Controlling system for cooling fan

A cooling fan and control system technology, applied in the direction of coolant flow control, engine cooling, fluid pressure actuation device, etc., can solve problems such as unpleasantness, engine power consumption fluctuations, operator insecurity, etc., to achieve significant reduction Effect of changing and stabilizing operating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

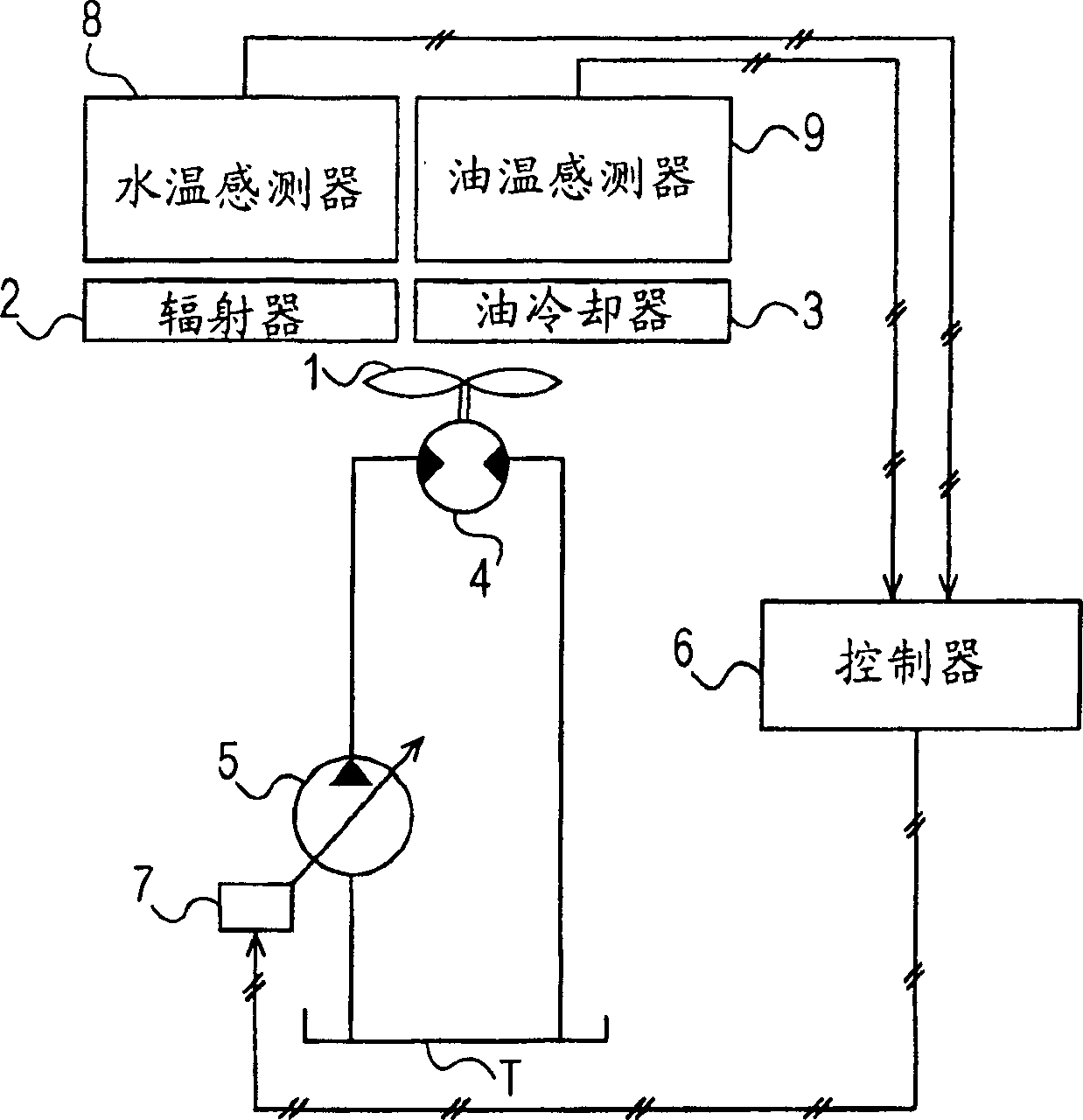

[0018] The following description is directed to an example in which the present invention is used for a hydraulic excavator driven hydraulically by, for example, fluid pressure. The hydraulic excavator is equipped with, for example, an engine cooling device for cooling an engine; a working oil cooling device for cooling working oil used to actuate a hydraulic actuator serving as a fluid pressure actuator; and a driver cooling device for cooling the interior of a cab. room cooling unit. In addition, these cooling devices are individually provided with cooling fans, or are provided with a common cooling fan. The cooling fan is rotated by a hydraulic motor serving as a fluid pressure motor hydraulically driven by a hydraulic pump as a fluid pressure pump. The control system for a cooling fan according to the invention is used as such a cooling fan.

