Valve plate and hydraulic apparatus with the same

A technology of hydraulic device and valve plate, applied in the field of hydraulic device, can solve the problems of large pressure fluctuation speed of piston chamber 6, damage of valve plate 2 and cylinder port 7, damage of valve plate cylinder port 7, etc., so as to prevent pulsation and prevent injection. The effect of small flow in the flow and discharge pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

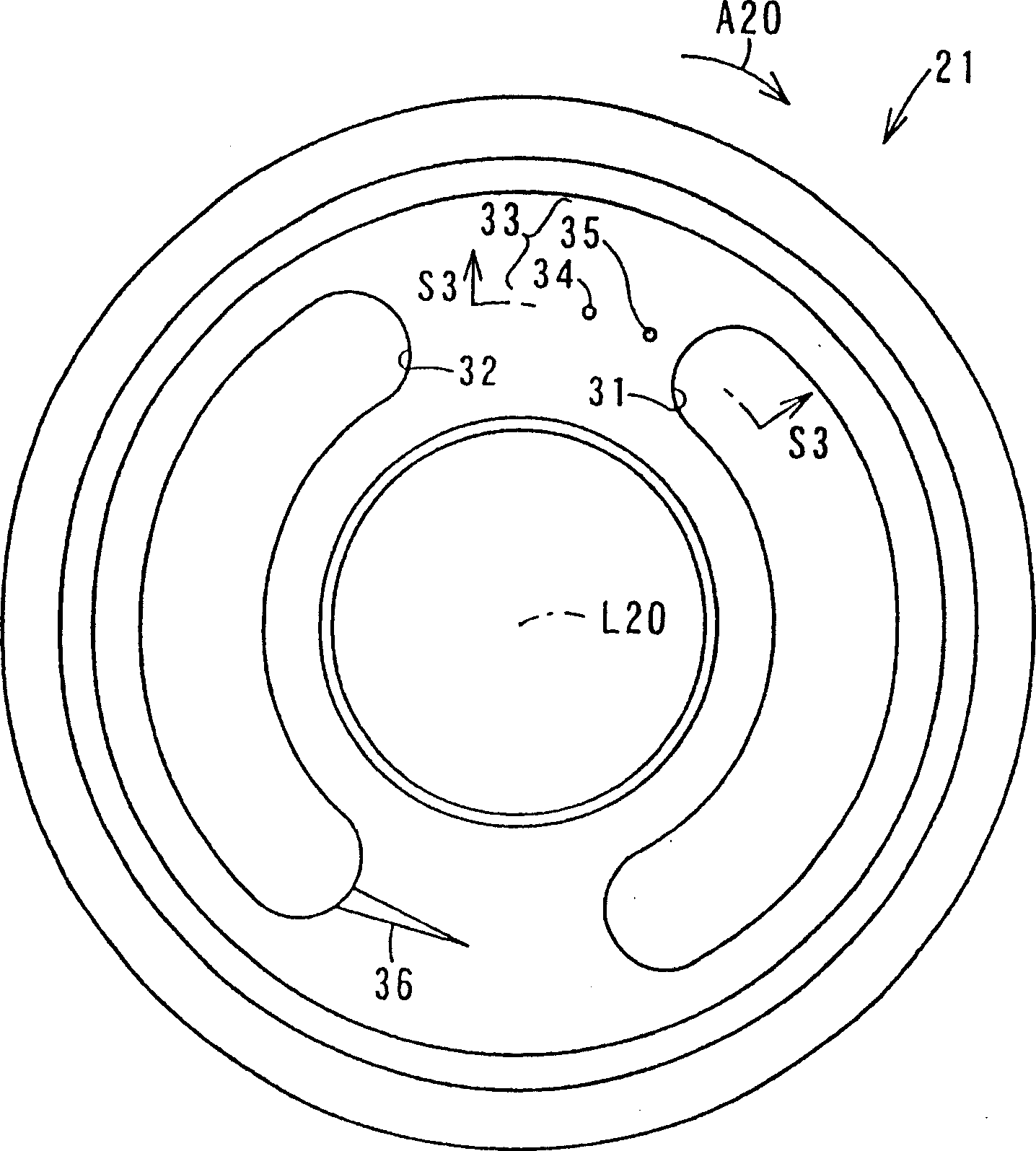

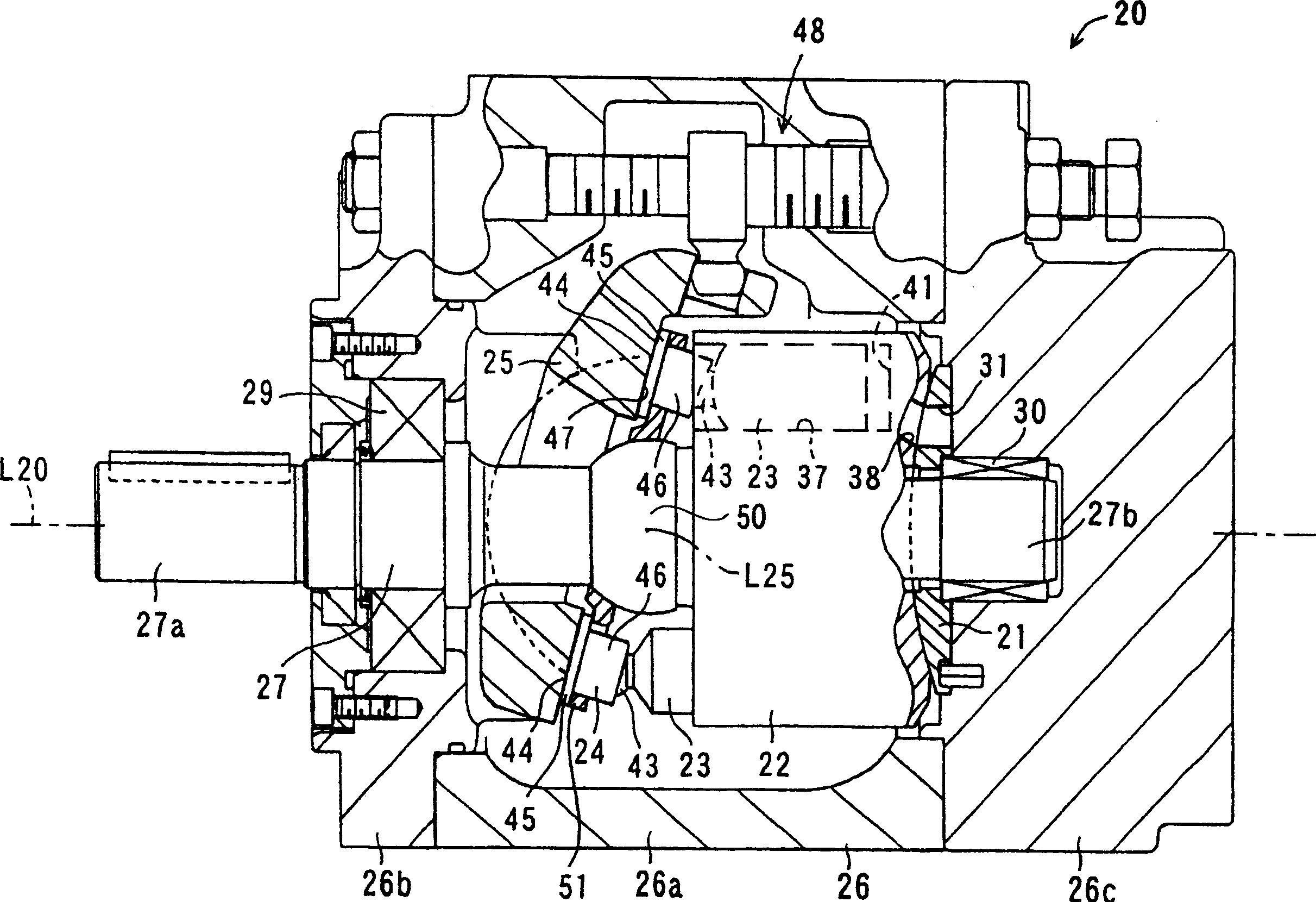

