Apparatus for scribing a substrate in use for a flat panel display

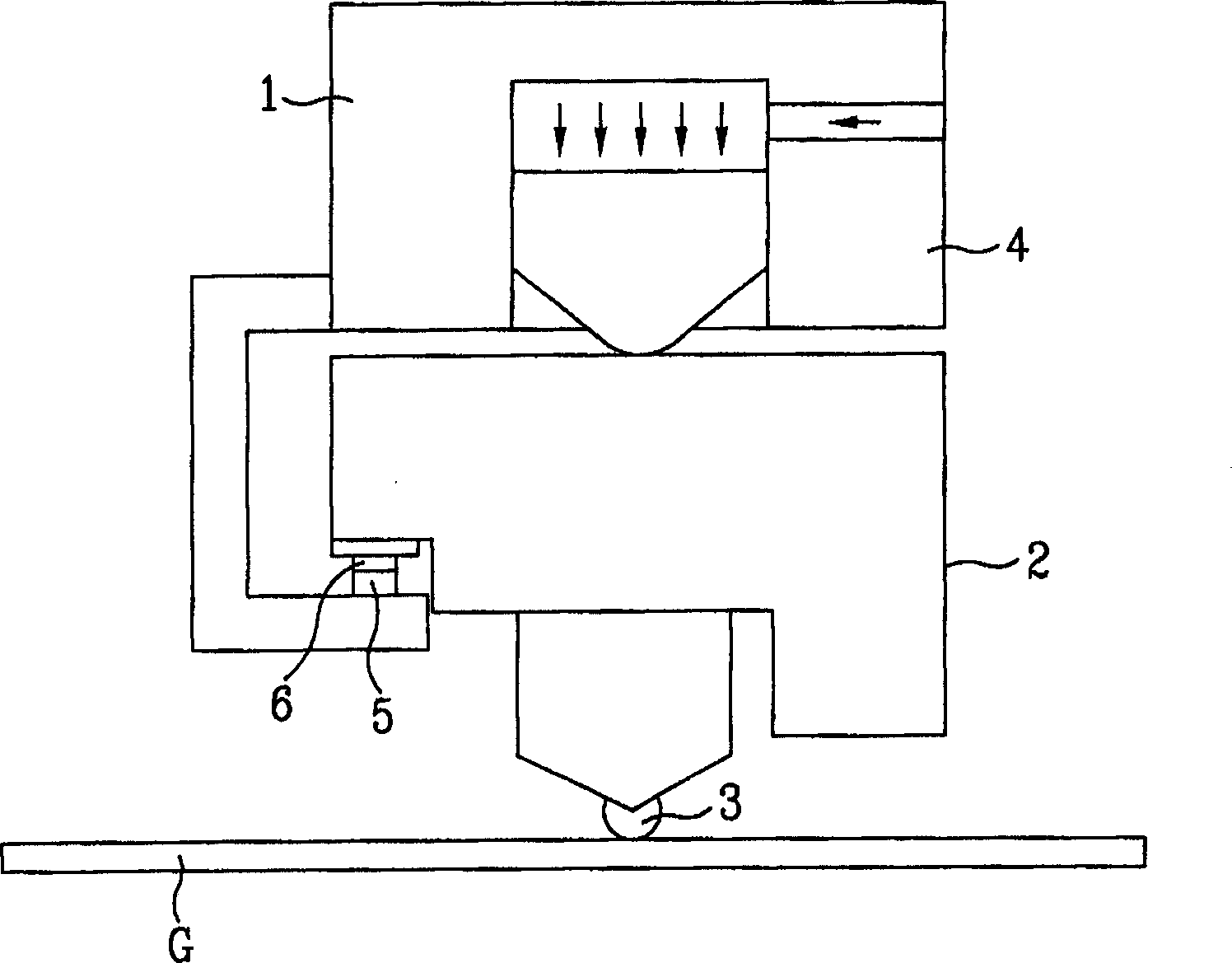

A flat-panel display and substrate technology, applied to fine working devices, paper/cardboard containers, glass cutting devices, etc., can solve the problems of reducing the accuracy of the position of the scribing wheel on the surface of the substrate, complex structure, large size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, preferred embodiments of the present invention will be described in detail, examples of the invention are illustrated in the accompanying drawings.

