Automatic-cut waste material injection mould

An injection molding and waste technology, which is applied in the field of injection molding molds that can automatically cut waste, can solve the problem of not being able to fully fill plastic, and achieve the effect of improving labor production efficiency, high product consistency and quality, and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

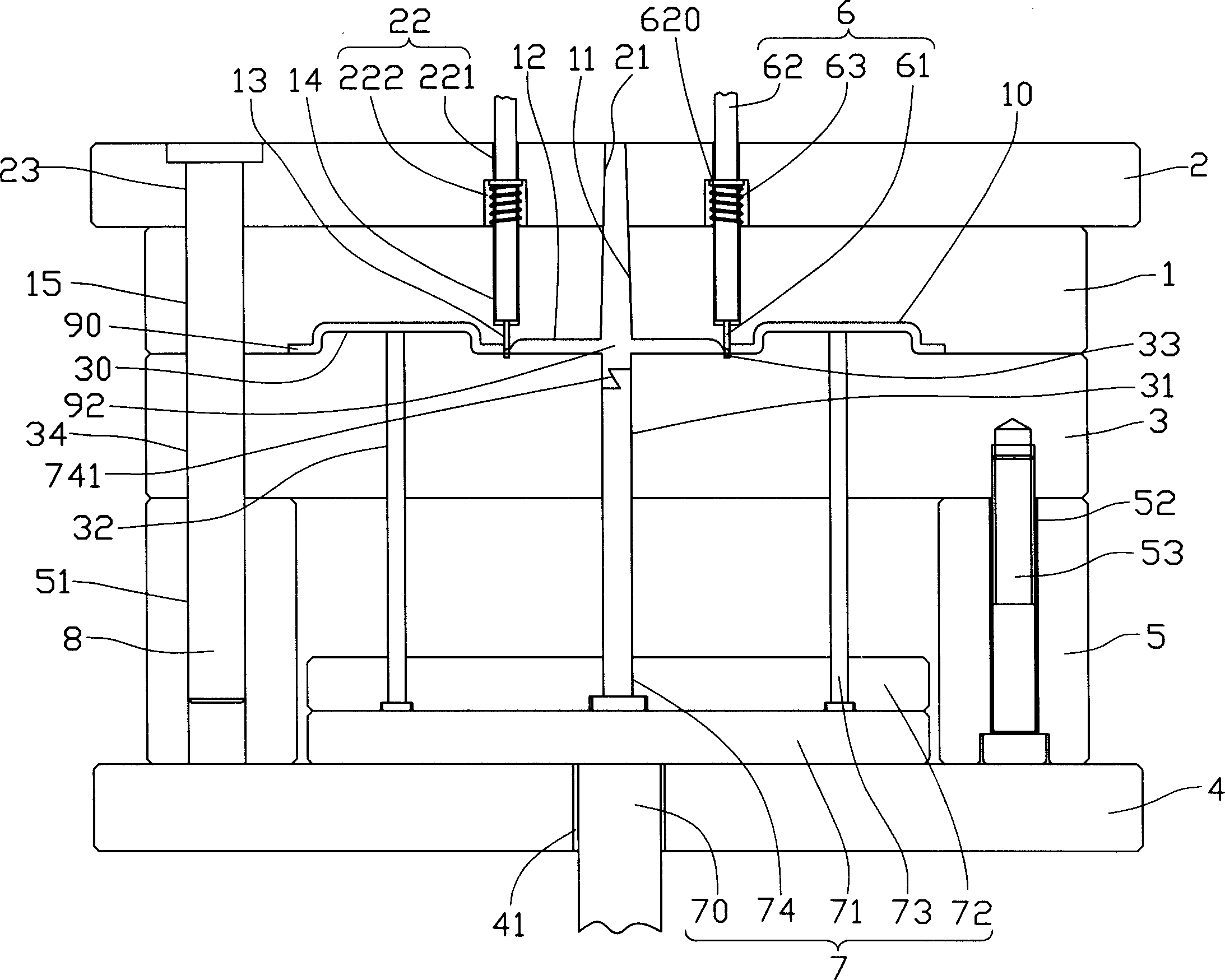

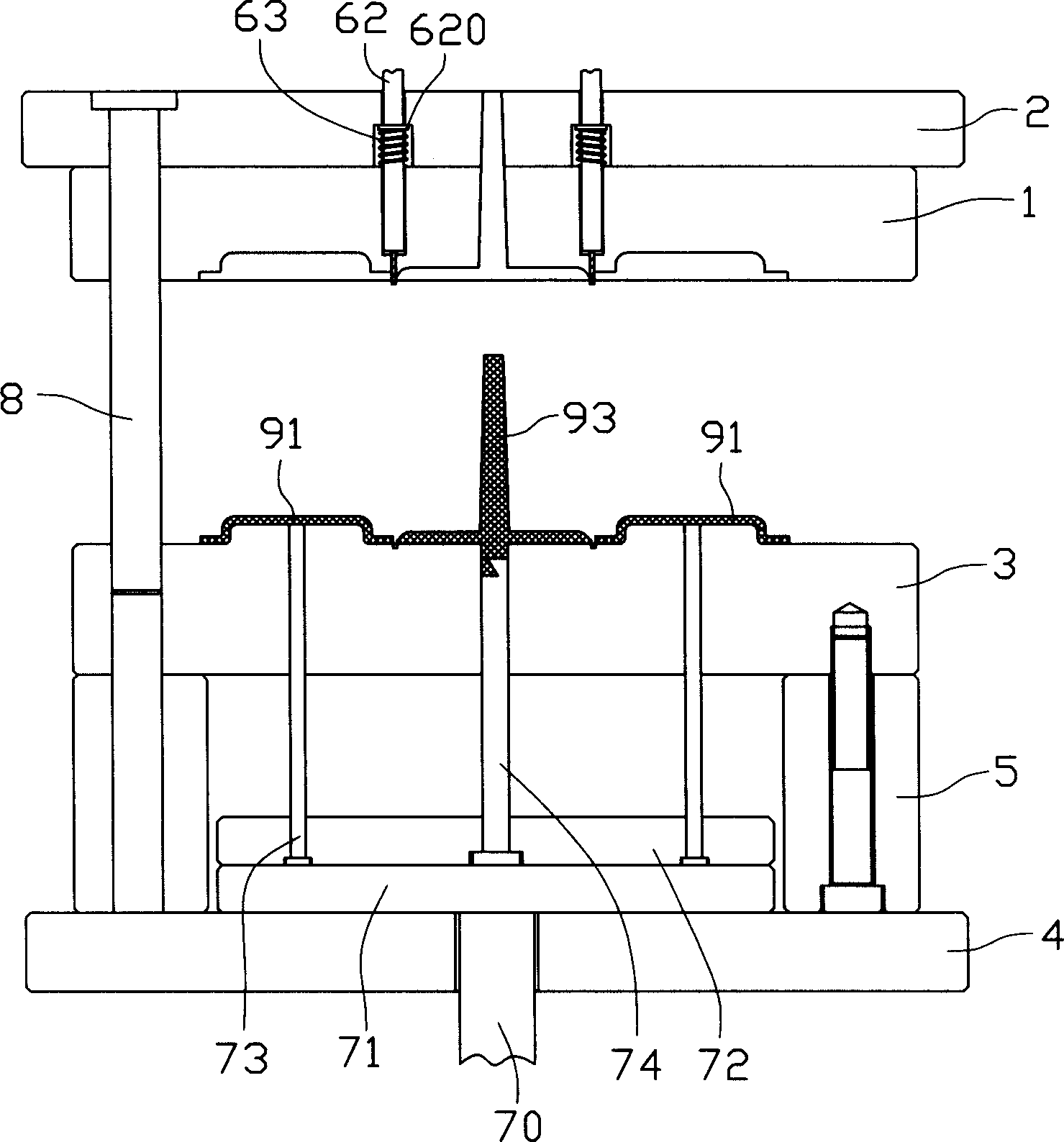

[0013] The preferred embodiments are listed below to illustrate the structure of the injection mold for automatically cutting waste.

