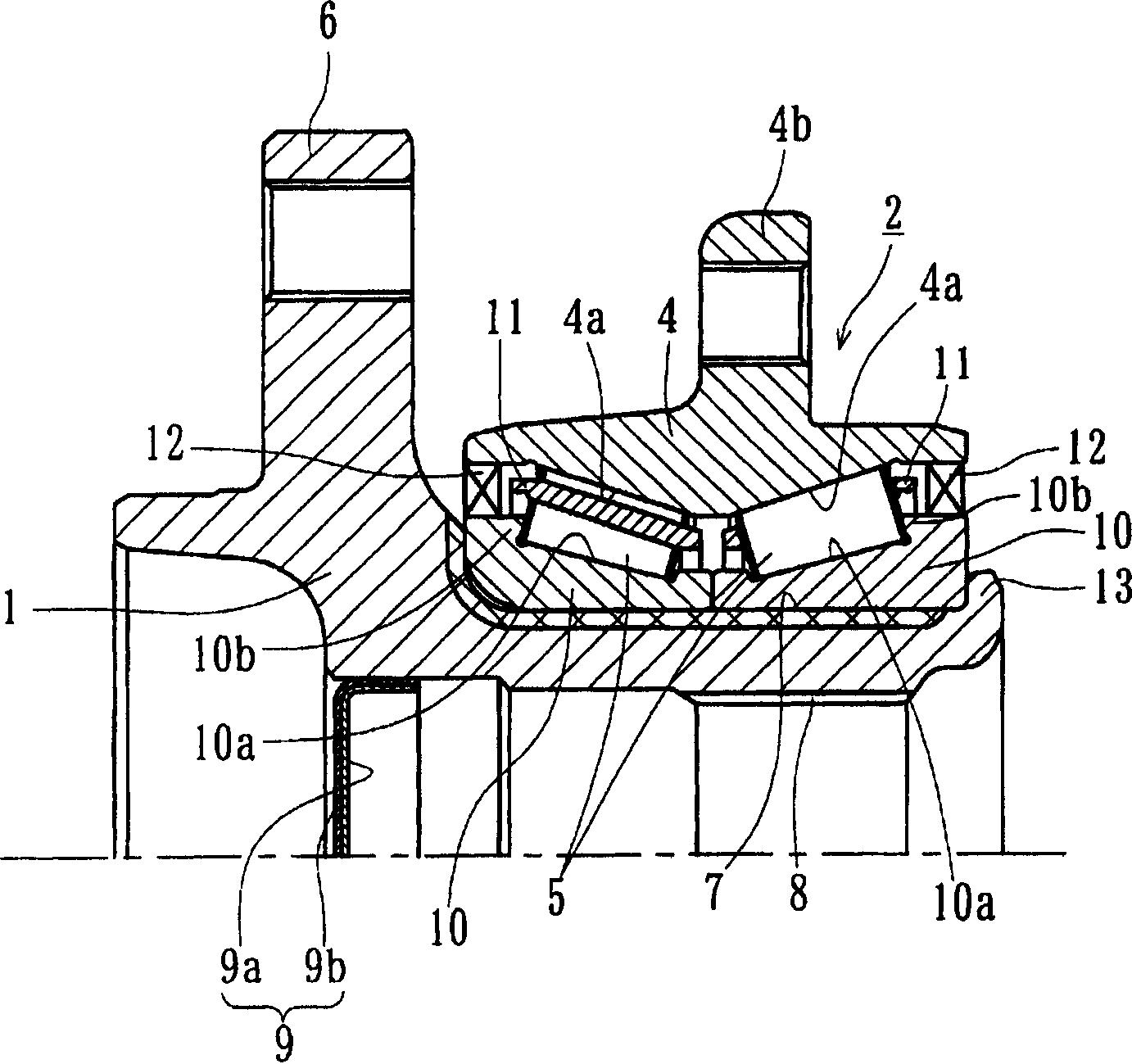

[0045] image 3 It is a longitudinal sectional view showing a second embodiment of the wheel bearing according to the present invention. In this embodiment, only the hub structure is different from the above-mentioned embodiment, so the same reference numerals are assigned to the same parts as those in the first embodiment above, and detailed description thereof will be omitted.

[0046] This wheel bearing is composed of a hub 14 and a multi-row rolling bearing 15 combined. The multi-row rolling bearing 15 has an inner member 16 , an outer member 4 , and multi-row rolling elements 5 , 5 rotatably accommodated between the two members 16 , 4 . Herein, the inner part 16 refers to the hub 14 and the inner ring 10 pressed into the hub 14 . The wheel hub 14 has a wheel mounting flange 6 integrated therewith, and the wheel mounting flange 6 is used to install a wheel (not shown) on the outer side end of the outer periphery. The raceway surface 14a and the cylindrical portion 7 axi...