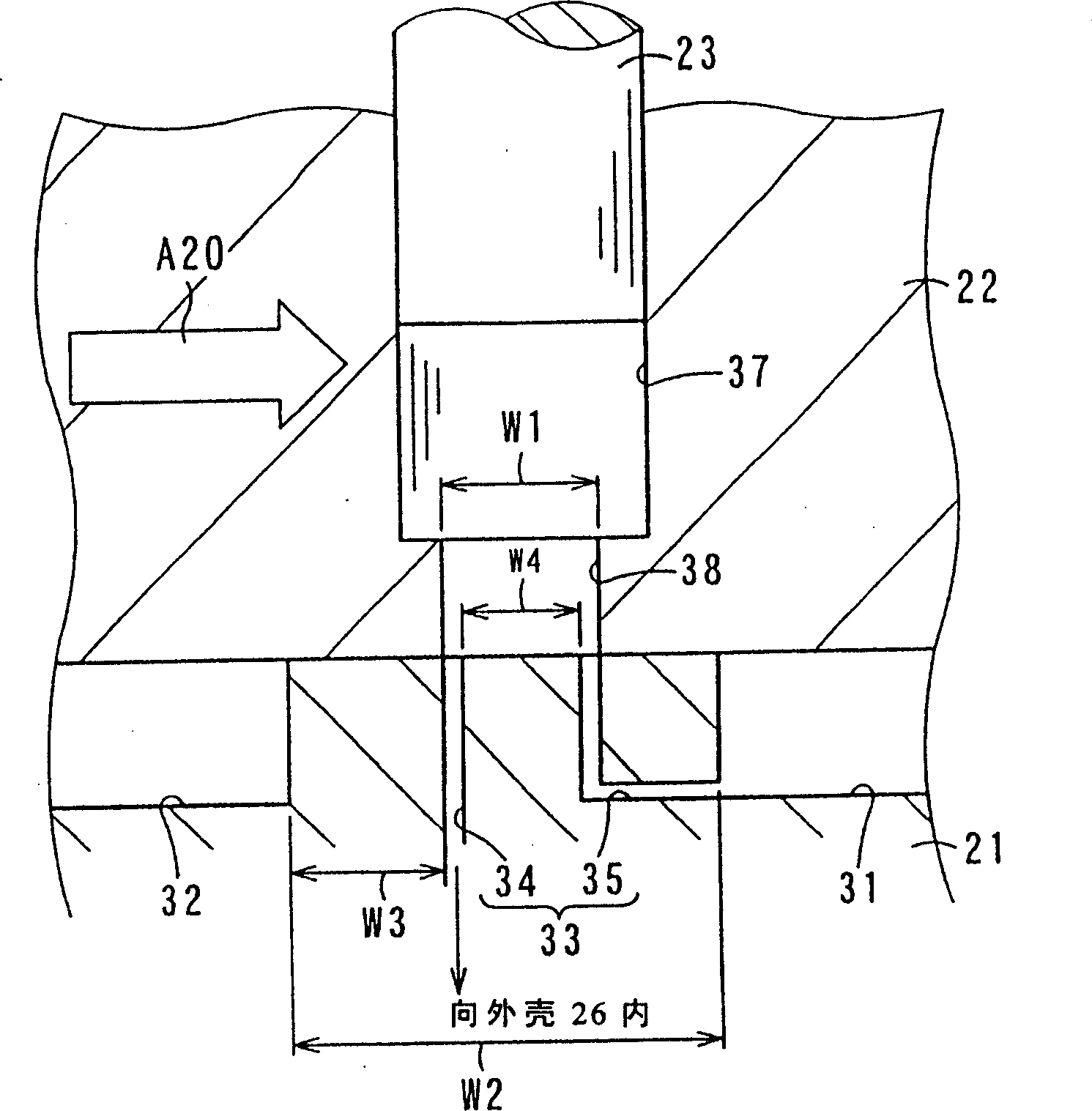

[0059] figure 1 It is a front view of the valve plate 21 of the piston pump 20 which concerns on one Embodiment of this invention. figure 2 is a sectional view of the piston pump 20 . figure 1 means from as figure 2 The valve plate 21 viewed from the cylinder block 22 side on the left. The piston pump 20 as a hydraulic device is a variable capacity swash plate type hydraulic pump installed on, for example, industrial machinery and construction machinery, and is driven by a driving force from a prime mover to supply working oil as a working fluid to the hydraulic pump. Installed in the driver of industrial machinery and construction machinery, and used to drive the driver. Such a piston pump 20 basically includes a valve plate 21 , a cylinder block 22 , a plurality of pistons 23 , a plurality of gates 24 , and a swash plate 25 , and these components are housed in a housing 26 that the piston pump 20 also includes. The housing 26 has a housing main body 26a, a front cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com