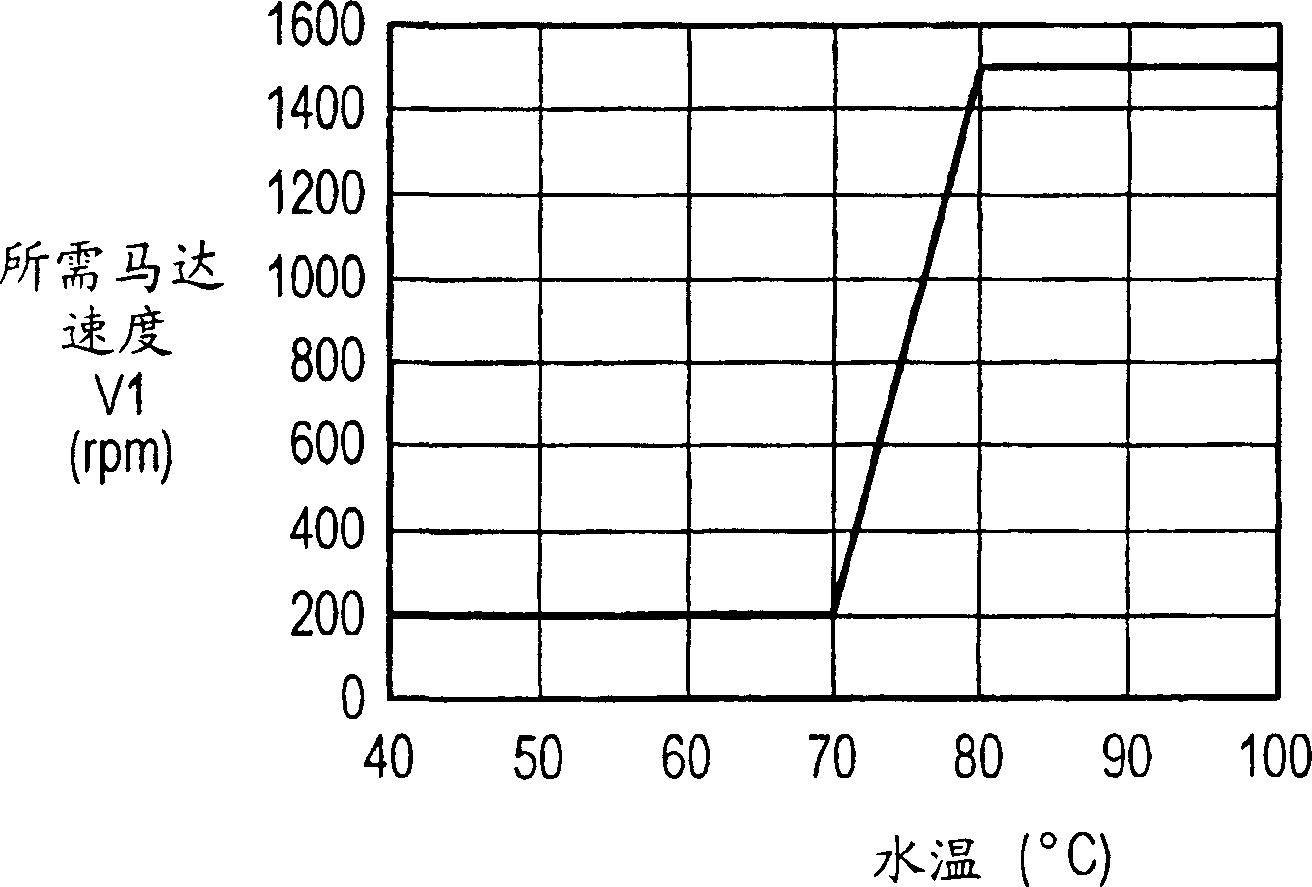

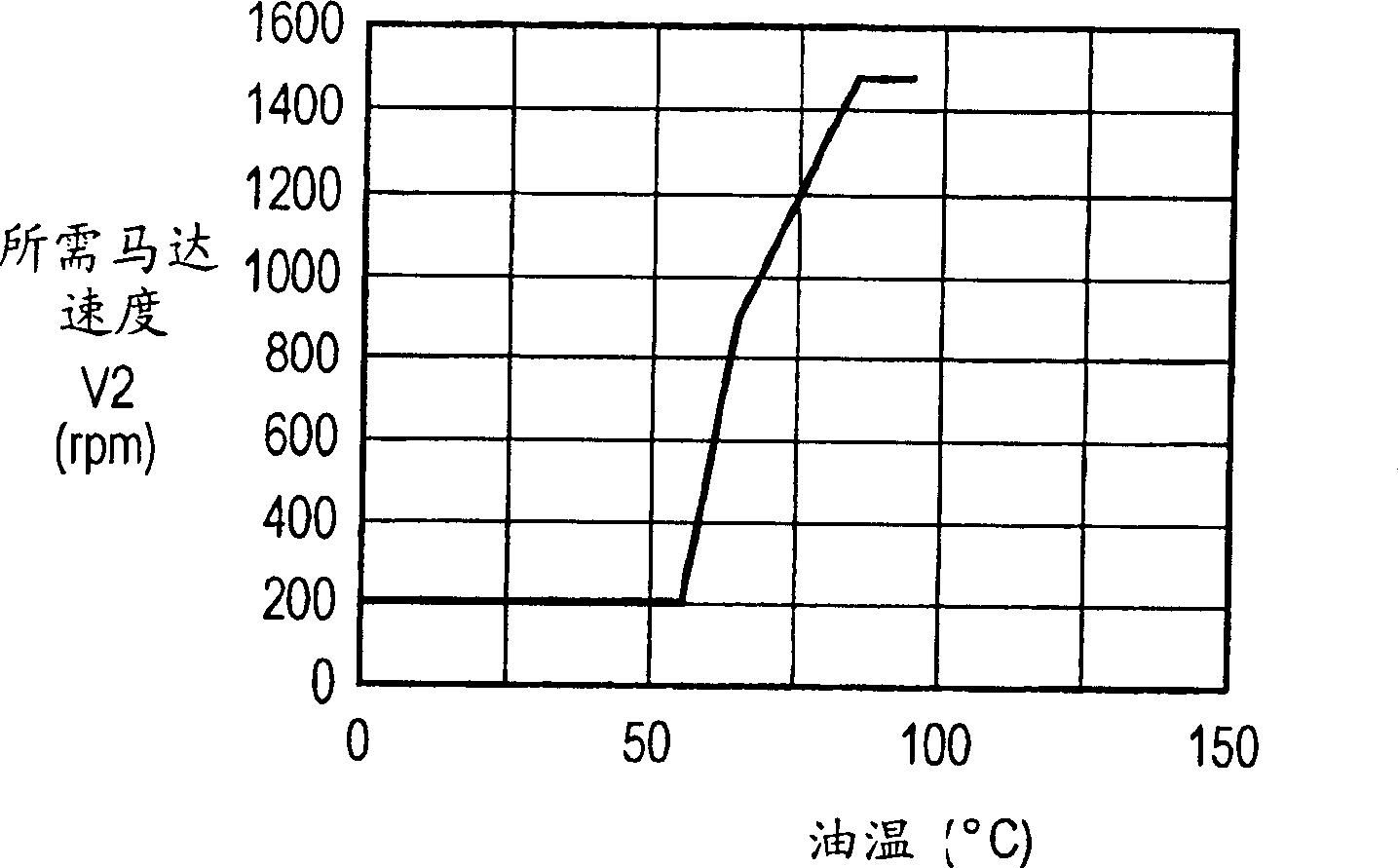

[0019] A control system for a cooling fan according to an exemplary embodiment of the present invention will now be described wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com