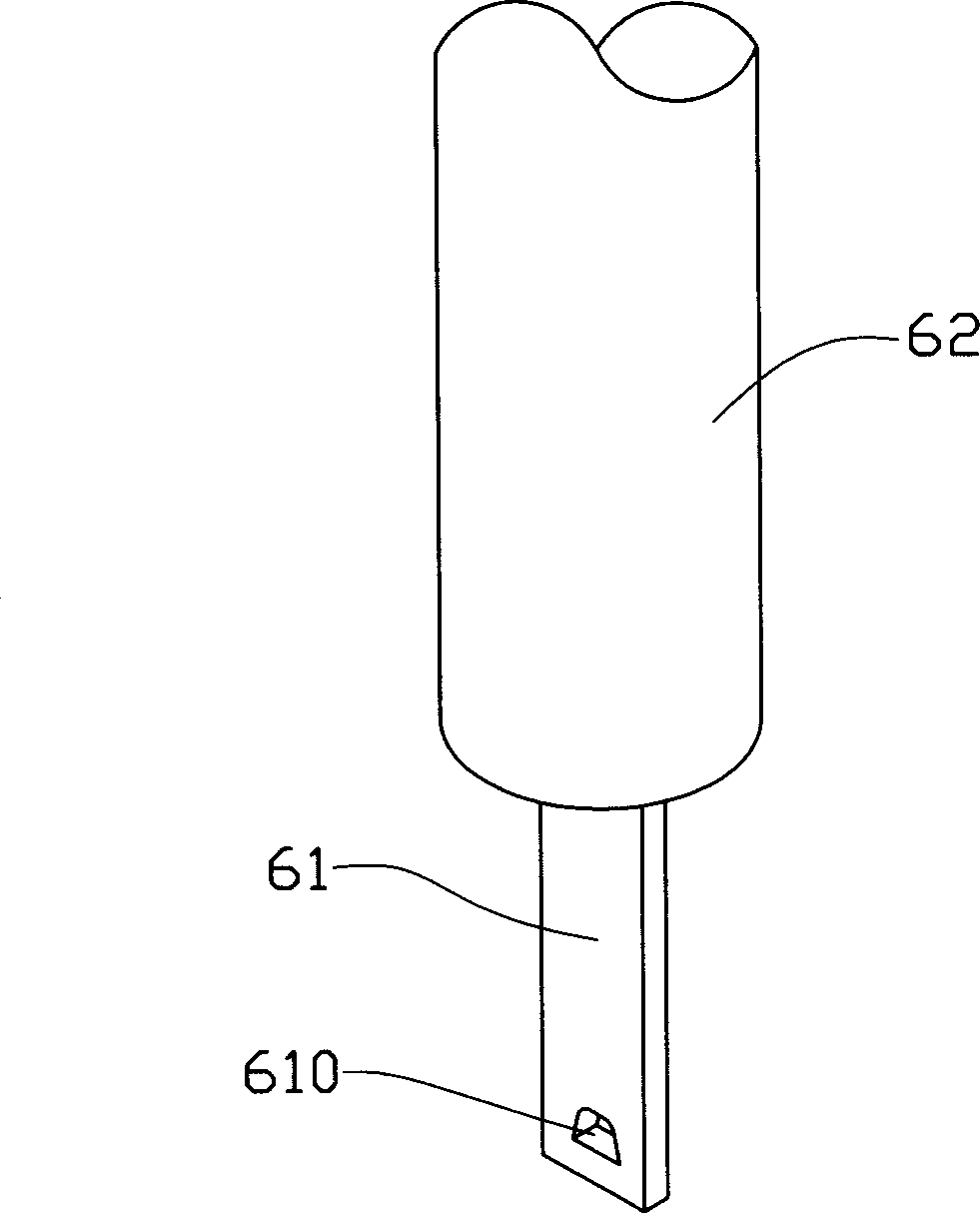

[0014] See figure 1 , a preferred embodiment of the present invention discloses an injection molding mold for automatically cutting waste, which mainly includes a fixed mold 1, a fixed template 2, a movable mold 3, a movable template 4, a mold foot 5, a material cutting mechanism 6 and an ejector Institution7. Among them, the fixed mold 1 and the movable mold 3 are aligned and matched through the guide rod 8, and the material cutting mechanism 6 is used to advance the product 91 ( image 3 Reference) and the waste material 93 at the runner 92 ( image 3 Refer to) automatic cutting and separation, the ejector mechanism 7 moves between the mold feet 5, and is used to eject the waste 93 at the product 91 and the runner 92 after the mold is opened.

[0015] One surface of the fixed mold 1 is provided with a plurality of profile surfaces 10 corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com