Embodiment 3

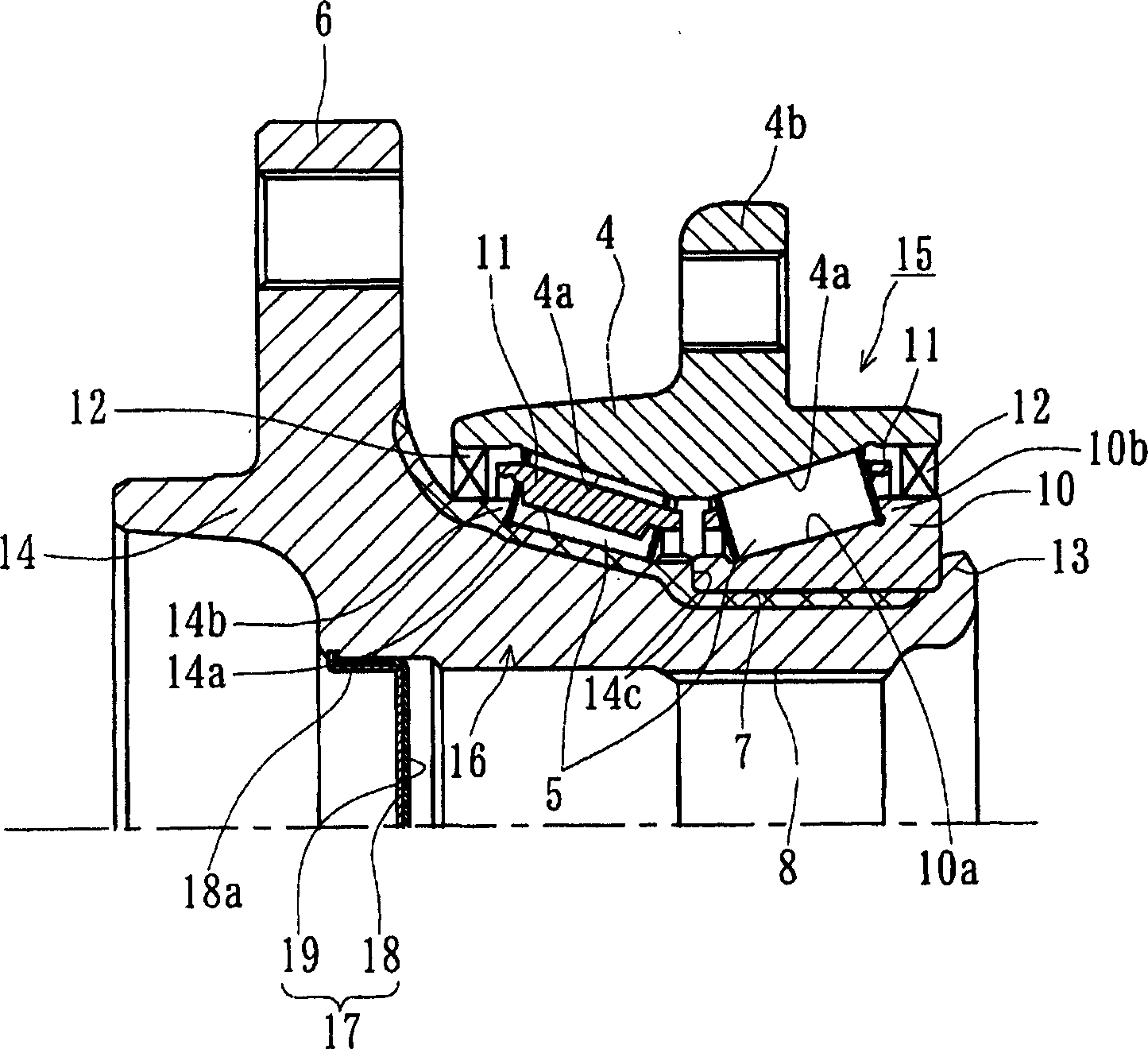

[0052] Figure 5 It is an enlarged view of main parts showing a third embodiment of the wheel bearing according to the present invention. The same reference numerals are assigned to the same parts, the same parts, the same functions, and the like as those in the aforementioned embodiment, and detailed description thereof will be omitted.

[0053] In the present embodiment, the cover 21 is press-fitted into the opening of the vehicle outer end portion of the hub 1 . The cover 21 is composed of a steel plate mandrel 21a and an elastic member 21b. The mandrel 21a is formed by stamping an austenitic stainless steel plate (JIS standard SUS304 series, etc.) or a rust-proof cold-rolled steel plate (JIS standard SPCC series, etc.). ) is formed in a substantially U-shaped cross section, and a part of the elastic member 21b bulges from the inner peripheral surface of the mandrel 21a at the fitting portion. The elastic member 21b is made of rubber or the like bonded by vulcanization, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com