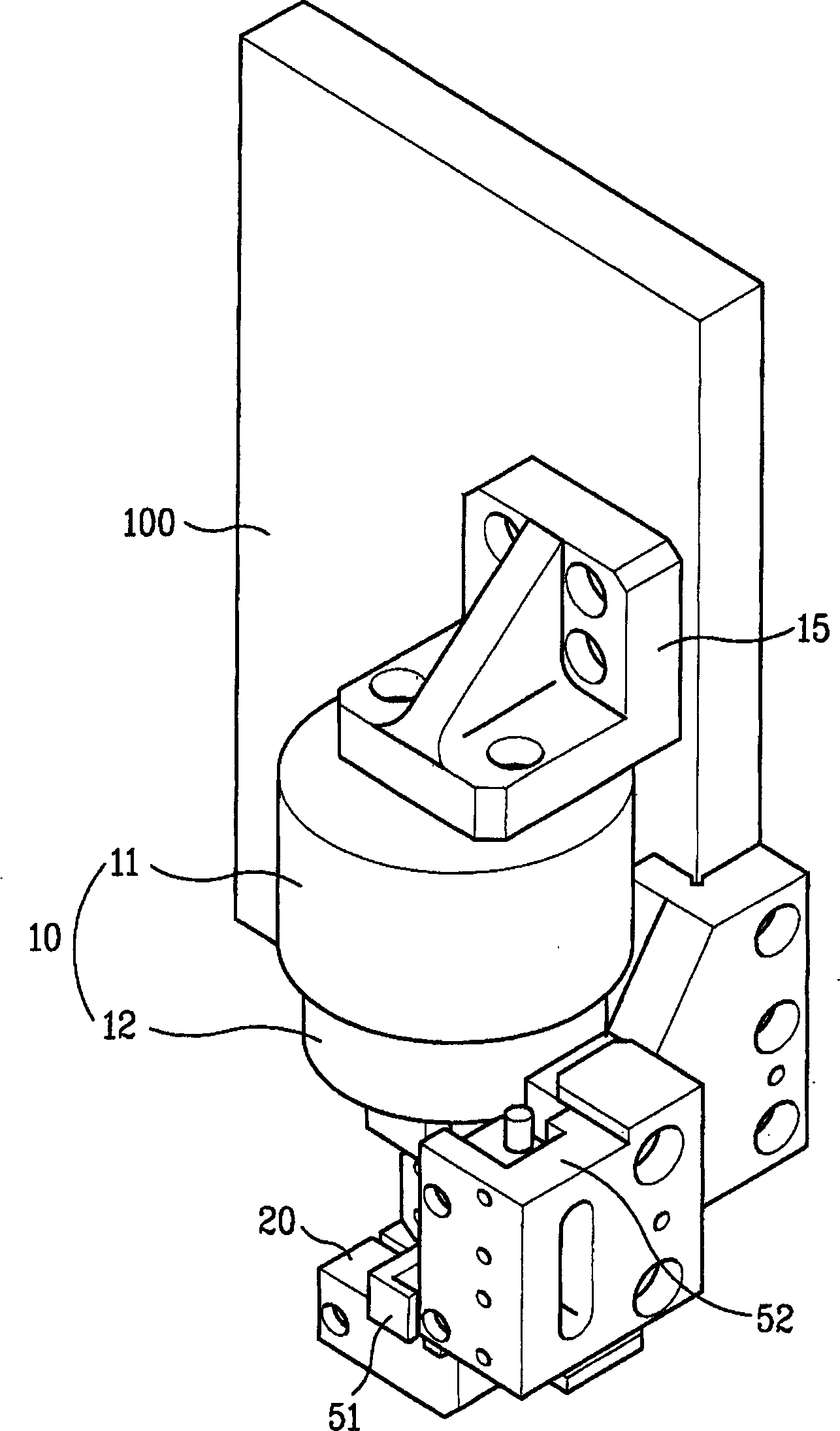

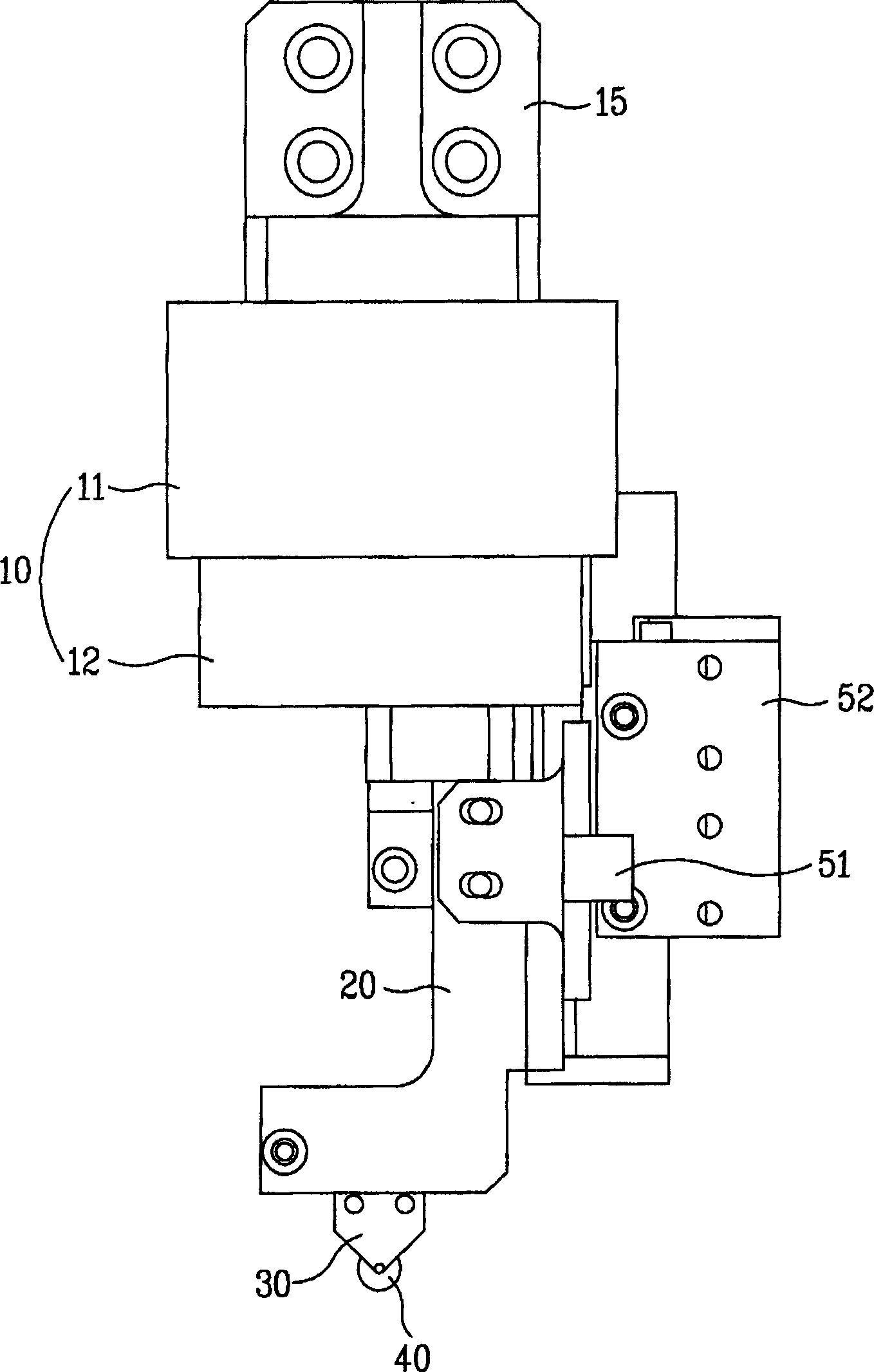

[0030] like Figure 2 to Figure 4 As shown, the substrate scribing device according to this clear embodiment includes: a voice coil motor 10 that generates a linear force; an ascending / descending block 20 that moves up and down depending on the linear force generated by the voice coil motor 10; a scribing wheel holder 30 that sets At the lower portion of the ascending / descending block 20; and the scribing wheel 40, which is provided on the scribing wheel holder, scribing the substrate.

[0031] The voice coil motor 10 is disposed on a support plate 100 disposed above a stage (not shown) on which a substrate is placed. The voice coil motor 10 includes: a stator 11 fixed on the support plate 100 ; and a mover 12 arranged inside the stator 11 and moving up and down. The stator 11 has a cylindrical body. An ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com